A kind of low-viscosity high-efficiency energy-saving engine oil and its preparation process

An engine oil and energy-saving technology, applied in the petroleum industry, lubricating compositions, etc., can solve problems such as low friction coefficient and low viscosity, achieve moderate viscosity, increase viscosity index, and excellent synergistic energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

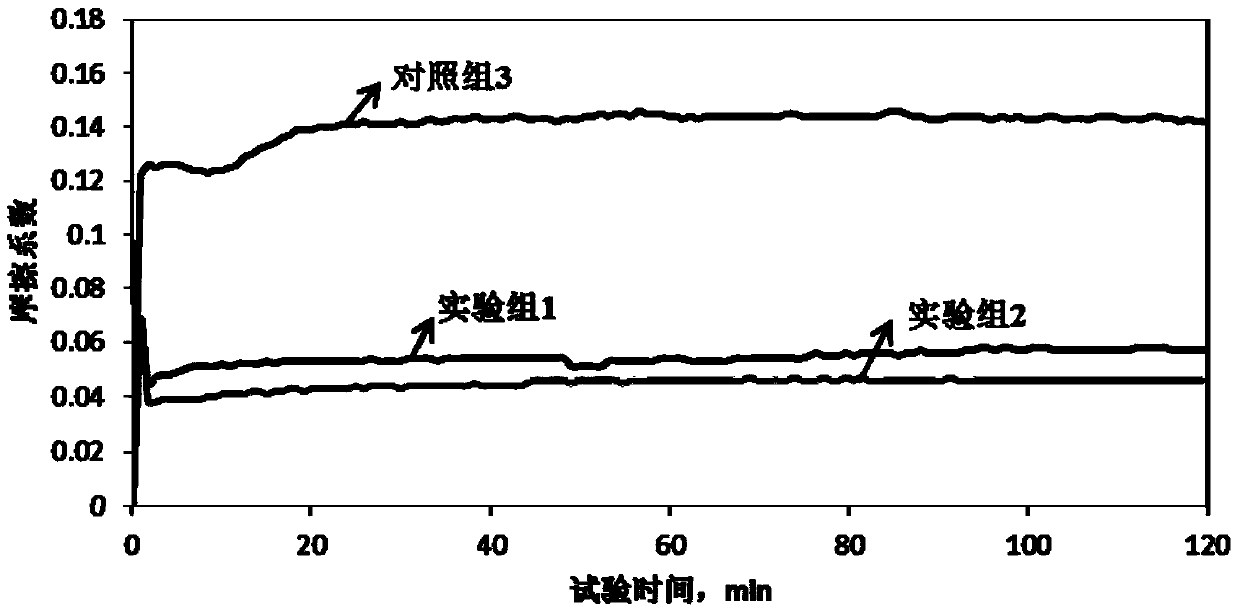

Examples

Embodiment 1

[0032] The low-viscosity high-efficiency energy-saving engine oil described in this embodiment includes high-quality mineral oil (100°C kinematic viscosity 4.094mm) by weight percentage 2 / s, viscosity index 134) 77% (this ratio includes the base oil used to dissolve MoDTC), engine oil compounding agent 9%, viscosity index improver polymethyl methacrylate (PMA) 13.7% and pour point depressant 0.3% %. First, the molybdenum dialkyldithiocarbamate is dissolved in the base oil of 10% of the formulation amount at an addition amount of 0.075wt% based on the molybdenum component, and then the remaining base oil is added to other components (engine oil compounding agent, Viscosity index improver and pour point depressant) to make internal combustion engine oil, then add the dissolved MoDTC to the prepared internal combustion engine oil in an external way, and stir at 60°C for 1 hour in a heating reactor.

[0033] The engine oil compounding agent described in this embodiment is OLOA 555...

Embodiment 2

[0035] The low-viscosity high-efficiency energy-saving engine oil described in this embodiment includes high-quality mineral oil (100°C kinematic viscosity 4.173mm) by weight percentage 2 / s, viscosity index 127) 48% (this ratio includes the base oil used to dissolve MoDTC), synthetic oil (100 ° C kinematic viscosity 3.931mm 2 / s, viscosity index 122) 30%, engine oil compounding agent 9%, viscosity index improver polymethyl methacrylate (PMA) 12.7% and pour point depressant 0.3%. First, the molybdenum dialkyldithiocarbamate is dissolved in the base oil of 10% of the formulation amount at an addition amount of 0.075wt% based on the molybdenum component, and then the remaining base oil is added to other components (engine oil compounding agent, Viscosity index improver and pour point depressant) to make internal combustion engine oil, then add the dissolved MoDTC to the prepared internal combustion engine oil in an external way, and stir at 60°C for 1 hour in a heating reactor. ...

Embodiment 3

[0038] Compared with Example 1, the only difference is that in this example, the amount of each component in the internal combustion engine oil is: engine oil compounding agent 8.0%, viscosity index improver polymethyl methacrylate (PMA) 11.8%, Base oil 80.0% (this ratio includes the base oil used to dissolve MoDTC) and pour point depressant 0.2%, molybdenum dialkyldithiocarbamate is added to internal combustion engine oil in an external way, and the amount added is 0.05% based on molybdenum components wt%.

[0039] The engine oil compounding agent described in this embodiment is OLOA 55501SN / GF-5 engine oil compounding agent produced by Chevron; the pour point depressant is PAMA type pour point depressant produced by Yingchuang Degussa Company.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com