Patents

Literature

73results about How to "Short filling time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

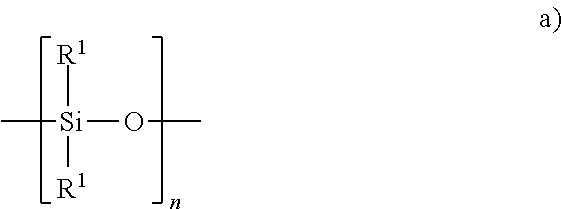

Solid fabric care composition with a polysaccharide

InactiveUS20110082066A1Short filling timeAvoid stickinessLiquid surface applicatorsSoftening compositionsWater solubleCleaning product

The present invention is a solid fabric care composition comprising a water-soluble carrier, a water-soluble polymer, a fabric care compound, a polysaccharide and a fragrance, wherein the water-soluble carrier is in particle form, having a coating comprising the water-soluble polymer and the fragrance, and a mixture of the fabric care compound and the polysaccharide being incorporated at least partly into the coating, or the coating of the water-soluble carrier being coated at least partly with a mixture of the fabric care compound and the polysaccharide. Also described herein are fabric care washing or cleaning products comprising the fabric care compositions.

Owner:HENKEL KGAA

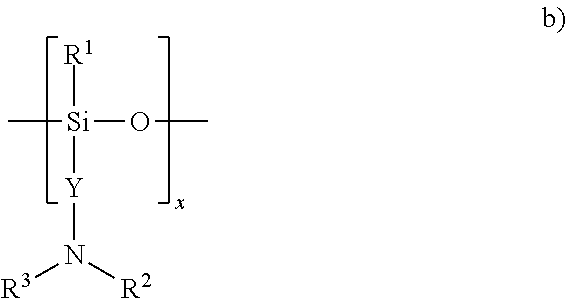

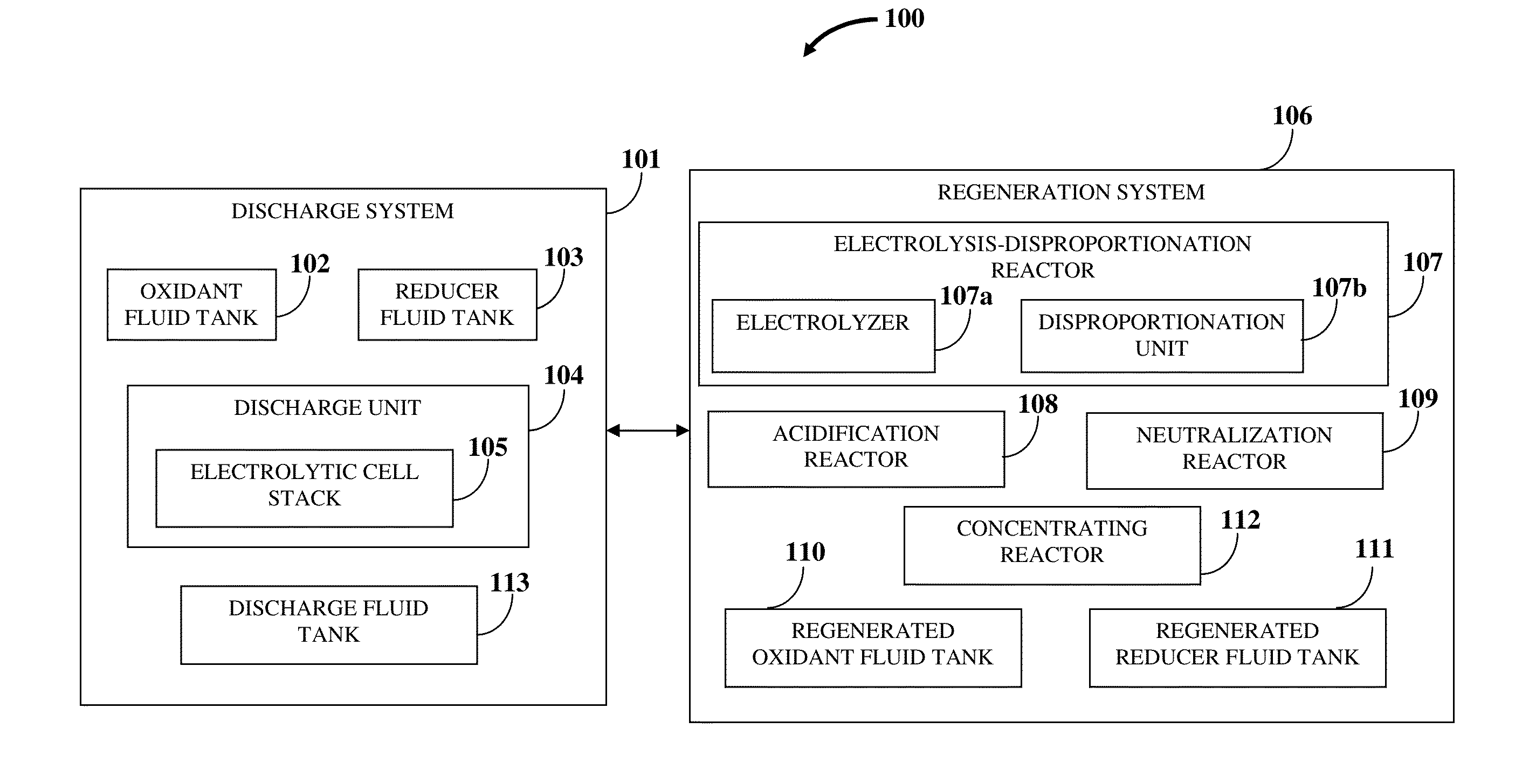

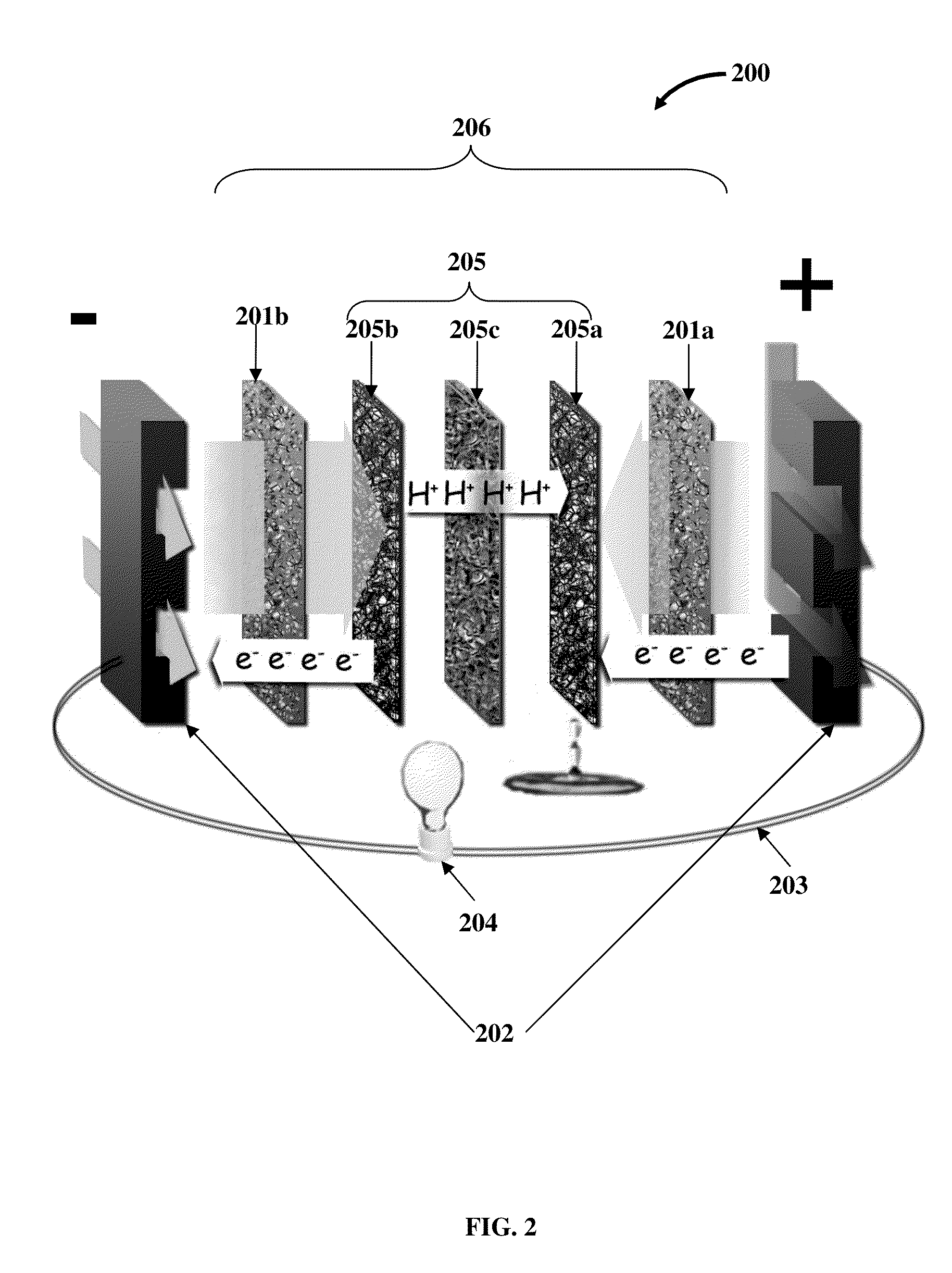

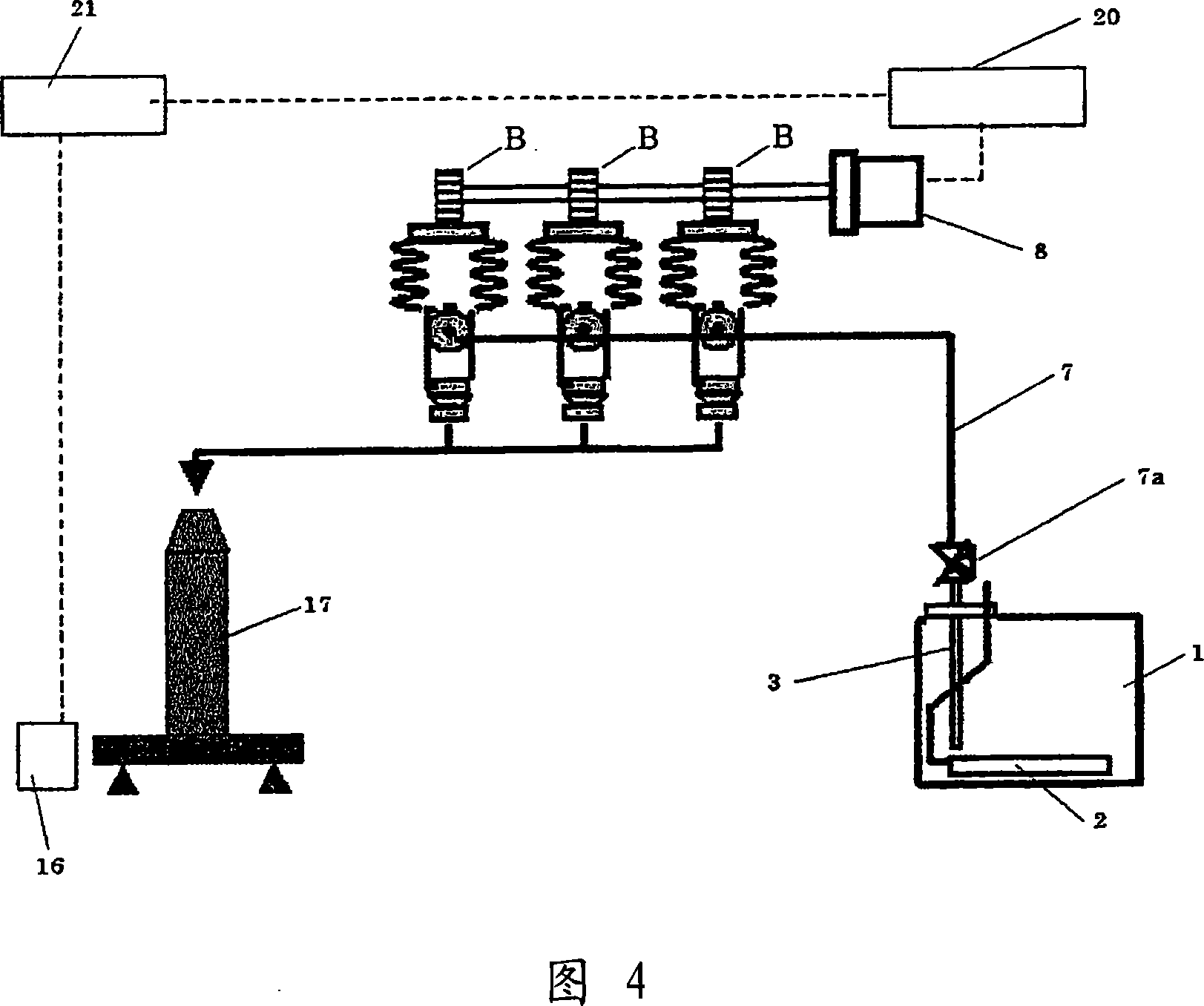

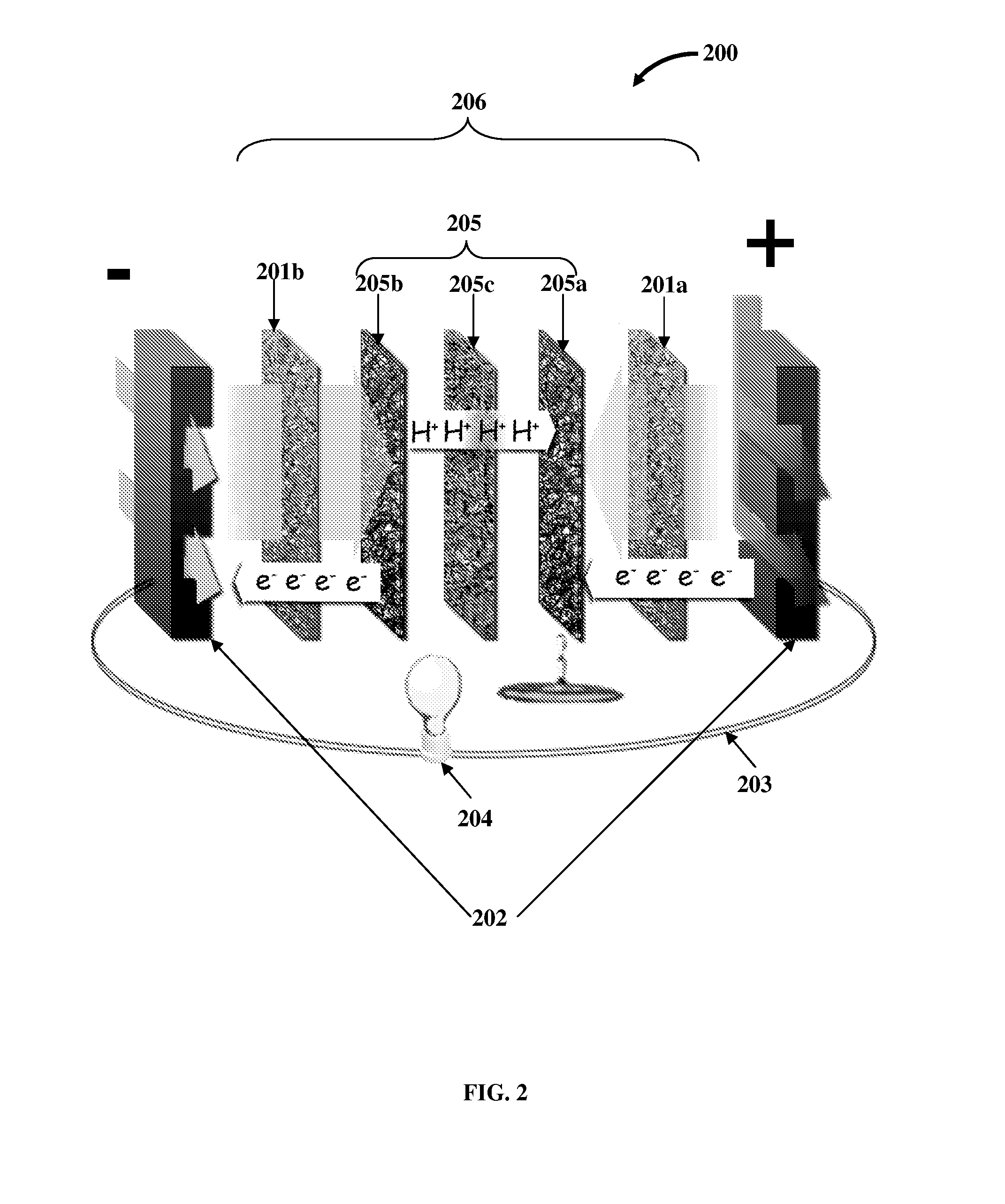

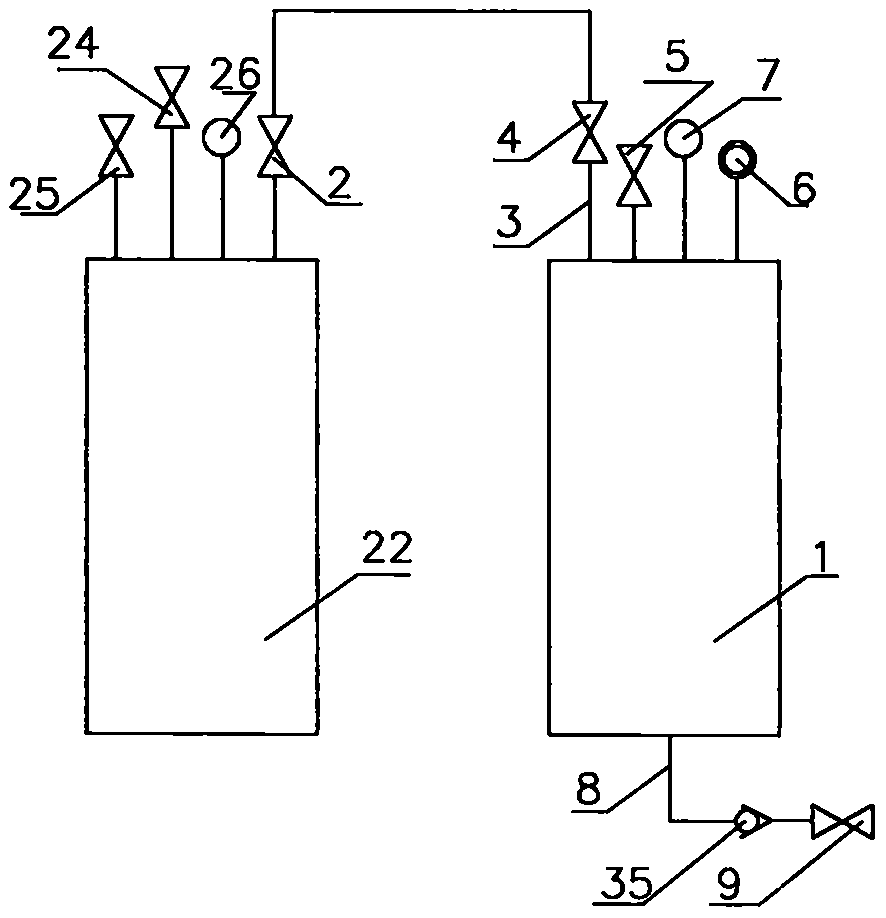

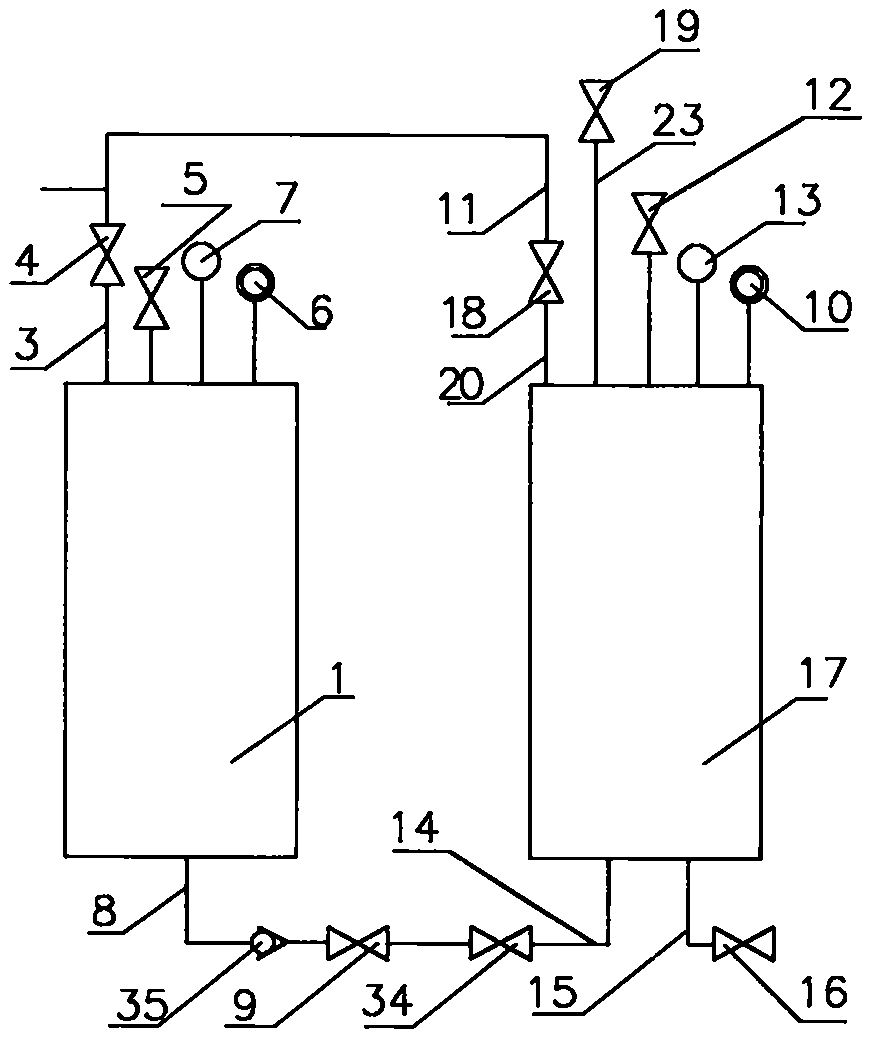

Flow Battery And Regeneration System With Improved Safety

InactiveUS20140170511A1Increase powerShort filling timeRegenerative fuel cellsIndirect fuel cellsProcess engineeringReducer

A method for producing electric power and regenerating an aqueous multi-electron oxidant (AMO) and a reducer in an energy storage cycle is provided. A discharge system includes a discharge unit, an acidification reactor, and a neutralization reactor. The acidification reactor converts an oxidant fluid including the AMO into an acidic oxidant fluid. The discharge unit generates electric power and a discharge fluid by transferring electrons from a positive electrode of an electrolyte-electrode assembly (EEA) to the AMO and from a reducer to a negative electrode of the EEA. The neutralization reactor neutralizes the discharge fluid to produce a neutral discharge fluid. The regeneration system splits an alkaline discharge fluid into a reducer and an intermediate oxidant in a splitting-disproportionation reactor and releases the reducer and a base, while producing the AMO by disproportionating the intermediate oxidant. The regenerated AMO and reducer are supplied to the discharge unit for power generation.

