Disc type movable polishing grinding tool

A polishing and disc technology, applied in abrasives, manufacturing tools, metal processing equipment, etc., can solve the problem of high-efficiency polishing of uneven stone surfaces, and achieve the effect of improving polishing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

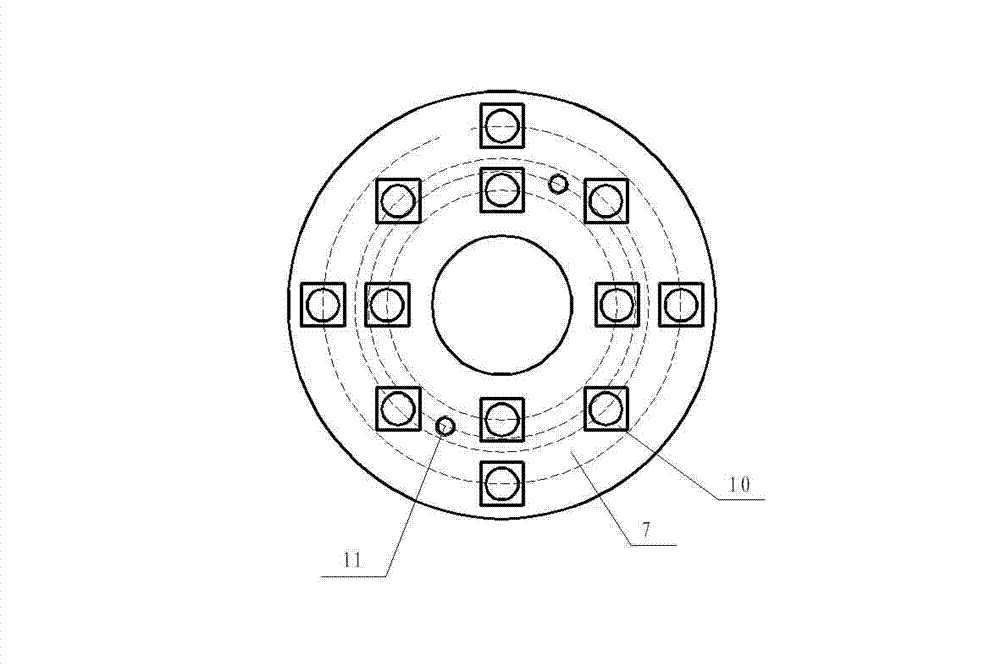

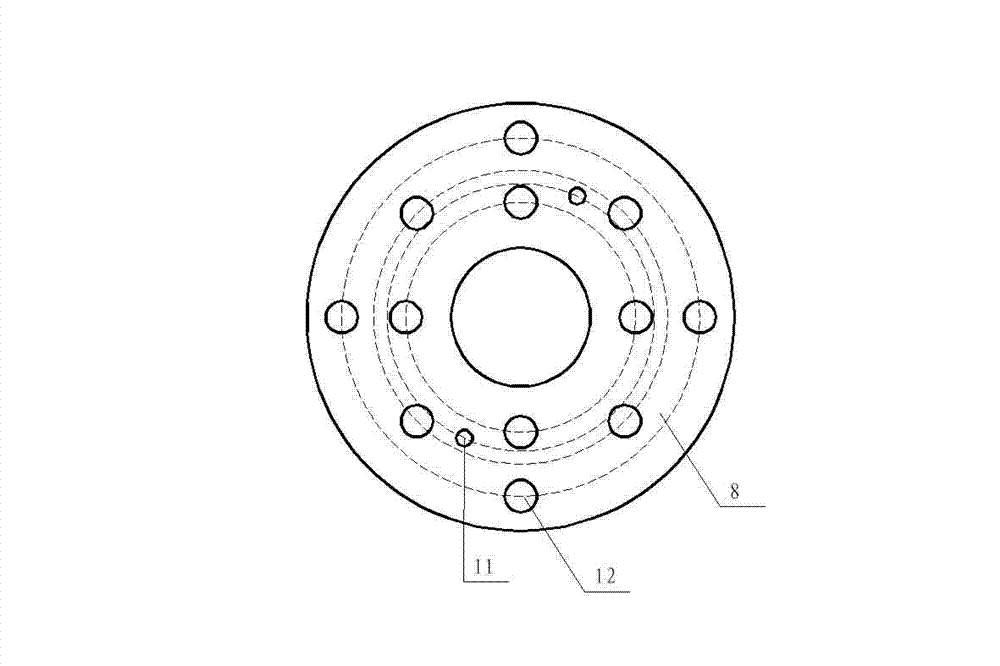

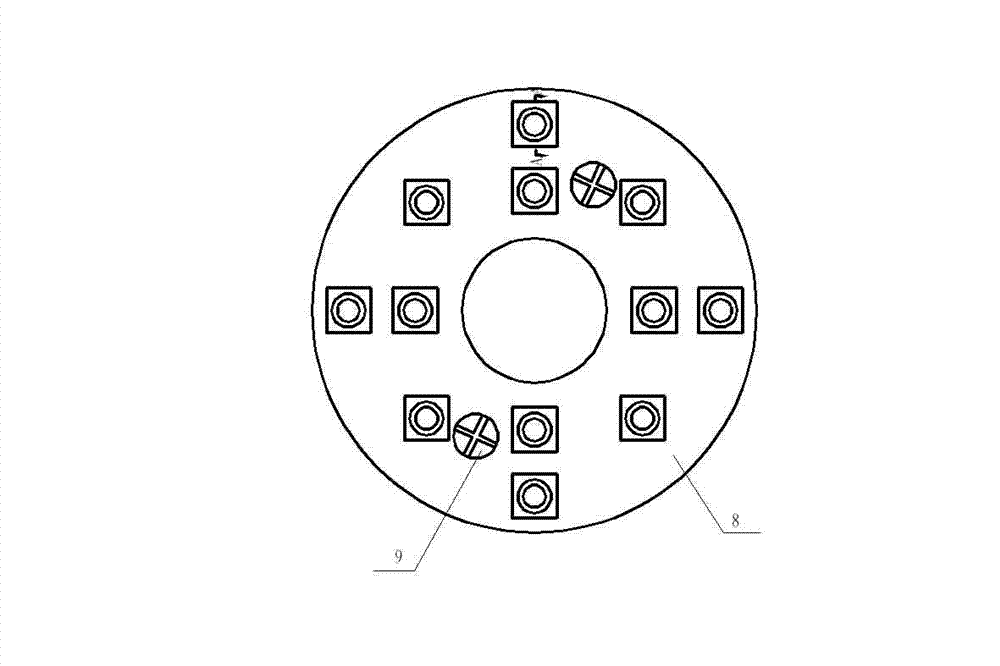

[0011] The disc-type movable polishing abrasive tool is provided with twelve grooves 10 and two screw holes 11 on the base of the grinding disc, and a grinding unit body is installed in each groove 10, and the grinding unit The body is composed of a base 1, a limit washer 2, a cover 3, a spring 4, a limit pin 5, and a single grinding head 6. The cover 3 is connected to the base 1, and the spring 4 is placed outside the single grinding head 6, and the limit pin 5 Fix the single grinding head 6 in the casing 3, and set a limit washer 2 between the casing 3 and the base 1, and form twelve through holes 12 and two screw holes 11 on the grinding disc cover plate 8, After the grinding disc cover 8 and the grinding disc base 7 are connected by two grub screws 9, the single grinding head 6 of the grinding unit passes through the through hole 12 of the grinding disc cover.

[0012] The number of grinding units can be set according to the required size of the grinding disc, and is not l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com