Engine oil baffle

A technology of oil baffle and circular arc plate, which is applied in the direction of mechanical equipment, engine components, machines/engines, etc., can solve the problems of not being able to play a good role in oil baffle, enhance the overall structural strength of the crankcase, and achieve the effect of oil baffle Good, easy to process, good oil blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

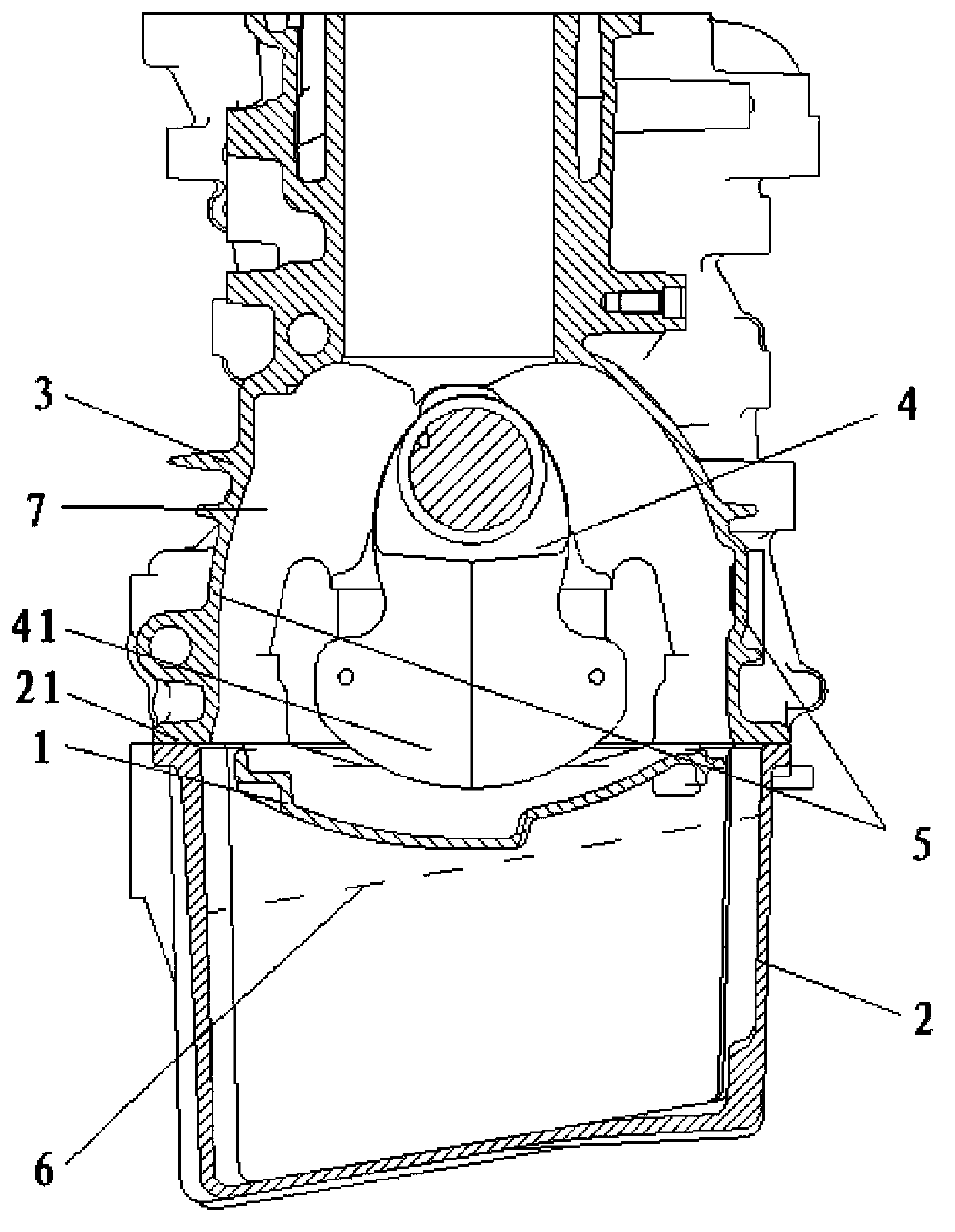

