Internal oil blocking structure of compressor and compressor with the oil blocking structure

A technology for compressors and components, which is applied to the field of internal oil blocking structures of compressors, can solve problems such as poor oil blocking effect of an oil blocking plate, and achieve the effects of good oil blocking effect, convenient manufacturing and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

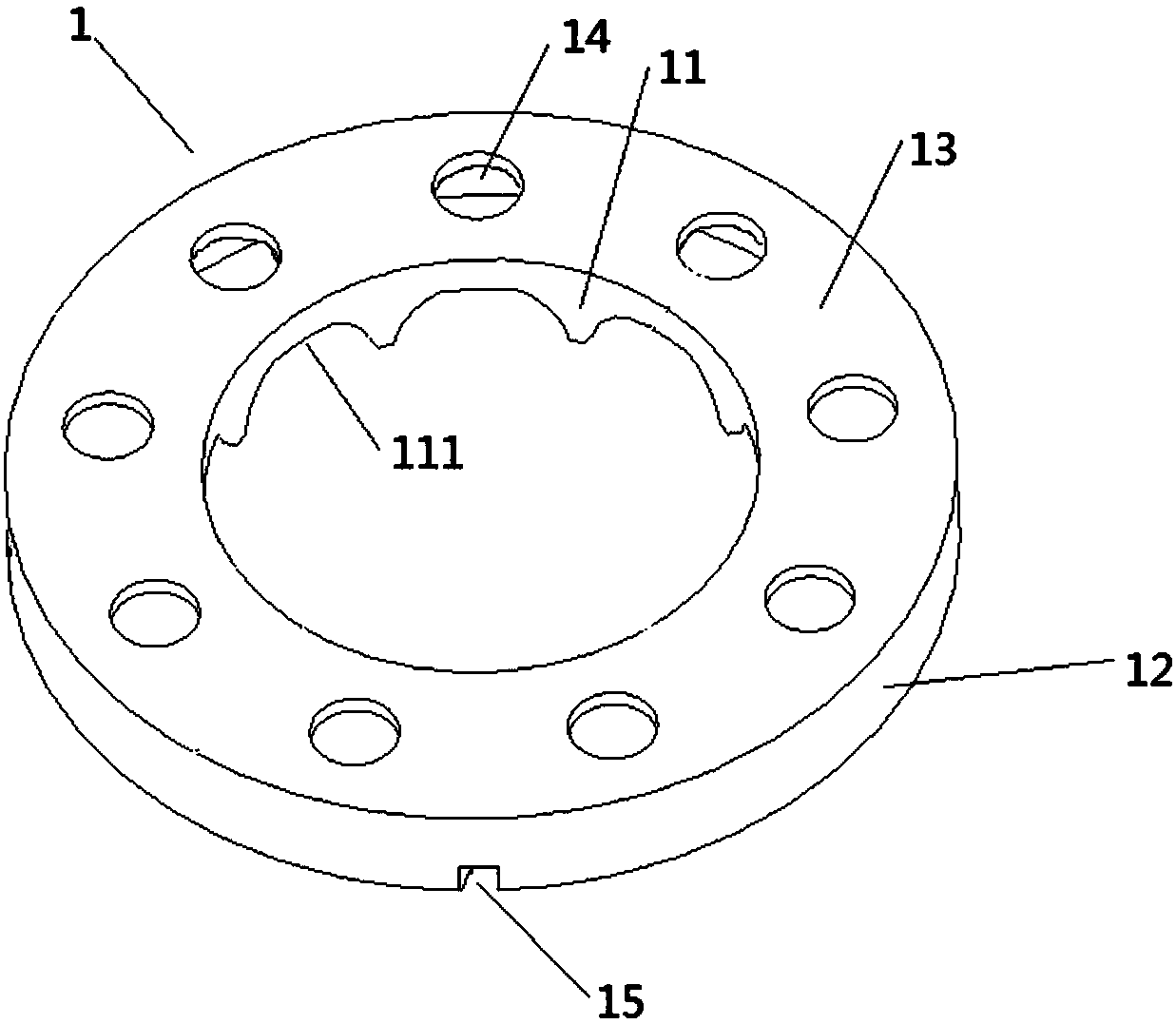

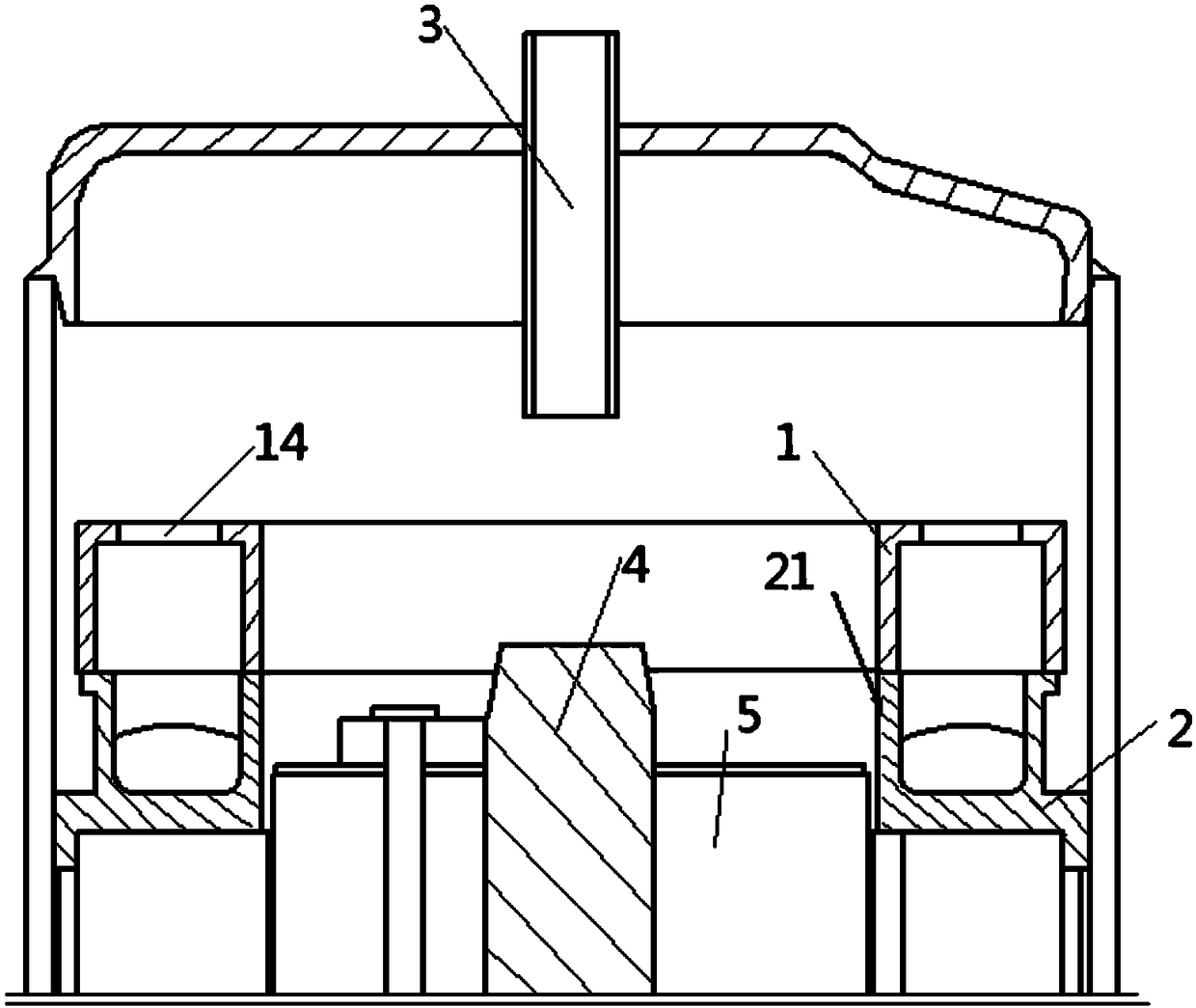

[0036] figure 1 Shown is the internal oil retaining structure of the compressor described in this embodiment, which includes an oil retaining member 1 arranged at a place where the refrigerant circulation area inside the compressor is relatively large. The oil retaining member 1 includes an inner oil retaining wall 11, an outer retaining wall The oil wall 12, the main body oil retaining wall 13, and the inner oil retaining wall 11 cooperate with the inner side of the end of the stator insulating frame 21. The inner oil retaining wall 11 is provided with a number of arc-shaped gaps 111 and the end of the stator insulating frame 21. The inner tooth guards are engaged with each other; the outer oil retaining wall 12 is fixedly matched with the outside of the end of the stator insulating frame 21, and the outer oil retaining wall 12 is provided with one or more correspondingly, on the outer end surface of the stator insulating frame 21, a buckle matching with the card slot 15 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com