Detachable oil baffle sealing ring

A technology of oil sealing ring and oil deflecting ring, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve problems such as industrial safety hazards, personnel slipping and falling, major fire risks, etc., and achieve high structural strength and protection Strong oil capacity, the effect of improving safety and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

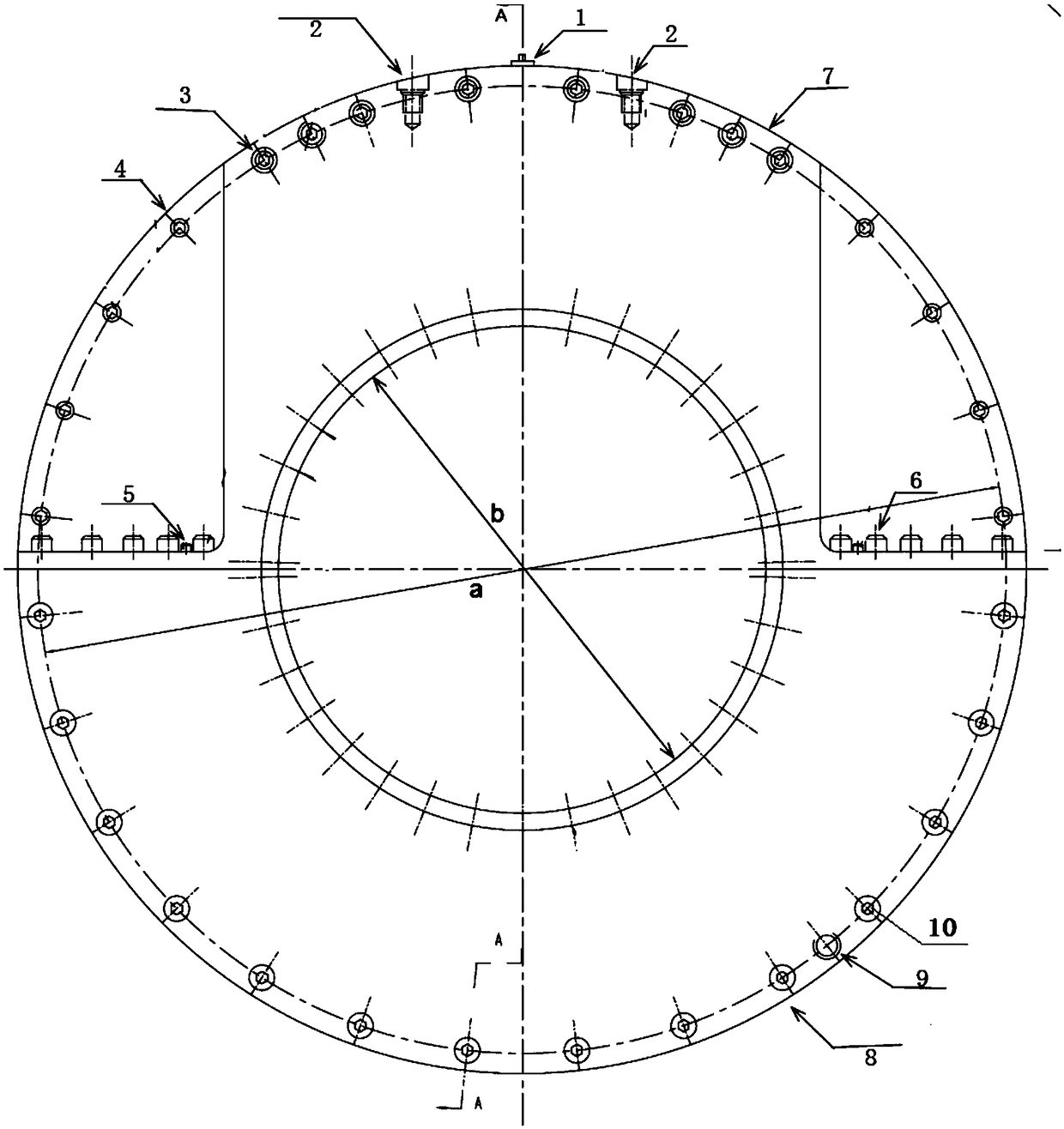

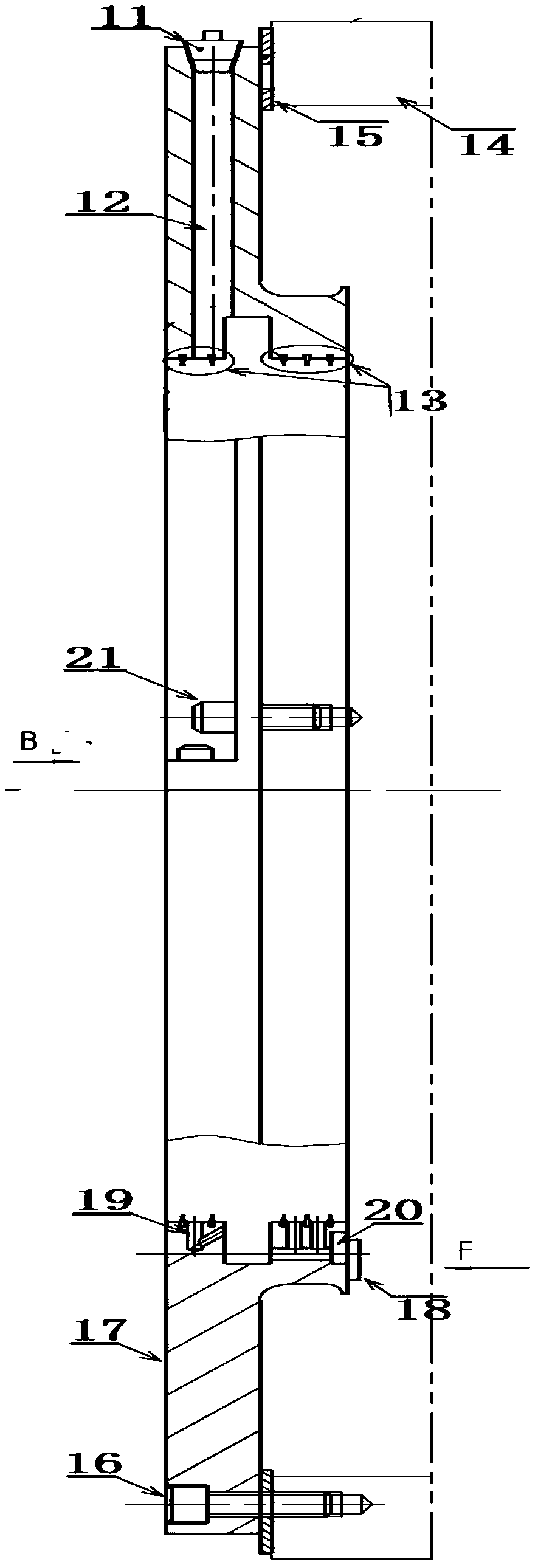