Owner:FTORION

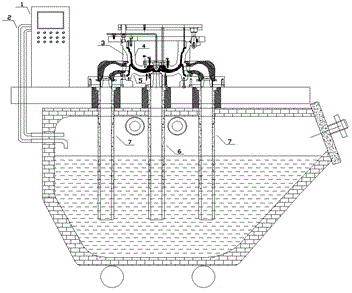

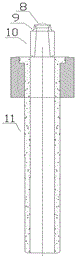

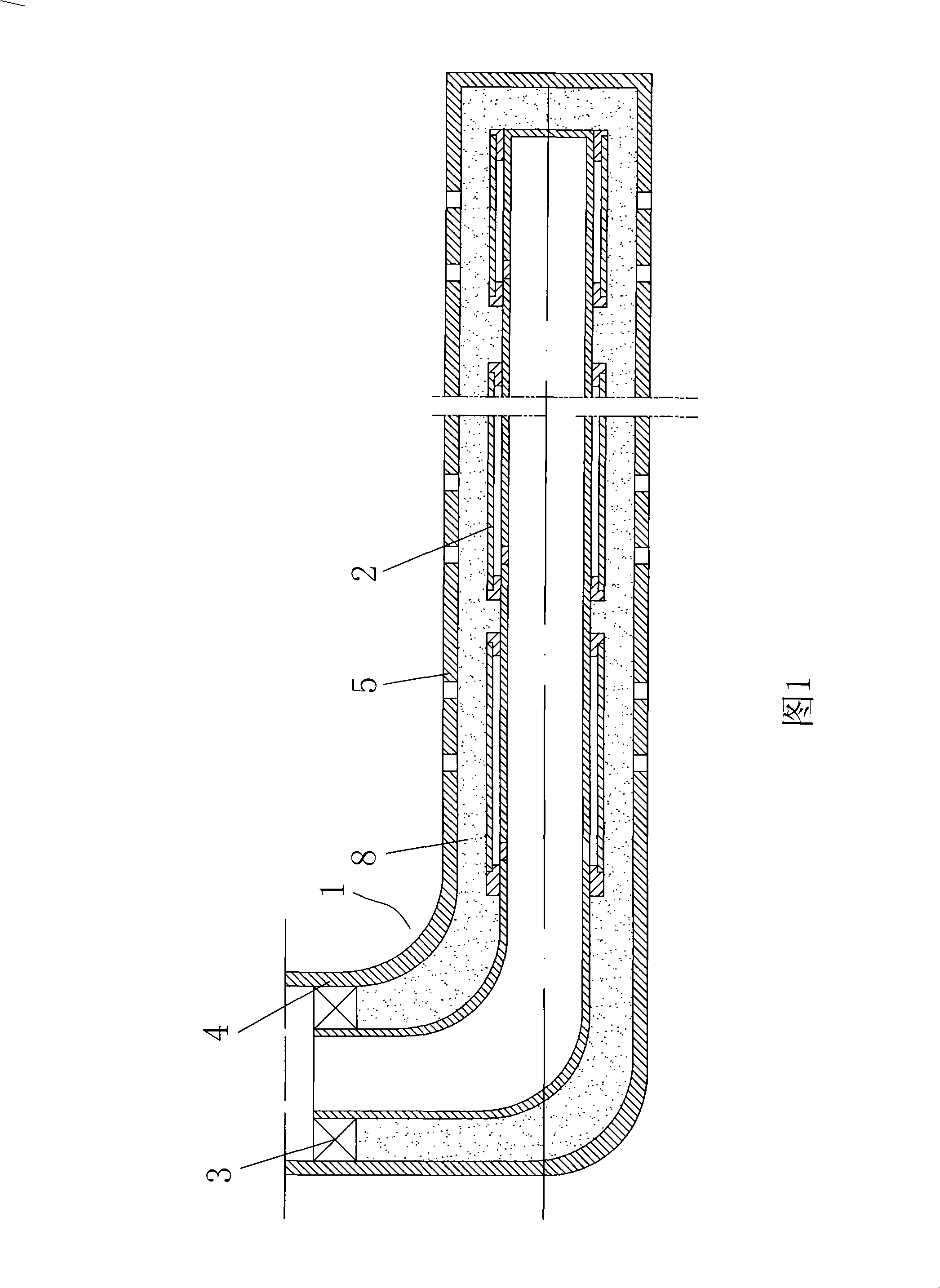

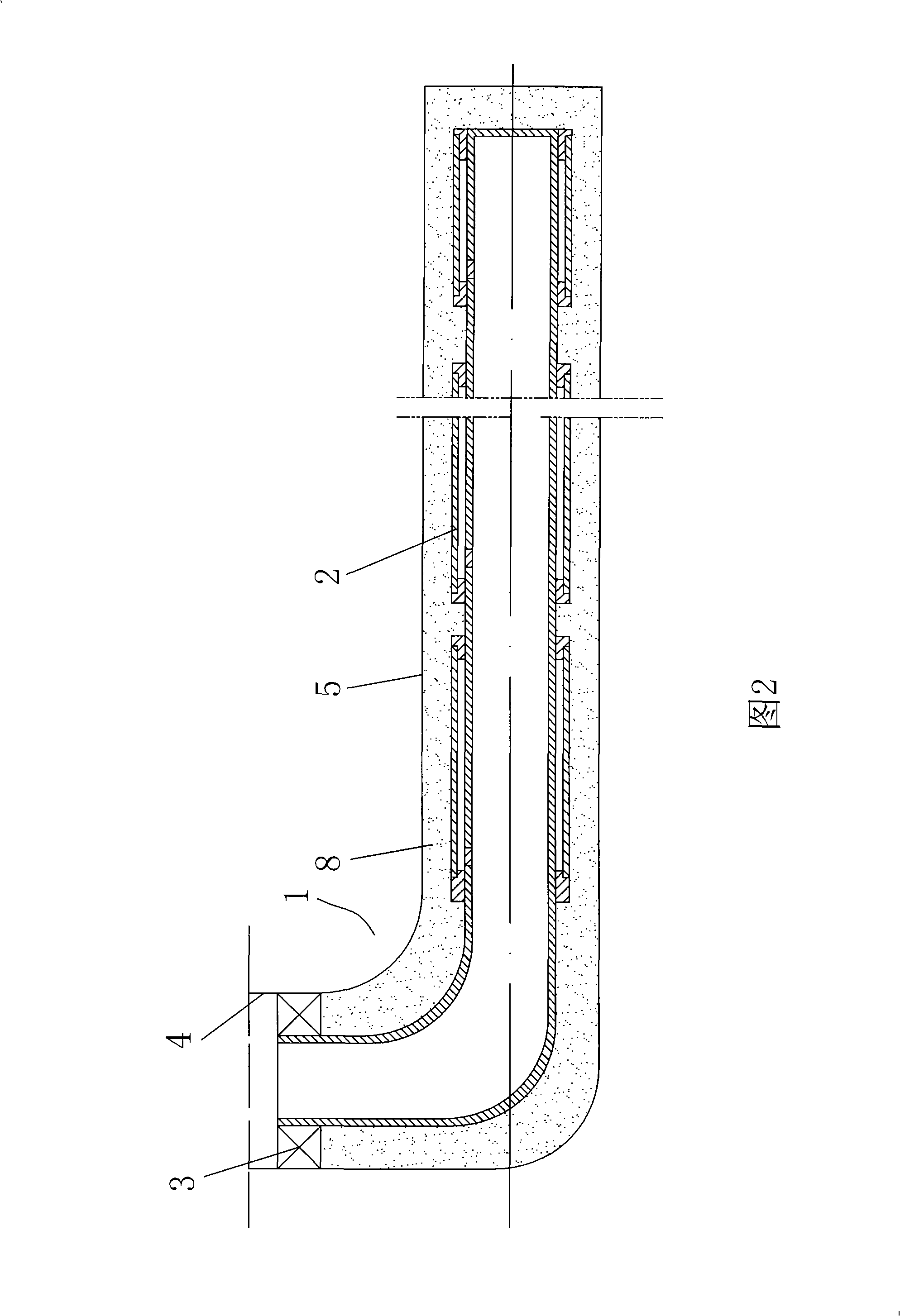

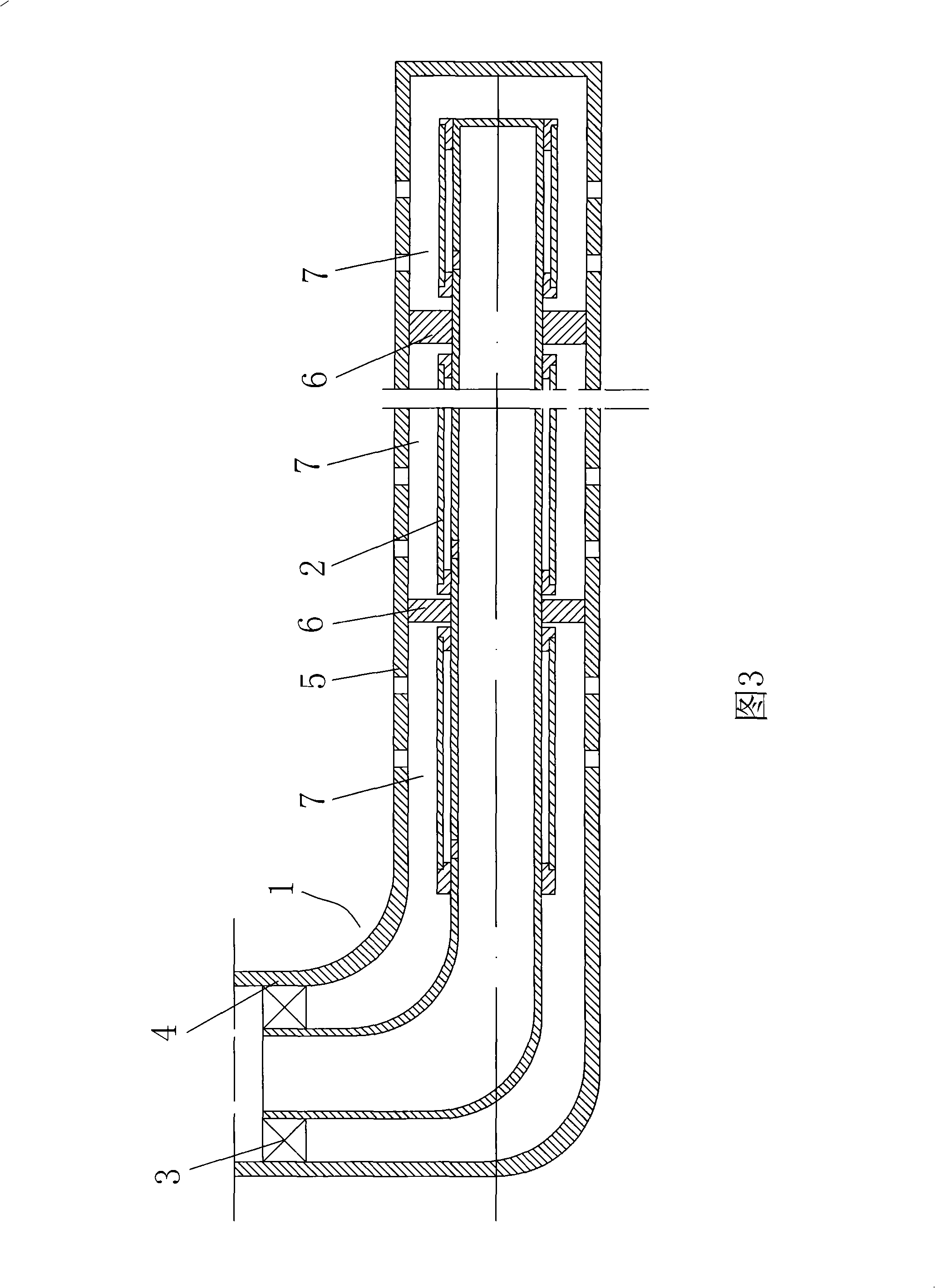

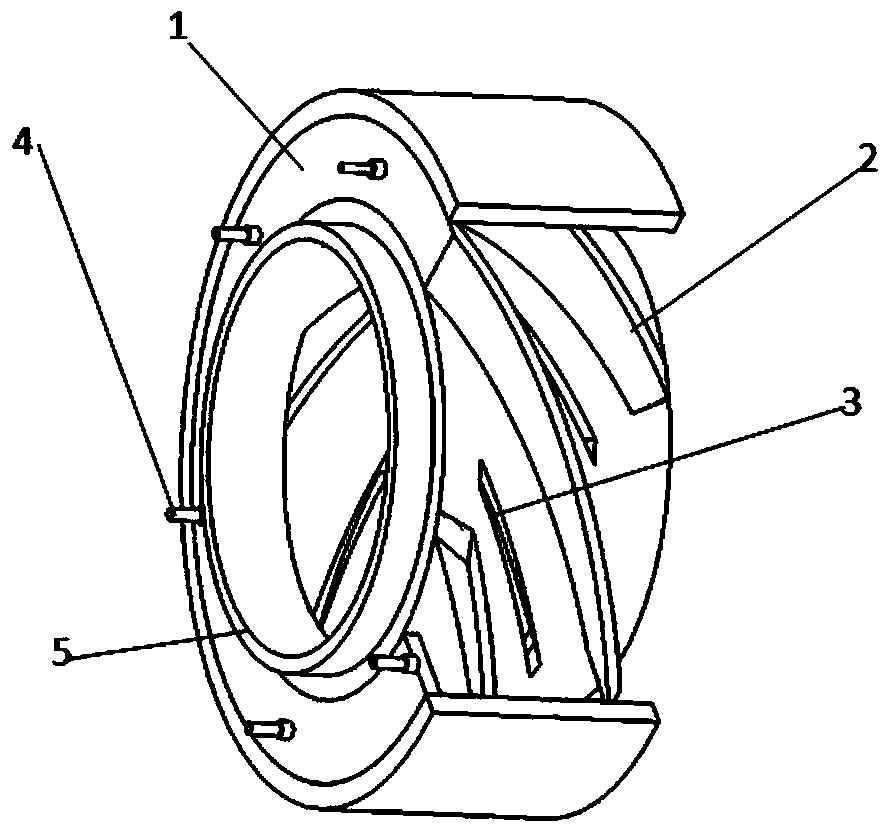

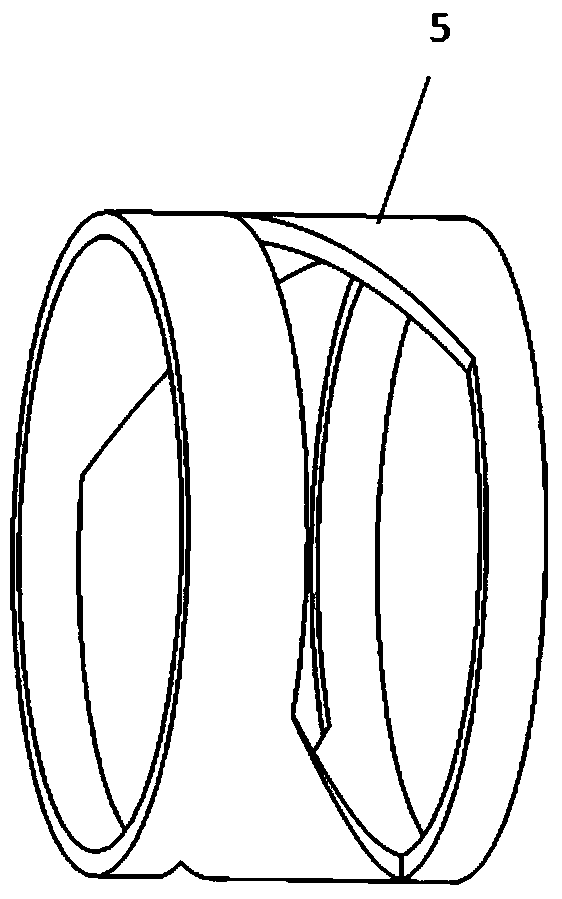

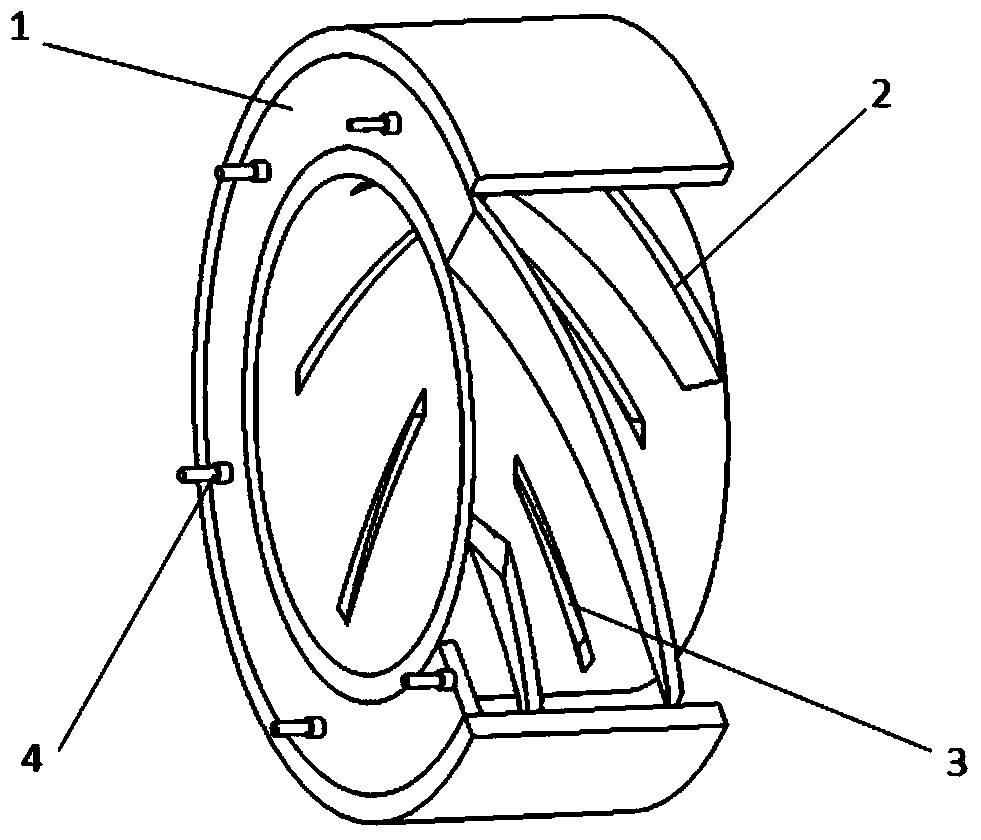

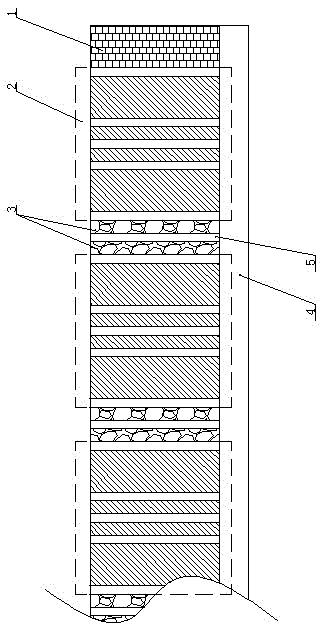

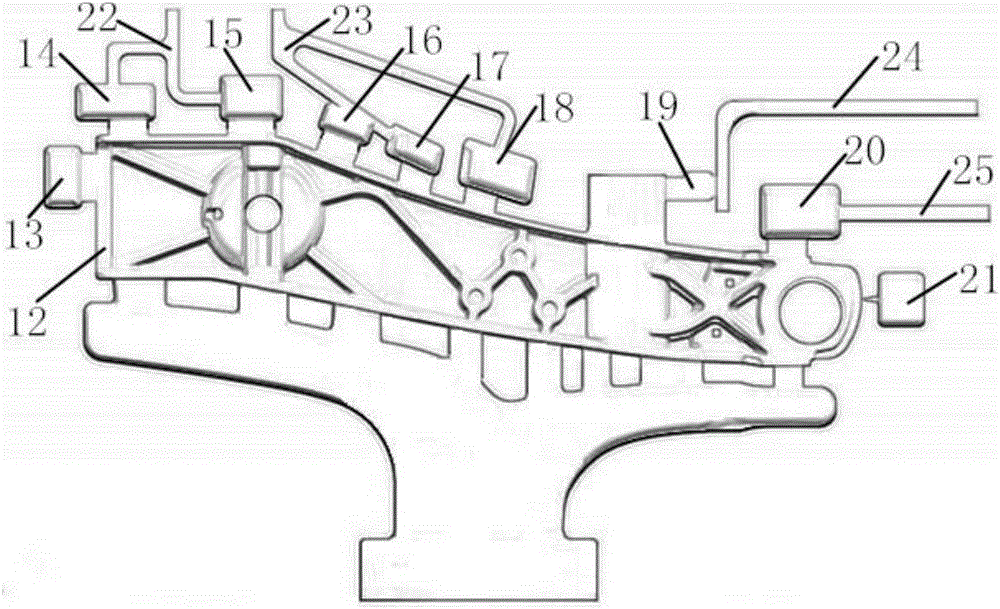

Evanescent mode pouring system of speed changing box body

The invention discloses an evanescent mode pouring system of a speed changing box body. The evanescent mode pouring system is provided with a sprue, wherein the sprue is sequentially communicated with a pouring cup, a first cross gate and a second cross gate from top to bottom, and the first cross gate and the second cross gate are respectively communicated onto the sprue along the radial direction of the sprue; the end part, away from of the sprue, of each of the first cross gate and the second cross gate is respectively provided with a first inner gate pouring port and a second inner gate pouring port. The pouring system is adopted for pouring a casting, so that the mold filling time is shortened, and the heat loss is reduced; moreover, the shrinkage porosity and cavity weakness can be greatly reduced, and the casting quality can be effectively improved.

Owner:HEFEI UNIV OF TECH

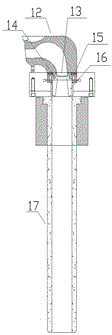

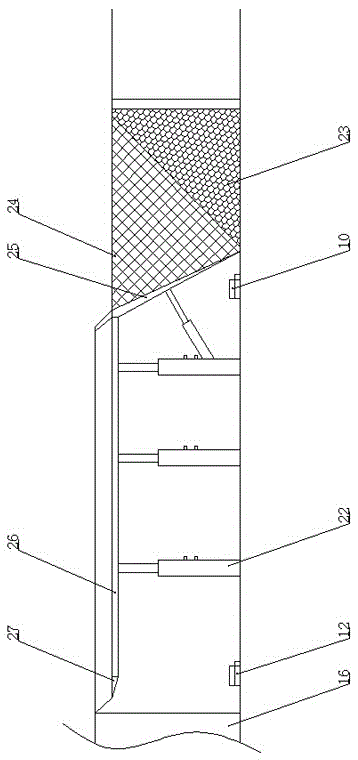

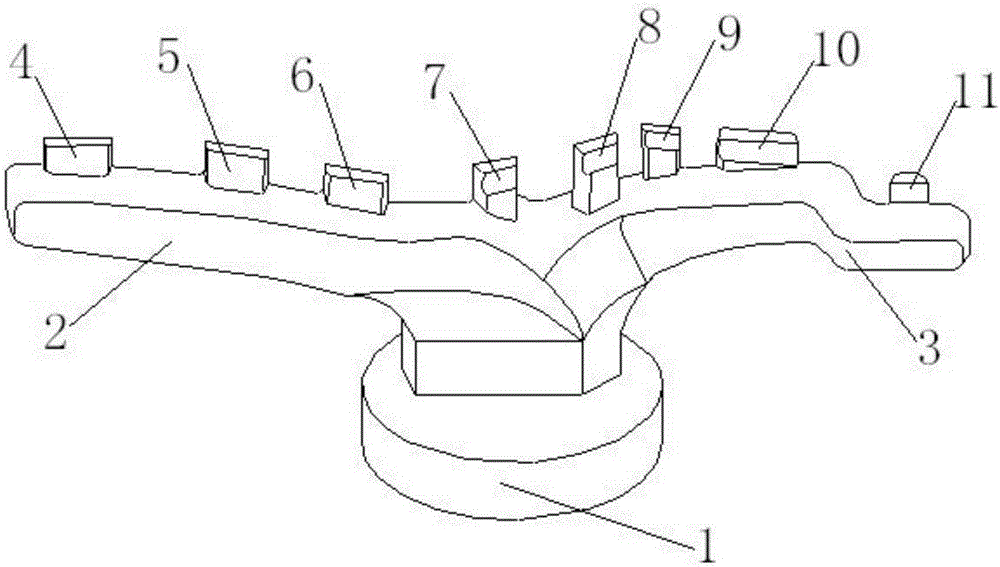

Combined pouring and purifying system for automobile aluminium alloy wheel with big diameter being more than 26 inches

The invention discloses a combined pouring and purifying system for automobile aluminium alloy wheels with big diameter being more than 26 inches; the system is composed of a control cabinet, compression and decompression pipes, side dies, a top die, a bottom die, one central pouring system and two lateral pouring system; the central pouring system is composed of a circular arc filter screen, an iron pouring gate, a ceramic vacuum cup and a ceramic liquid-rising pipe; each lateral pouring system is composed of a lateral pouring feeding inlet, a cap-shaped filter screen, another iron pouring gate, another ceramic vacuum cup, a ring-shaped sealing gasket and another ceramic liquid-rising pipe; the feeding interface of each lateral pouring system is assembled at the die assembly place of two side dies and a Lip middle-upper part area; the volume of each lateral pouring feeding inlet is 100-200cm<3>; the width of the section thereof is 2.0-4.0mm, and the height thereof is 25.0-50.0mm; the invention has the characteristics that the mould filling time is short; the casting period is short; the casting defect is less; the interior quality of a casting is excellent; the casting process is convenient to control, and the like.

Owner:JIANGSU KAITE AUTO PARTS

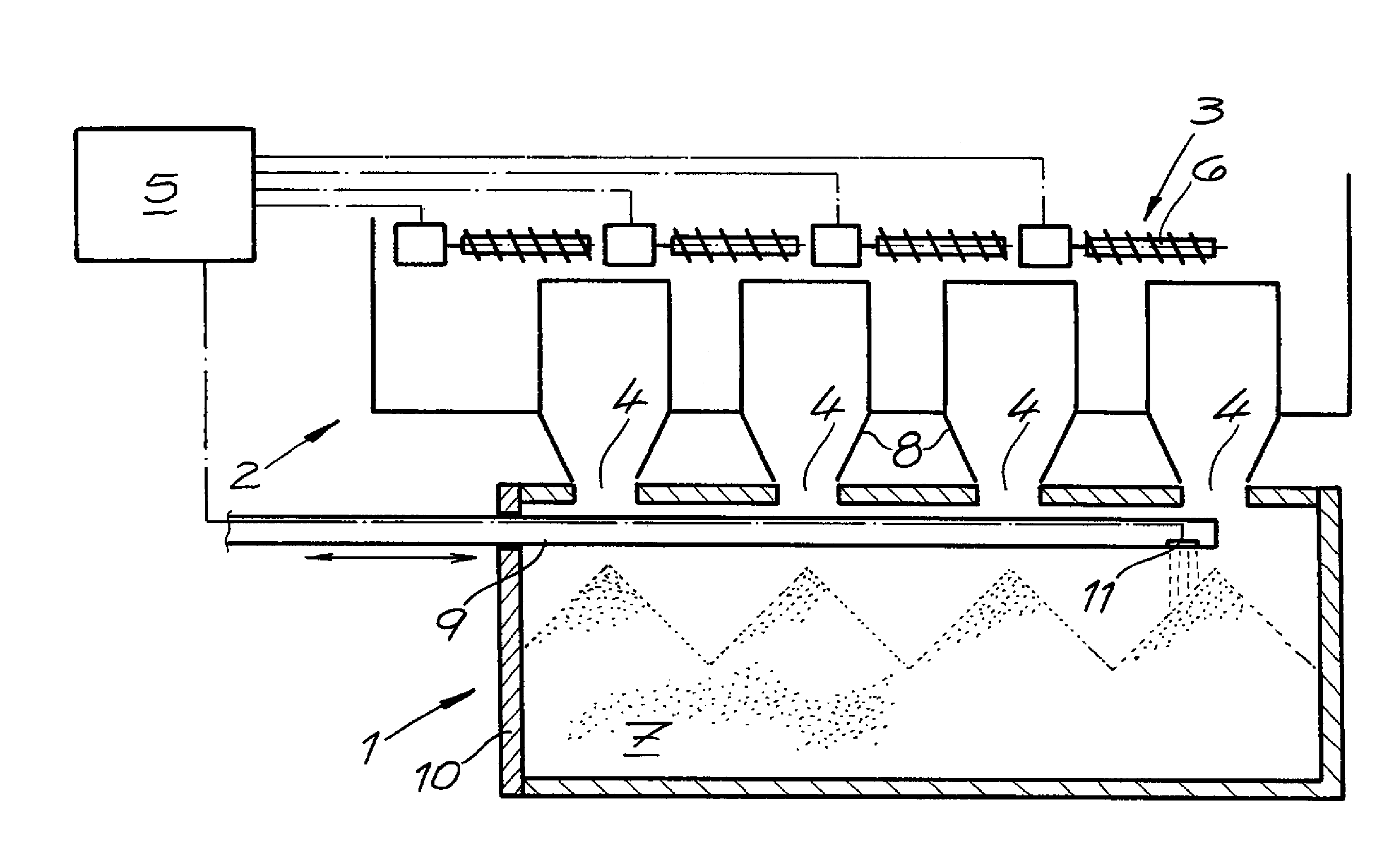

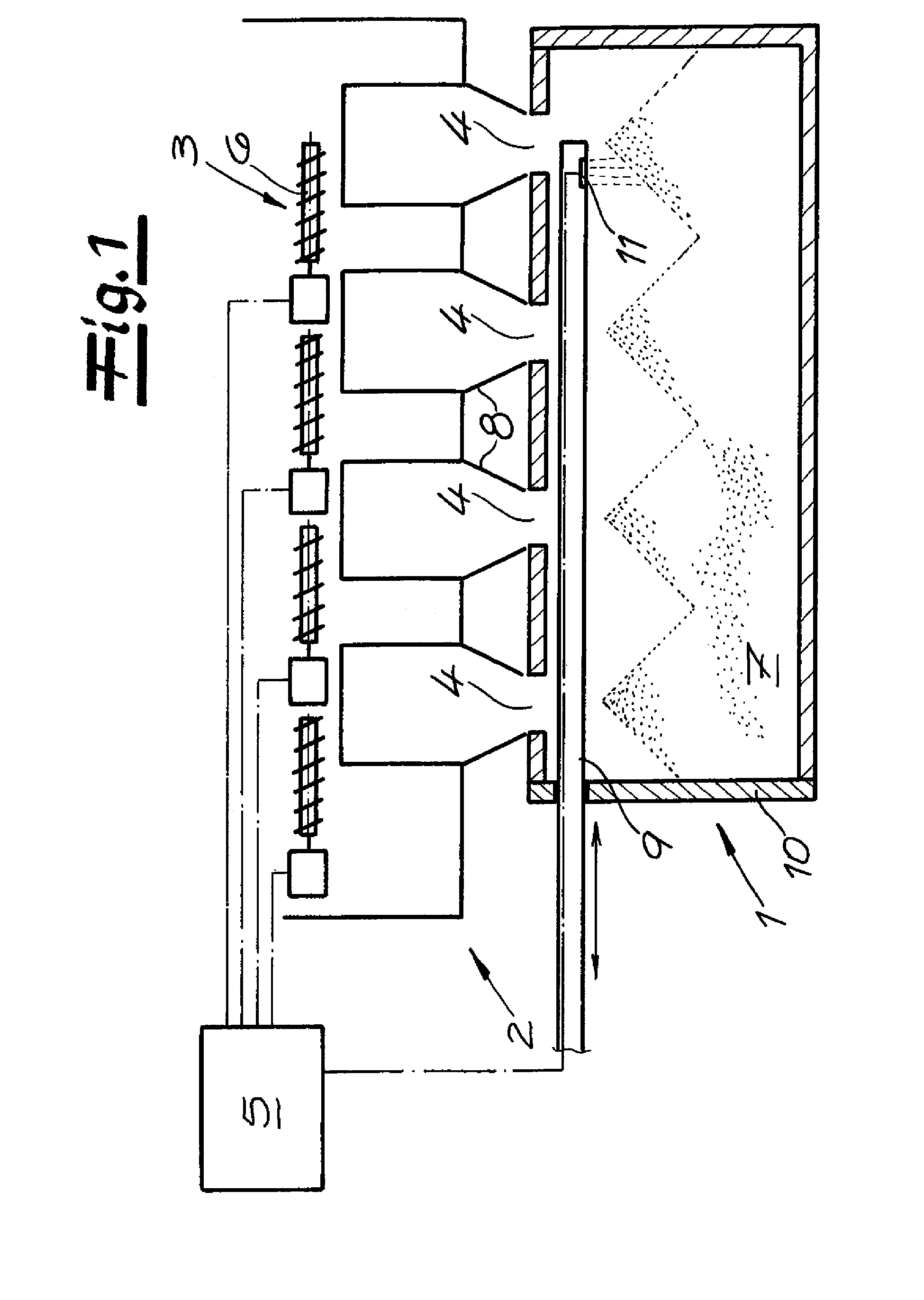

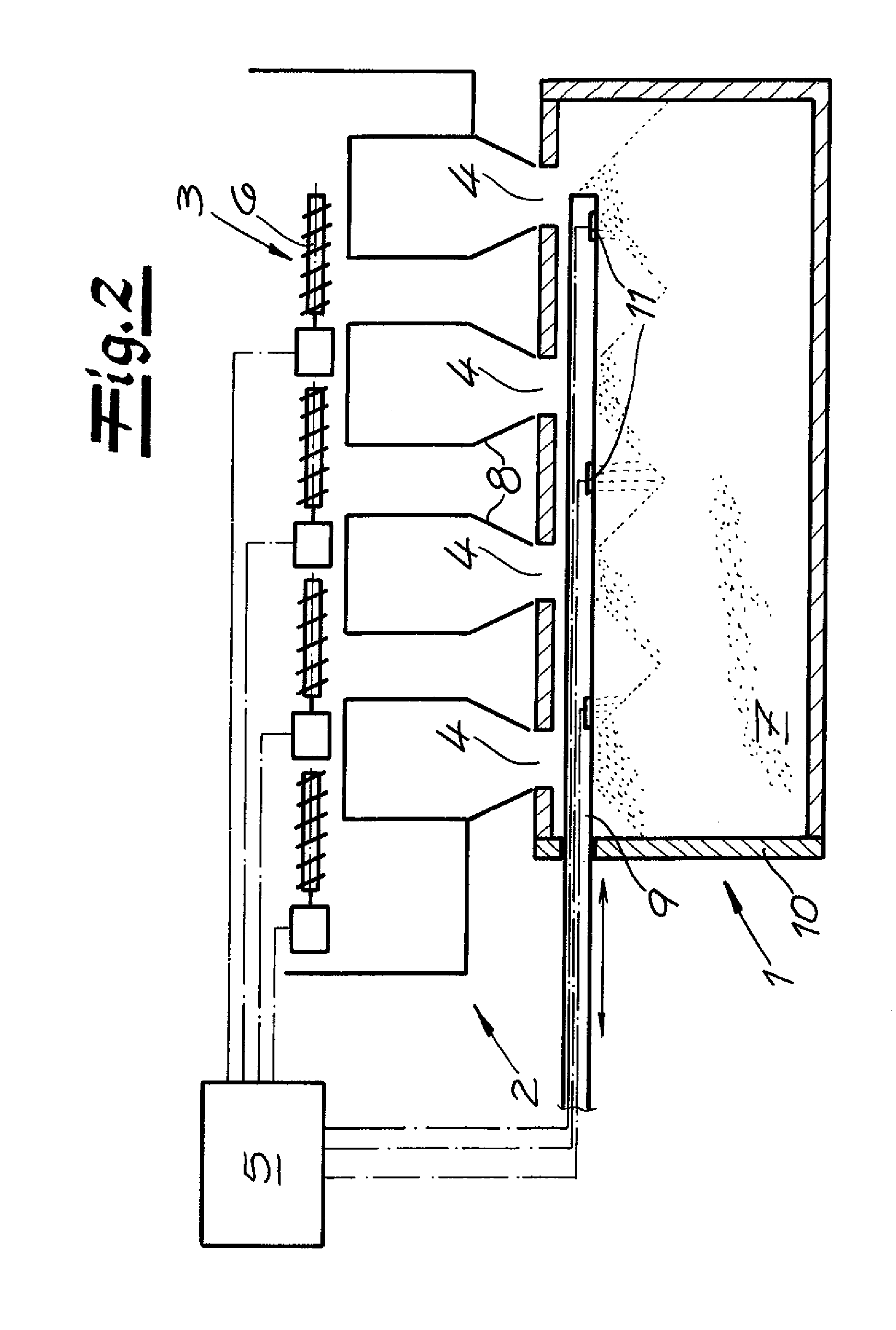

Leveling apparatus for and method of filling an oven chamber of a coke-oven battery

