[0012]As mentioned above, the relatively high cost of phased arrays has precluded the use of phased arrays in all but the most specialized applications.

Assembly and component costs, particularly for active transmit / receive channels, are major cost drivers.

Phased array costs can be reduced by utilizing

batch processing and minimizing touch labor of components and assemblies. It would be advantageous to provide a tile sub-array for an Active, Electronically Scanned Array (AESA) that is compact, which can be manufactured in a cost-effective manner, that can be assembled using an automated process, and that can be individually tested prior to assembly into the AESA. There is also a need to lower acquisition and

life cycle costs of phased arrays, while at the same time improving bandwidth,

polarization diversity and robust RF performance characteristics to meet increasingly more challenging antenna performance requirements.

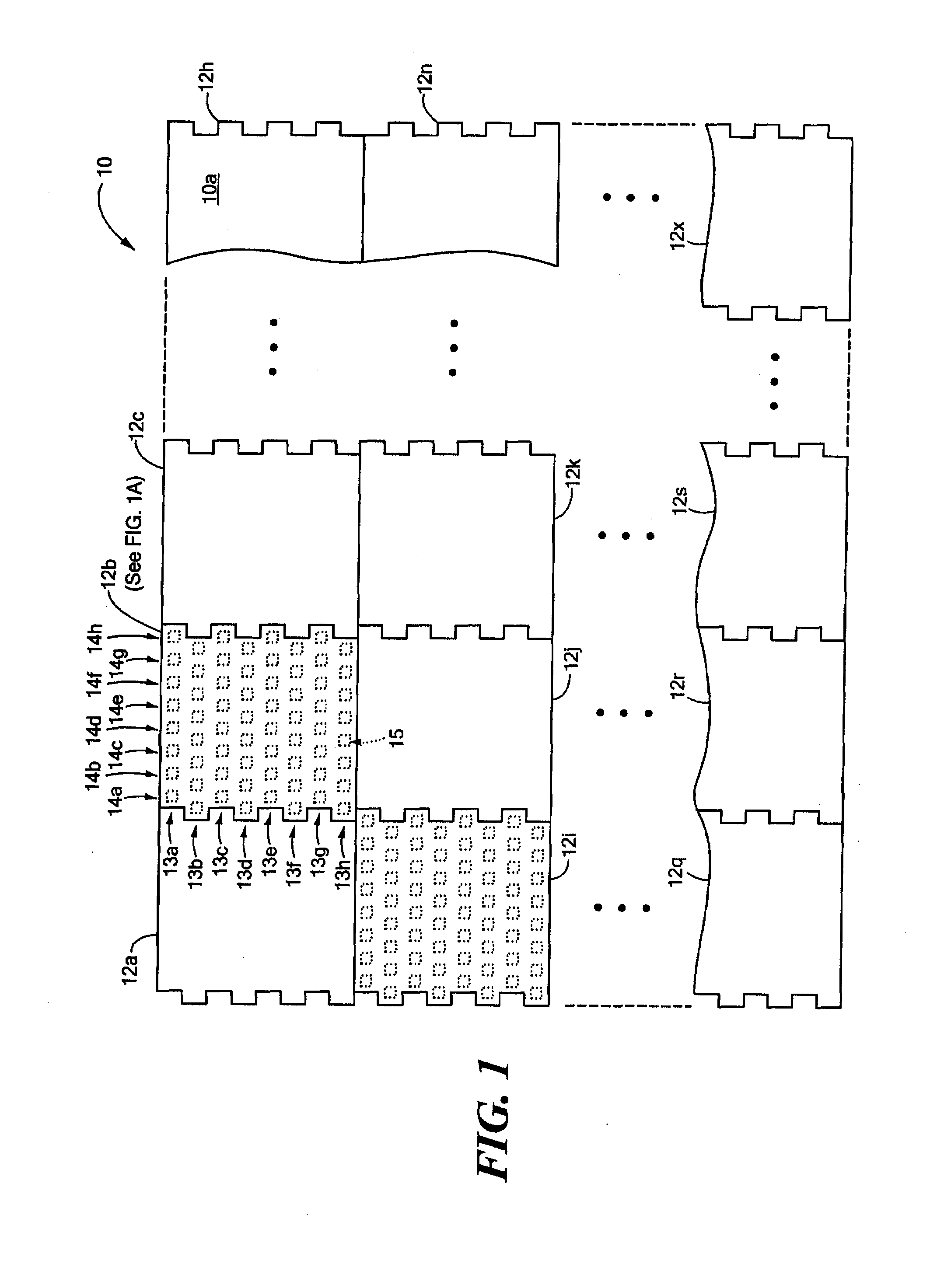

[0013]At least some embodiments of a tile sub-array architecture described herein enable a cost effective phased array solution for a wide variety of phased array

radar missions or communication missions for ground, sea and airborne platforms. In addition, in at least one embodiment, the tile sub-array provides a thin, lightweight construction that can also be applied to conformal arrays on an aircraft wing or

fuselage or on a Unmanned Aerial Vehicle (UAV).

[0014]In one so-called “packageless T / R channel” embodiment, a tile sub-array simultaneously addresses cost and performance for next generation

