Silicon single-crystal pulling equipment and growing method

A silicon single crystal and equipment technology, applied in the field of Cz method silicon single crystal pulling equipment, can solve problems such as accelerating the melting of polycrystalline silicon raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

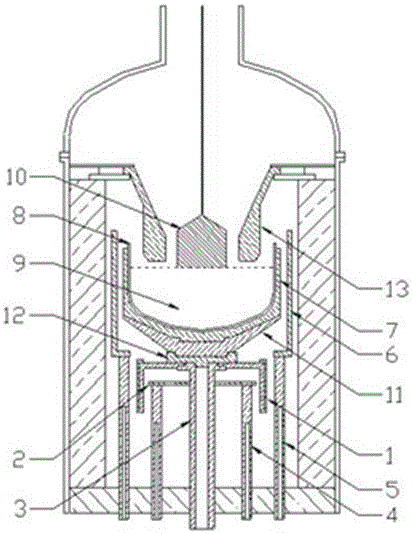

[0029] The CZ method is used to grow 8-inch direction integrated circuit-grade single crystal silicon silicon single crystal, the amount of raw materials added is 100 kg, and the diameter of the quartz crucible used is 22 inches.

[0030] Below the crucible tray is a heat shield mounted on a graphite support. The length of the auxiliary heat shield is 300mm, the outer diameter of the auxiliary heat shield is 476mm, and the inner diameter of the auxiliary heat shield is 406mm. The outer layer of the auxiliary heat shield is made of graphite material with a thickness of 20mm and a thermal conductivity of 2.8W / m / K. The inner layer of the auxiliary heat shield is made of graphite material with a thickness of 15mm and a thermal conductivity of 107W / m / K.

[0031] There is a bottom heater inside the auxiliary heat shield and directly below the graphite crucible. In the raw material melting process, the height of the bottom heater from the bottom of the graphite support plate is 20...

Embodiment 2

[0034]As in Example 1, only in the raw material melting process, the input power of the heater at the bottom is controlled to be 35 kW, and the polysilicon raw material melting takes 4.5 hours. After the raw material is melted, turn off the heater at the bottom and start pulling and growing the silicon single crystal. During the equal-diameter growth process of silicon single crystal, the average growth rate is controlled at 1.2mm / min.

Embodiment 3

[0036] Same as Example 1, only in the raw material melting process, the input power of the heater at the bottom is controlled to be 25 kW, and the polysilicon melting takes 5 hours. After the raw material is melted, the bottom heater is turned off, the water-cooled electrode continues to cool the bottom heater, and the silicon single crystal is pulled and grown. When the mass of the solution in the quartz crucible is less than 40 kg, an input power of 25 kW is applied to the bottom heater to heat the bottom of the crucible. During the equal-diameter growth process of silicon single crystal, the average growth rate is controlled at 1.2mm / min.

[0037] The silicon single crystal cutting and sampling test results show that the radial resistivity fluctuation range at the end of the equal-diameter section of the silicon single crystal is improved compared with Example 1, which is conducive to improving the local uniformity of the resistivity of a single silicon wafer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com