High-carbon chromium bearing steel GCr15 and production method thereof

A technology of high-carbon chromium bearing steel and its production method, which is applied in the field of high-carbon chromium bearing steel GCr15 and its converter production, can solve problems such as titanium nitride inclusions and affecting the fatigue life of steel, and achieve improved performance, improved processing performance, and increased Effect of fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

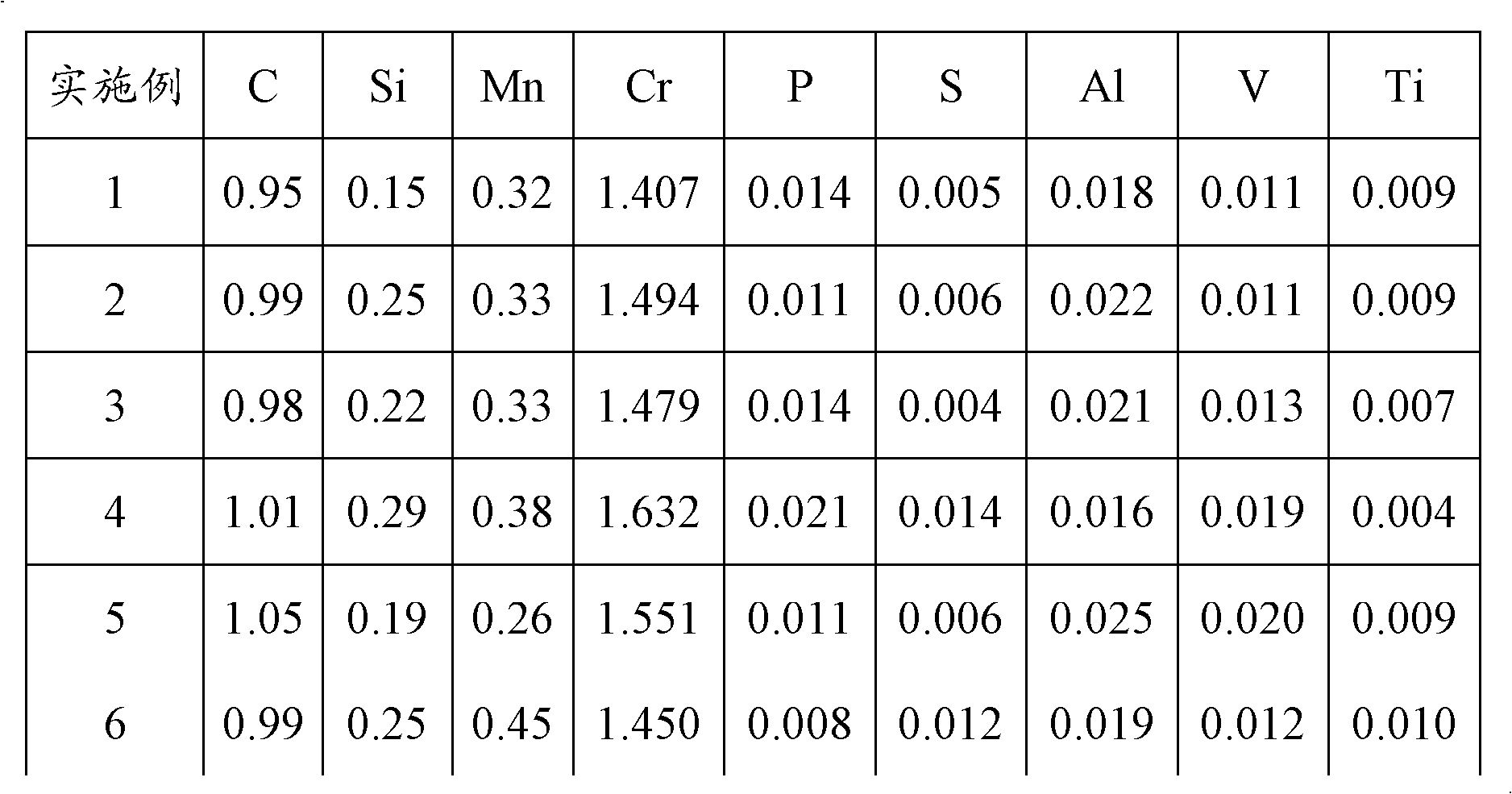

Examples

Embodiment 1

[0047] (1) Primary smelting: Prepare materials according to the following ratio: 65t of molten iron, 5t of scrap steel, first add scrap steel and then add molten iron; send the raw materials into the primary smelting furnace for smelting at 1600°C, and adjust the C content to 0.06wt at the end of smelting %, using a sliding plate to block slag to tap steel to achieve slag-free tapping, the steel ladle is added with 200kg refining slag for slag washing and combined with strong deoxidation and pre-deoxidation;

[0048] (2) Refining: heat the molten steel to be refined for re-refining, add deoxidizer aluminum particles at 0.2kg / t, quickly make white slag, control the basicity of steel slag to 4.0, the sulfur content is 0.025wt%, and the phosphorus content is 0.015wt%. Add 7 packs of large packs of covering agent to cover the liquid surface, blow Argon softly, strictly control the argon pressure to ensure that the liquid surface is not exposed, and refine for 45 minutes;

[0049] ...

Embodiment 2

[0055] (1) Primary smelting: prepare materials according to the following ratio: 66t of molten iron, 4t of scrap steel, first add scrap steel and then add molten iron; send the raw materials into the primary smelting furnace for smelting at 1660°C, and adjust the C content to 0.08wt at the end of smelting %, using a sliding plate to block slag to tap steel to achieve slag-free tapping, the steel ladle is added with 300kg refining slag for slag washing and combined with strong deoxidation and pre-deoxidation;

[0056] (2) Refining: heat the molten steel to be refined for re-refining, add deoxidizer aluminum particles at 0.3kg / t, rapidly make white slag, control the basicity of steel slag to 5.0, the sulfur content is 0.020wt%, and the phosphorus content is 0.010wt%. Add 10 packs of large packs of covering agent to cover the liquid surface, blow Argon softly, strictly control the argon pressure to ensure that the liquid surface is not exposed, and refine for 48 minutes;

[0057]...

Embodiment 3

[0063] (1) Primary smelting: Prepare materials according to the following ratio: 68t of molten iron, 2t of scrap steel, first add scrap steel and then add molten iron; send the raw materials into the primary smelting furnace for smelting at 1680°C, and adjust the C content to 0.10wt at the end of smelting %, use sliding plate to stop slag to tap steel to realize slag-free tapping, and use ladle plus 350kg refining slag for slag washing and combination of strong deoxidation and pre-deoxidation in the tapping process;

[0064] (2) Refining: Before refining the molten steel, send the pouring waste produced in step (1) into the molten steel to be refined in the ladle refining furnace (LF furnace) for heating and re-refining, and add deoxidizer aluminum at 0.4kg / t granule, quickly make white slag, control the alkalinity of steel slag to 6.0, sulfur content to 0.018wt%, phosphorus content to 0.010wt%, add 12 packs of large bags of covering agent to cover the liquid surface, blow Ar s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com