Method for preparing NbSi-base ultrahigh-temperature alloy through EBM (Electron Beam Melting)

A technology of ultra-high temperature alloy and forming technology, which is applied in the direction of improving energy efficiency and process efficiency, and can solve the problem of difficult to meet the forming requirements of Nb-Si-based alloy investment casting, multi-machining and post-processing, and coarsening of alloy structure. and other problems, to achieve the effect of eliminating the process of designing and manufacturing molds, avoiding machining and post-processing, and high material utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

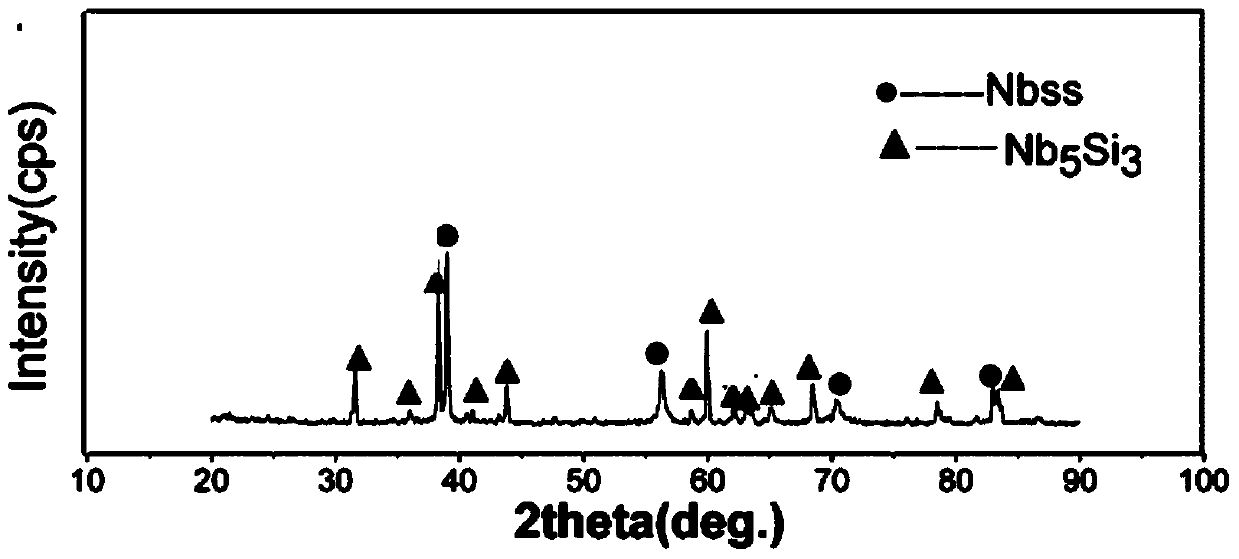

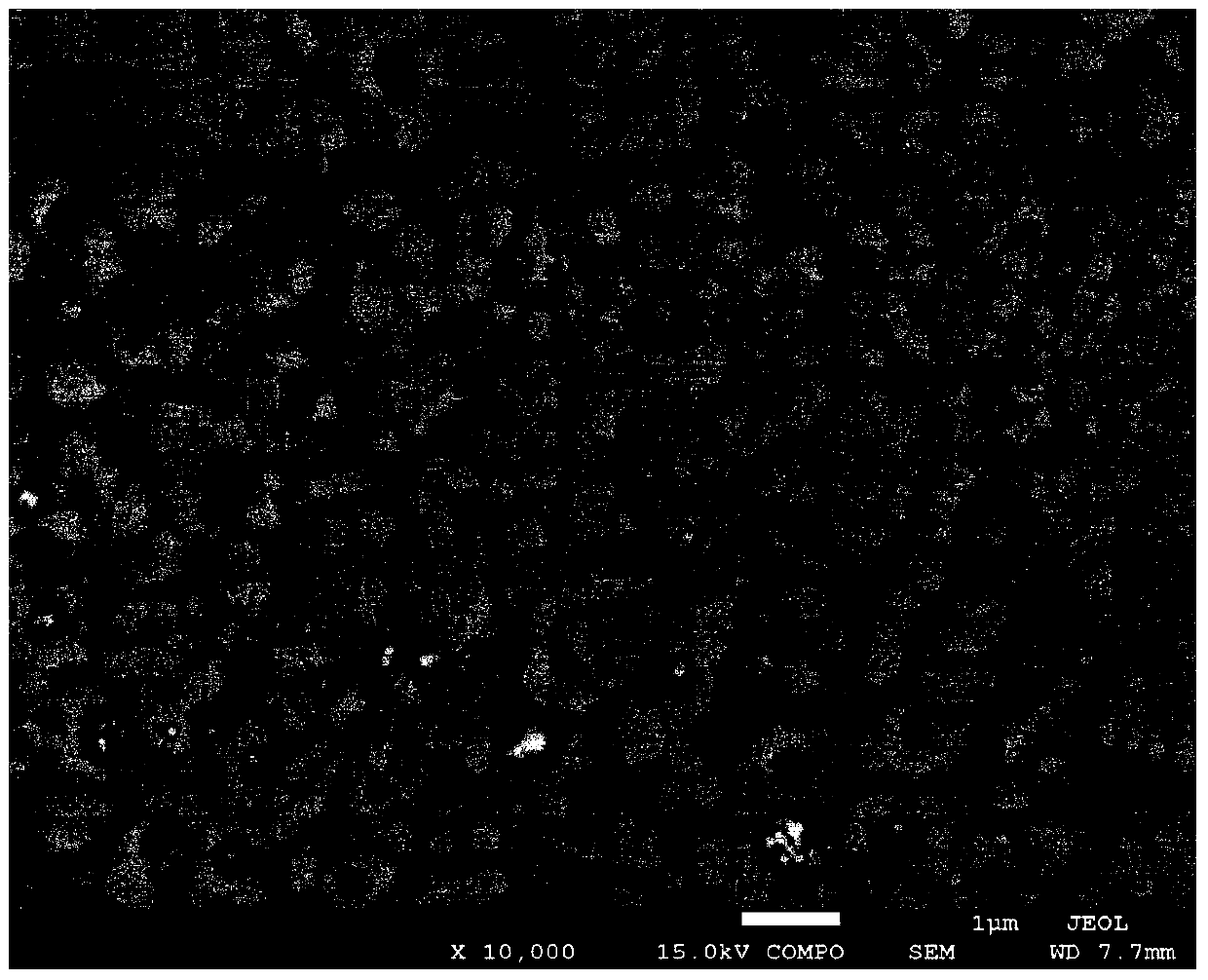

[0036] Nb-18Si-24Ti-2Cr-2Al-2Hf (at.%, atomic percent) superalloy prepared by EBM technology:

[0037] (1). Nb-18Si-24Ti-2Cr-2Al-2Hf pre-alloyed powder prepared by argon atomization method, the powder is spherical or nearly spherical, and the diameter is between 50 and 150 μm;

[0038] (2). First, use the 3D drawing software (Magics) to establish a 3D CAD model of the NbSi alloy sample, and save it as an STL file; then use the layering software (EBM assembler) to perform layered slice processing on the STL file in the height direction, and segment Slices with a uniform thickness (0.1mm), which contain the cross-sectional profile information of the alloy sample; use layering software to save the slice as an ABF file, and import it into the electron beam rapid prototyping equipment (EBM);