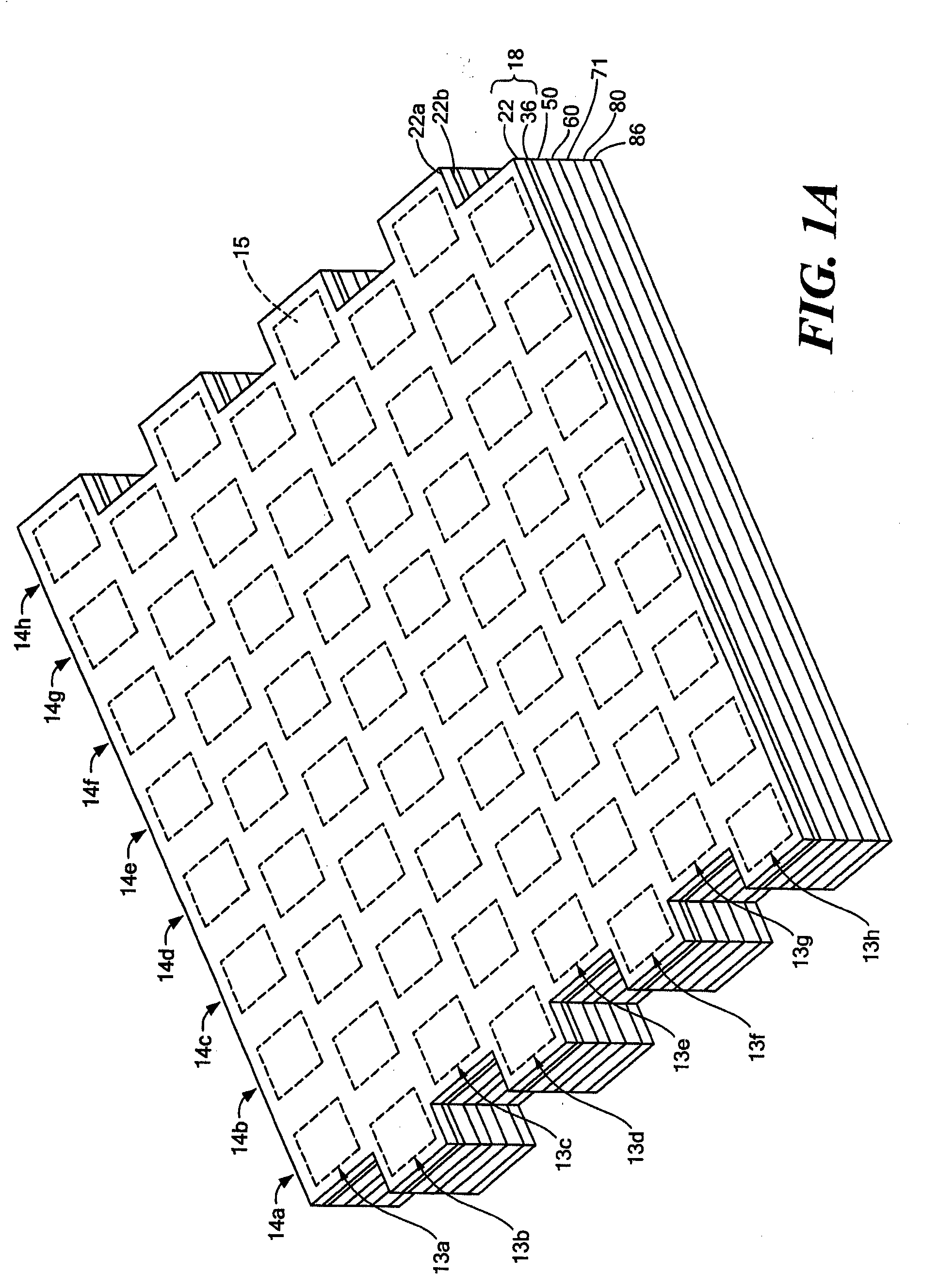

radar and communication systems. Many phased array designs are optimized for a single mission or platform. In contrast, the flexibility of the tile sub-array architecture described herein enables a solution for a larger set of missions. For example, in one embodiment, a so-called upper multi-layer assembly (UMLA) and a lower multi-layer assembly (LMLA), each described further herein, serve as common building blocks. The UMLA is a layered

RF transmission line assembly which performs RF

signal distribution,

impedance matching and generation of polarization diverse signals. Fabrication is based on multi-layer printed wiring board (PWB) materials and processes. The LMLA integrates a

package-less Transmit / Receive (T / R) channel and an embedded

circulator layer sub-assembly. In a preferred embodiment, the LMLA is bonded to the UMLA using a

ball grid array (BGA) interconnect approach. The

package-less T / R channel eliminates expensive T / R module

package components and associated assembly costs. The key building block of the package-less LMLA is a lower multi-layer board (LMLB). The LMLB integrates RF, DC and Logic

signal distribution and an embedded

circulator layer. All T / R channel monolithic

microwave integrated circuits (MMIC's) and components, RF, DC / Logic connectors and thermal spreader interface plate can be assembled onto the LMLA using pick and place equipment.

[0016]With this particular arrangement, a tile sub-array can be manufactured without the need to perform any back-

drill and back-fill operations typically required to eliminate RF via stubs. The RF matching pad technique refers to a technique in which a conductor is provided on blank

layers (i.e.,

layers with no

copper) of a circuit board or in

ground plane layers (with etched relief area) of a circuit board. The conductor and associated relief area provided the mechanism to adjust impedance characteristics of RF vias (also referred to as RF interconnect circuits) provided in a circuit board. Since the need to utilize back-

drill and back-fill operations is eliminated, the RF matching pad approach enables a standard, low

aspect ratio drill and plate manufacturing operation to produce an RF via that connects inner circuit layers and which also has a low

insertion loss characteristic across a desired

frequency band such as X-Band (8 GHz-12 GHz).

[0017]As is known, mode suppression vias help electrically isolate the RF interconnects from surrounding circuitry, thereby preventing signals from “leaking” between

signal paths. In conventional systems, the mode suppression vias are also drilled and plated at the same time the interconnecting RF via is drilled and plated.

[0018]With the RF matching pad approach of the present invention, however, all RF and mode suppression vias can be drilled and plated through the entire assembly and there is no need to utilize and back drill and fill operations on the RF interconnects. Thus, manufacturing costs associated with back drill and back fill operations can be completely eliminated while simultaneously improving RF performance because channel to channel variations due to drill tolerances and backfill material tolerances are eliminated.

Login to View More

Login to View More