InactiveUS8568568B2Shorten filling timeImproved resultCoke oven safety devicesCharging-discharging device combinationsEngineeringBiomedical engineering

A coking oven has a battery of longitudinally extending and transversely spaced coking chambers each provided with a plurality of downwardly open and longitudinally spaced filling holes. Coal is charged into the chambers through the respective filling holes. A respective longitudinally movable leveling rod in each of the chambers can level coal charged by the filling equipment into the chambers. Sensors provided on the leveling rods scan from above transversely and longitudinally spaced points on a surface of the coal charged through the holes into the respective chambers. A controller connected to the sensors records a respective measurement corresponding to a vertical position of the surface at each the points and determines from the measurements thereof a three-dimensional filling-level profile of the surface of the charged coal for controlling operation of the filling equipment and filling of the chambers with the coal.

Owner:UHDE GMBH

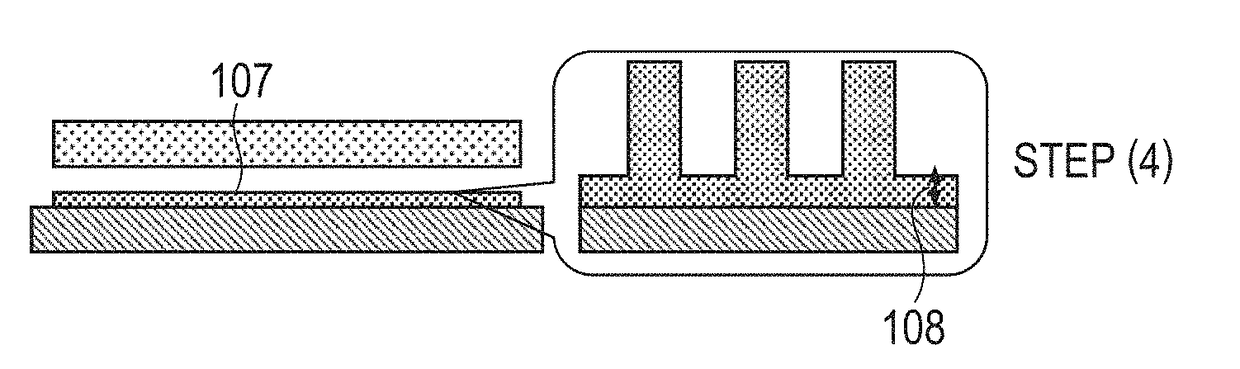

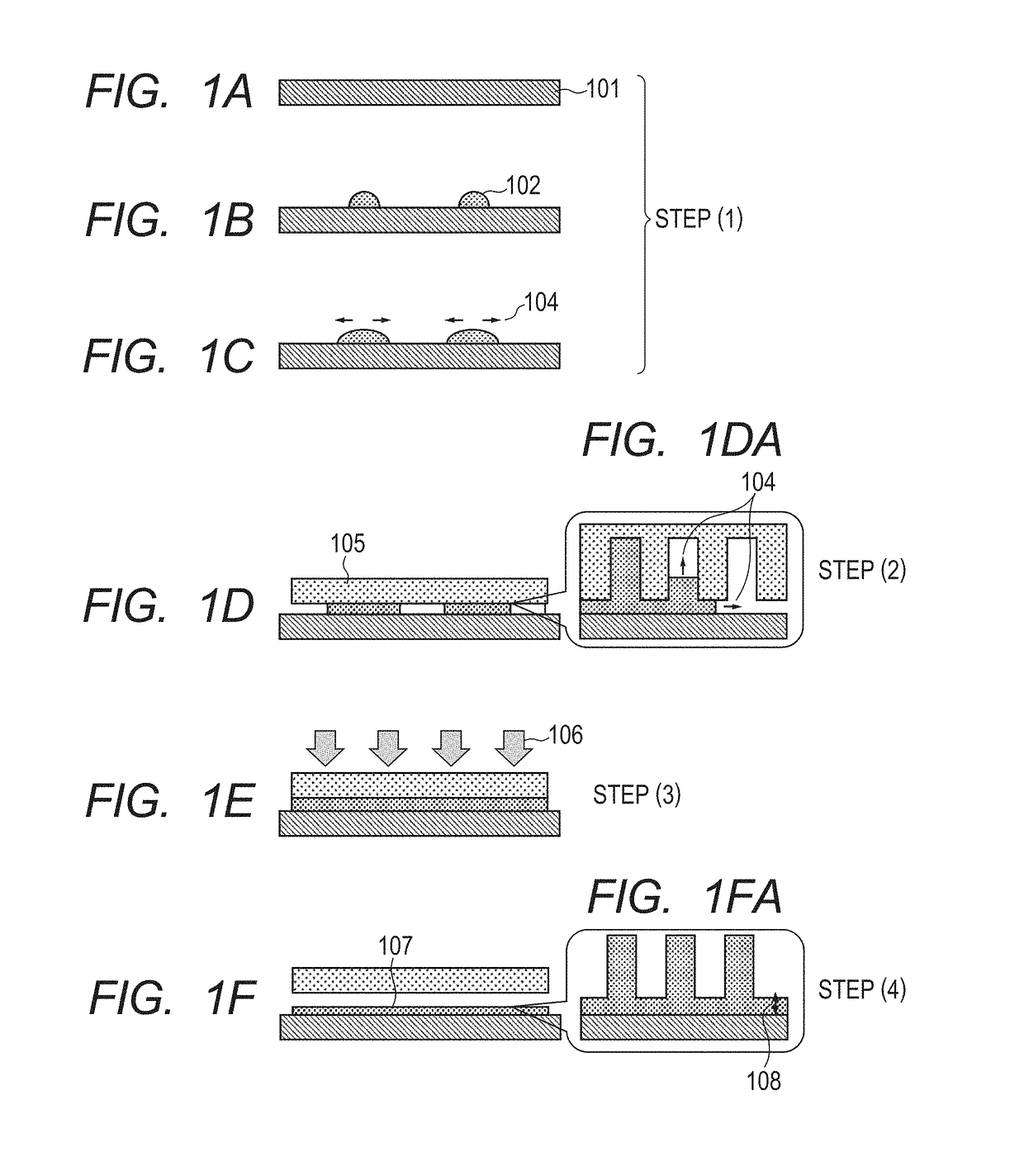

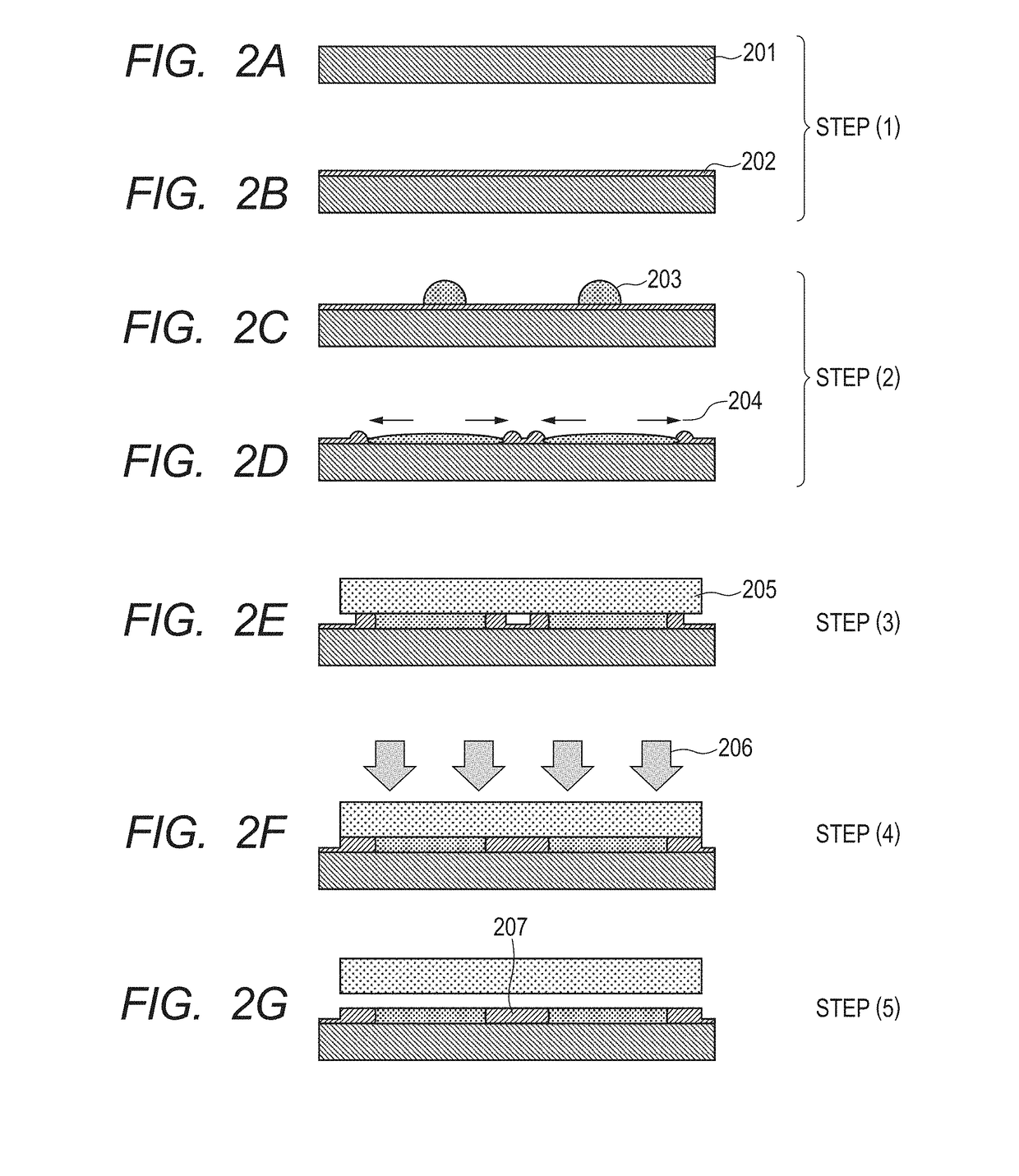

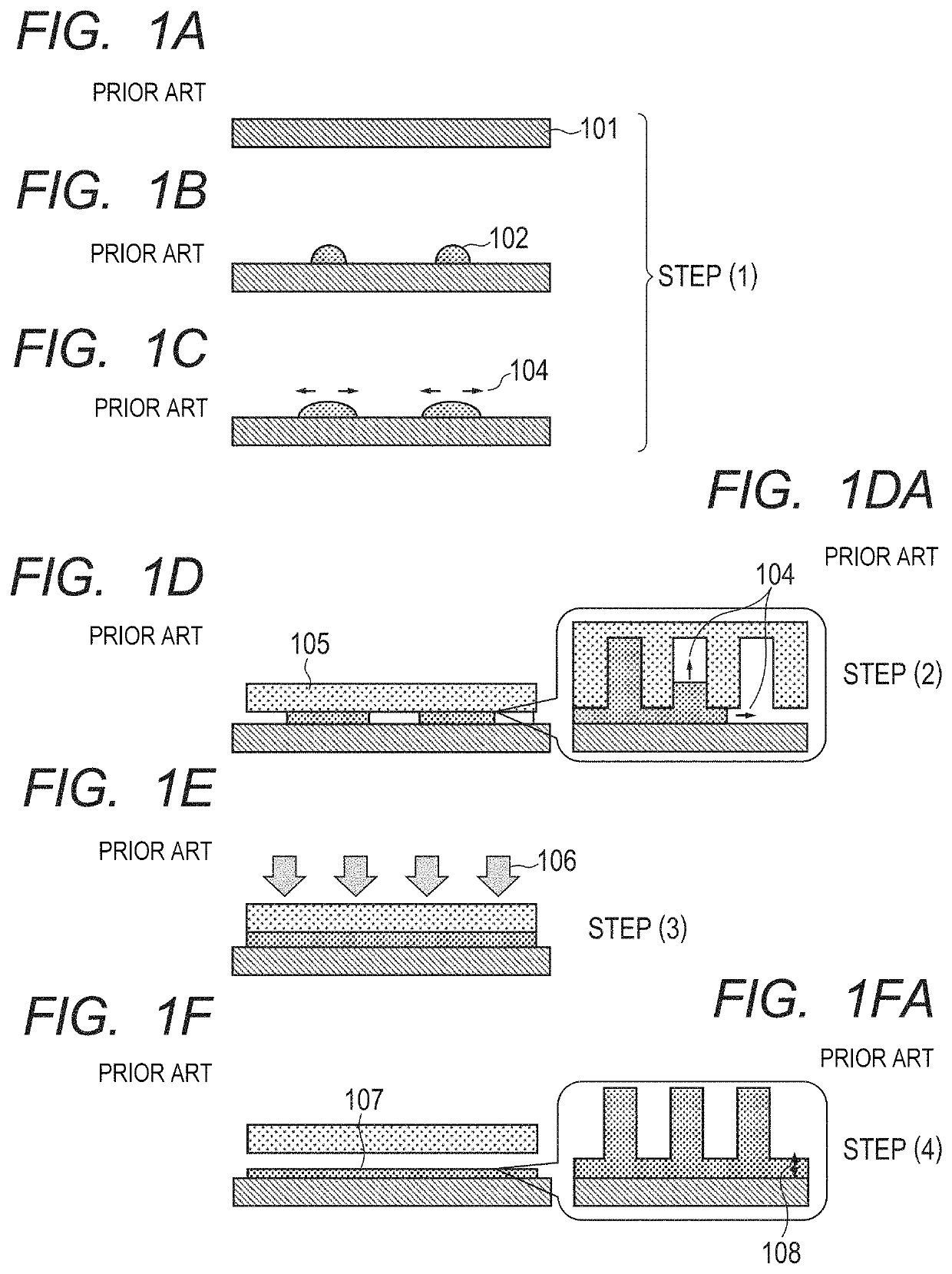

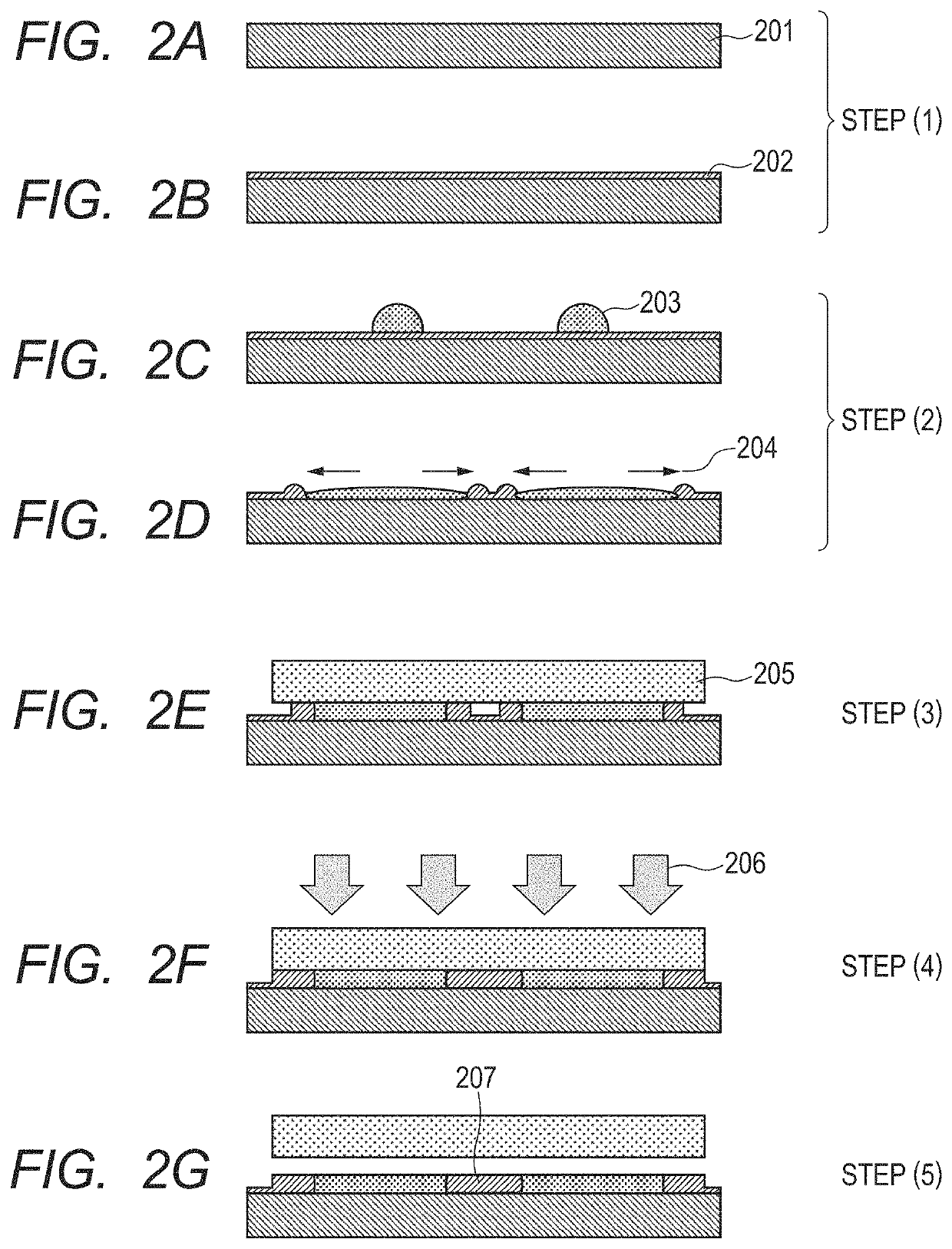

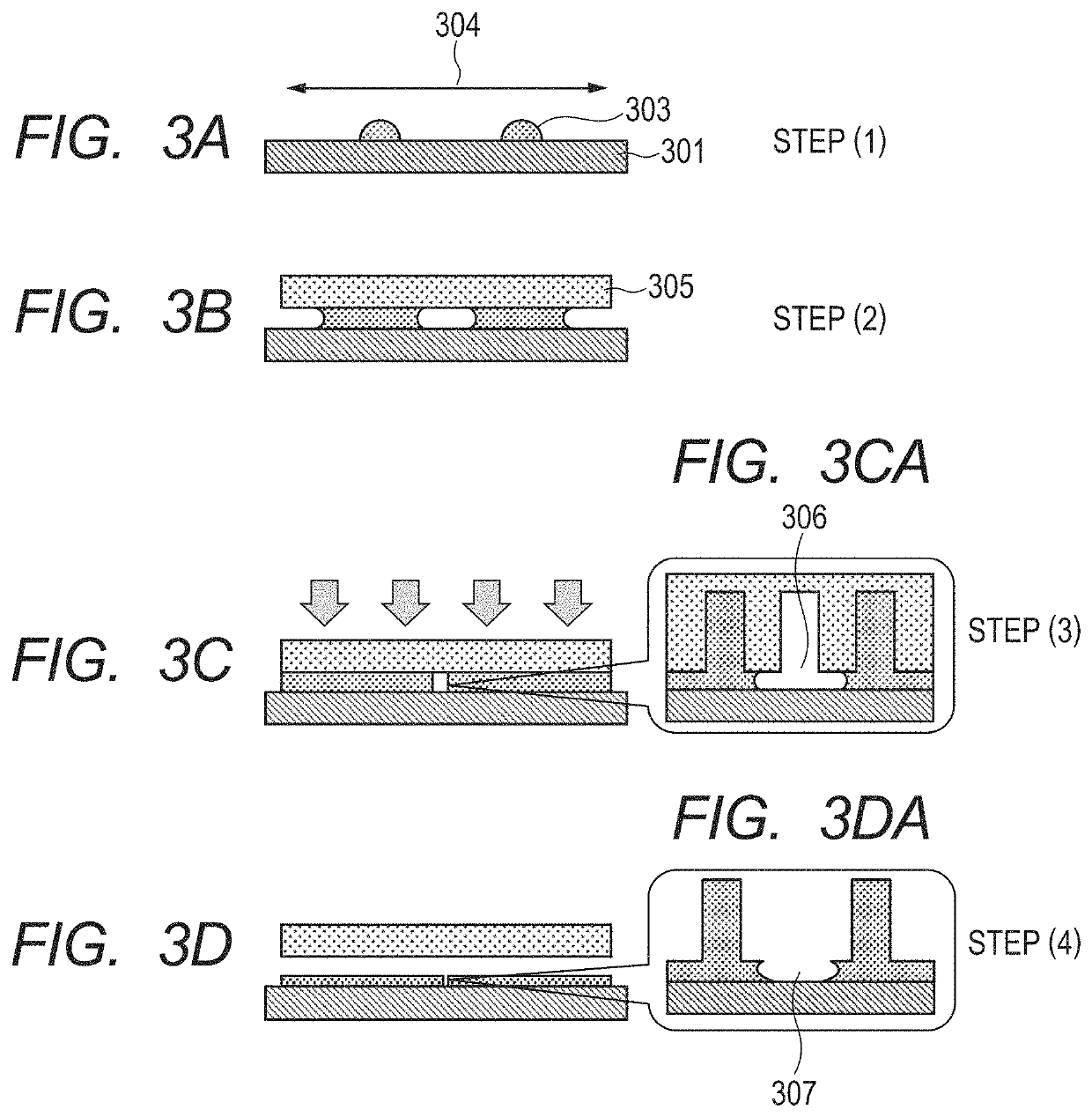

Pattern forming method as well as production methods for processed substrate, optical component, circuit board, electronic component and imprint mold

ActiveUS20170283620A1Improve throughputShorten filling timeInksPhotomechanical coating apparatusSolventElectronic component

A pattern is formed on a substrate with forming a layer of a curable composition (A1) containing a component (a1) serving as a polymerizable compound and a component (e1) on a surface of the substrate, then dispensing droplets of a curable composition (A2) containing at least a component (a2) serving as a polymerizable compound dropwise discretely onto the layer of the curable composition (A1), subsequently sandwiching a mixture layer of the curable composition (A1) and the curable composition (A2) between a mold and the substrate, then irradiating the mixture layer with light to cure the layer, and releasing the mold from the mixture layer after the curing, a surface tension of a composition of components of the curable composition (A1) except a solvent being higher than a surface tension a composition of components of the curable composition (A2) except a solvent.

Owner:CANON KK

Transferring method of powder toner for electrophotograph and transferring apparatus thereof, and filling method of powder toner and the filling apparatus thereof

InactiveCN101103316AQuality assurancePrevent proliferationSolid materialElectrographic process apparatusEngineeringReciprocating motion

The present invention aims at providing a powder toner transferring method which fluidizes a powder toner with a gas supplied from an air supply means, sucks the fluidized powder toner with a suction means and transfers the powder toner by discharging the powder toner in a toner storage container, where the suction of the powder toner by means of the suction means is performed with a reciprocating-motion pump. The present invention also aims at providing a powder toner filling method that comprises the powder toner transferring process.

