High-density pure molybdenum selective laser melting producing method

A selective laser melting and densification technology, which is applied in the direction of additive manufacturing, energy efficiency improvement, process efficiency improvement, etc., can solve the problems of poor mechanical properties of parts, achieve high density, avoid machining and post-processing, and optimize the process The effect of the parameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

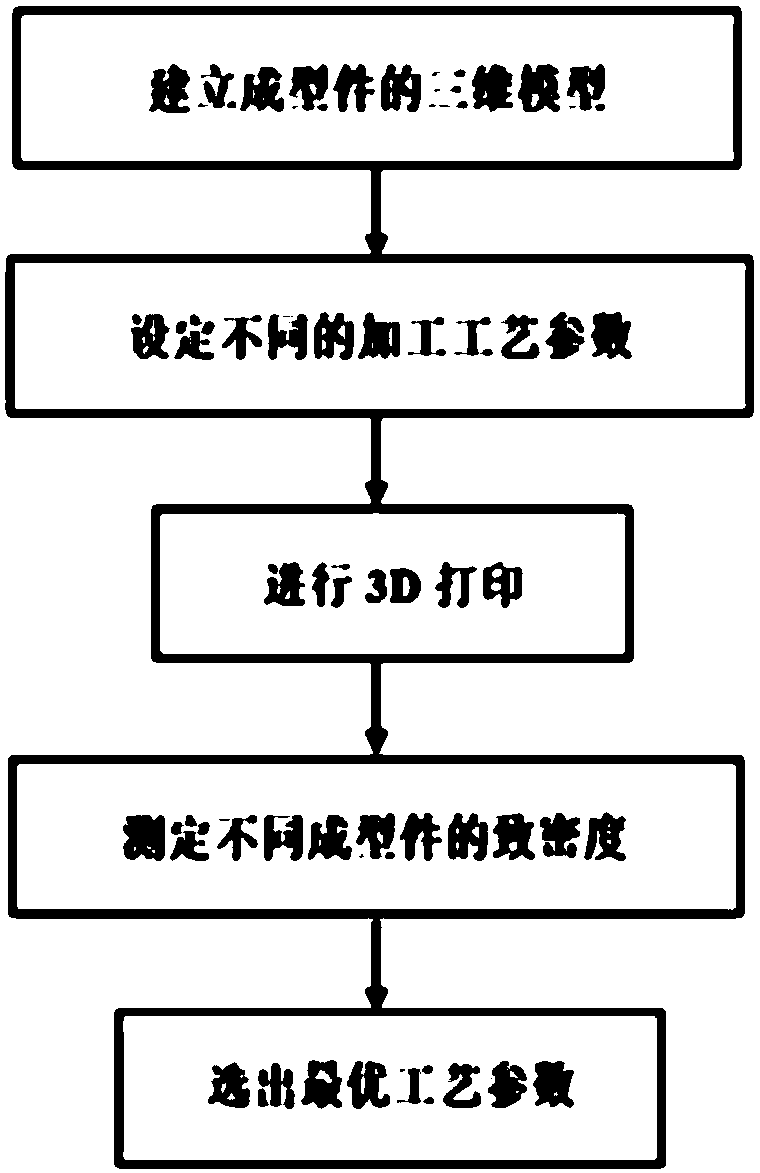

[0033] A method for preparing high-density pure molybdenum by selective laser melting, the preparation process specifically includes the following steps:

[0034] (1) According to the shape of the pure molybdenum forming part to be processed, establish a three-dimensional model on the computer and output it as an STL format file. Input it into the 3D printing editing software, perform two-dimensional processing, and slice the model layeredly in the height direction. The slice data includes the contour information and processing path of the formed part, and import it into the selective laser melting equipment;

