Oil stopping mechanism of turbine guide bearing

A water guide bearing and bearing technology, which is applied in the field of bearing components, can solve the problems of uneven distribution of lubricating oil, unreasonable overall design, and insufficient oil blocking effect, and achieves good oil blocking effect, simple structure and reasonable overall design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

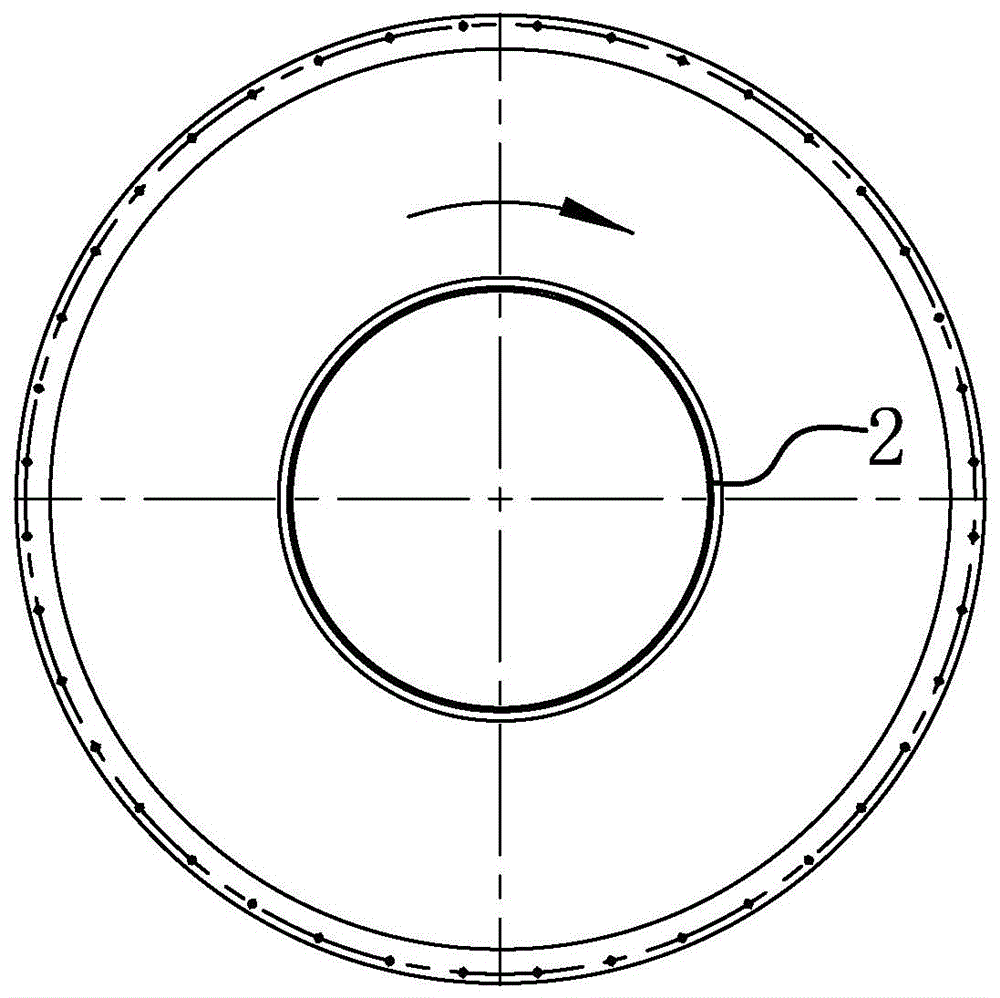

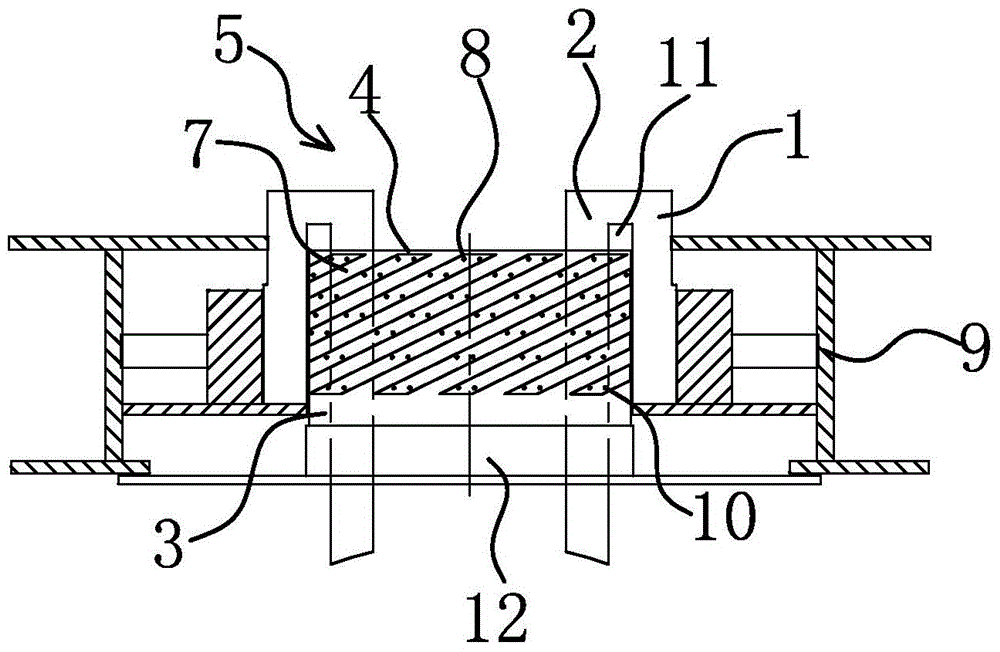

[0022] Such as Figure 1-2 As shown, the water guide bearing oil retaining mechanism includes a cylindrical body 4 arranged at the main shaft 2 with the shaft collar 1 and located in the annular space 3 formed between the main shaft 2 and the shaft collar 1. The main shaft 2 is fixed On the main shaft seat 9 and between the main shaft 2 and the main shaft seat 9, there is a bearing 6 sleeved outside the collar 1. The bearing 6 is rotatably connected with the main shaft 2. The feature is that the body 4 There is a pressure forming structure 5 which can form a positive pressure when the main shaft 2 rotates so as to prevent the loss of lubricating oil. The pressure forming structure 5 forms a positive pressure on the main shaft 2, that is, when the main shaft 2 rotates, since the main body 4 is provided with a helical groove 7, the main shaft 2 and the helical groove 7 rotate relatively, so that the gap between the main shaft 2 and the main body 4 The gap in the gap forms press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com