Owner:RICOH KK

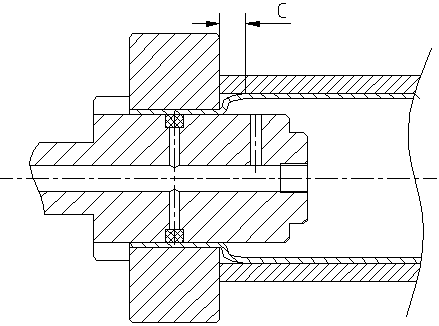

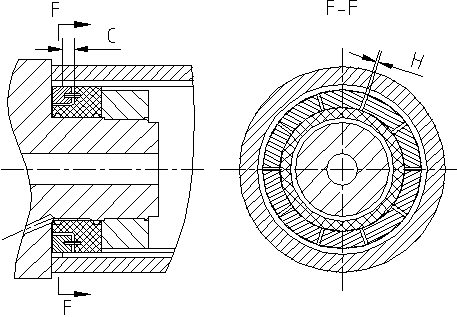

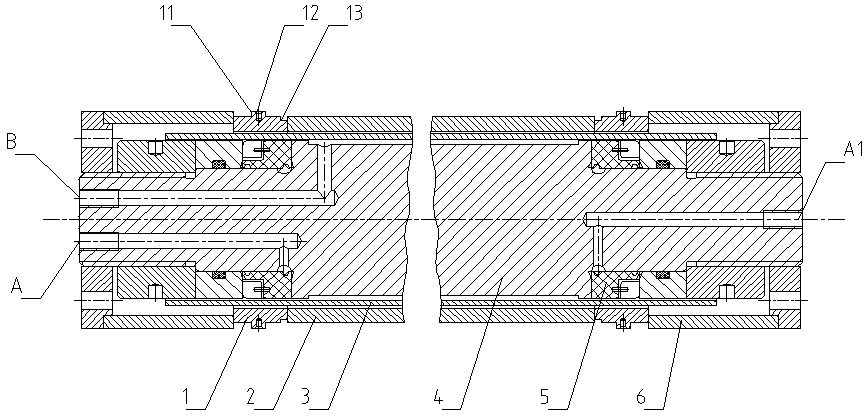

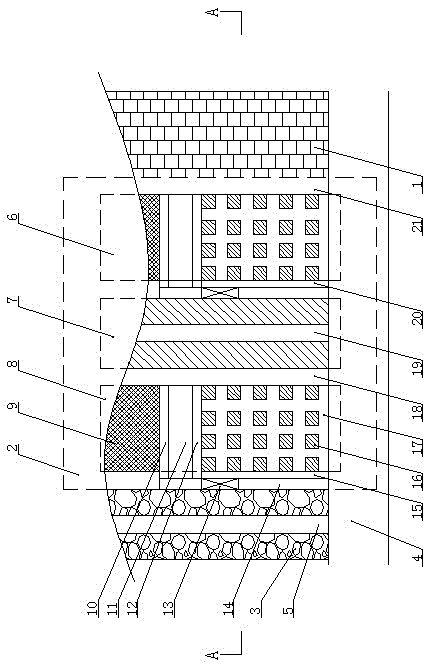

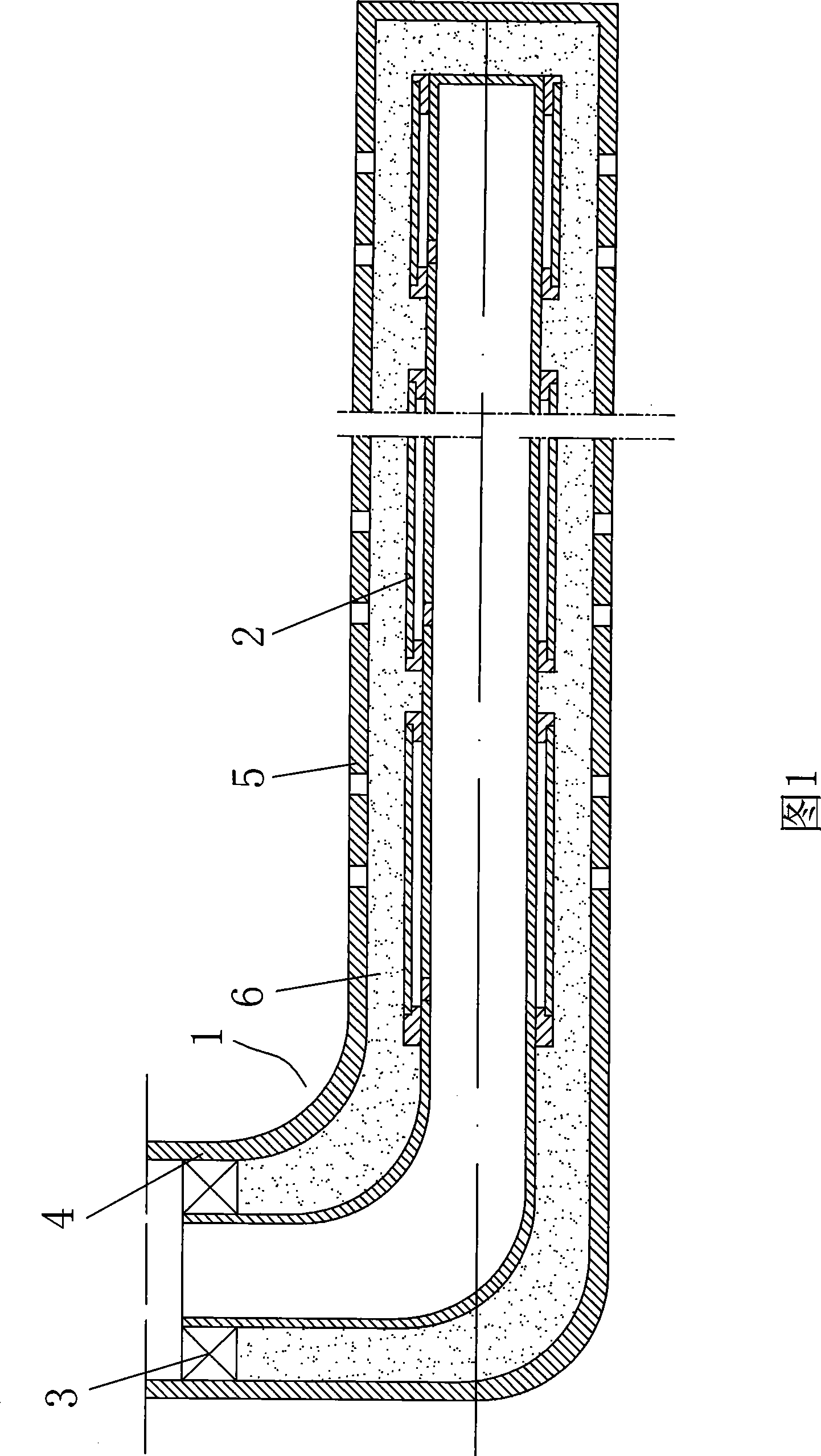

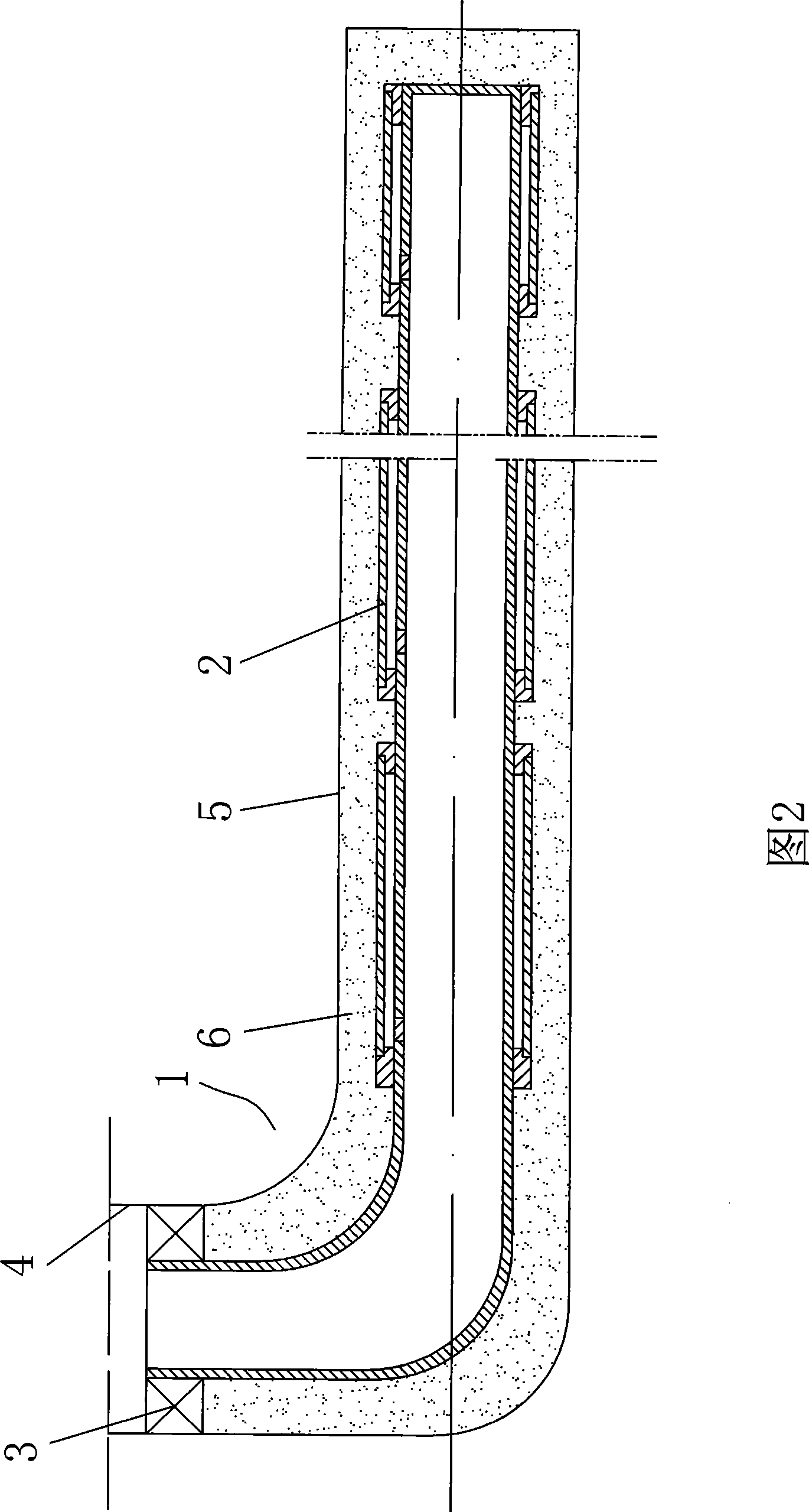

Horizontal production-injection well completion structure possessing flow control function

ActiveCN101338660AWith flow control functionReduce trafficFluid removalStructural engineeringInjection well

The present invention relates to a horizontal injection-production well completion structure with flow control function. The horizontal injection-production well completion structure comprises a well wall and a flow control filter. The well wall consists of a rising section and a horizontal section. The flow control filter is arranged in the horizontal section of the well wall and is fixedly connected with the well wall. A cavity between the flow control filter and the well wall is filled with glass hollow particles. The horizontal injection-production well completion structure with the flow control function of the present invention has the characteristics of being easy for realizing, low well completion cost and strong function for axial anti-fluid-channeling.

Owner:ANTON BAILIN OILFIELD TECH (BEIJING) CO LTD

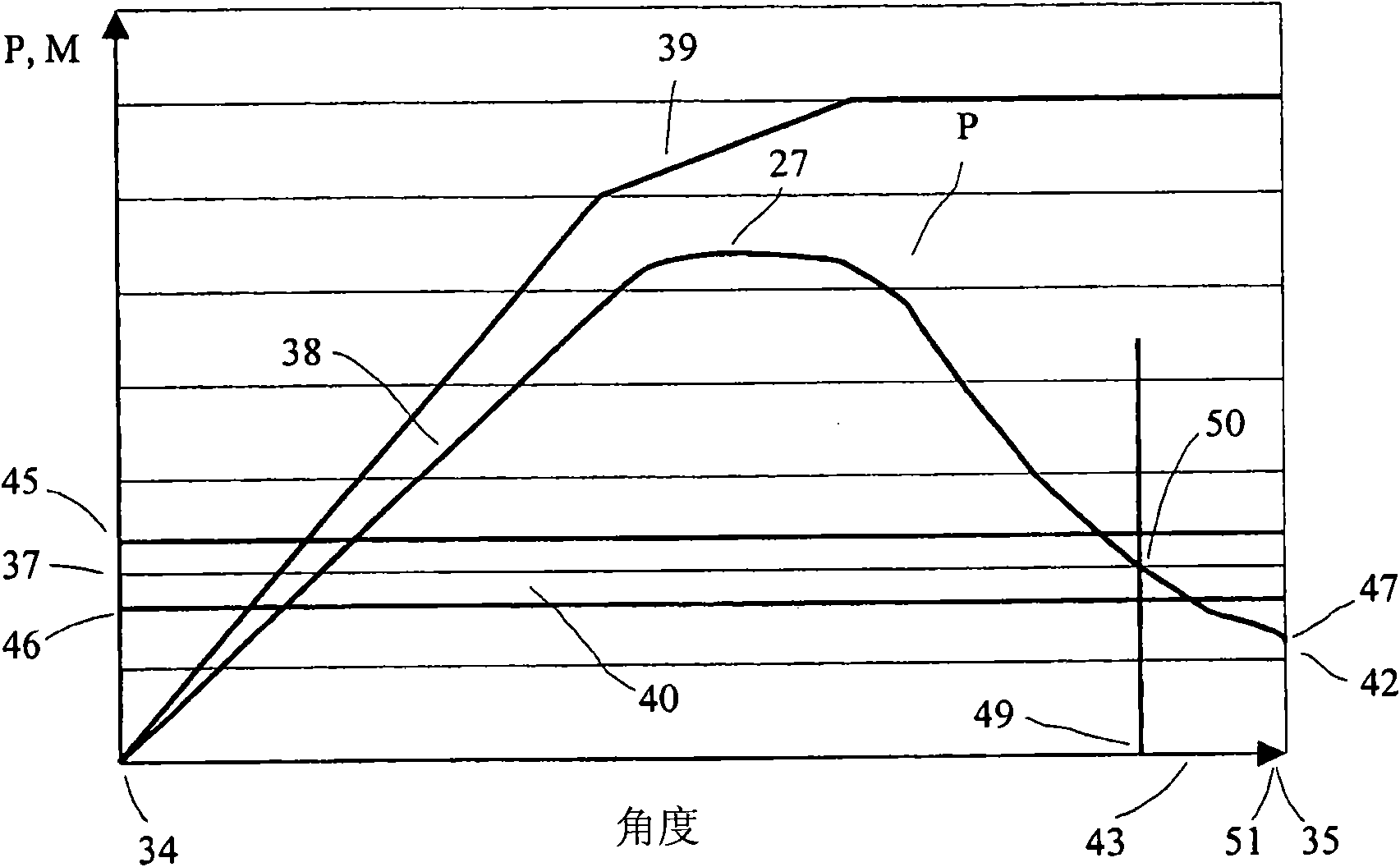

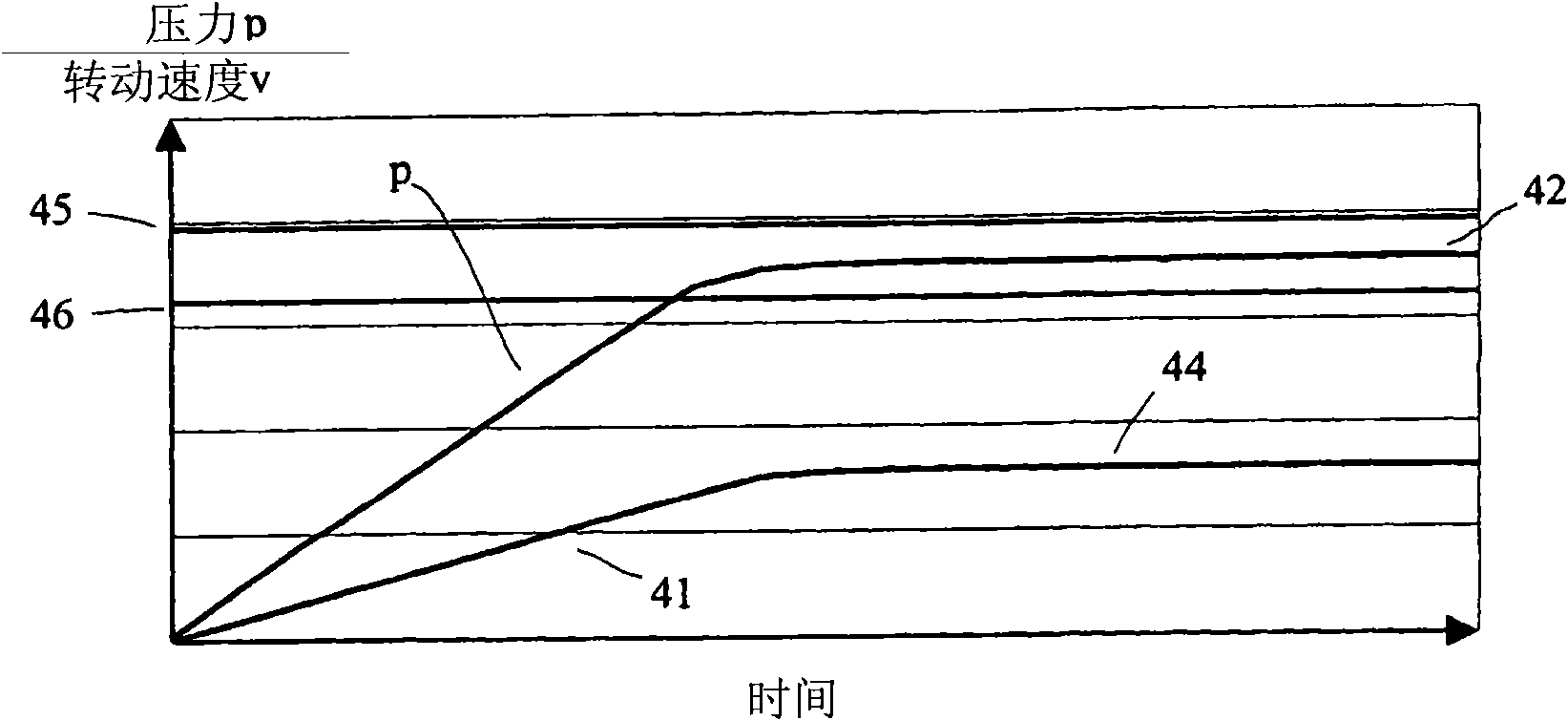

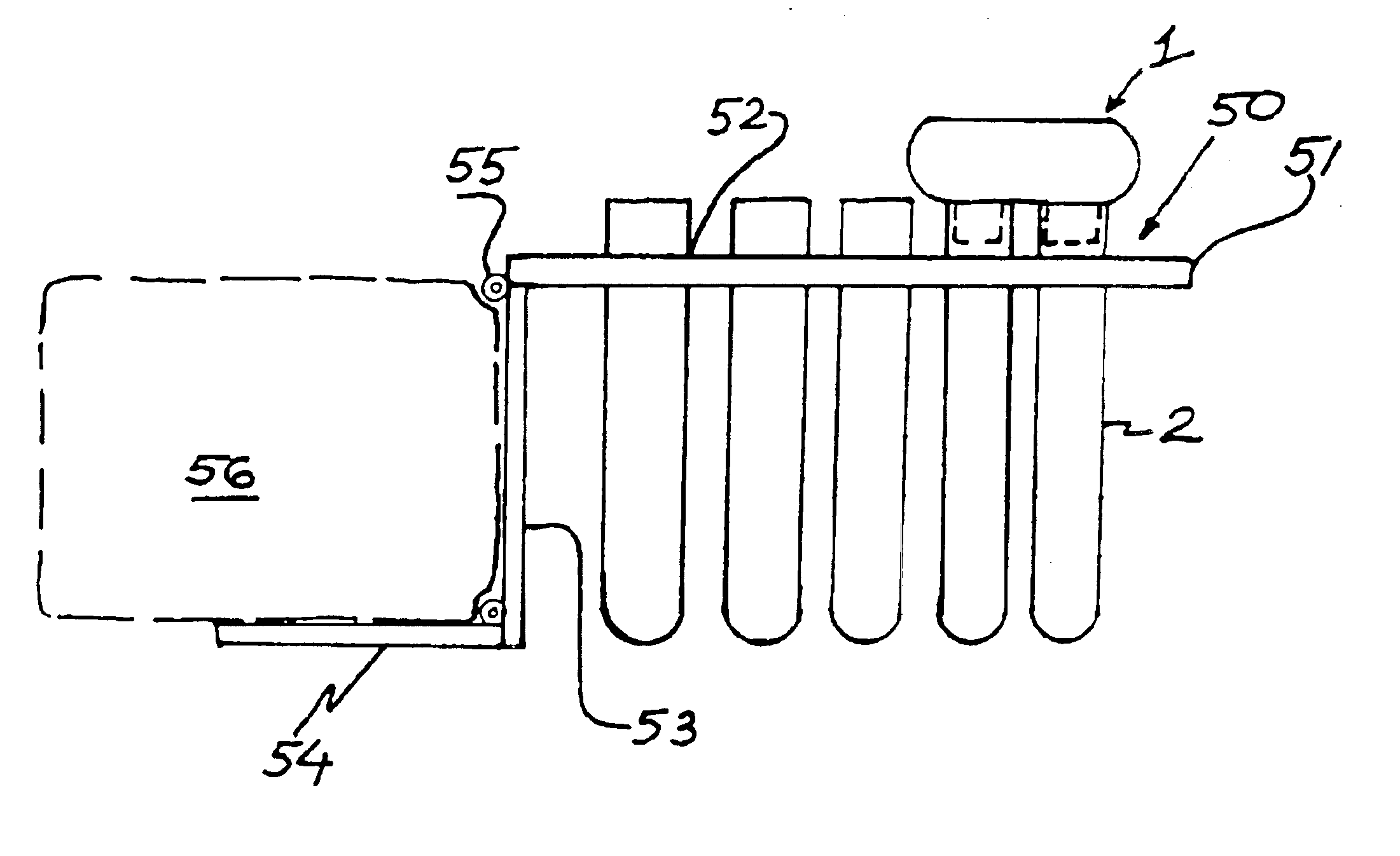

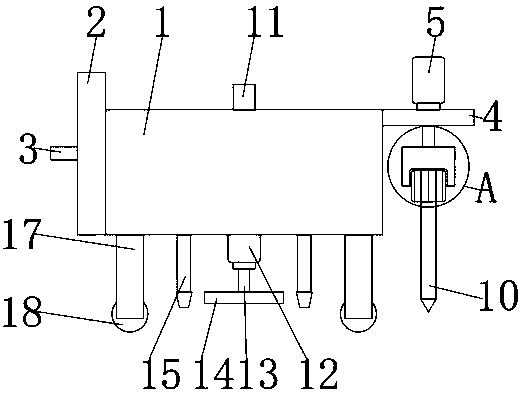

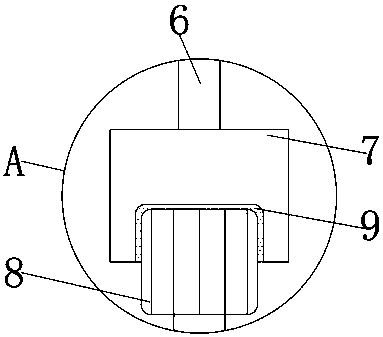

Method and filling system for filling bags

ActiveCN102046471AWaiting Time OptimizationReduce waiting timeSolid materialEngineeringPressure sensor

The invention relates to a filling system for filling valve bags, and to a method for operating a filling system, which comprises at least one rotating packing machine having a drive for rotating the packing machine, and a plurality of filling nozzles, which are distributed across the periphery of the rotating packing machine. The filling nozzles are provided for receiving the valve bags and can be fixed to the filling nozzles at an opening, and they may be filled with a pourable material through the filling nozzles. The valve bags are placed onto the filling nozzles at a defined insertion position and are automatically released at a defined release position. The invention provides a controller in order to control the filling process. A pressure sensor (10) is associated with at least one filling nozzle in order to determine a degree of the filling pressure of the valve bag disposed at the filling nozzle. The controller determines a representative characteristic pressure value for the filling pressure present at a predetermined position (51) in front of the release position by means of a pressure sensor, and adjusts a rotational speed of the packing machine to the speed of the drive by way of a control unit.

Owner:HAVER & BOECKER

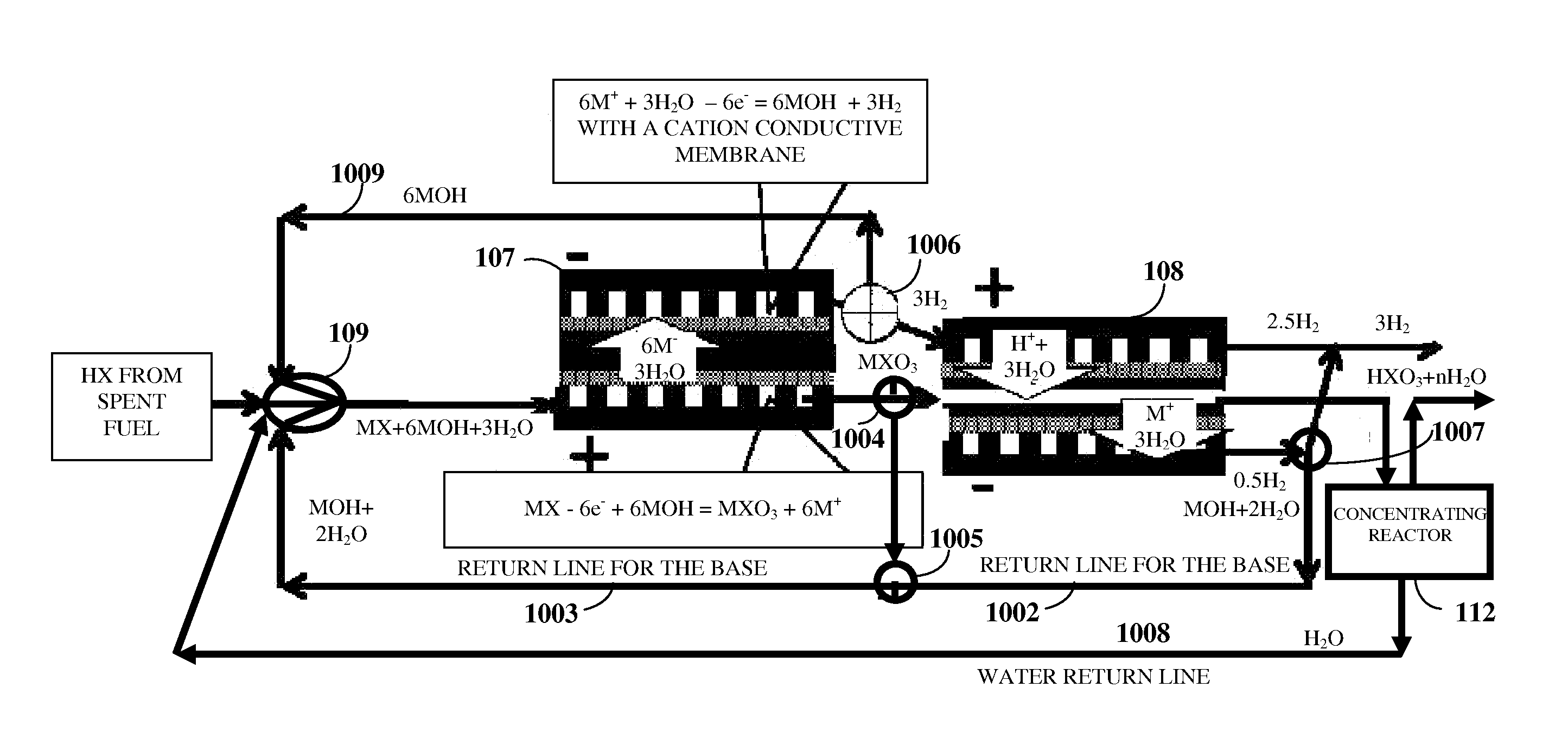

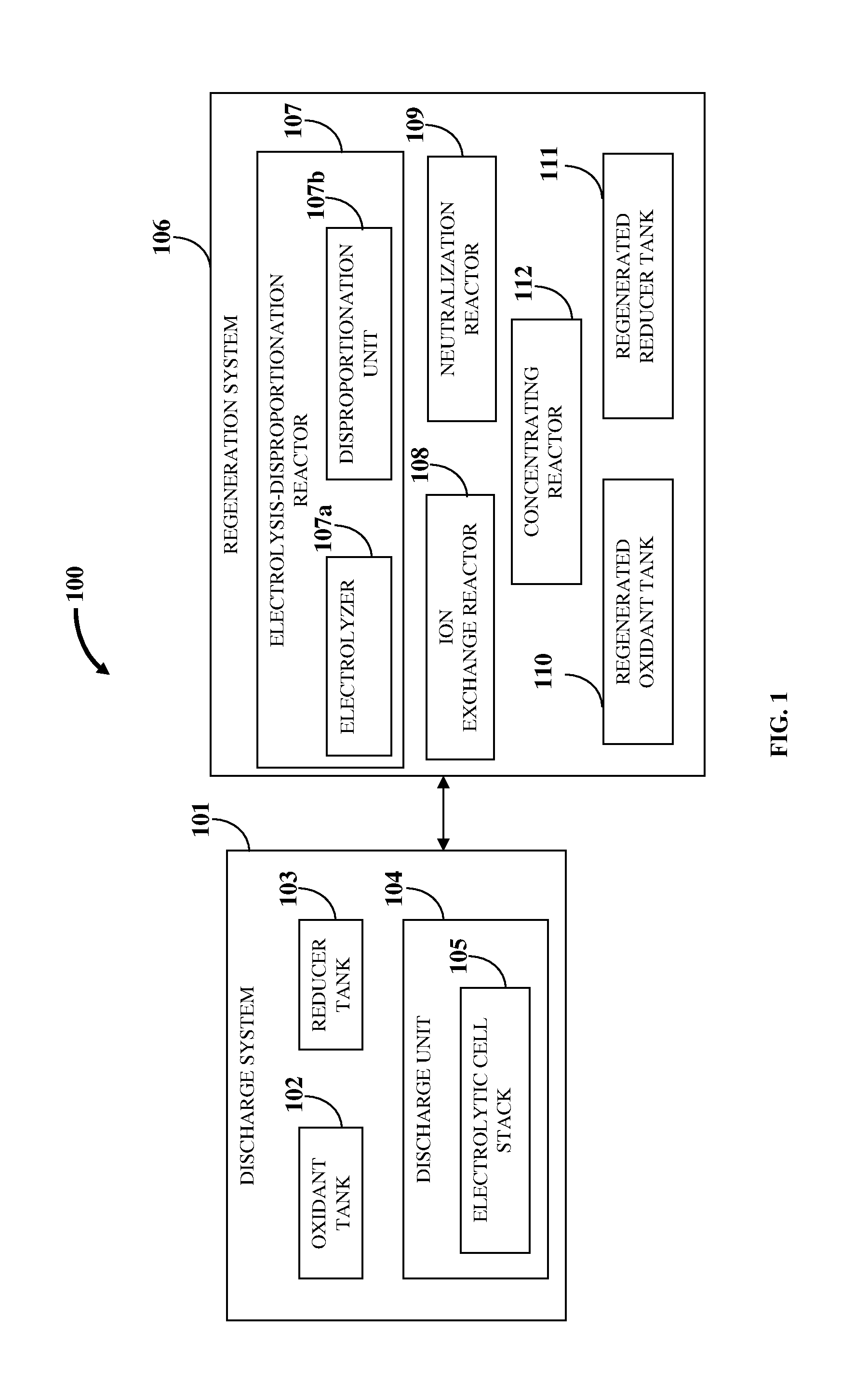

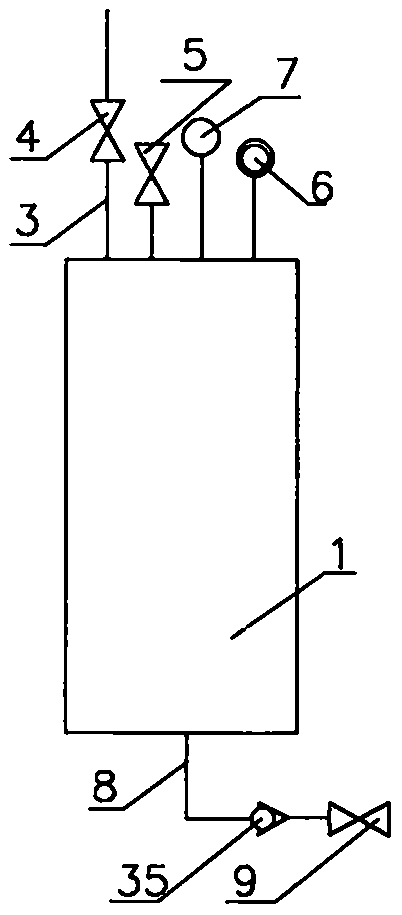

Flow Battery And Regeneration System

InactiveUS20140050999A1Improve energy efficiencyShort filling timeFuel cells groupingRegenerative fuel cellsElectrolysisIon exchange