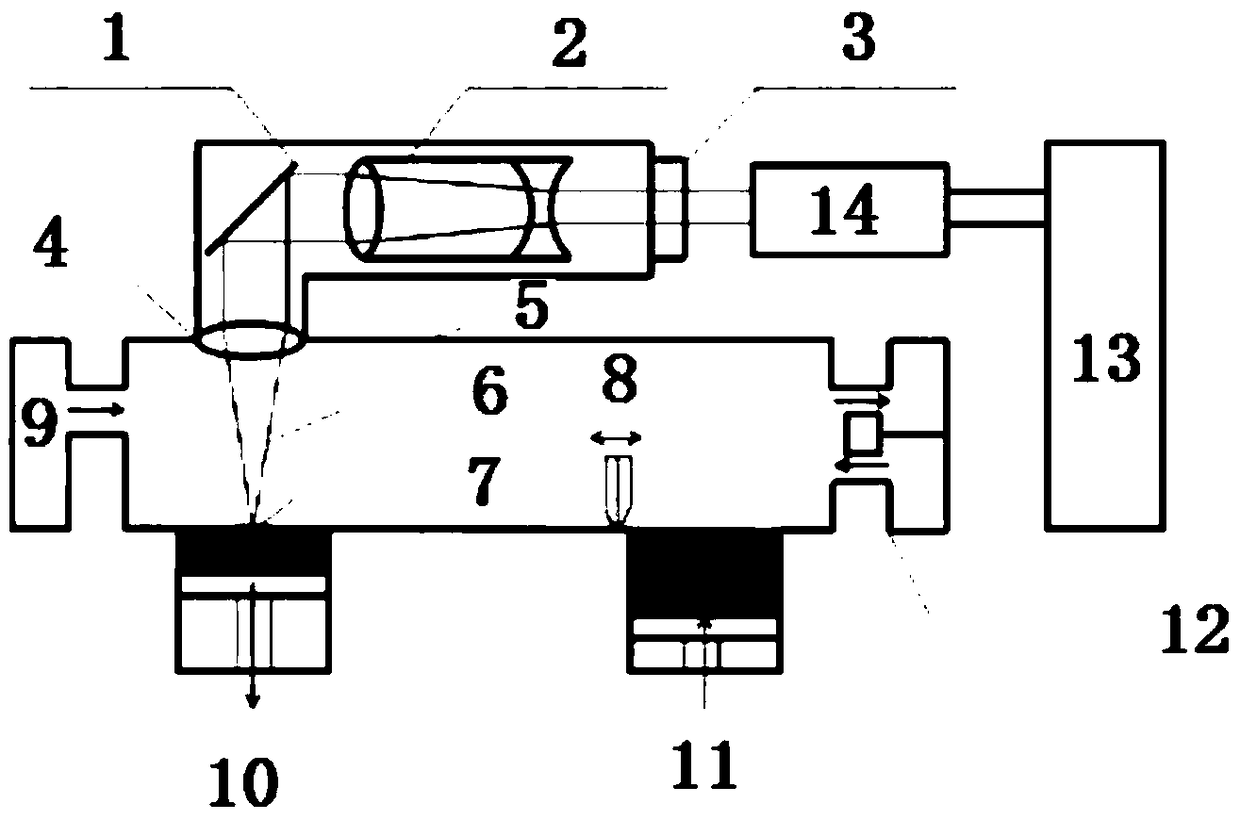

[0035] (2) Set the processing parameters of the pure molybdenum sample: the diameter of the laser spot is 75 μm, the laser power is 325 W, the scanning speed is 400 mm / s, the scanning distance is 60 μm, the cross hatching scanning strategy is adopted, and the laser scanning direction is rotated layer by layer 67 °, to minimize the overlapping of laser scanning vectors o...

Embodiment 1

[0047] A preparation method for selective laser melting of pure molybdenum with high surface quality, comprising the following steps:

[0048] (1) Model the three-dimensional solid model of the formed part through CAD software on the computer, then output the model in STL format, and then input it into the 3D printing editing software for two-dimensional processing.

[0049] (2) Import the gas-atomized spherical pure molybdenum powder into the feeding bin, the powder particle size is 13-53 μm, fix the forming substrate on the workbench of the selective laser melting equipment, close the bin door, and fill it with a purity of 99.9% after vacuuming. % argon as a shielding gas to ensure that the oxygen content in the forming chamber is ≤100ppm.

[0050] (3) Set different processing parameters, change the laser power and scanning speed, control the scanning distance to 60 μm in this preparation method, and adopt the Cross hatching scanning strategy. Start the selected area laser ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com