Machine oil collector-insulating board assembly for engine of vehicle

A technology of oil collector and vehicle engine, which is applied in the direction of engine lubrication, engine components, machine/engine, etc. It can solve problems such as easy loosening, affecting sealing effect, oil leakage, etc., and achieves simplified installation procedures and simplified overall Machine assembly, reducing the effect of stabilizing oil pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

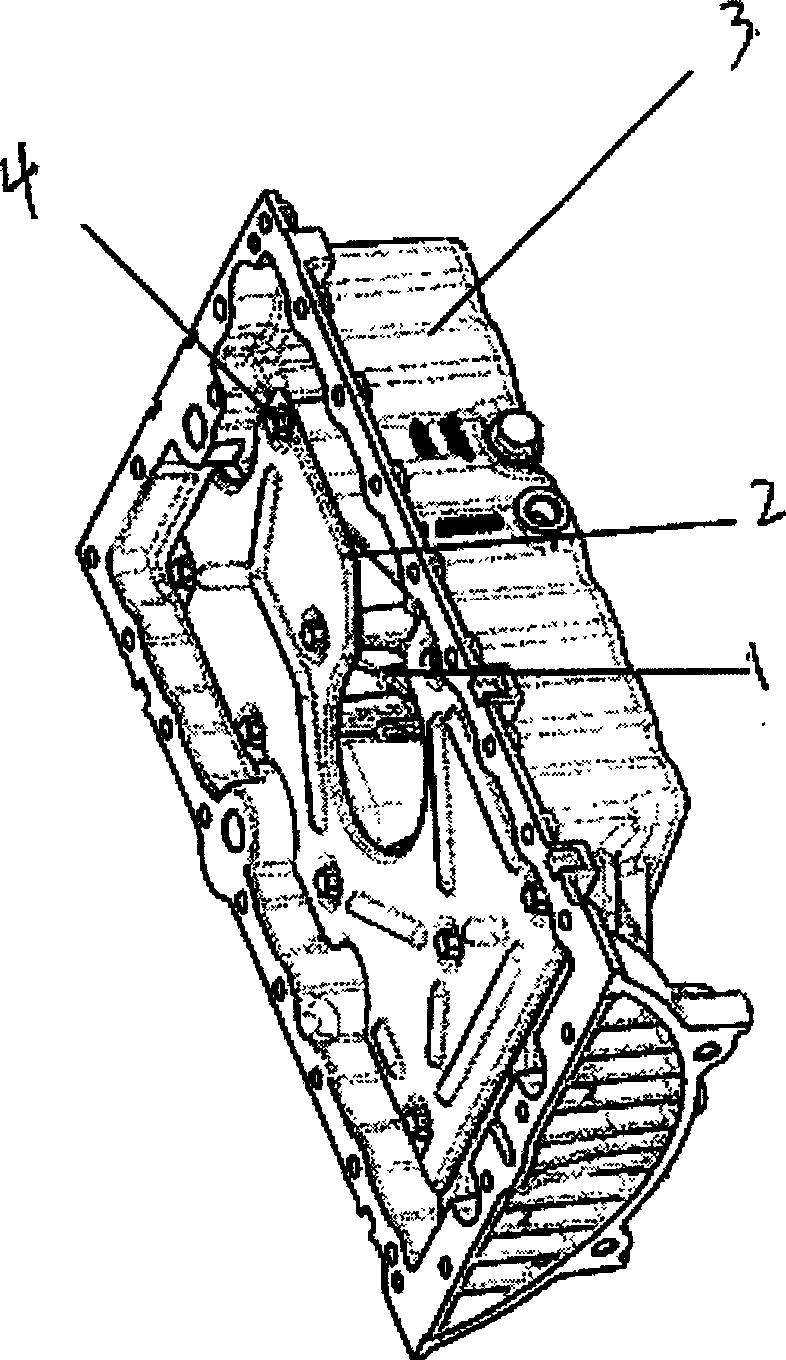

[0018] attached figure 1 It is a structural schematic diagram of the existing oil baffle plate 2 and the oil sump 1 of the oil pan, figure 2 It is a schematic diagram of the existing oil baffle structure. The oil baffle plate 2 is fixed in the oil pan and supported by the ribs 3 in the oil pan. There are bolt holes on the ribs 3 in the oil pan, and the bolts 4 can be inserted into the bolt holes 13 of the oil baffle to fix the oil baffle 2 .