Methods for generating electric power and a discharge fluid from an oxidant and a reducer using a discharge system, and regenerating an oxidant and / or the reducer from the discharge fluid using a regeneration system are provided. A discharge unit of the discharge system generates electric power and the discharge fluid by transferring electrons from a positive electrode of a 5-layer electrolyte-electrode assembly (5EEA) to an aqueous multi-electron oxidant (AMO) and from a reducer to a negative electrode of the 5EEA. The regeneration system neutralizes the discharge fluid to produce a salt form of the discharge fluid. The regeneration system electrolyzes the salt form of the discharge fluid into an intermediate oxidant in an electrolysis-disproportionation reactor and releases the reducer, while producing the AMO by disproportionating the intermediate oxidant. The regeneration system converts a salt form of the AMO into an acid form of the AMO in an ion exchange reactor.

Owner:FTORION

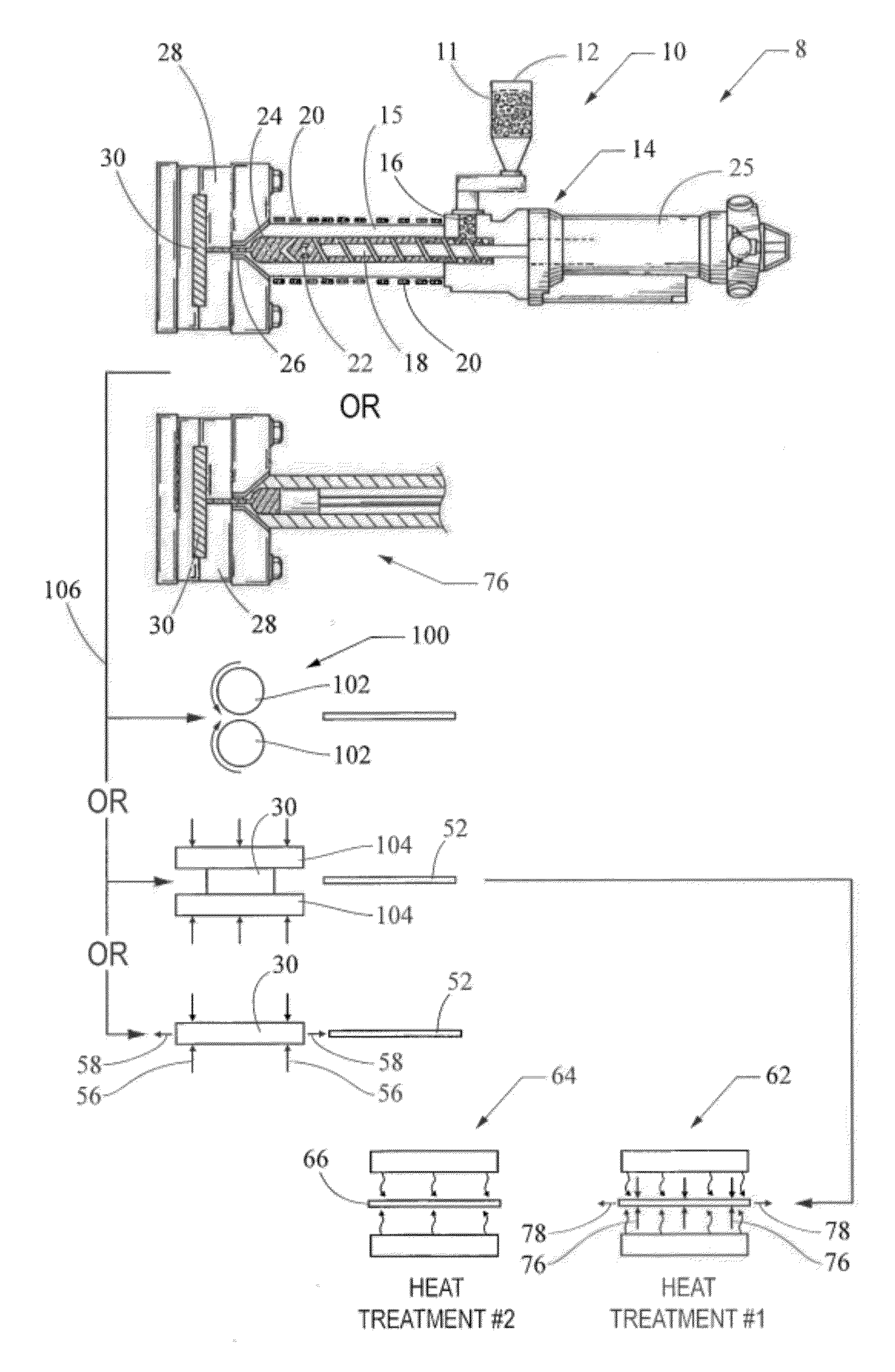

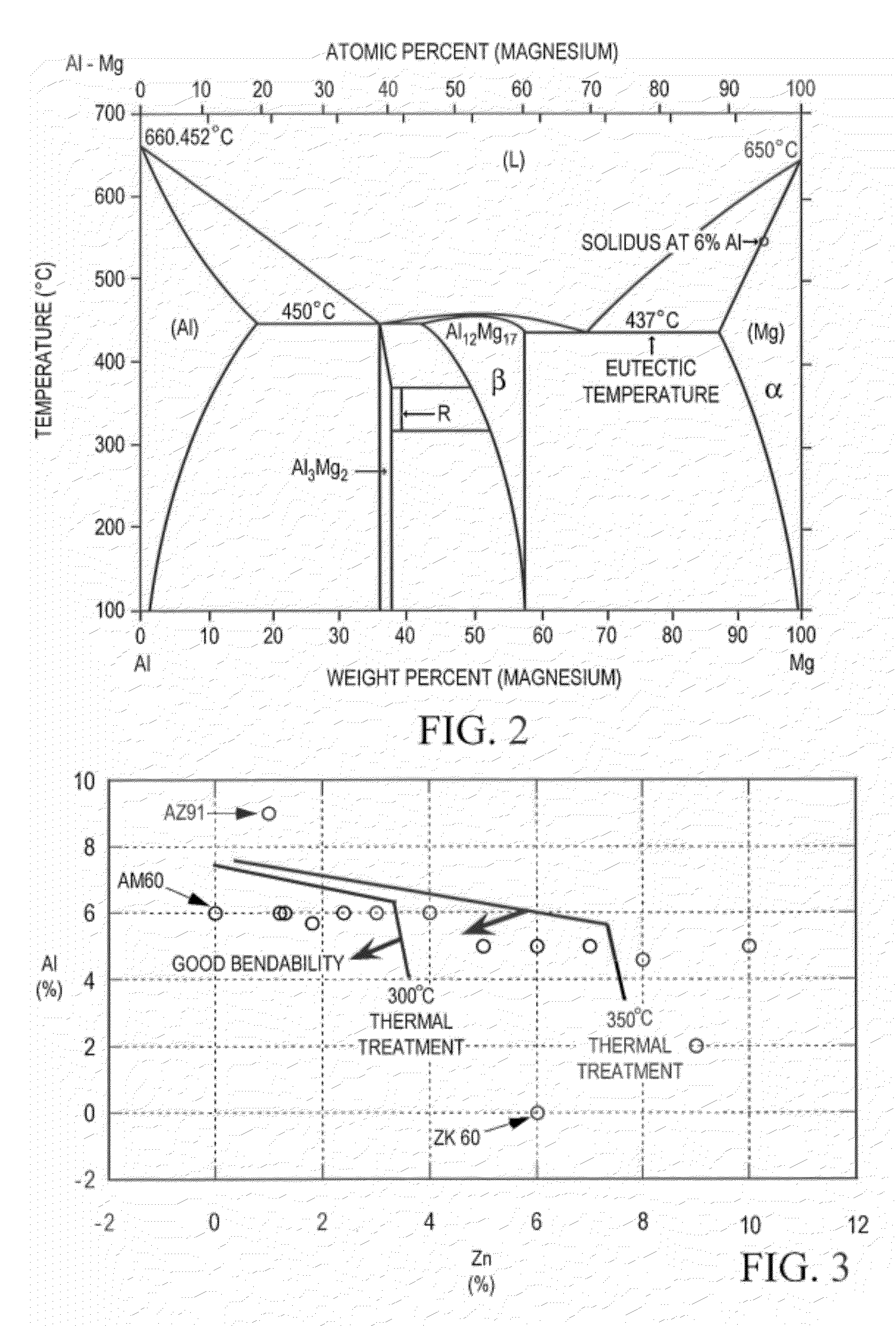

Method and apparatus of forming a wrought material having a refined grain structure

ActiveUS20120305145A1Provide formabilityProvide impact resistanceMould handling/dressing devicesMetal alloyShell molding

A method of forming a wrought material having a refined grain structure is provided. The method comprises providing a metal alloy material having a depressed solidus temperature and a low temperature eutectic phase transformation. The metal alloy material is molded and rapidly solidified to form a fine grain precursor that has fine grains surrounded by a eutectic phase with fine dendritic arm spacing. The fine grain precursor is plastic deformed at a high strain rate to cause recrystallization without substantial shear banding to form a fine grain structural wrought form. The wrought form is then thermally treated to precipitate the eutectic phase into nanometer sized dispersoids within the fine grains and grain boundaries and to define a thermally treated fine grain structure wrought form having grains finer than the fine grains and the fine dendritic arm spacing of the fine grain precursor.

Owner:THIXOMAT

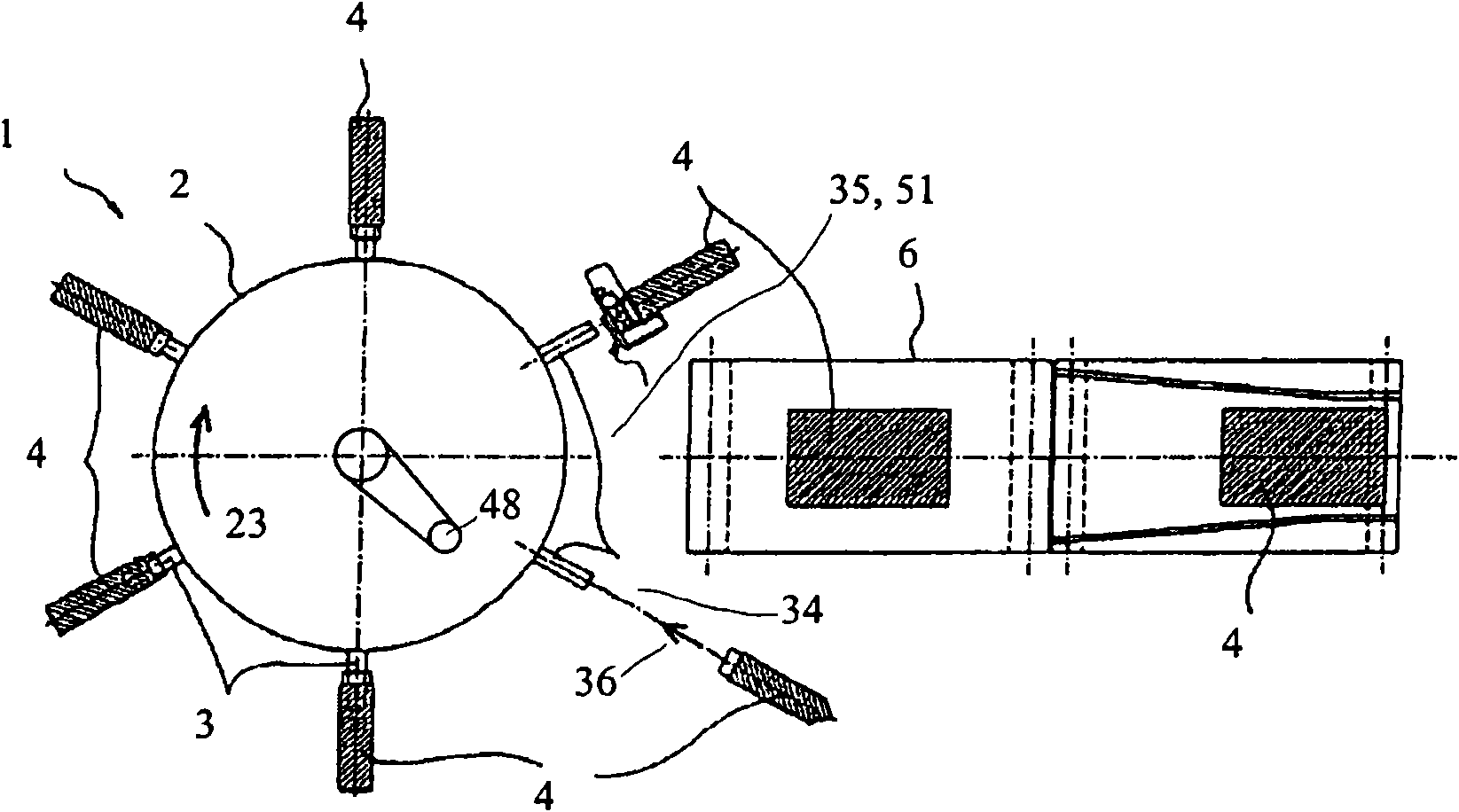

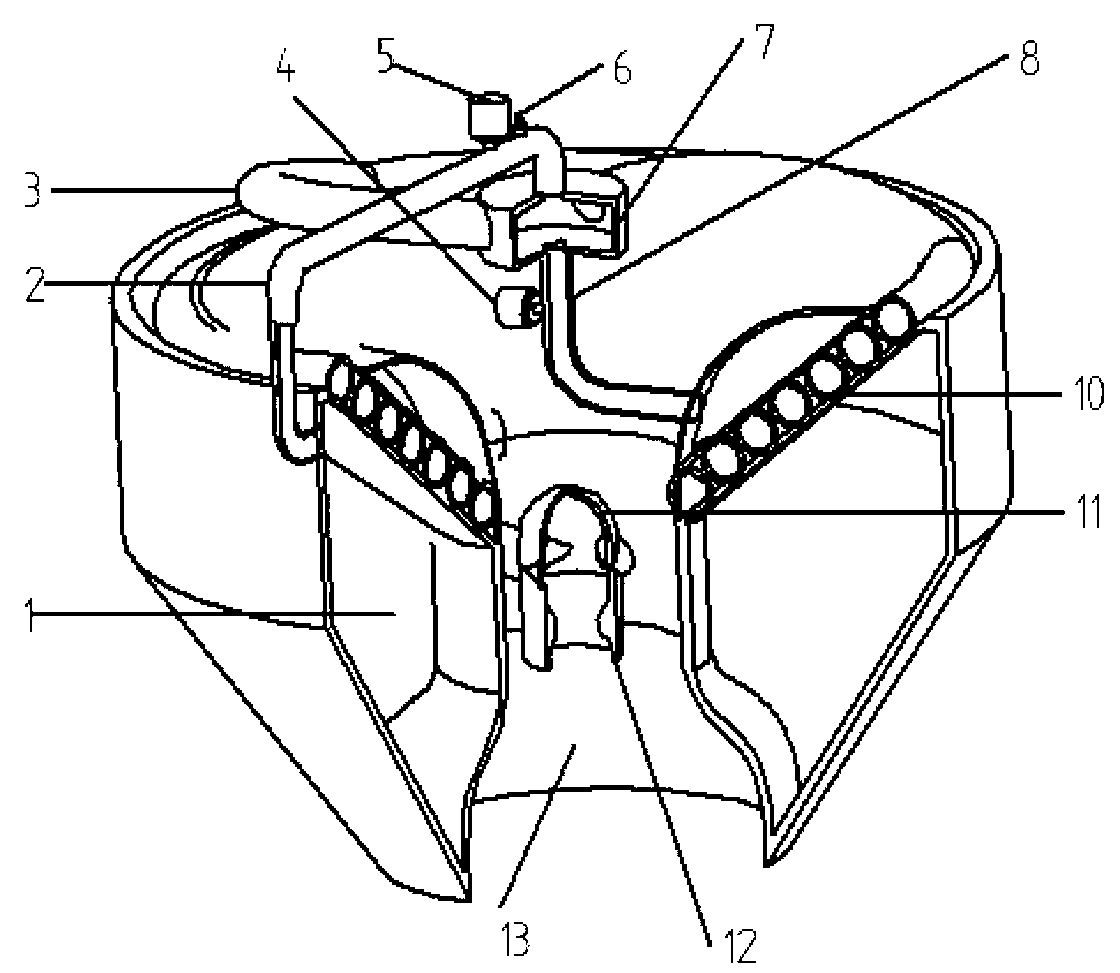

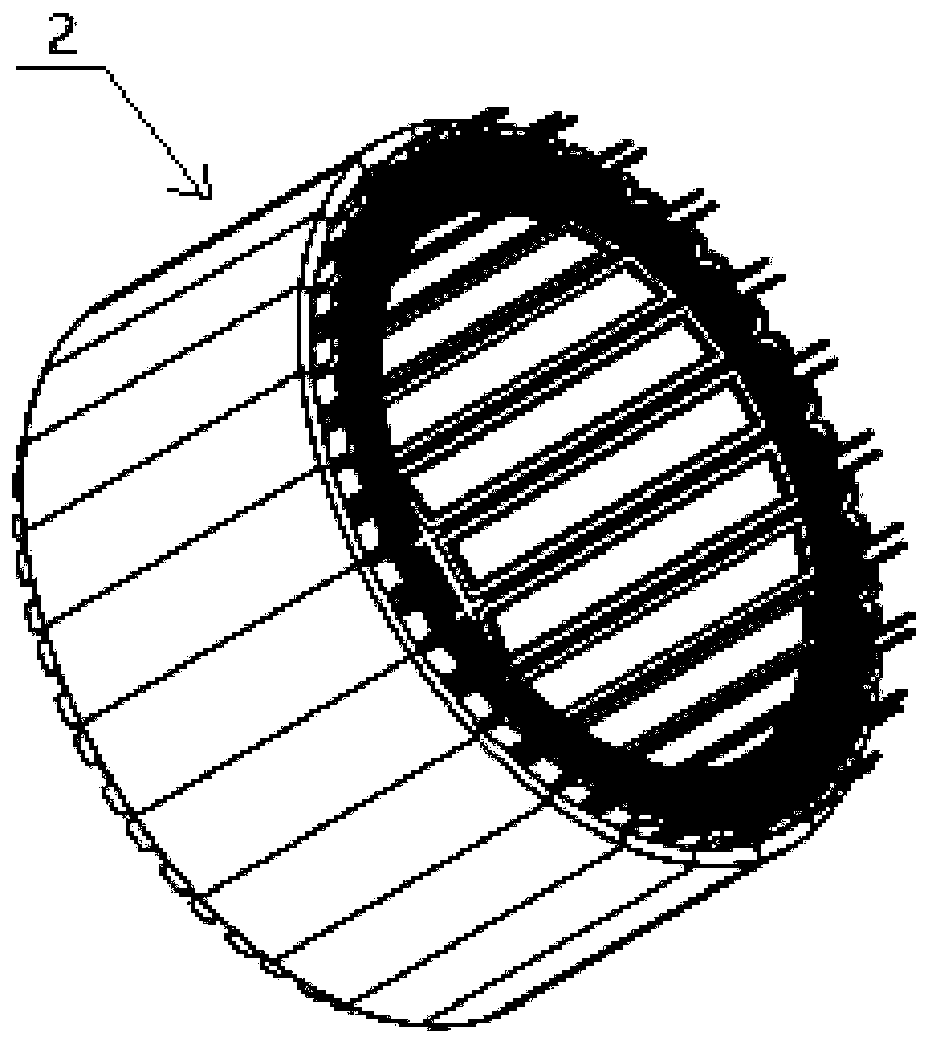

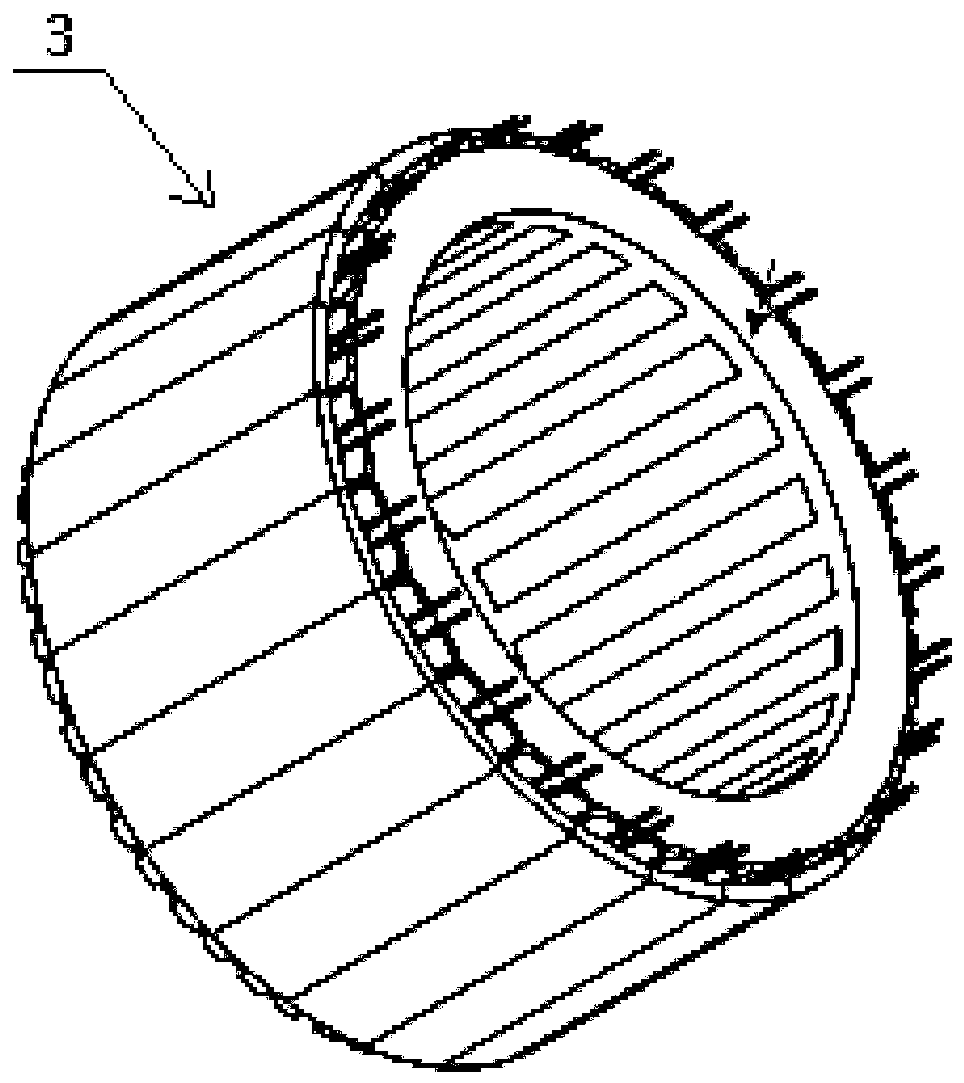

Spiral multi-channel pulse detonation engine

InactiveCN103899436AEffective use of space sizeShort filling timeIntermittent jet plantsRocket engine plantsInlet channelDeflagration to detonation transition

The invention discloses a spiral multi-channel pulse detonation engine which comprises an engine shell, spiral partition plates, gas inlet slots, a plurality of spark plugs and a gas inlet rotor. The engine shell is circular, the spiral partition plates are fixed onto an inner ring wall of an annular cavity to form spiral channels, and the gas inlet slots are formed in the inner ring wall and are positioned among the spiral partition plates; two spiral slots which are in identical shapes are formed in the gas inlet rotor and are used as common gas inlet channels. The gas inlet rotor is in close fit with an inner ring of the engine shell and can freely rotate. The multiple spark plugs are mounted at the ends of the engine, are correspondingly matched with the spiral channels on the inner ring wall and are controlled by a computer, an automatic ignition effect can be realized according to the rotational speed of the gas inlet rotor and phase of the gas inlet channels, and accordingly a multi-tube time-sharing initiation effect can be realized. The spiral multi-channel pulse detonation engine has the advantages that a low-energy ignition mode is adopted by the engine, so that axial DDT (deflagration to detonation transition) distances can be shortened, and the spatial size of the engine can be effectively utilized; the gas inlet slots are formed in positions along a detonation chamber, and gas can flow into the spiral multi-channel pulse detonation engine via the gas inlet slots, so that the spiral multi-channel pulse detonation engine is short in filling time and high in gas inlet filling speed, and the detonation frequency can be increased.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

