Novel powder high-temperature alloy and preparing method thereof

A superalloy and powder technology, applied in the field of new powder superalloy and its preparation, can solve the problems of poor uniformity of microstructure and deterioration of alloy processing performance, shorten melting time and homogenization time, increase density and improve purity degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment one: a kind of novel powder superalloy of the present invention and preparation method thereof, specifically comprise the following steps:

[0025] 1) According to the powder superalloy composition distribution ratio, as shown in Table 1, calculate and determine the consumption of each raw material;

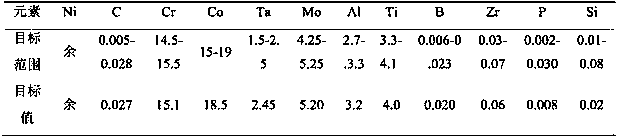

[0026] Table 1 Alloy chemical composition ratio, wt%

[0027]

[0028] The alloy feeding amount is 2000kg, and the ingredient list is shown in Table 2.

[0029] Table 2 ingredient list

[0030] serial number Raw material type Feeding amount 1 Ni 993.1 2 C 0.44 3 NiP 0.93 4 co 370.1 5 NiTa 81.6 6 Al 63.6 7 Cr 303.9 8 Mo 104 9 Ti 79.6 10 Zr 1.2 11 NiB 2.2

[0031] 2) Surface treatment is carried out on the electrolytic nickel and electrolytic cobalt in the raw materials until the surface is clean and bright in color, and then dried with nickel-tantalum alloy, metal tungs...

Embodiment 2

[0039] A kind of novel powder superalloy of the present invention and preparation method thereof, specifically comprise the following steps:

[0040] 1) According to the powder superalloy composition distribution ratio, as shown in Table 3, calculate and determine the consumption of each raw material;

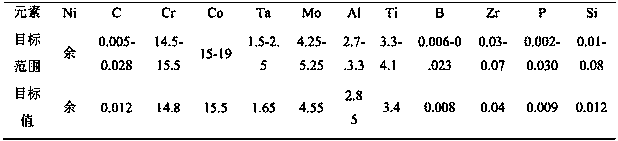

[0041] Table 3 Alloy chemical composition ratio, wt%

[0042]

[0043] The alloy feeding amount is 3000kg, and the ingredient list is shown in Table 4.

[0044] Table 2 ingredient list

[0045] Table 4 ingredient list

[0046]

[0047]

[0048] 2) Surface treatment is carried out on the electrolytic nickel and electrolytic cobalt in the raw materials until the surface is clean and bright in color, and then dried with nickel-tantalum alloy, metal tungsten, pure titanium, pure aluminum, and pure chromium at 100°C for 5 hours stand-by;

[0049] 3) The electrolytic nickel, pure chromium, electrocobalt, nickel-tantalum alloy, pure tungsten and carbon in step 2) are firs...

Embodiment 3

[0056] A kind of novel powder superalloy of the present invention and preparation method thereof, specifically comprise the following steps:

[0057] 1) According to the powder superalloy composition distribution ratio, as shown in Table 5, calculate and determine the consumption of each raw material;

[0058] Table 5 Alloy chemical composition ratio, wt%

[0059]

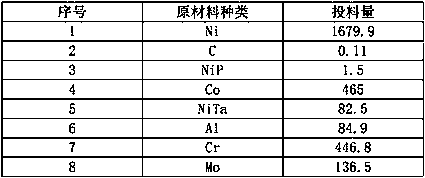

[0060] The alloy feeding amount is 2000kg, and the ingredient list is shown in Table 6.

[0061] Table 6 ingredient list

[0062] serial number Raw material type Feeding amount 1 Ni 1041.3 2 C 0.18 3 NiP 2.71 4 co 344.1 5 NiTa 62.7 6 Al 61.6 7 Cr 307.9 8 Mo 100.6 9 Ti 75.8 10 Zr 1 11 NiB 1.4

[0063] 2) Surface treatment is carried out on the electrolytic nickel and electrolytic cobalt in the raw materials until the surface is clean and bright in color, and then dried with nickel-tantalum alloy, metal tungsten, pure titan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com