Automatic printing device

A technology of automatic printing and the first printing roller, which is applied in the direction of printing device, printing, printing machine, etc., can solve the problems of ink waste, inconvenient printing of pending printed matter, and difficulty in adjusting the speed of two printing rollers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following is further described in detail through specific implementation methods:

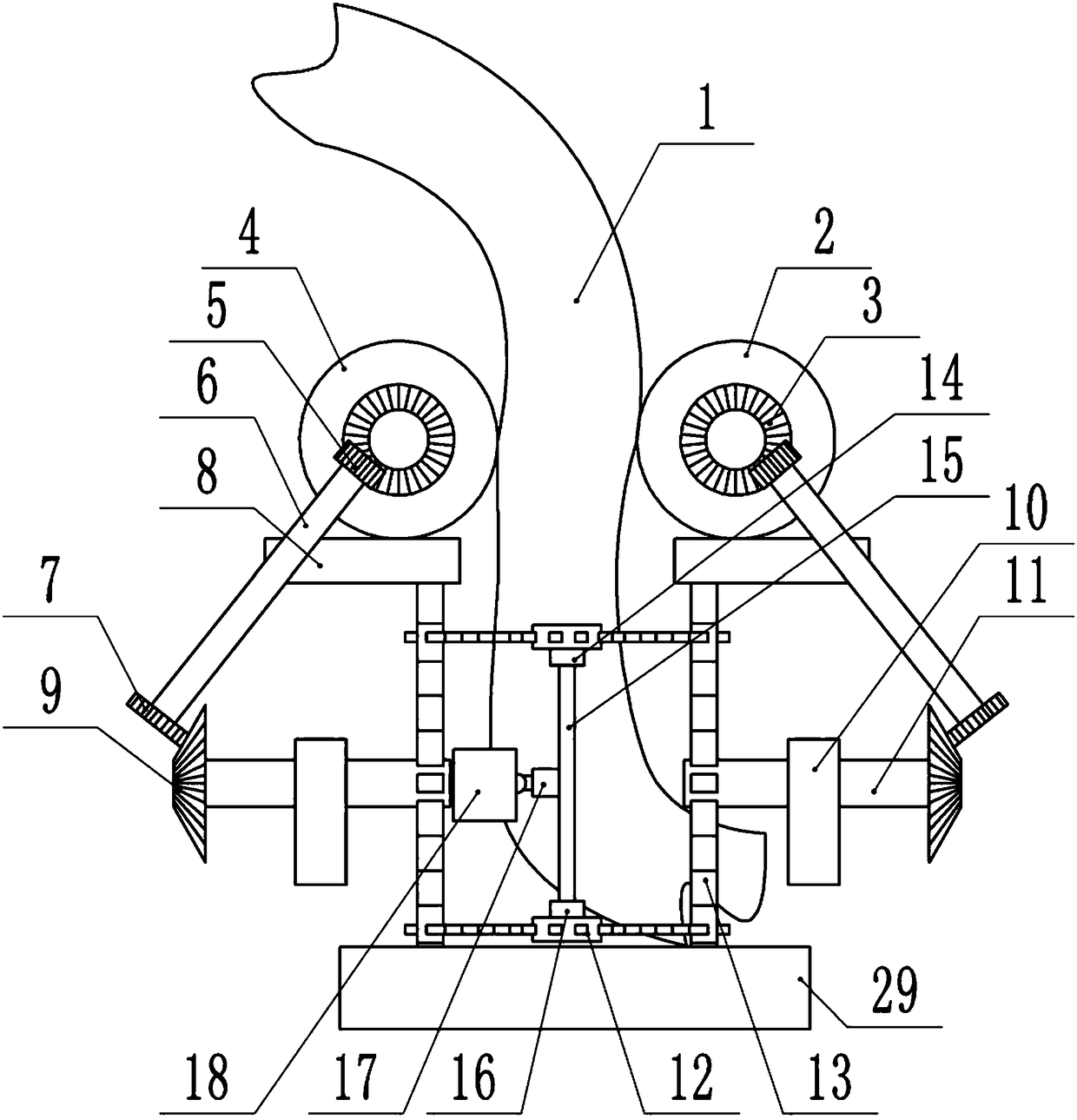