[0039] (3). Put the Nb-18Si-24Ti-2Cr-2Al-2Hf pre-alloyed powder into the molding cavity, put the Ti6Al4V forming substrate with a thickness of 10mm on the platform that can be lifted in the f...

Embodiment 2

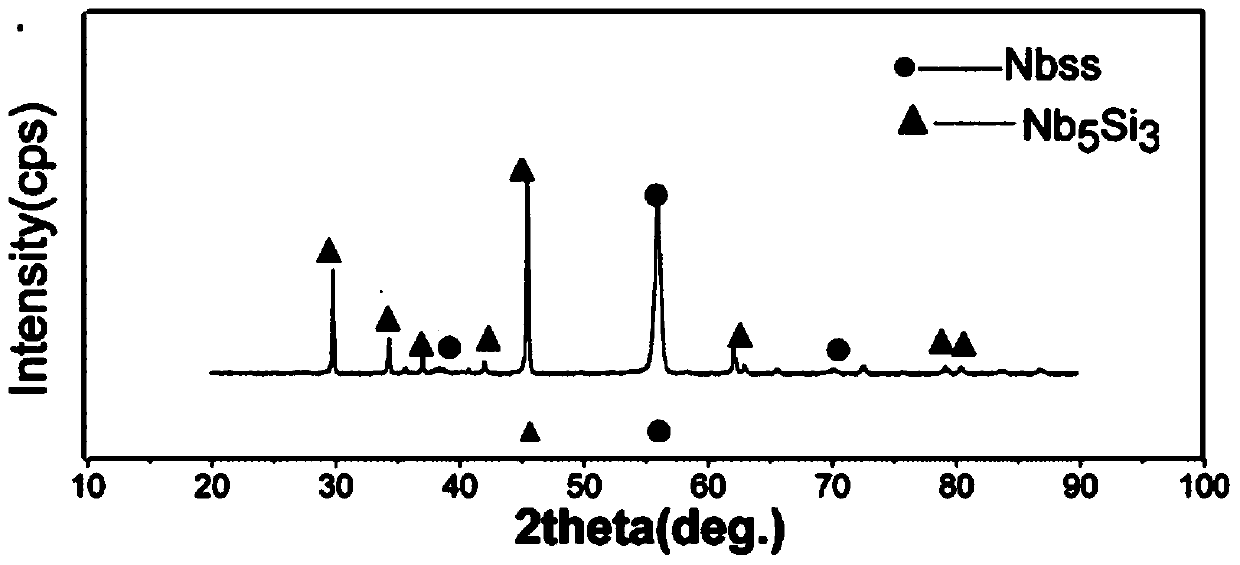

[0047] Nb-16Si-22Ti-4Cr-2Al-2Hf (at.%, atomic percent) superalloy prepared by EBM technology:

[0048] (1). Nb-16Si-22Ti-4Cr-2Al-2Hf pre-alloyed powder prepared by argon atomization method, the powder is spherical or nearly spherical, and the diameter is between 50 and 150 μm;

[0049] (2). First, use the 3D drawing software (Magics) to establish a 3D CAD model of the NbSi alloy sample, and save it as an STL file; then use the layering software (EBM assembler) to perform layered slice processing on the STL file in the height direction, and segment Slices with a uniform thickness (0.07mm), which contain the cross-sectional profile information of the alloy sample; use layering software to save the slice as an ABF file, and import it into the electron beam rapid prototyping equipment (EBM);

[0050] (3). Put the Nb-16Si-22Ti-4Cr-2Al-2Hf pre-alloyed powder into the forming cavity, put the Ti6Al4V forming substrate with a thickness of 10mm on the platform that can be lifted in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com