A continuous casting tundish dispersion-type breathable ring upper nozzle seat brick and its refining method by argon blowing

A continuous casting tundish and nozzle seat brick technology, which is applied to casting equipment, casting molten material containers, manufacturing tools, etc., can solve the problems of unstable "circular air flow, small effect, etc., and achieve the suppression of submerged nozzle nodules. , Promote the effect of floating and removing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

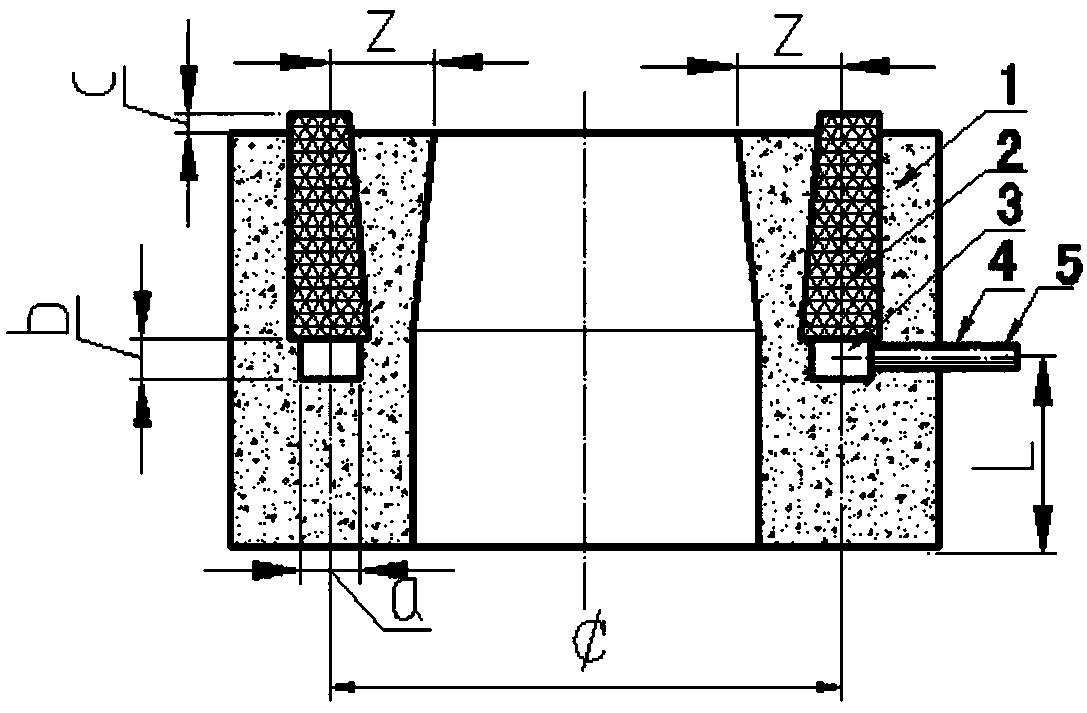

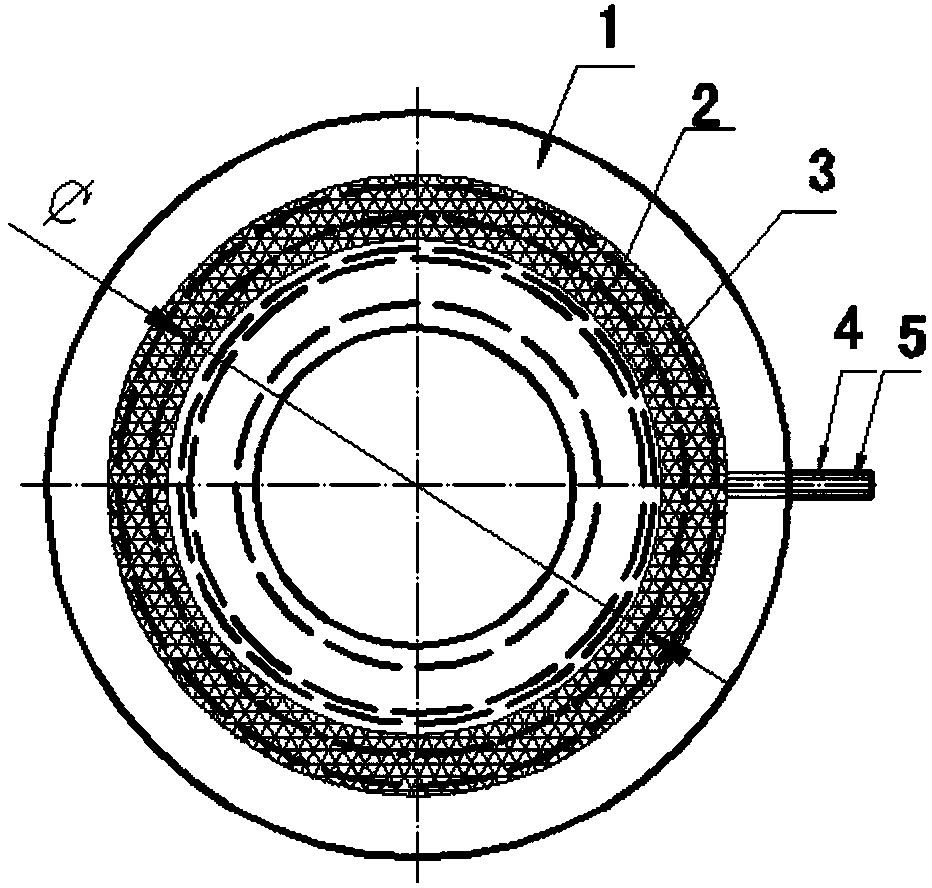

[0045] A kind of continuous casting tundish dispersion type breathable ring upper nozzle seat brick, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, it includes the upper nozzle block body 1, the diffused breathable ring 2, the air chamber 3, and the air intake pipe 4. The middle part of the upper nozzle block body 1 is provided with an upper nozzle installation hole that penetrates up and down. An annular diffused breathable ring 2 and an annular air chamber 3 are arranged from top to bottom, the upper part of the diffused breathable ring protrudes from the upper surface of the upper nozzle block body 1, and the air chamber is located at the bottom of the diffused breathable ring , and communicate with the diffused air-permeable ring, the side of the air chamber is connected with an air intake pipe 4, one end of the air intake pipe communicates with the air chamber, and the other end stretches out from the side of the upper nozzle block body 1, th...

Embodiment 2

[0065] The continuous casting tundish diffused breathable ring upper nozzle seat brick as described in Example 1, the difference lies in:

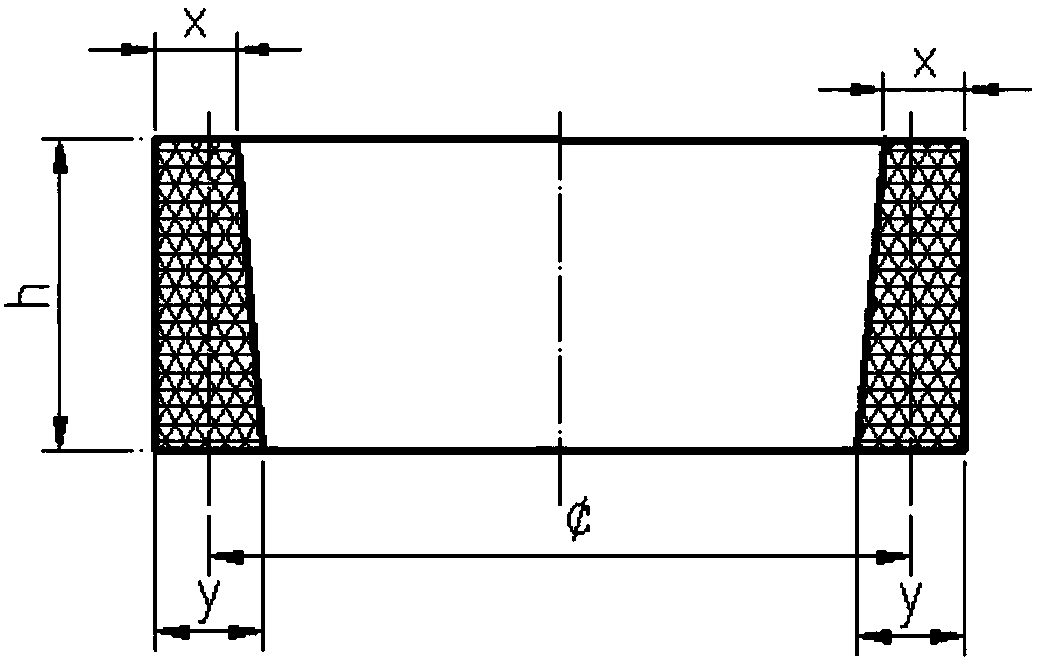