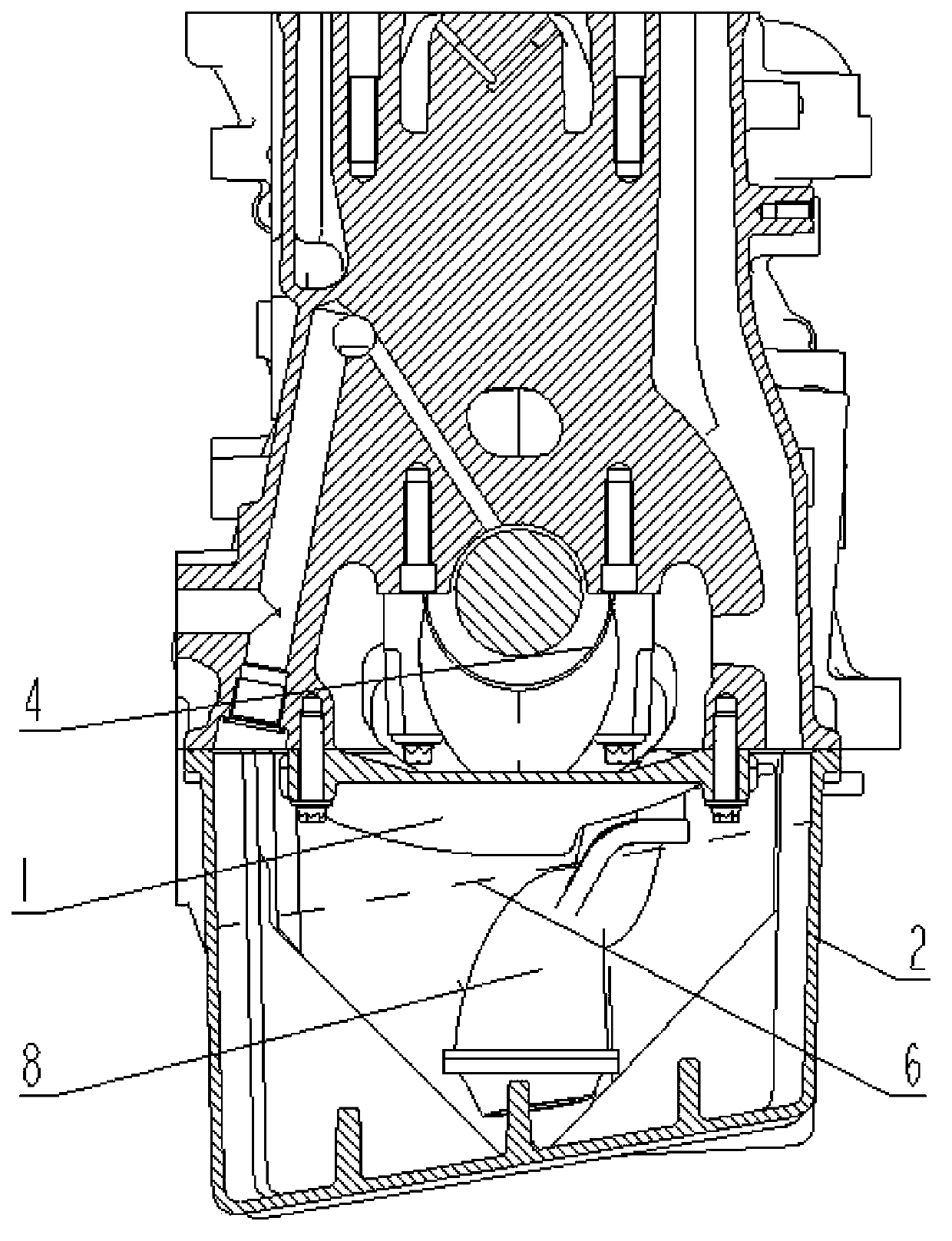

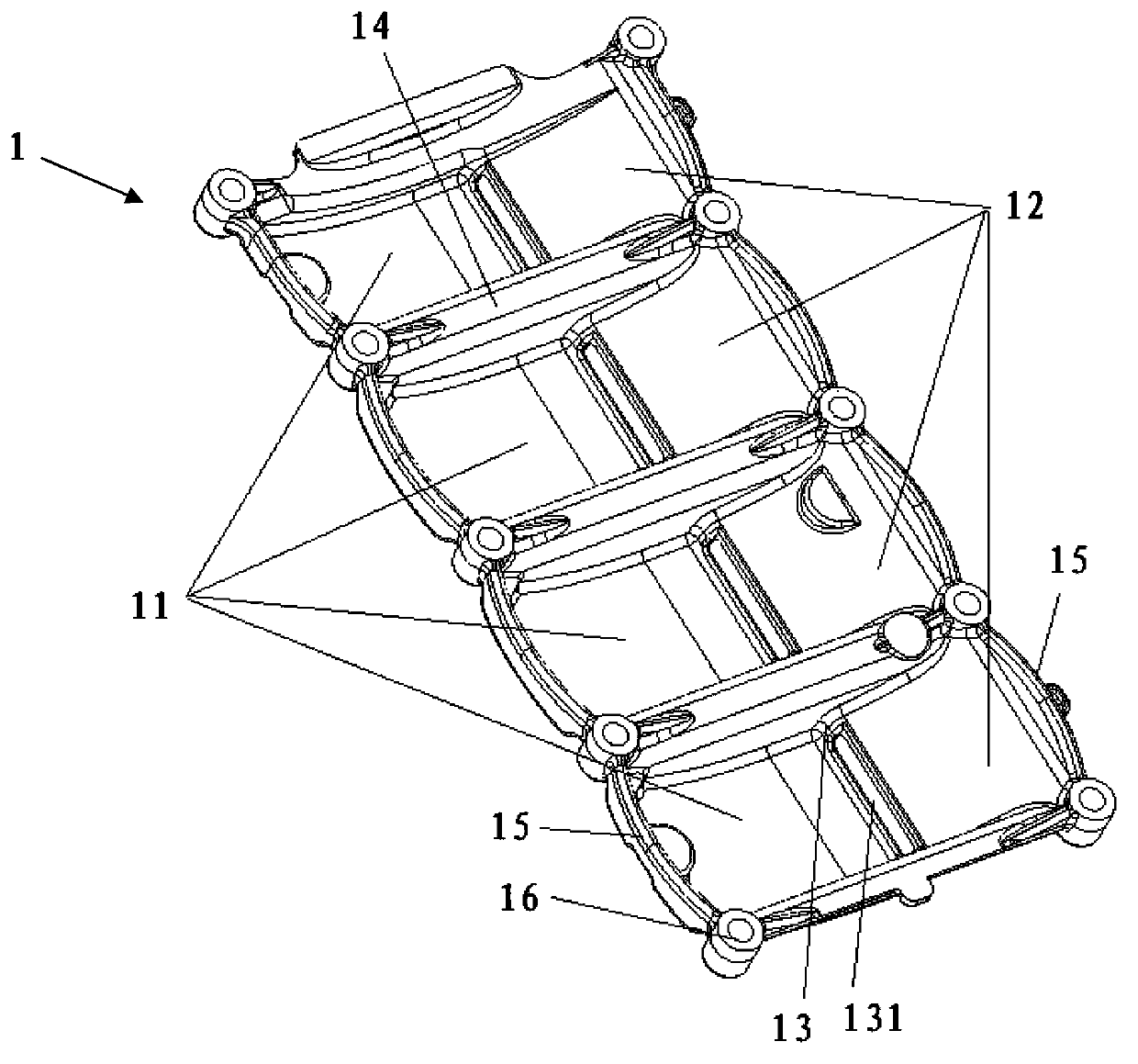

[0041] Such as figure 1 , 2 As shown, the oil baffle 1 is connected to the skirts on both sides of the upper crankcase 3, preferably to the skirts 5 on both sides of the cylinder block. It is located above the oil level 6 in the oil sump below the balance weight 41 of the crankshaft 4 and above the oil filter 8 . Specifically, the oil baffle 1 is fixed on the bottom end surface 21 of the cylinder body. The oil baffle 1 includes: a first arc plate 11 , a second arc plate 12 , and a transition plate 13 . The transition plate 13 has a strip-shaped oil drain hole 131, and the strip-shaped direction of the oil drain hole 131 is consistent with the axial direction of the crankshaft 4. The transition plate 13 connects the first arc plate 11 and the second arc plate 12, and the transition plate 13 The angle with the vertical direction is less than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com