A closed motor and motor base with internal and external cooling air passages

An external cooling and closed technology, applied in the direction of cooling/ventilation devices, electromechanical devices, electrical components, etc., to achieve the effect of light weight, simple structure and high power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

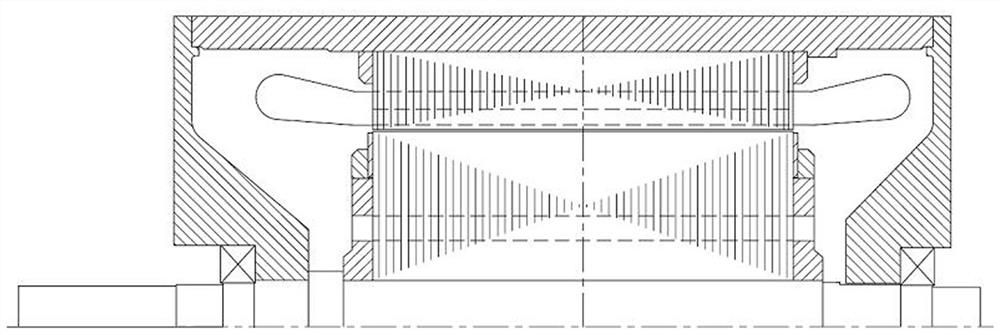

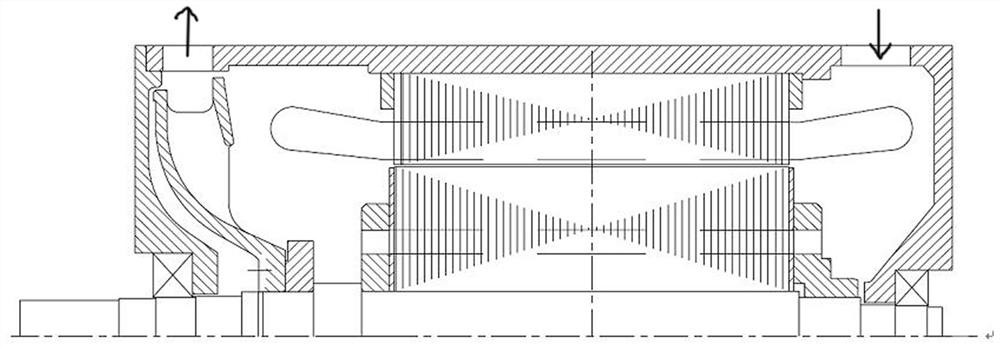

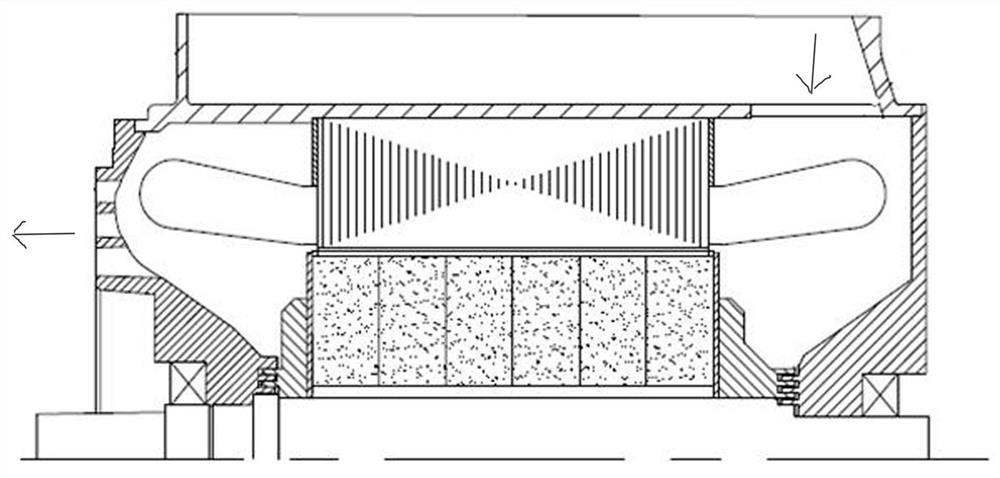

[0018] Such as Figure 4-7As shown, a closed motor with internal and external cooling air passages, including a cylindrical frame 1, a stator 2, a rotor 3, a drive end cover 4 and a non-drive end cover respectively connected to both ends of the frame 1 5. Rotor 3 is punched with evenly distributed axial ventilation holes 6 in the circumferential direction of the iron core. The frame 1 is composed of the inner layer frame 7, the outer layer frame 8, the drive end plate 9 of the frame and the non-drive end end of the frame. The double-layer cylindrical machine base 1 composed of plates 10, the inner layer machine base 7, the outer layer machine base 8, the machine base driving end plate 9 and the machine base non-driving end end plate 10 form a hollow area, and multiple A square cooling plate 11 (the square cooling plate 11 is composed of four end faces and two side faces, the four end faces are the first end face, the second end face, the third end face, and the fourth end face...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com