[0066] The diffused air-permeable ring 2 has a circular cross-section, an isosceles trapezoid with a large upper side and a smaller lower side in its longitudinal section, the upper end width x of the ring is 40 mm, the lower end width y is 50 mm, and the height h is 90 mm . The longitudinal centerline of the lower end of the diffusion-type breathable ring 2 coincides with the longitudinal centerline of the annular air chamber 3, and the distance z from the upper edge of the installation hole of the upper nozzle is 35 mm. ¢ is the diameter of the central circle of the ring, and its size is designed according to the upper diameter of the upper nozzle installation hole and the distance x between the longitudinal centerline of the lower end of the diffused breathable ring 2 and the upper edge of the upper nozzle installation hole, such as sla...

Embodiment 3

[0082] The continuous casting tundish diffused breathable ring upper nozzle seat brick as described in Example 1, the difference lies in:

[0083] The diffused air-permeable ring 2 is circular in cross section, and its longitudinal section has a right-angled trapezoid with a large upper side and a smaller lower side. The upper width x of the ring is 35mm, the lower width y is 45mm, and the height h is 100mm. The longitudinal centerline of the lower end of the diffusion-type breathable ring 2 coincides with the longitudinal centerline of the annular air chamber 3, and the distance z from the upper edge of the installation hole of the upper nozzle is 40mm. ¢ is the diameter of the central circle of the ring, and its size is designed according to the upper diameter of the upper nozzle installation hole and the distance x between the longitudinal centerline of the lower end of the diffused air-permeable ring 2 and the upper edge of the upper nozzle installation hole. The diameter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com