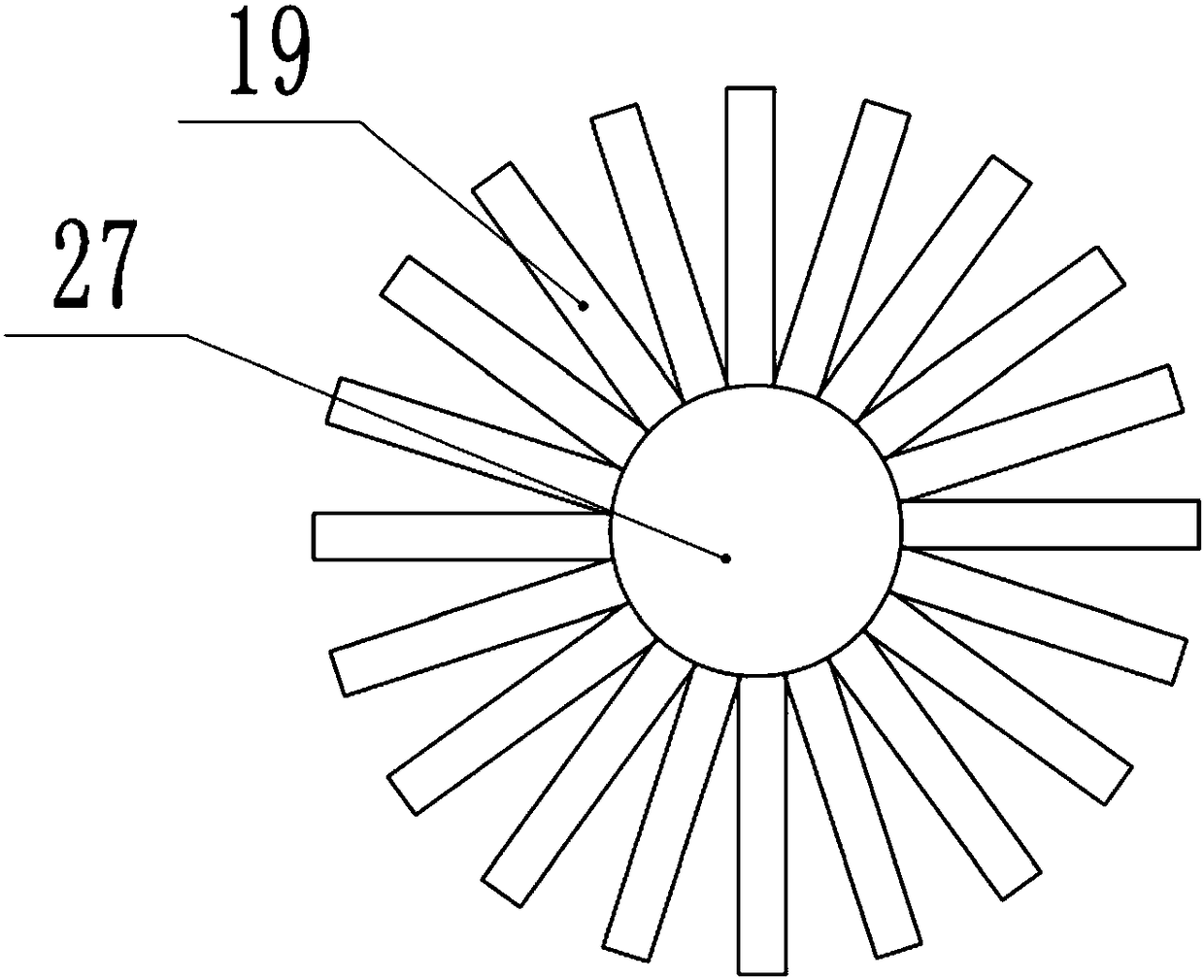

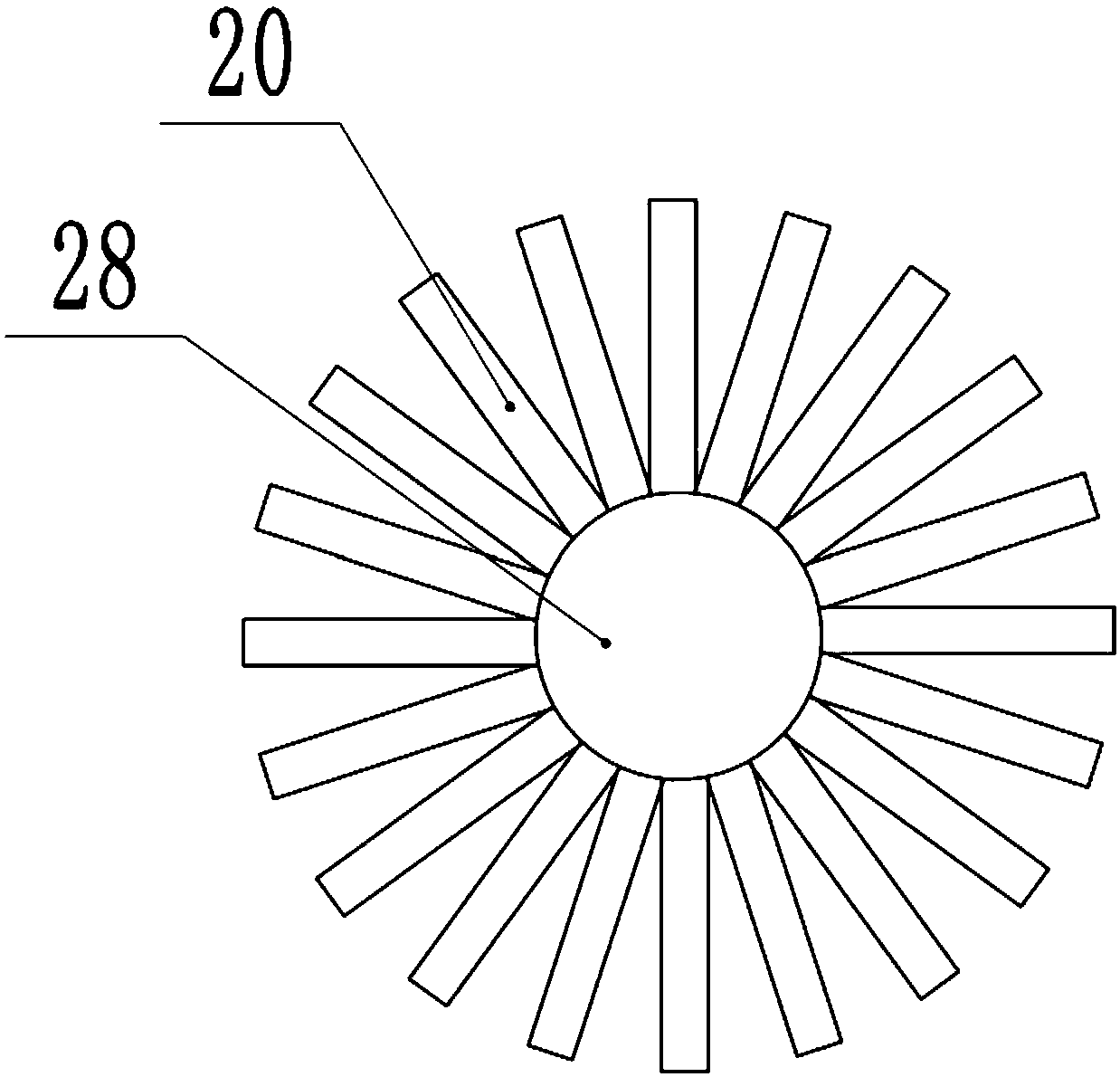

[0019] The reference signs in the accompanying drawings of the description include: the product to be printed 1, the first printing roller 2, the fourth helical gear 3, the second printing roller 4, the second helical gear 5, the linkage shaft 6, the first helical gear 7, the sponge block 8. The third helical gear 9, fixed block 10, rotating shaft 11, planetary rotating member 12, transmission rotating member 13, first bearing 14, connecting shaft 15, second bearing 16, connecting block 17, motor 18, transmission rotating rod 19 , planetary rotating rod 20, dividing plate 21, piston head 22, spring 23, roller 24, weight 25, stay cord 26, transmission rotating ring 27, planetary rotating ring 28, ink tank 29.

[0020] The embodiment is basically as attached Figure 1-Figure 4 Shown: an automatic printing device, including a frame, on which a first printing roller 2 and a second print...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com