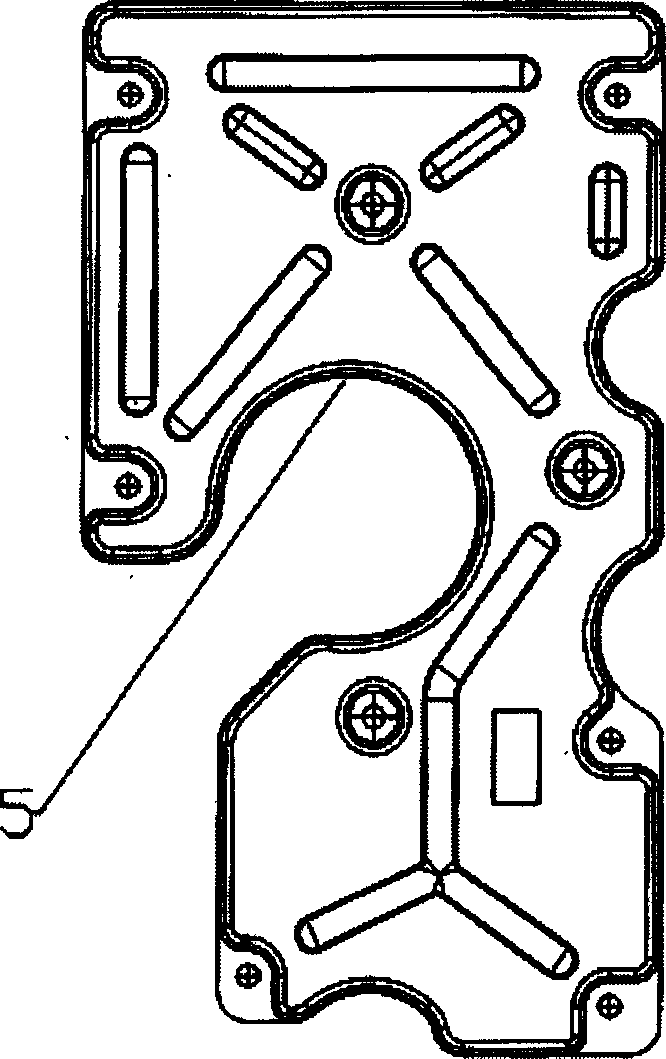

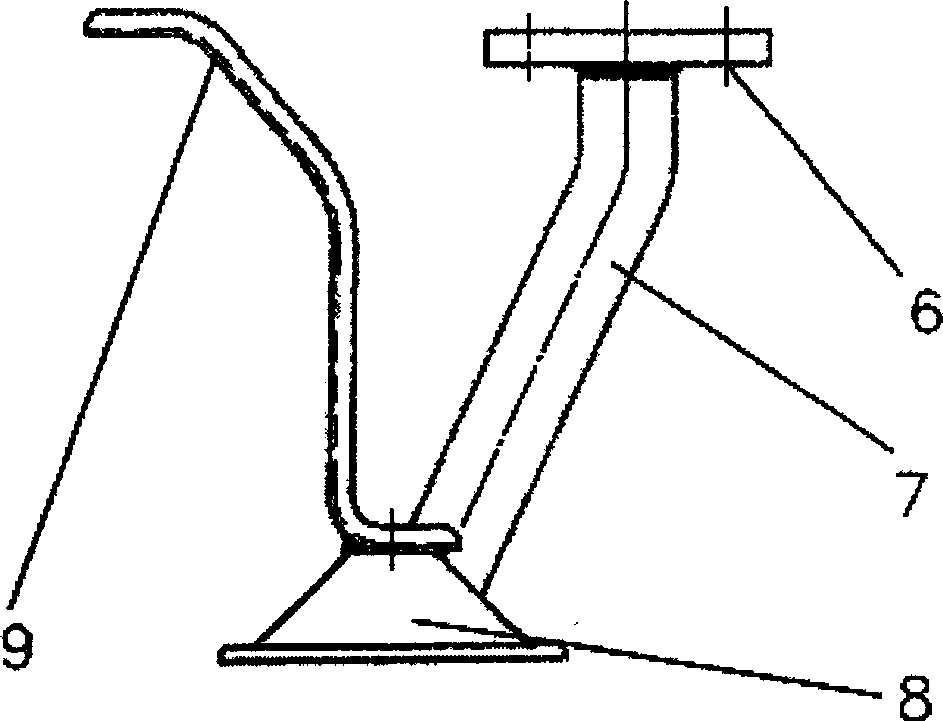

[0019] attached image 3 It is an assembly diagram of an existing oil collector with a flange face. During assembly, the flange surface 6 and the oil pump need to be fixed by two bolts, and the bracket 9 is connected to the frame with bolts.

[0020] attached Figure four It is a structural schematic diagram of an existing double-bracket oil collector. When assembling the oil collector of the double bracket, the oil suction pipe 7 is inserted into the frame, the installation hole of the oil collector adopts a clearance fit, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com