Preparation method of 5356 aluminum alloy ingot

An aluminum alloy ingot and alloy technology, which is applied in the field of preparation of 5356 aluminum alloy ingot, can solve the problems of difficult alloy processing, welding wire is easy to break, easy to produce pores, etc., to avoid hazards and environmental pollution, to facilitate temperature control, The effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

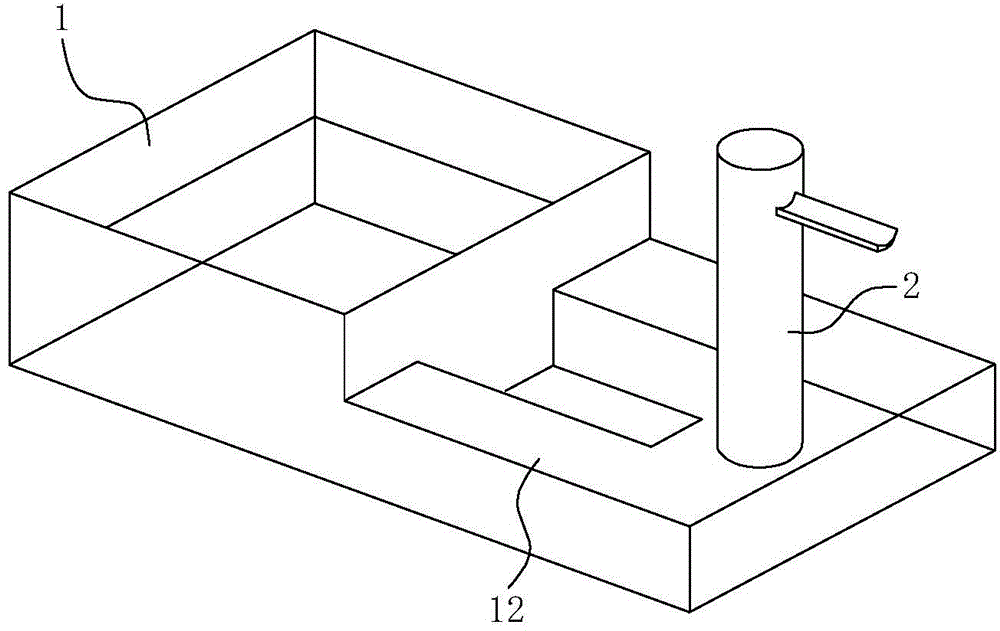

[0031] The preparation method of the 5356 aluminum alloy ingot of the present embodiment comprises the following steps:

[0032] (1) Ingredients: by weight percentage, the ingredients include Mg 4.5%, Mn 0.1%, Cr 0.08%, Ti 0.10%, and the balance of Al;

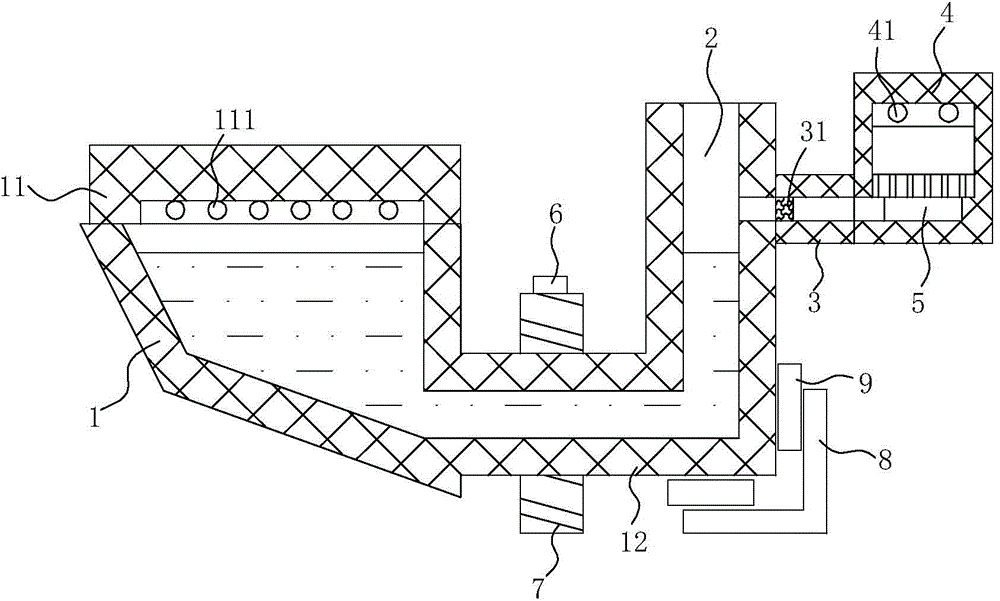

[0033] (2) Preloading and radiation heating: first add pure aluminum ingots to the crucible of the vacuum electromagnetic guide device, and then supply power to the resistance wire of the crucible heating cover to heat the pure aluminum ingots in the crucible until the pure aluminum ingots in the crucible melt It is a melt; carry out slag removal treatment on the surface of the melt;

[0034] (3) Induction heating and electromagnetic stirring: supply alternating current to the induction coil with a power of 25kw to keep the heating temperature at 680-750°C; the melt in the crucible is heated and circulates along the annular pipe connected to the crucible;

[0035] (4) Feeding and sufficient smelting: add components Mg, Mn, Cr...

Embodiment 2

[0040] The preparation method of the 5356 aluminum alloy ingot of the present embodiment comprises the following steps:

[0041] (1) Ingredients: by weight percentage, the ingredients include Mg 4.7%, Mn 0.05%, Cr 0.05, Ti 0.15%, and the balance of Al;

[0042](2) Preloading and radiation heating: first add pure aluminum ingots to the crucible of the vacuum electromagnetic guide device, and then supply power to the resistance wire of the crucible heating cover to heat the pure aluminum ingots in the crucible until the pure aluminum ingots in the crucible melt It is a melt; carry out slag removal treatment on the surface of the melt;

[0043] (3) Induction heating and electromagnetic stirring: supply alternating current to the induction coil with a power of 20kw to keep the heating temperature at 680-750°C; the melt in the crucible is heated and circulates along the annular pipe connected to the crucible;

[0044] (4) Feeding and sufficient smelting: add components Mg, Mn, Cr,...

Embodiment 3

[0049] The preparation method of the 5356 aluminum alloy ingot of the present embodiment comprises the following steps:

[0050] (1) Ingredients: by weight percentage, the ingredients include Mg 5.5%, Mn0.12%, Cr 0.20%, Ti0.17%, and the rest of Al;

[0051] (2) Preloading and radiation heating: first add pure aluminum ingots to the crucible of the vacuum electromagnetic guide device, and then supply power to the resistance wire of the crucible heating cover to heat the pure aluminum ingots in the crucible until the pure aluminum ingots in the crucible melt It is a melt; carry out slag removal treatment on the surface of the melt;

[0052] (3) Induction heating and electromagnetic stirring: supply alternating current to the induction coil with a power of 22kw to keep the heating temperature at 680-750°C; the melt in the crucible is heated and circulates along the annular pipe connected to the crucible;

[0053] (4) Feeding and sufficient smelting: add components Mg, Mn, Cr, Ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com