Forming method of maraging steel mold adopting selective laser melting

A maraging steel, laser selective melting technology, applied in the direction of process efficiency improvement, energy efficiency improvement, additive manufacturing, etc., can solve the problems of inability to obtain ideal high-efficiency cooling channels, unfavorable normal development of enterprises, and reduced service life of molds, etc. , to improve cooling efficiency and service life, avoid macro segregation, and save labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

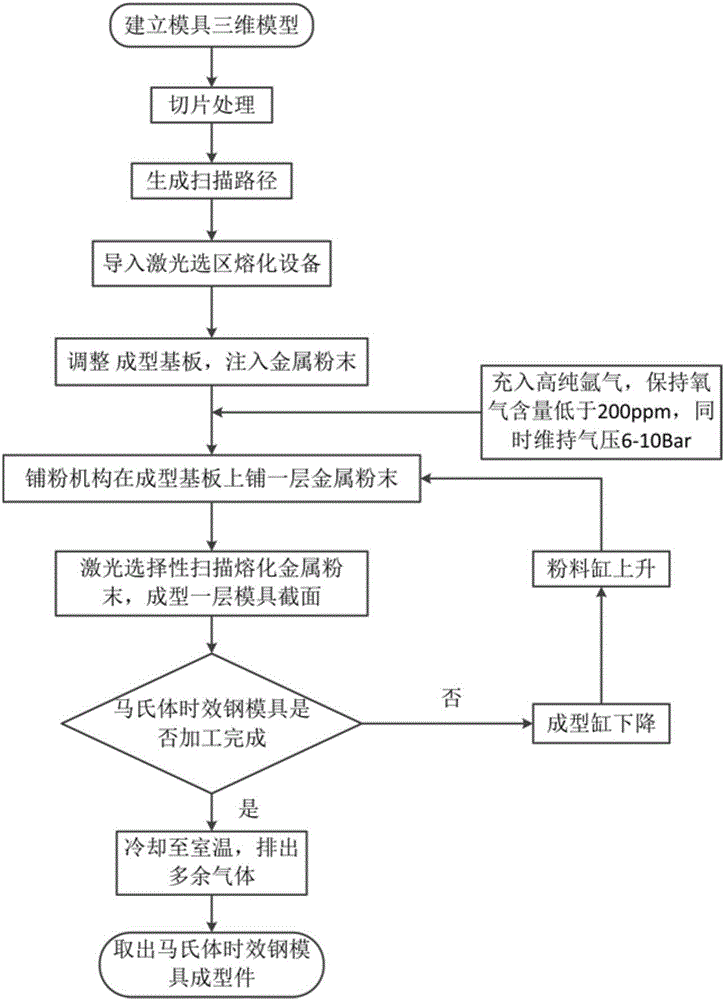

[0039] like figure 1 shown. The invention discloses a method for forming a maraging steel mold by laser selective melting, comprising the following steps:

[0040] Step 1: According to the shape of the maraging steel mold to be processed, establish a three-dimensional digital model of the mold, and then save it as an STL format file. Use a slicing software to slice the three-dimensional digital model to keep the thickness of the slice consistent, and slice Import the final file into the Rpath path planning software to obtain the path data of laser scanning, and finally import the scanning path data into the laser selective melting equipment;

[0041] Step 2: Adjust the forming abutment of the laser selective melting equipment through the human-machine interface, fix the polished and cleaned stainless steel forming substrate on the forming abutment with screws, and adjust the powder spreading mechanism at the same time so that the lowest end of the powder coating brush and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com