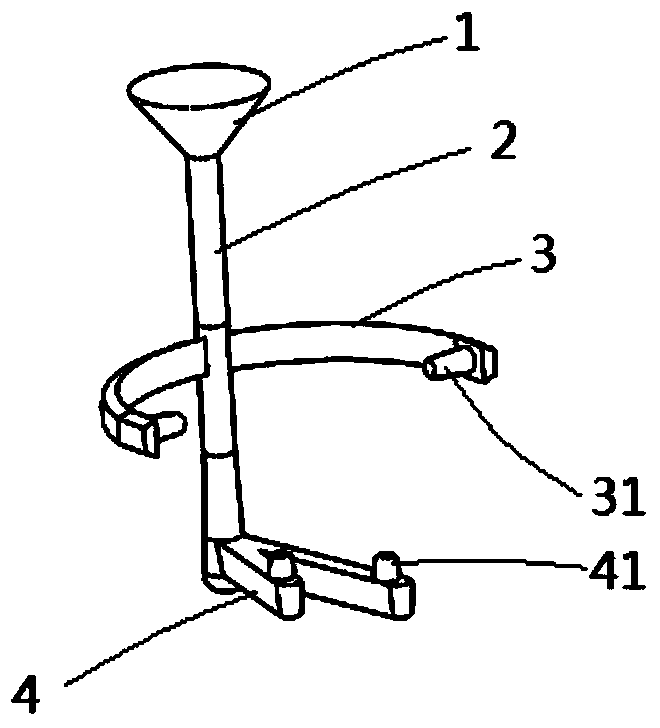

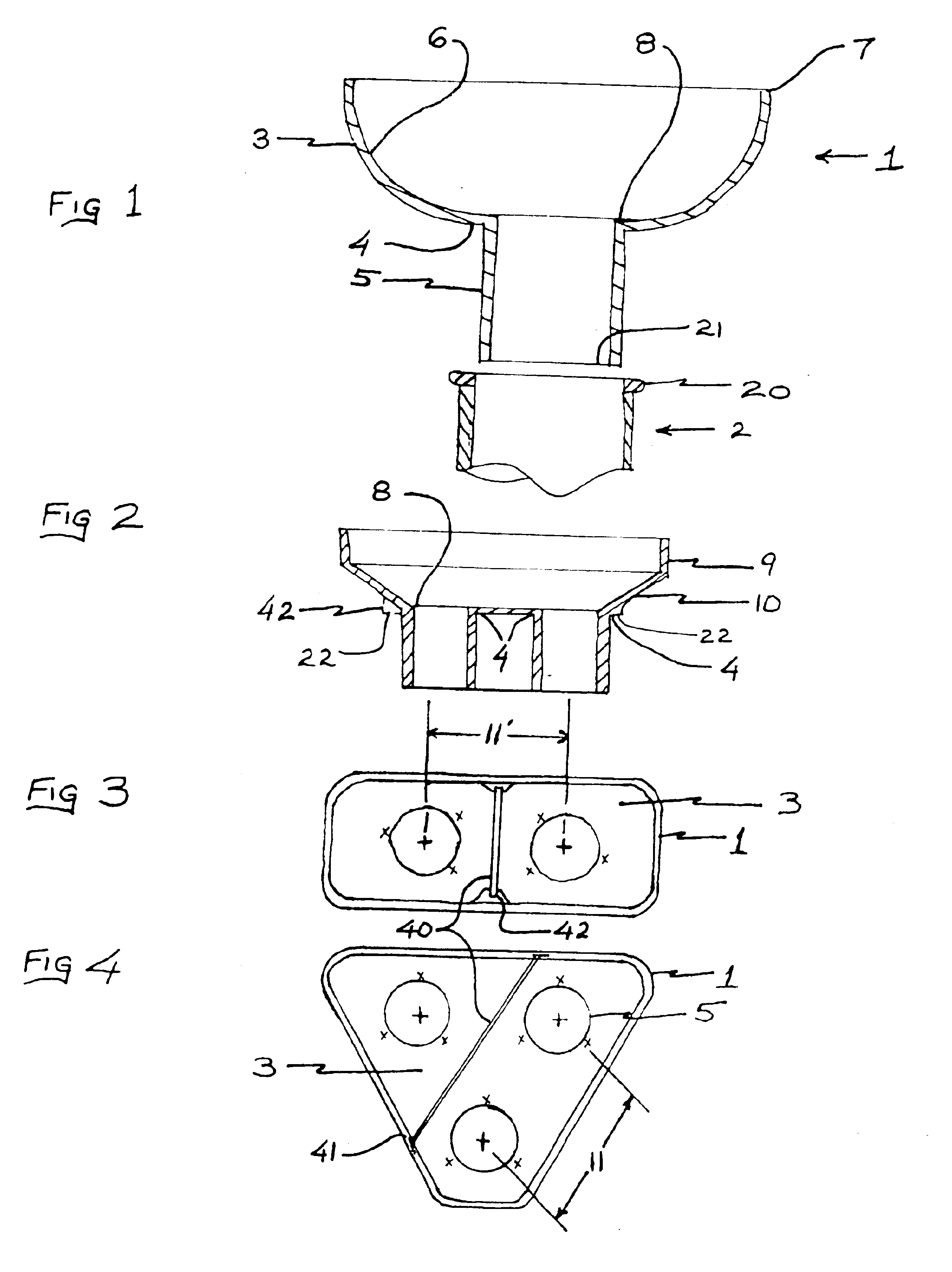

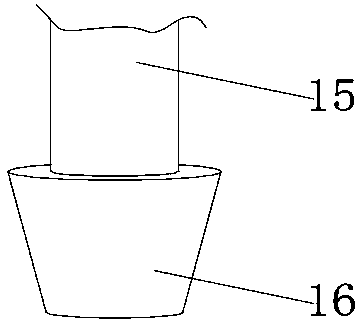

Paintball filling system

InactiveUS6845794B2Short filling timeReduced paintball lossLiquid fillingAmmunition loadingStructural engineeringMechanical engineering

Disclosed is a filling system for loading one or more paintball reservoir tubes with paintballs. The system is made of a paintball fill funnel and a support for at least one, and preferably a plurality of reservoir tubes. The fill funnel is dimensioned to fit within the reservoir tube and rest on the rim of the reservoir tube. A support shoulder, rim, or plurality of support shoulders on the outside of the fill funnel form a stable plane atop the tube rim. Each funnel can have more than one spout that communicates with a central funnel chamber for filling a plurality of paintball reservoir tubes simultaneously. The tube support can take a variety of configurations.

Owner:JOHNSON LANCE G

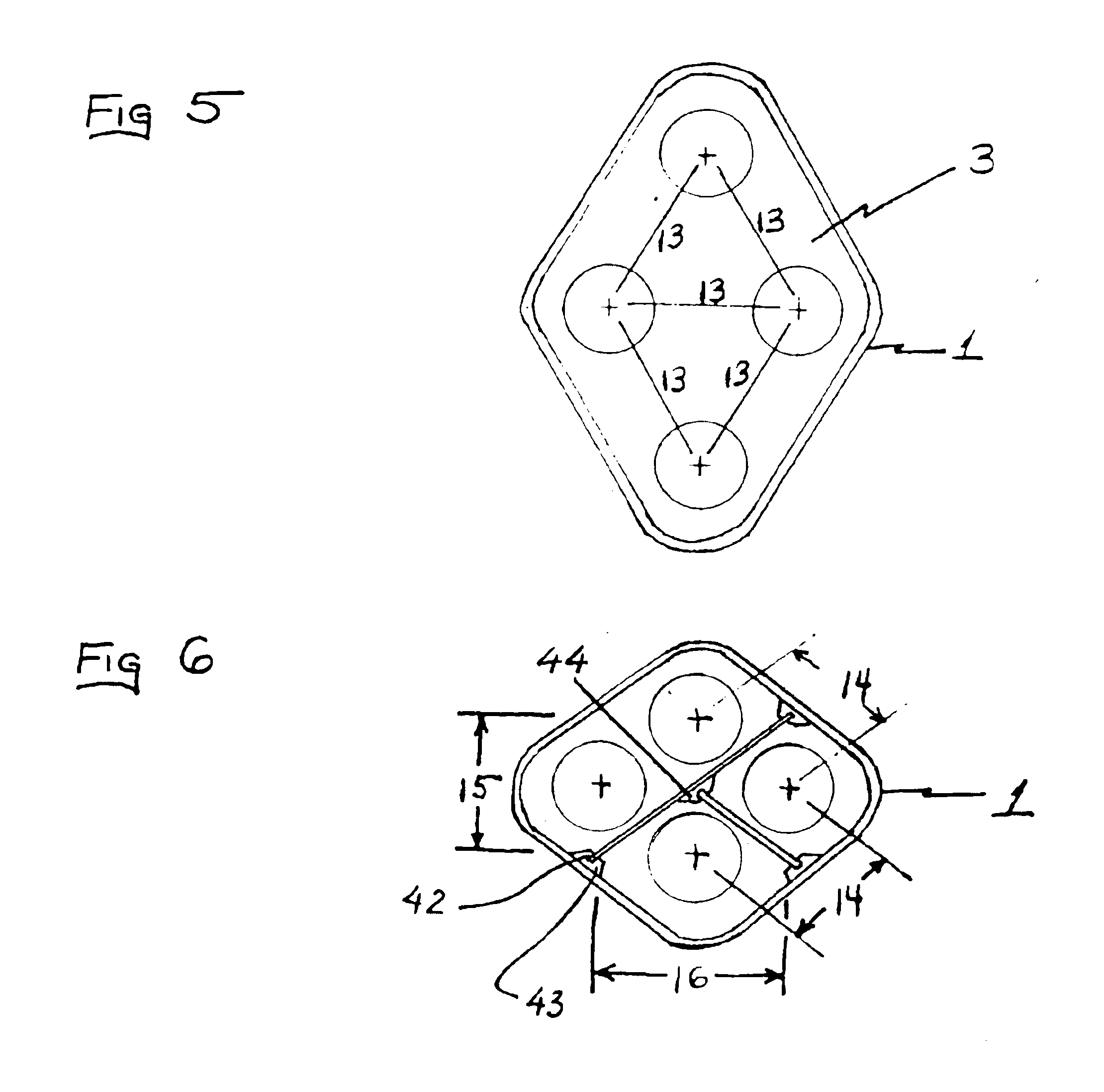

Cooling, heating and power integrated system based on fuel cell and hydrogen storage device of fuel cell for extravehicular spacesuit

InactiveCN102935899AReduce quality lossShort filling timeSpace suitsFuel cell auxillariesAutomotive engineeringIntegrated systems

The invention discloses a cooling, heating and power integrated system based on a fuel cell and a hydrogen storage device of the fuel cell for an extravehicular spacesuit. The integrated system comprises a fuel cell hydrogen storage device, a proton exchange membrane fuel cell, a thermoelectric cooling component, a liquid cooling suit and a radiator. The liquid cooling suit is used for collecting human body metabolism produced heat and electric equipment produced heat in the extravehicular spacesuit; the fuel cell hydrogen storage device is used for absorbing heat transmitted from the liquid cooling suit and releasing hydrogen to be used by the proton exchange membrane fuel cell simultaneously; the proton exchange membrane fuel cell is used for using the hydrogen released by the hydrogen storage device to generate power to provide power sources for the extravehicular spacesuit; the thermoelectric cooling component is used for matching cooling capacities that can be supplied by the fuel cell hydrogen storage device with heat dissipating capacities needed by the liquid cooling suit so as to enable the capacities to be balanced; and the radiator is used for discharging waste heat produced in a proton exchange membrane fuel cell power generation process and heat discharge by the thermoelectric cooling component into space. The system has the advantages of being small in size, few in consumptive working medium requirements, quick in regeneration process and the like.

Owner:SCI RES TRAINING CENT FOR CHINESE ASTRONAUTS +1

High-frequency conical spiral tube type pulse detonation engine

InactiveCN103075271AShort filling timeReduce time and distanceRocket engine plantsHigh frequencyOperating frequency

The invention discloses a high-frequency conical spiral tube type pulse detonation engine. A multiple-tube coaxial stacking type inverted frustum-shaped structure is adopted, and is embedded in a conical ring-shaped passage between an outer casing and an inner casing of the engine, and the conical ring-shaped passage is positioned between an oxidizer storage cavity and an isolation gas storage cavity. During work, the gas in the cavities at the two sides can be preheated by the high temperature of gas in a conical spiral detonation tube, meanwhile, the conical spiral detonation tube is cooled by the gas in the cavities to avoid burnout of the detonation tube, and the heat cycle efficiency of the engine is improved by a heat return principle. The conical spiral detonation tube is provided with a reinforcing section, the filling time of combustible mixing gas is very short, the DDT (deflagration to detonation transition) distance and time can be obviously shortened, and the working efficiency of the engine is improved. The periodic thrust is generated by the high-speed spraying of high-temperature and high-pressure gas generated by pulse detonation waves. The high-frequency conical spiral tube type pulse detonation engine has the advantages that the structure is simple, the boosting components and rotary components are saved, the size is small, and the processing is convenient.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

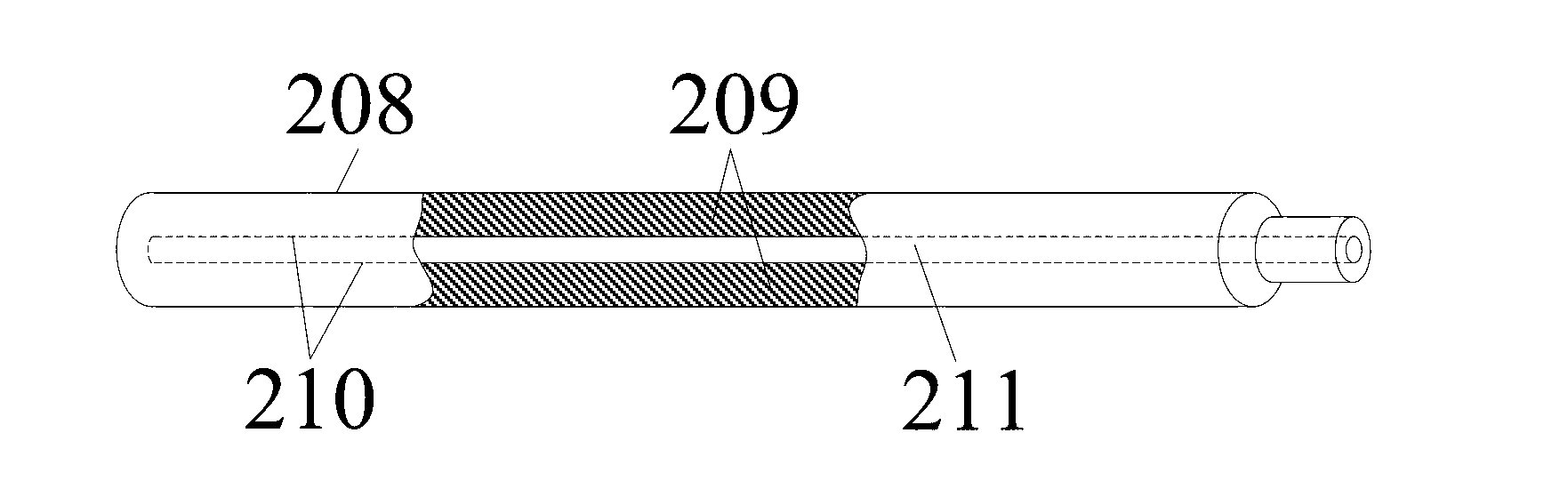

Composite pipe hydraulic expansion method, manufacturing device and obtained composite pipe

ActiveCN103629445AGood removal effectGuaranteed bonding qualityPipe elementsRigid pipesEngineeringScrew thread

The invention provides a composite pipe hydraulic expansion method, which comprises the following steps that (1) a plug provided with a sealing ring in the circumferential direction is inserted into an inner pipe; (2) sealing pressure liquid is introduced to a position between the plug and an inner ring of the sealing ring for sealing the end part of the inner pipe; (3) the expansion is carried out, before the expansion, a sleeve ring with the same inner diameter as an outer pipe of a composite pipe is arranged in a way of tightly pasting the end surface of the outer pipe of the composite pipe requiring the expansion, and in addition, the innermost end of the sealing ring is arranged outside the end surface of the outer pipe of the composite pipe. The sealing position exceeds the end surface of the outer pipe, so the pressure inside an inner pipe cavity can reach the end part of the outer pipe, and the combining quality is ensured. The defect of composite blind region reservation at the end part of the composite pipe manufactured in the prior art is overcome, and the composite pipe can be used without cutting off the blind region, so the cost is reduced in aspects of both materials and the process. The cutting is not needed, so great convenience is brought for the subsequent processing of external screw threads formed at the pip end of the composite pipe before the expansion.

Owner:QINGDAO ZHONGRUITAI MESNAC TECH CO LTD

Metal mine transverse drift four-mining one-reserving retreat mining structure and method

InactiveCN105626072AIncrease productionImprove mining efficiencyUnderground miningSurface miningPhysicsMetal

The invention relates to a metal mine transverse drift four-mining one-reserving retreat mining structure and method. The structure comprises a drift roadway close to a mineral vein in the extending direction of the mineral vein and mining regions arranged on the mineral vein at equal intervals. Reserving regions are arranged between adjacent mining regions at intervals. Each mining region is internally provided with primary mining regions located on the two sides, a to-be-mined region and the corresponding reserving regions located between the primary mining regions and the to-be-mined regions. Transverse drifts are arranged on the two sides of each primary mining region, on the two sides of each to-be-mined region and the middle of each reserving region. Working roadways communicated with the transverse drifts on the two sides of the primary mining regions or the two sides of the to-be-mined regions are transversely arranged in the primary mining regions and the to-be-mined regions. The working roadways divide the mineral vein in the mining regions into an outer side front mining region and an inner side blast region. Mining efficiency can be greatly improved, mining safety is greatly improved, and the yield of high-quality ore can be increased.

Owner:林立荣

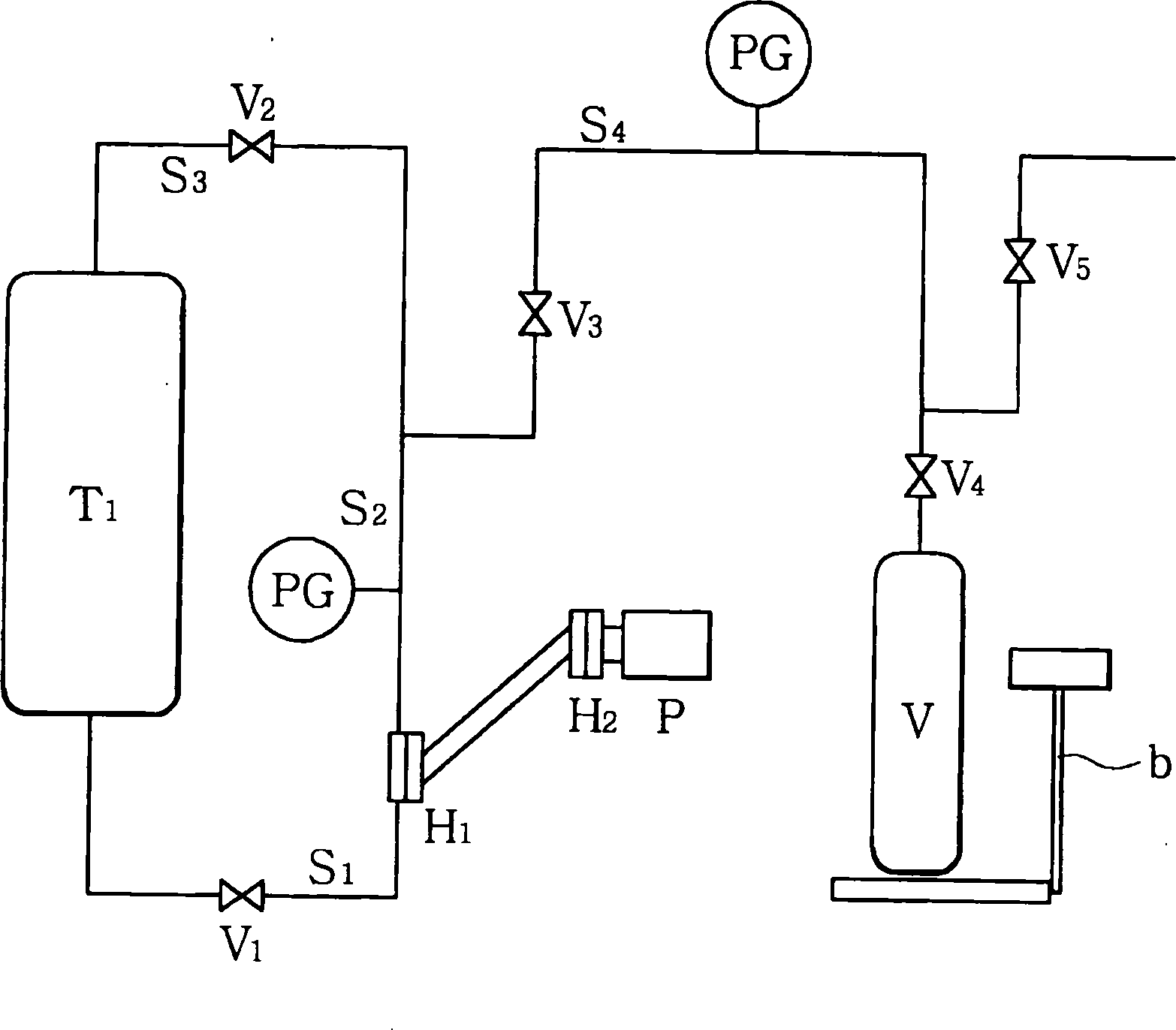

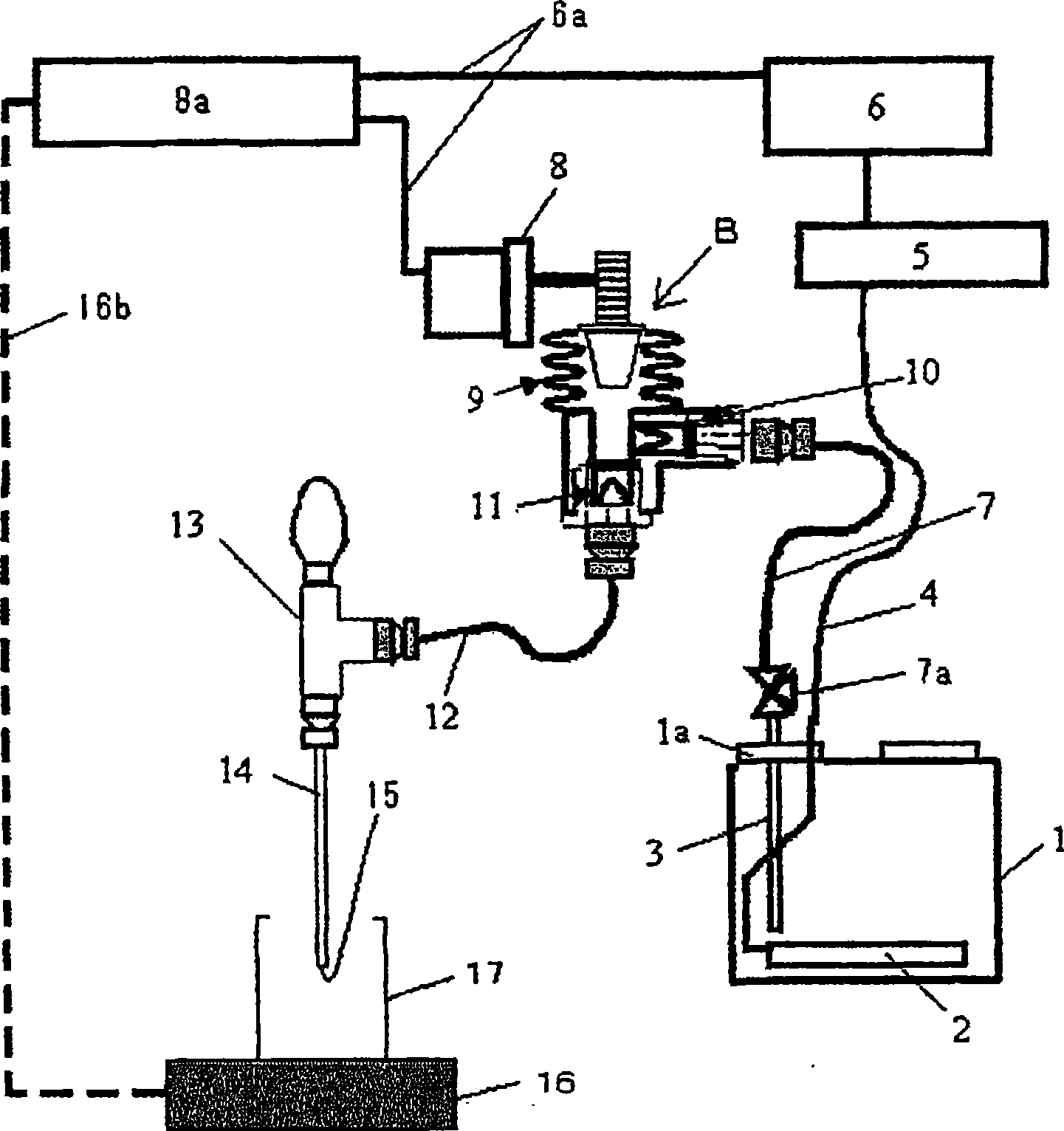

Method of charging low temperature liquified gas

InactiveCN1880831AFilling safetyBarrier generationVessel mounting detailsFlexible member pumpsDiaphragm pumpProduct gas

Disclosed is a method of charging a low temperature liquefied gas in a high pressure charging cylinder using a diaphragm pump. The method is advantageous in that it is possible to charge a low temperature liquefied gas which is to be made highly pure in a high pressure gas cylinder using a simple process in which the liquefied gas does not deteriorate and small energy is consumed.

Owner:ULSAN CHEM

Novel horizontal well sand preventing well completion structure

Owner:ANTON BAILIN OILFIELD TECH (BEIJING) CO LTD

Liquid hydrogen vaporization and self-pressurizing device

ActiveCN108953988ASimple processReduce energy consumptionPressure vesselsFluid handledHigh pressure hydrogenVaporization

The invention relates to a liquid hydrogen vaporization device, and specifically relates to a liquid hydrogen vaporization and self-pressurizing device. The liquid hydrogen vaporization and self-pressurizing device is used in the process of vaporizing liquid hydrogen into gasified hydrogen through an evapourizer and increasing the pressure of the hydrogen to form high-pressure hydrogen. When applied to the hydrogen energy field, the liquid hydrogen vaporization and self-pressurizing device can be specifically applied in hydrogen refueling stations adopting vaporization and pressure increasingof transported liquid hydrogen. When the high-pressure liquid hydrogen vaporization device is used for vaporizing the liquid hydrogen and achieving self-pressurizing, the pressure ranges from 10MPa to200MPa, a hydrogen compressor is not needed, and energy consumption is reduced. The invention further relates to three ways of filling the liquid hydrogen into the high-pressure liquid hydrogen vaporization device. In the two ways, pressure difference squeezing is adopted, and the liquid hydrogen in a high-pressure liquid hydrogen storage tank is conveyed into the high-pressure liquid hydrogen vaporization device; in the other way, the liquid hydrogen is conveyed to the high-pressure liquid hydrogen vaporization device through a liquid hydrogen high pressure pump. Cold energy of the liquid hydrogen is fully utilized by the liquid hydrogen vaporization and self-pressurizing device. Compared with prior equipment, the liquid hydrogen vaporization and self-pressurizing device can work withoutthe hydrogen compressor in the liquid hydrogen vaporizing and self-pressurizing process, and energy consumption is reduced obviously.

Owner:靳殷实

Pattern forming method as well as production methods for processed substrate, optical component, circuit board, electronic component and imprint mold

ActiveUS10829644B2Improve throughputShorten filling timeInksPhotomechanical coating apparatusEngineeringElectronic component

A pattern is formed on a substrate with forming a layer of a curable composition (A1) containing a component (a1) serving as a polymerizable compound and a component (e1) on a surface of the substrate, then dispensing droplets of a curable composition (A2) containing at least a component (a2) serving as a polymerizable compound dropwise discretely onto the layer of the curable composition (A1), subsequently sandwiching a mixture layer of the curable composition (A1) and the curable composition (A2) between a mold and the substrate, then irradiating the mixture layer with light to cure the layer, and releasing the mold from the mixture layer after the curing, a surface tension of a composition of components of the curable composition (A1) except a solvent being higher than a surface tension a composition of components of the curable composition (A2) except a solvent.

