High-efficiency and high-rate lithium battery structure

A high-rate, lithium-ion battery technology, applied in the direction of secondary batteries, structural parts, battery pack components, etc., can solve problems such as increasing the discharge rate of lithium batteries, limiting the discharge rate of lithium batteries, and affecting the conductivity of lithium batteries. Simple and direct structure, good sealing and insulation, and the effect of reducing resistance and heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

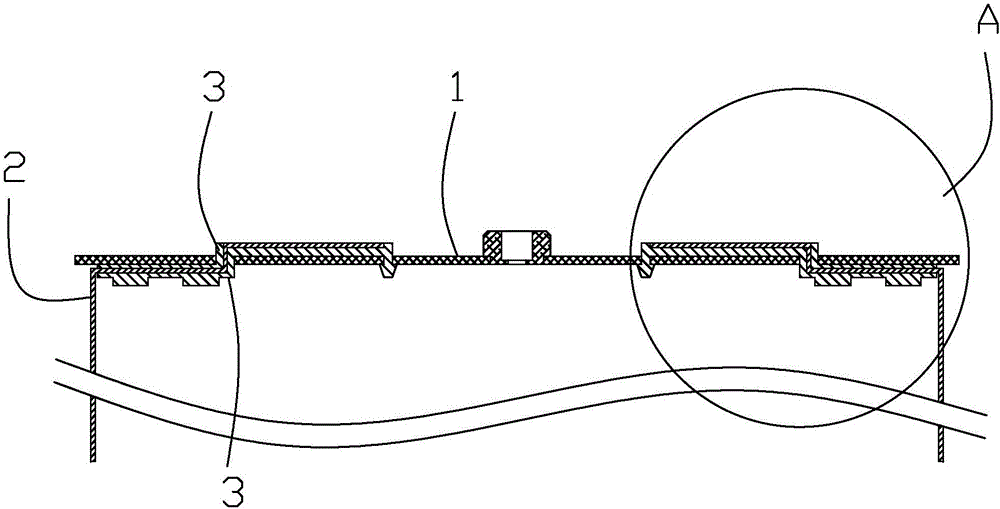

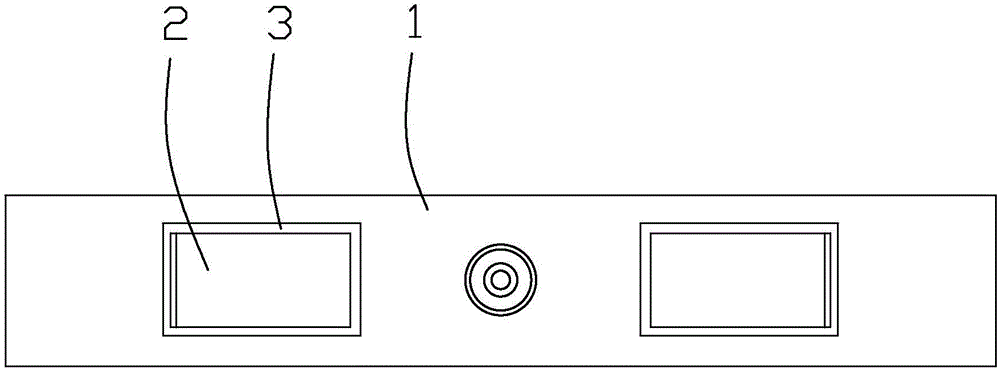

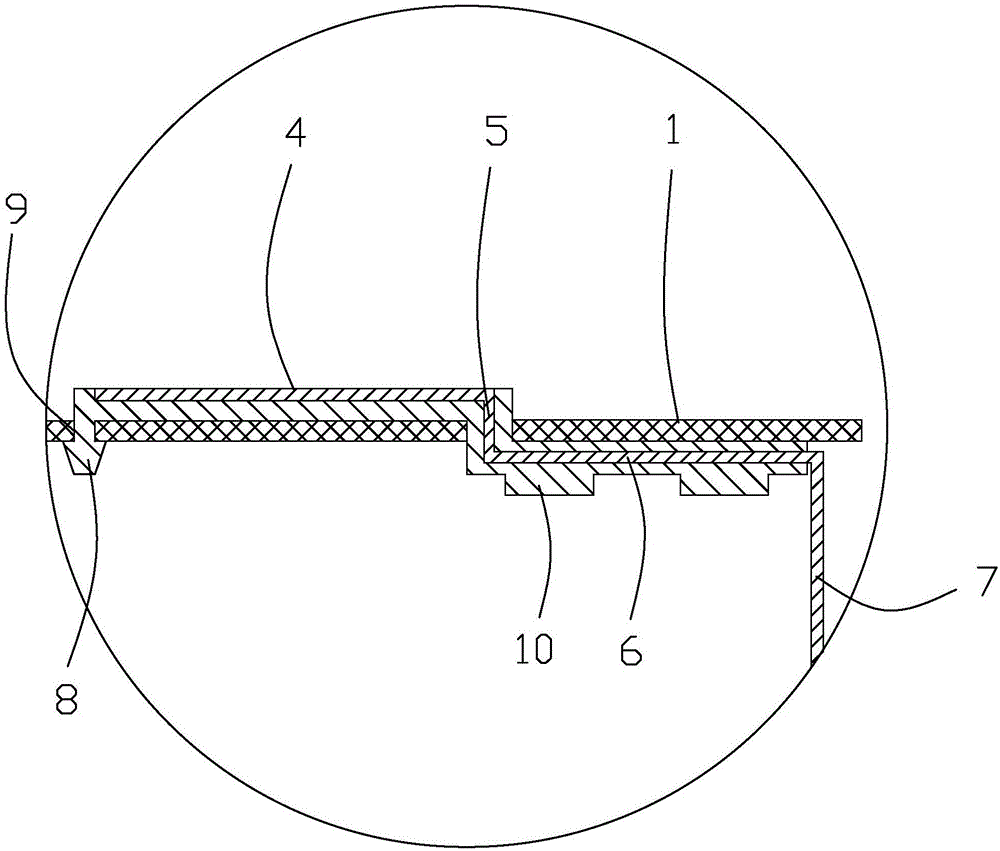

[0019] In this embodiment, a high-efficiency high-rate lithium battery structure, such as figure 1 As shown, the lithium battery includes a cover 1, and an electrode ear 2 is arranged under the cover, and the front end part 4 of the electrode ear passes through the cover and is located on the surface of the cover. The electrode-taking lugs include copper-taking lugs and aluminum-taking lugs. The two taking-electrode lugs are respectively arranged on both sides of the safety valve. They are connected to the cover and the insulating layer in the same structure. In this embodiment, the The copper tab and the aluminum tab are collectively referred to as the tab.

[0020] The electrode ear is sheet-shaped, and the electrode ear includes a front part 4 and a rear end part 6. The front part and the rear end part are connected by a connecting part 5, and the front part, the connecting part and the rear end part form the electrode ear in a stepped shape Structure, the rear end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com