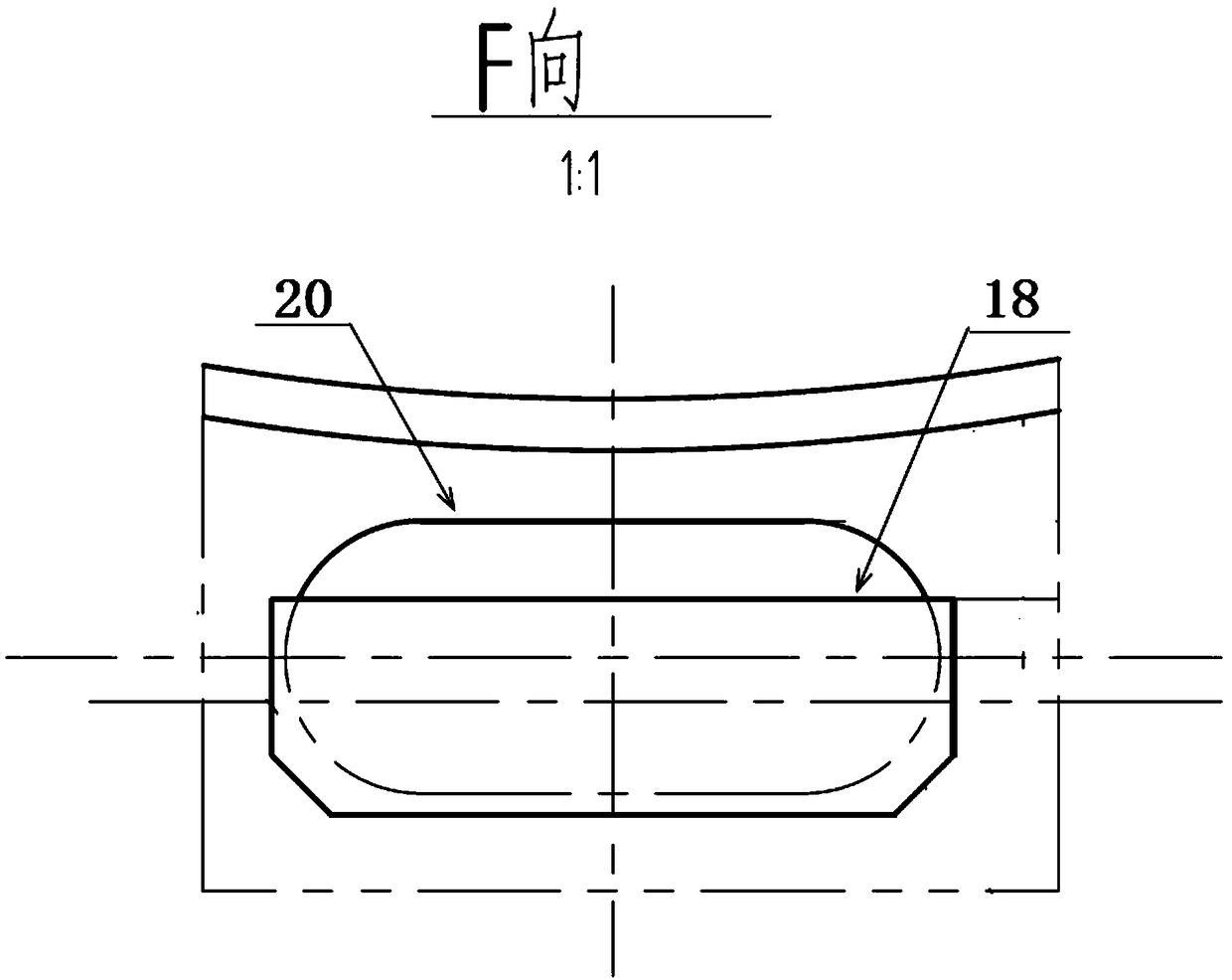

[0025] Such as figure 1 As shown, a detachable oil retaining seal ring, including probe installation sealing hole 1, hoisting hole 2, upper positioning hole 3, upper mounting bolt hole 4, mid-section positioning pin 5, mid-section fastener 6, The upper oil deflector ring 7, the lower oil deflector ring 8, the lower positioning hole 9 and the lower mounting bolt hole 10. Wherein the probe installation sealing hole 1 is a through hole opened at the top of the upper oil deflector ring 7 for installing temperature, vibration and other measuring devices. If not installed, a sealing screw plug can be installed at the end to ensure sealing. There is one hoisting hole 2 on the left and right sides of the probe installation sealing hole 1, which is provided with an internal thread for installing lifting lugs. The upper positioning hole 3 is set on the edge of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com