Owner:CANON KK

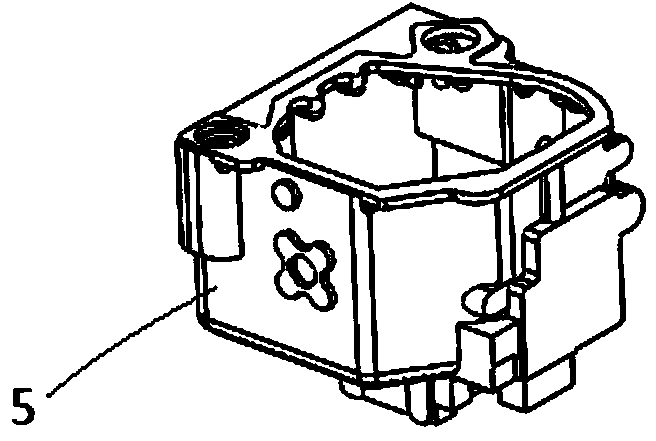

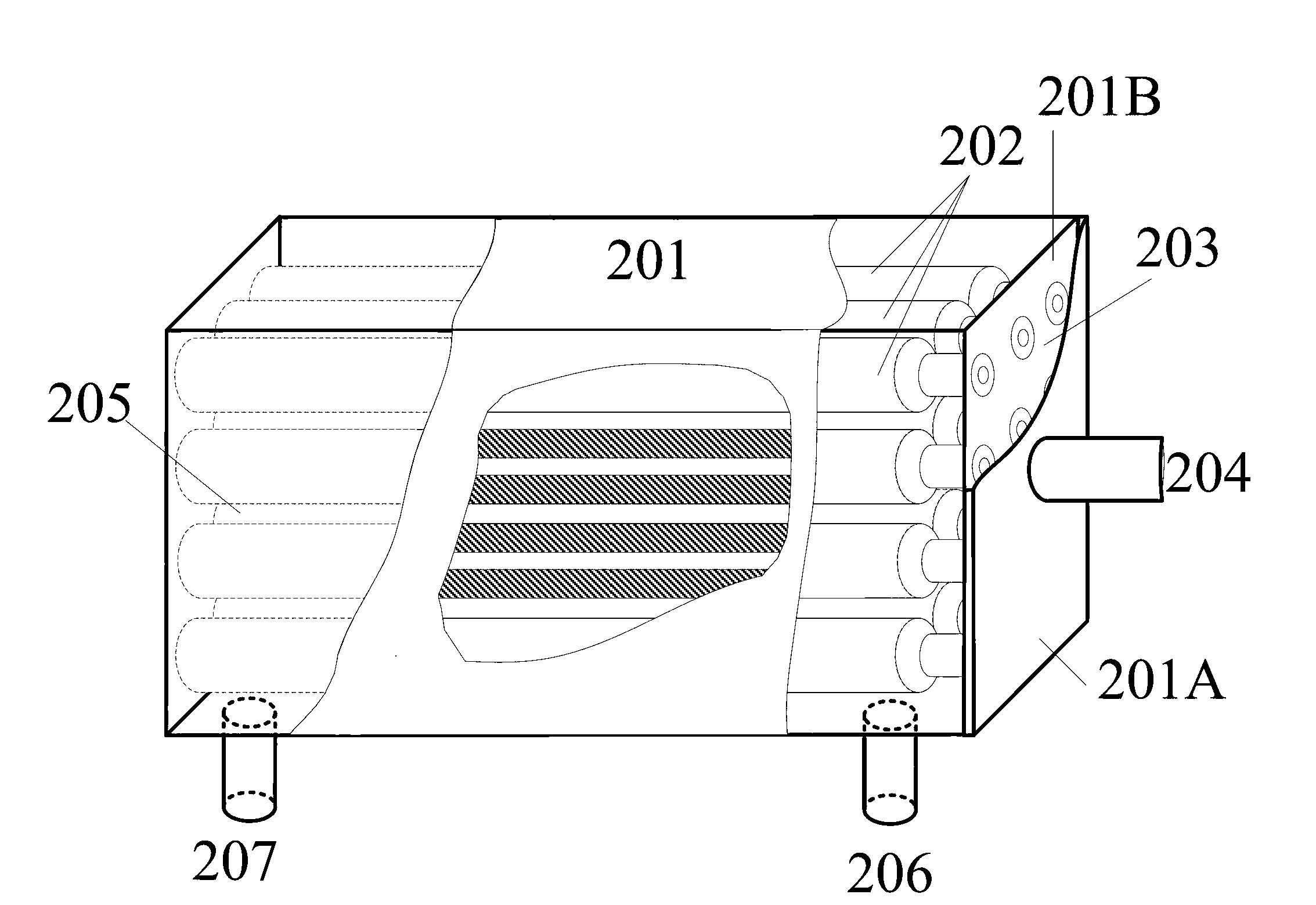

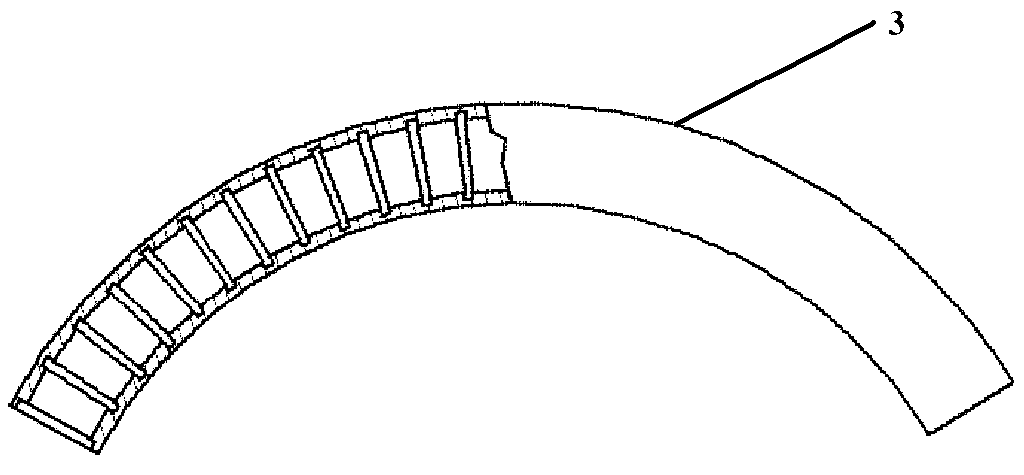

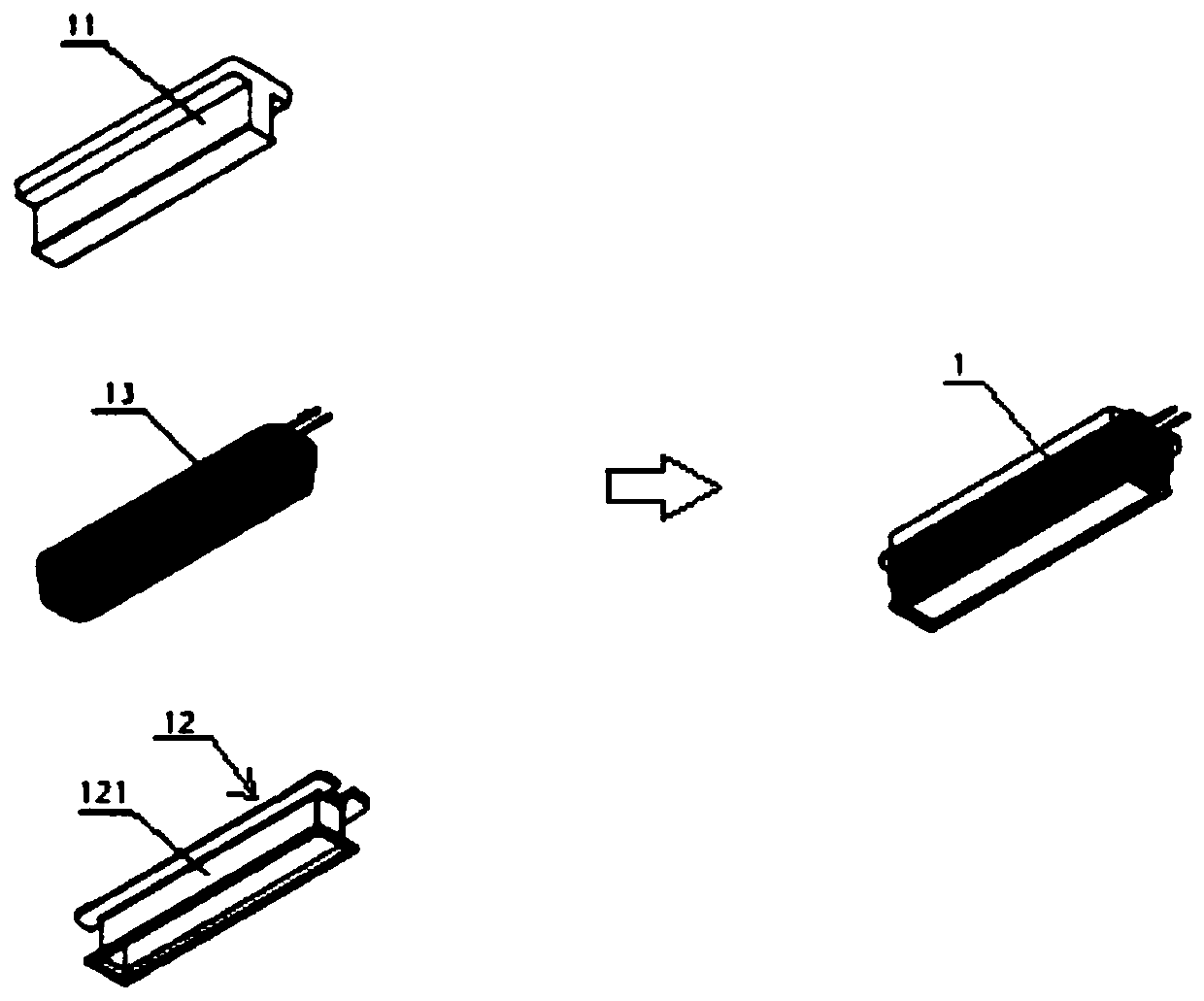

Motor, stator core, stator segment, and machining method thereof

InactiveCN110445322ASmall sizeImprove convenienceMagnetic circuit stationary partsManufacturing stator/rotor bodiesEngineeringConductor Coil

The embodiment of the present invention provides a motor, a stator core, a stator segment, and a machining method thereof. The method for machining the stator segment comprises: acquiring a winding stator segment around which a concentrated winding is wound; and potting and solidifying the winding stator segment to obtain a stator segment in which the concentrated winding is wrapped in a potting material. The motor, the stator core, the stator segment and the machining method thereof provided by the embodiment of the invention can reduce the machining requirements for a potting model and improve the machining efficiency.

Owner:SCHAEFFLER TECH AG & CO KG

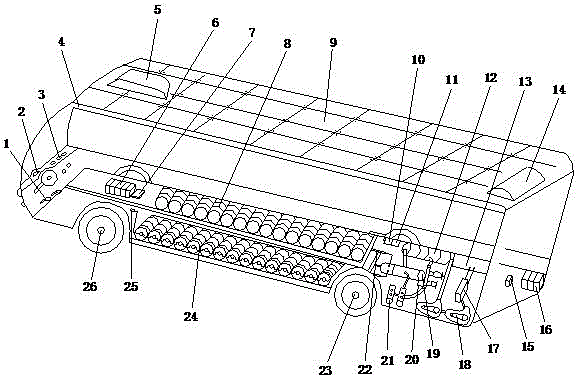

Short wheelchair frame extrusion casting system

The invention provides a short wheelchair frame extrusion casting system, and belongs to the technical field of the structure of an extrusion casting mold. The short wheelchair frame extrusion casting system comprises a casting head, a long main runner, a short main runner, a plurality of branch runners, a casting cavity, more than four slag ladles and a plurality of exhaust blocks, wherein an inner pouring gate is formed in each branch runner; the casting head is connected to the main runners which are connected to the branch runners; the branch runners are connected to the casting cavity; the filling tail end of the casting cavity is connected to the slag ladles and the exhaust blocks; and the long main runner and the short main runner extend out along the left and right sides of the casting head. The short wheelchair frame extrusion casting system has the beneficial effects that the filing time of an aluminum alloy solution is short, the temperature loss is low, molding and feeding are facilitated, the void ratio of products is low, the internal quality of extrusion castings is high, the inner pouring gates are liable to be cut off, and the production efficiency is improved.

Owner:UNIV OF SCI & TECH BEIJING

Automatic compression aerated and charged hybrid air energy vehicle

InactiveCN105059126AShort filling timeSmall external power lossPropulsion partsVehicular energy storageManufacturing technologySolar power

The invention relates to the technical field of manufacturing of a hybrid power vehicle, and particularly relates to an automatic compression aerated and charged hybrid air energy vehicle which comprises a vehicle body, a front axle steering support assembly, a rear axle driving assembly, an auxiliary device, a solar power generation system, a voltage and electric quantity boosting system and a pneumatic assembly, wherein the solar power generation system comprises a plurality of solar photovoltaic power generation panels installed at the top of the vehicle body, a photoelectric converter installed at the rear end of the top of the vehicle body, and a solar photovoltaic battery pack arranged at the rear end in the vehicle body. According to the invention, solar power generation serves as a triggered power supply, and a set of power boost amplification current which is made according to the principle of a Tesla coil is recovered and converted by the power generation system so as to generate sufficient power drive; and a compressor works so as to aerate a high pressure gas holder of the air energy vehicle, and residual power is used for charging all vehicle-mounted circuit equipment accumulators, so that the vehicle provided by the invention is energy-saving and environment-friendly.

Owner:冯新民

Transferring method of powder toner for electrophotograph and transferring apparatus thereof, and filling method of powder toner and the filling apparatus thereof

InactiveCN100520627CQuality assurancePrevent proliferationSolid materialElectrographic process apparatusReciprocating motionEngineering

The present invention aims at providing a powder toner transferring method which fluidizes a powder toner with a gas supplied from an air supply means, sucks the fluidized powder toner with a suction means and transfers the powder toner by discharging the powder toner in a toner storage container, where the suction of the powder toner by means of the suction means is performed with a reciprocating-motion pump. The present invention also aims at providing a powder toner filling method that comprises the powder toner transferring process.

Owner:RICOH KK

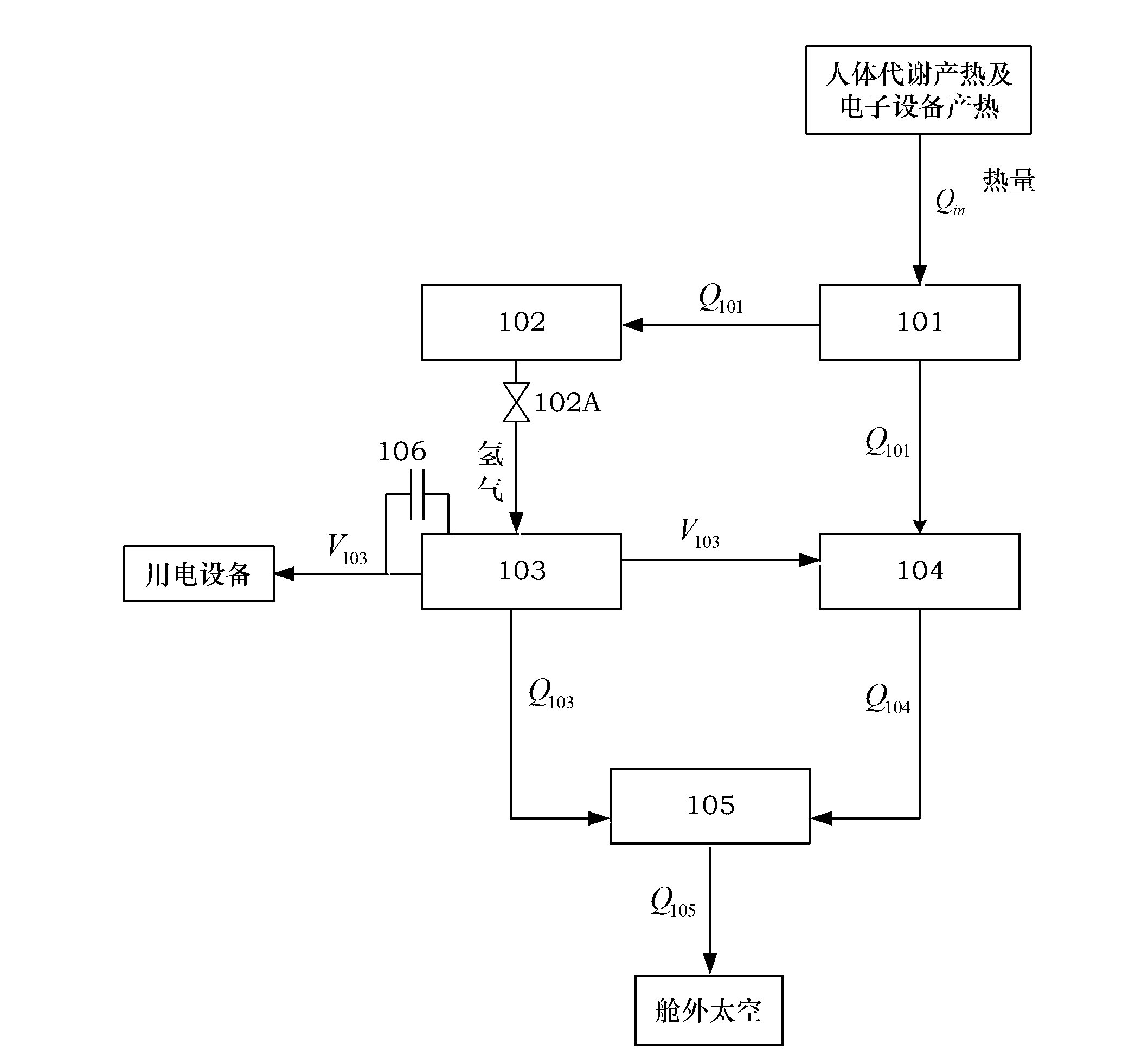

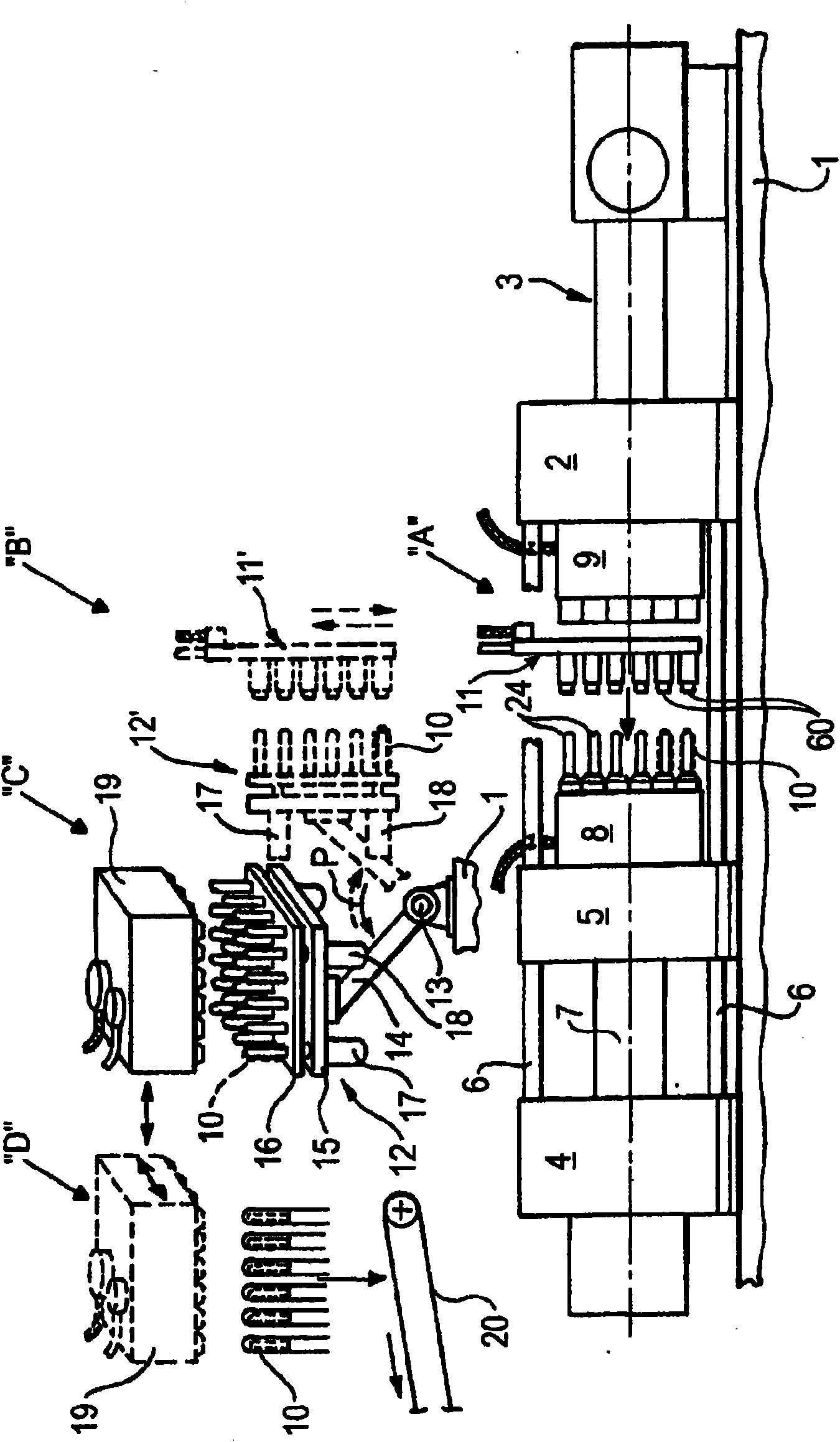

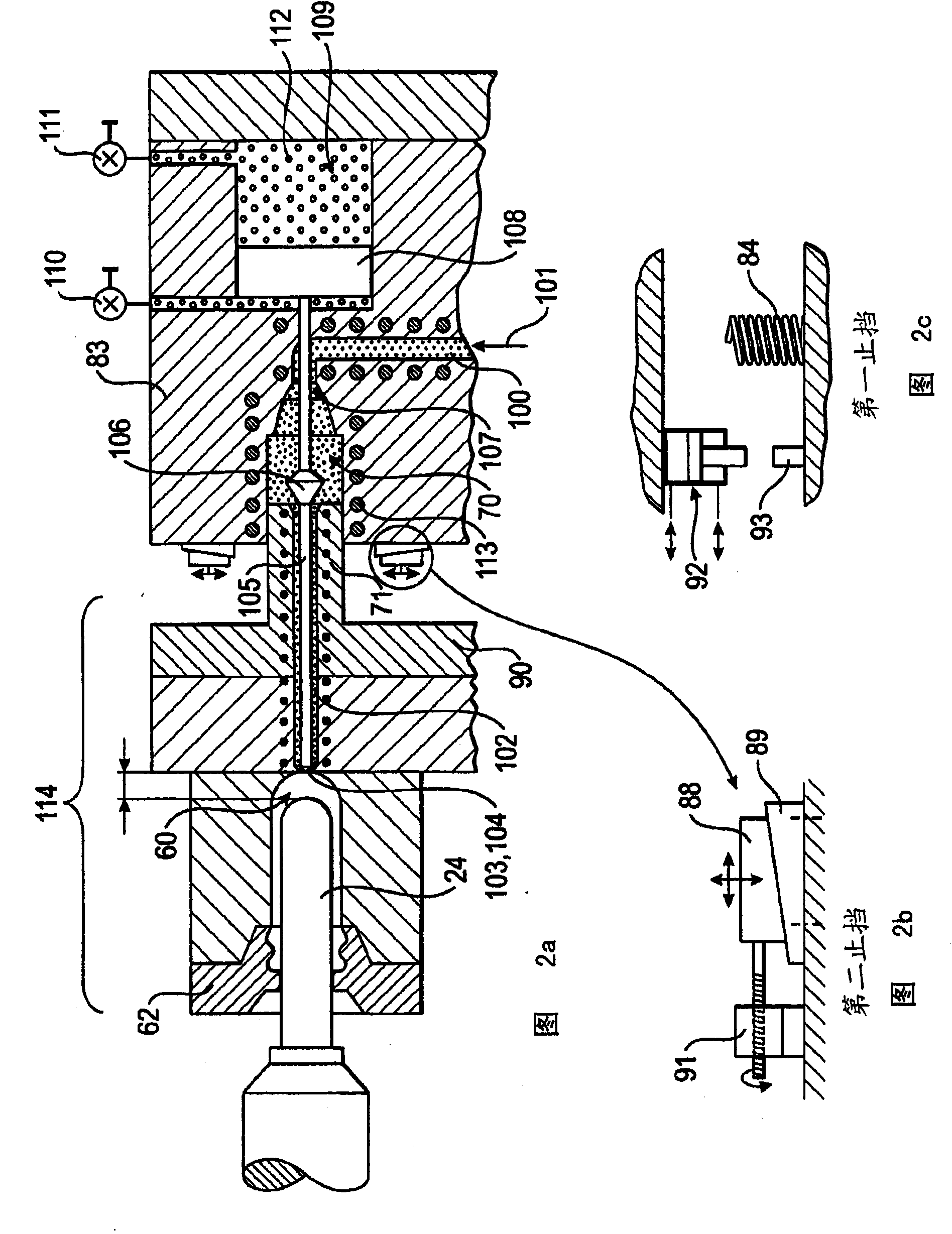

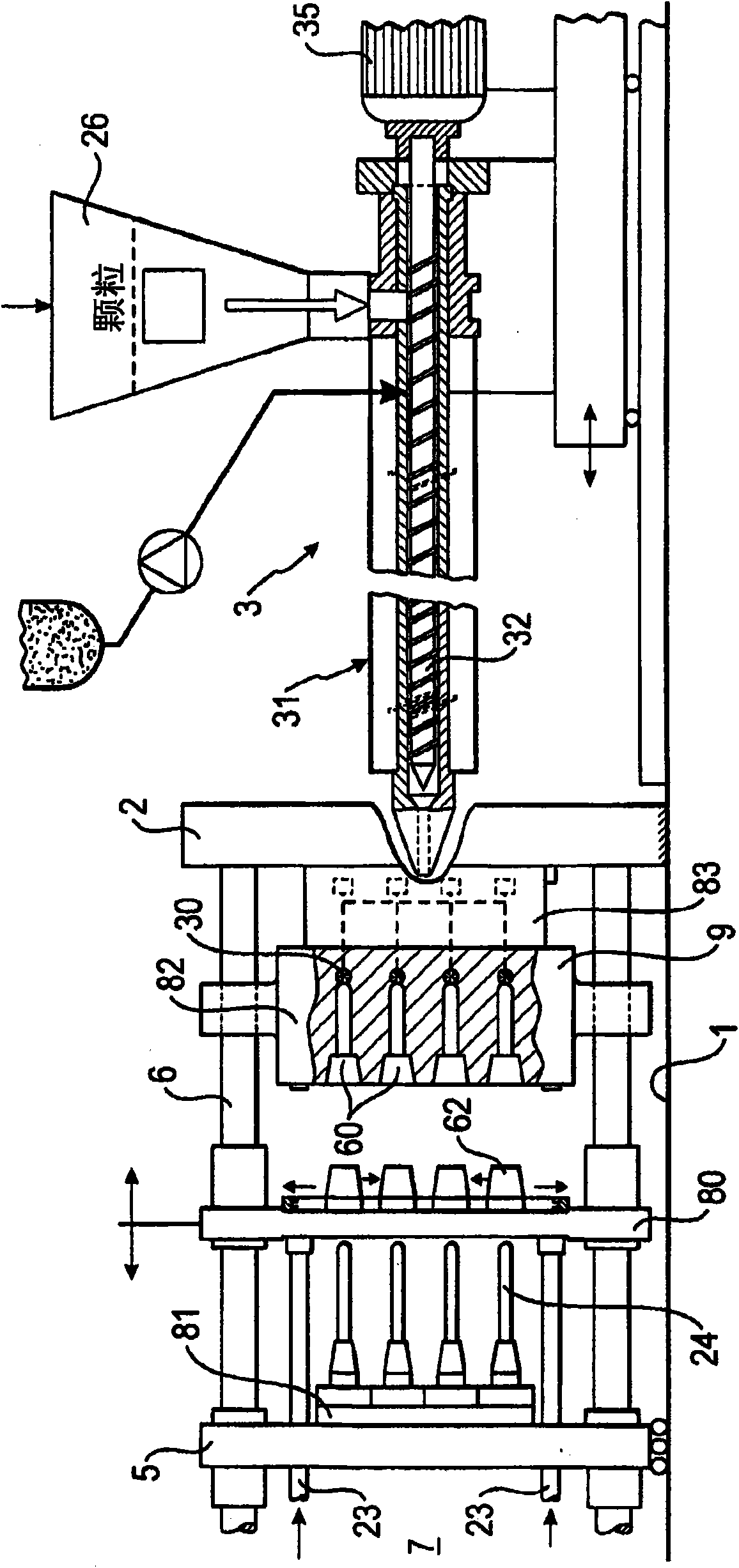

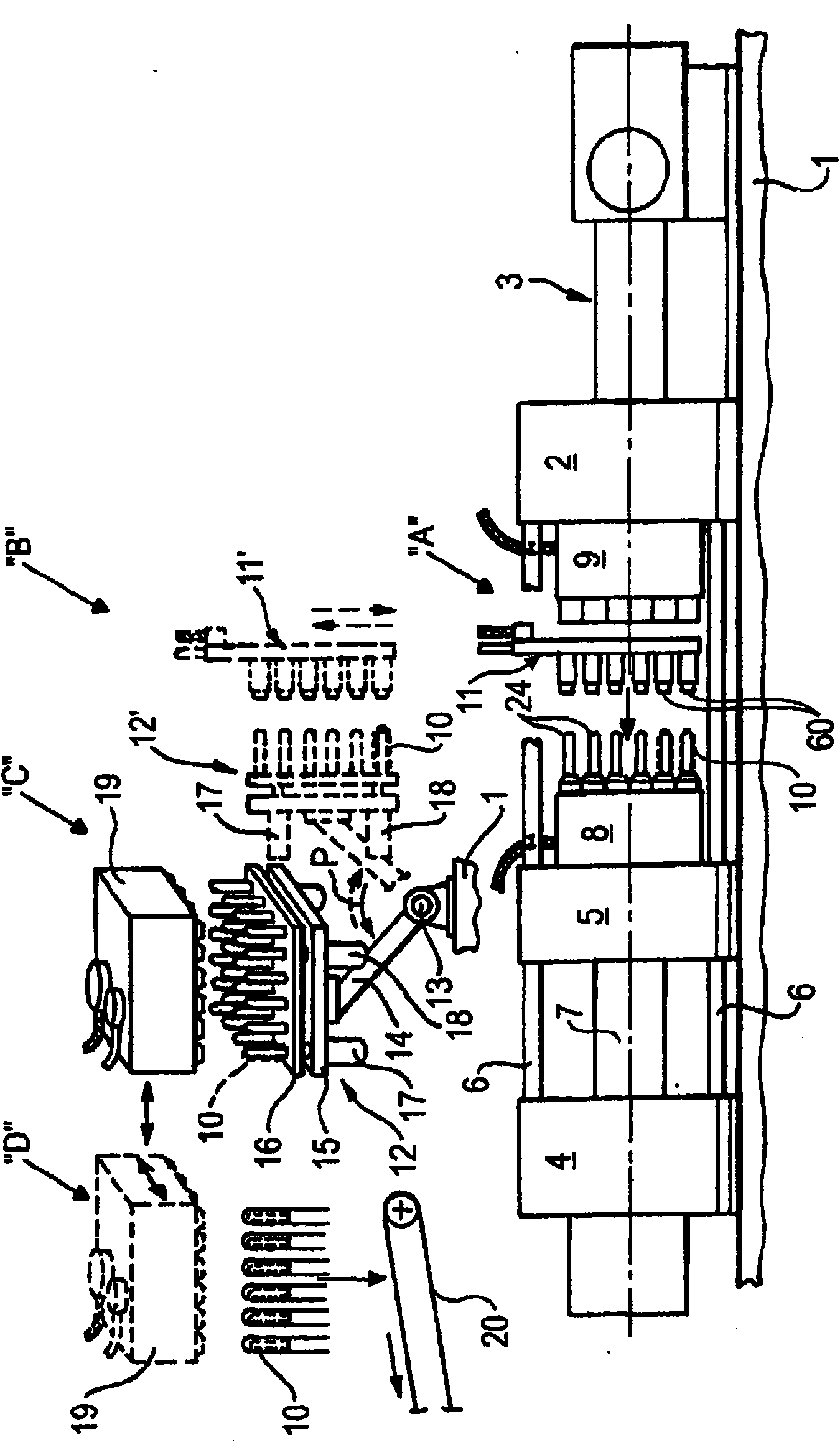

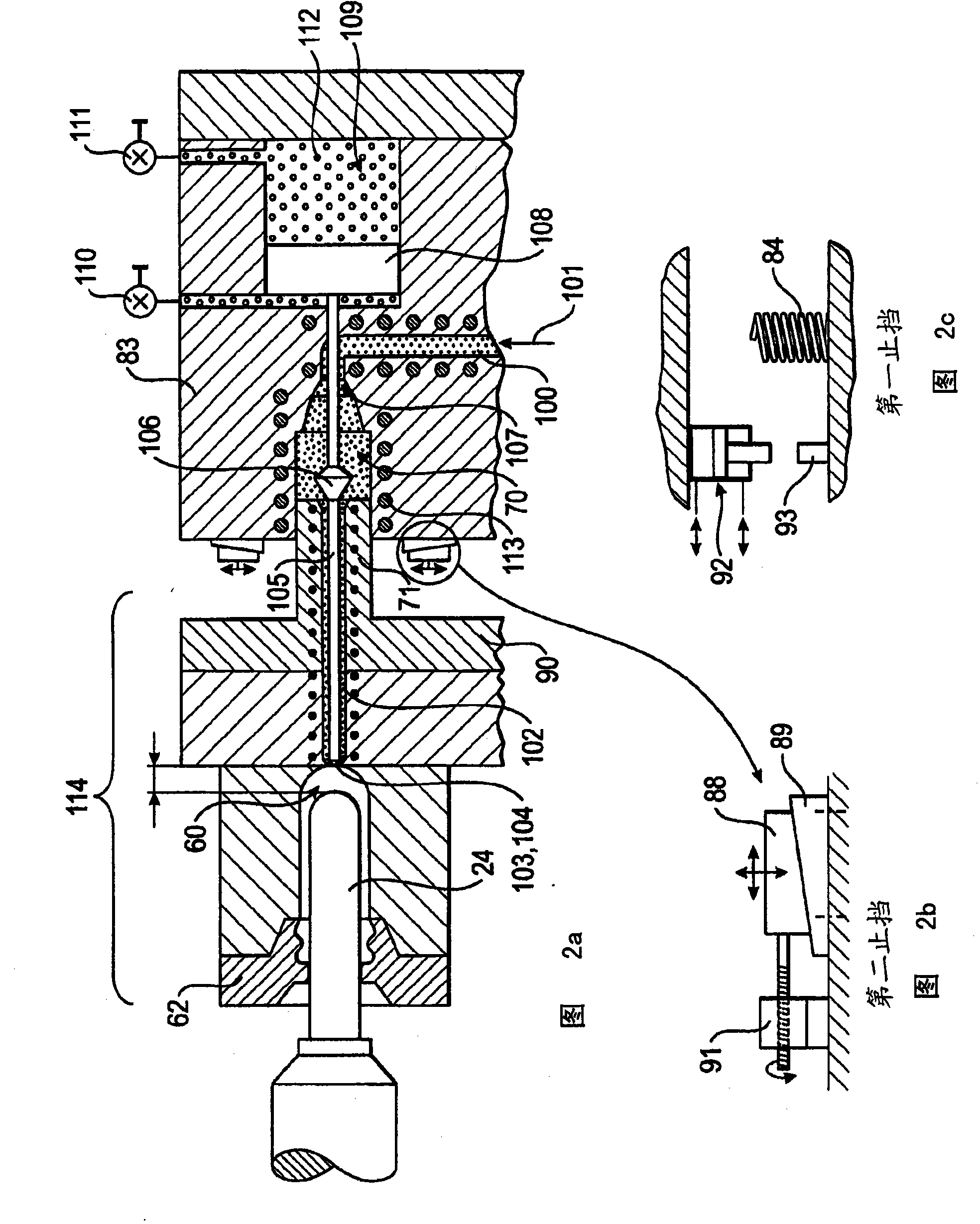

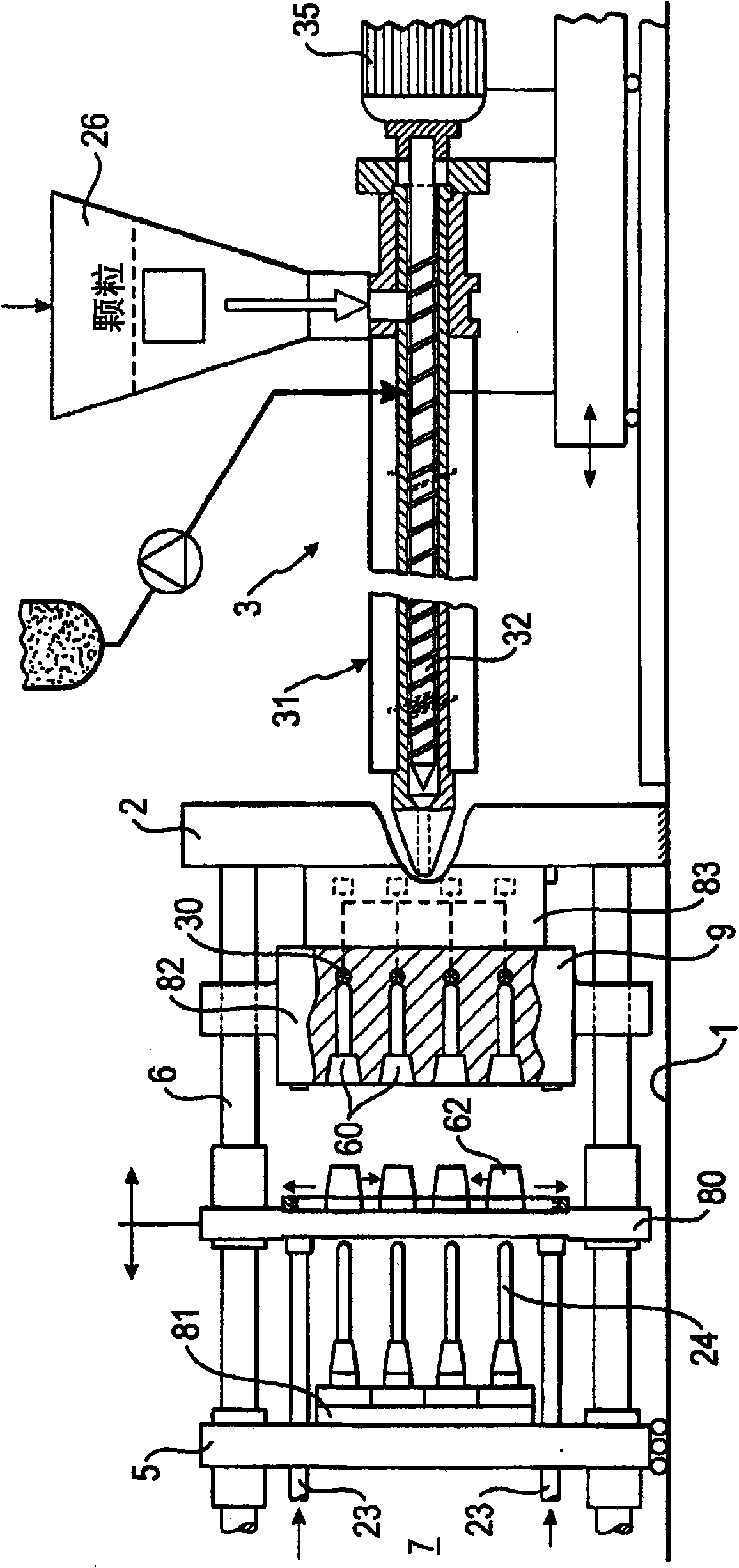

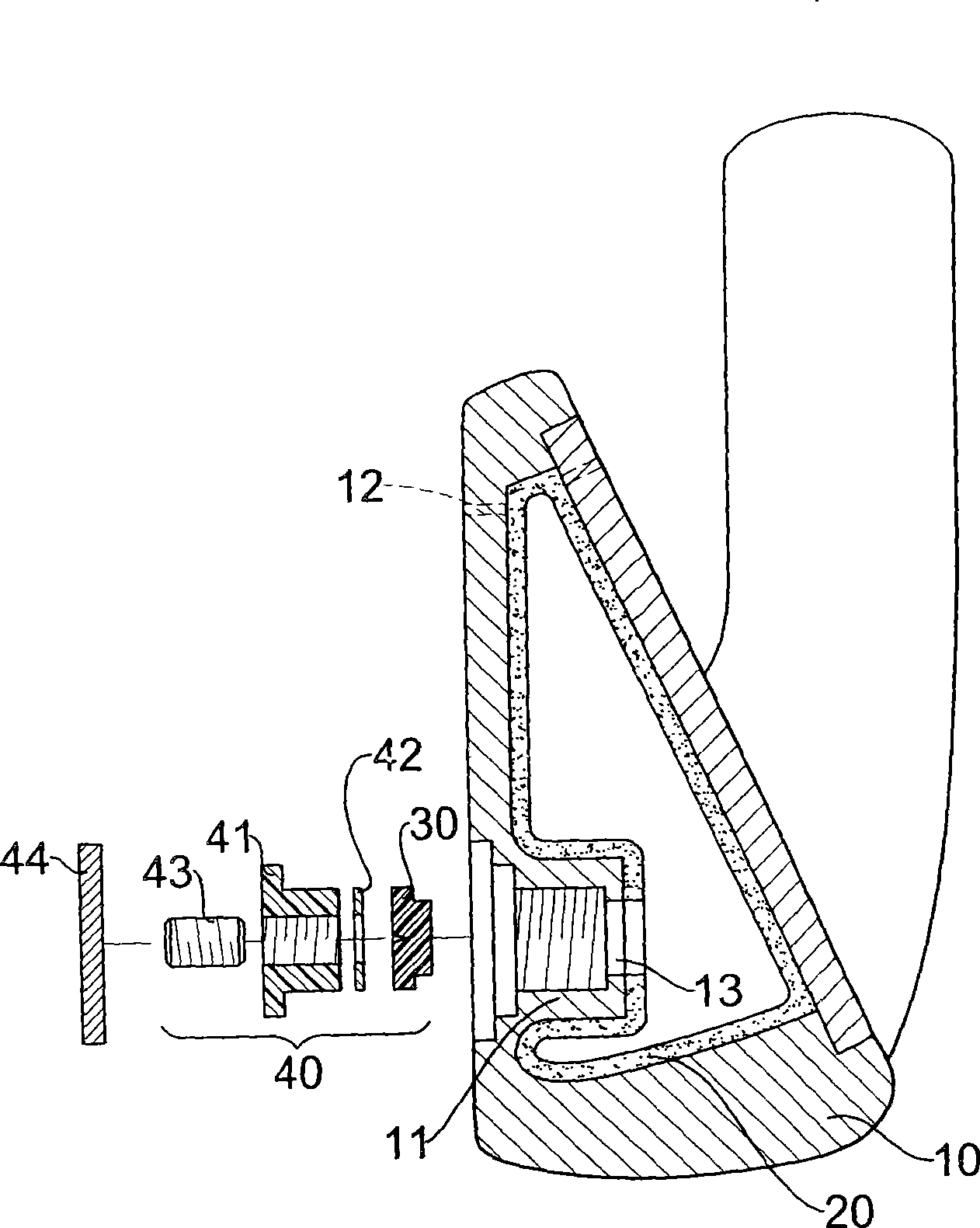

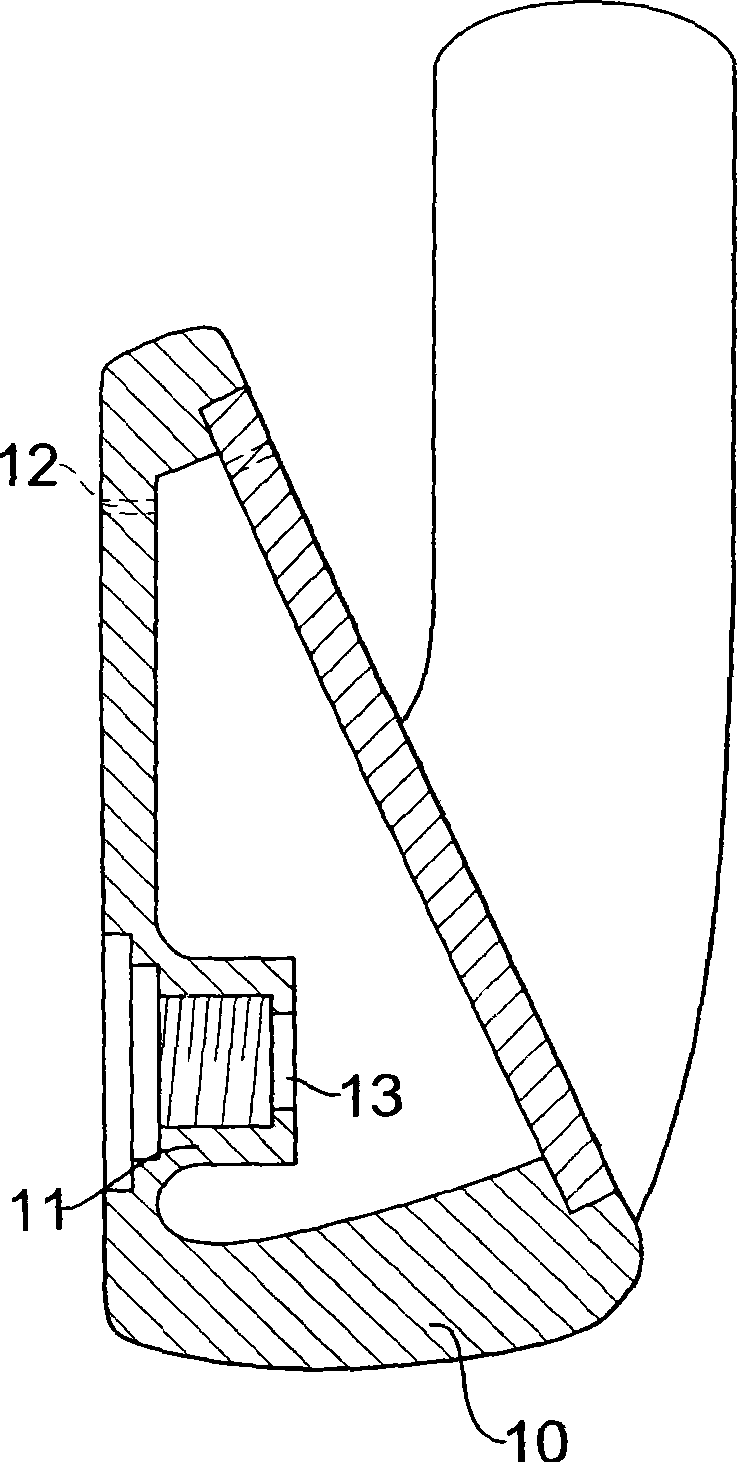

Compression injection moulding method and device for preforms

The invention relates to a method and a device for the compression injection moulding of preforms (10) by means of an injection moulding machine comprising one movable and one fixed tool carrier plate (2, 5) and a mould with a plurality of mould nests or cavities (60), the movable mould half (8) being designed with cores (24) and the melt being introduced into the cavities (60) on the fixed mould-half (9) side via controlled valves. The cores (24) penetrate the mould nests or cavities (60) before completion of the melt dosage to such a depth that said mould nests are at least substantially closed to the exterior. The melt is introduced into the mould nests or cavities (60) when the moulds are not completely sealed, the valves are closed and the compression pressure is produced by means of the cores (24) by the complete closure of the moulds.

Owner:NETABTAL MASCHEN

Compression injection moulding method and device for preforms

The invention relates to a method and a device for the compression injection moulding of preforms (10) by means of an injection moulding machine comprising one movable and one fixed tool carrier plate (2, 5) and a mould with a plurality of mould nests or cavities (60), the movable mould half (8) being designed with cores (24) and the melt being introduced into the cavities (60) on the fixed mould-half (9) side via controlled valves. The cores (24) penetrate the mould nests or cavities (60) before completion of the melt dosage to such a depth that said mould nests are at least substantially closed to the exterior. The melt is introduced into the mould nests or cavities (60) when the moulds are not completely sealed, the valves are closed and the compression pressure is produced by means of the cores (24) by the complete closure of the moulds.

Owner:NETABTAL MASCHEN

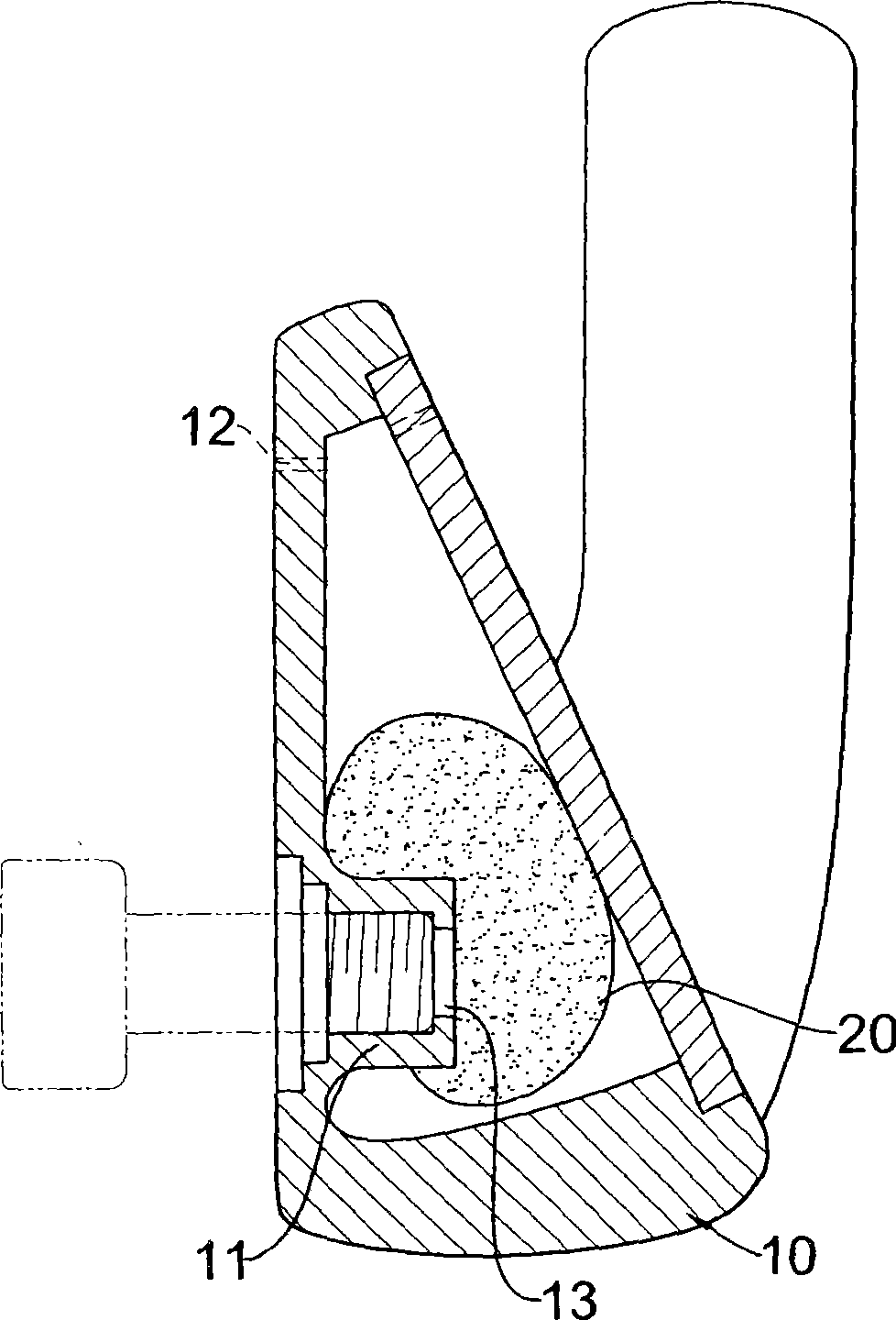

Golf bar head equipped with hollow shock-absorbing material and air pressure function and production method thereof

InactiveCN101480522ALess discomfortImprove practicalityGolf clubsRacket sportsPressure functionEngineering

The invention relates to a golf club head which is provided with shock-absorbing material and has air pressure function, and a manufacturing method of the golf club head. The golf club head comprises a hollow golf club head, a female thread combined base and at least one exhaust hole; the manufacturing method comprises the following steps: enabling the shock-absorbing material with gas barrier property to be shot into the hollow normal temperature golf club head and infusing gas into the melt glue center of the shock-absorbing material to ensure that the shock-absorbing material and the gas are filled according to the hot-to-cold (inside-to-outside) characteristics to form a hollow gas barrier shock-absorbing structure; fixedly arranging an elastic gas infusing pad on the female thread combined base by using a male thread combined base of a thread combined device; then enabling the compressed gas to penetrate through the elastic gas infusing pad through a threaded hole of the male thread combined base by means of a hollow needle to finish the infusion of the preset air pressure gas; and finally fixing and sealing the threaded hole of the male thread combined base by using a screw, so that the infused gas can not leak outwards to generate the air pressure function, thus, the invention not only can achieve the better shock-absorbing effect and reduce the consumption of the shock-absorbing material, but also have better batting rebounding force and batting sense, thereby improving the practicability of the golf club head.

Owner:SUPER WAY TECH +1

Compaction vibration system for high-rise building foundation

InactiveCN110952523AEvenly distributedImprove the compaction effectSoil-shifting machines/dredgersSoil preservationHydraulic cylinderArchitectural engineering

The invention discloses a compaction vibration system for a high-rise building foundation. The compaction vibration system comprises a machine body, wherein one side of the machine body is connected with a first fixing plate; a pushing handle is arranged in the middle of one side of the first fixing plate; the top of the other side of the machine body is connected with a second fixing plate; and the top of the second fixing plate is connected with a first hydraulic cylinder. According to the compaction vibration system for the high-rise building foundation, gravel soil, sandy soil, silt and the like below the foundation can be evenly distributed conveniently, and therefore the compaction effect is better, the sunken position of the ground can be filled conveniently, and the ground is keptflat; and the filling consumption time is short, few personnel are used, and therefore the labor cost is reduced.

Owner:河南裕鸿建筑工程有限公司

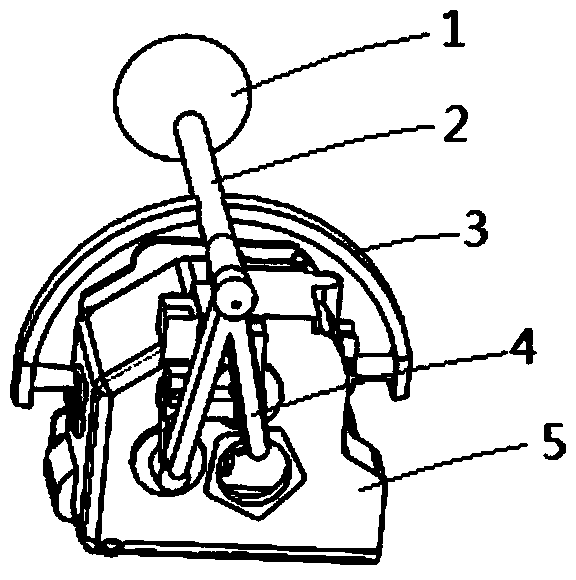

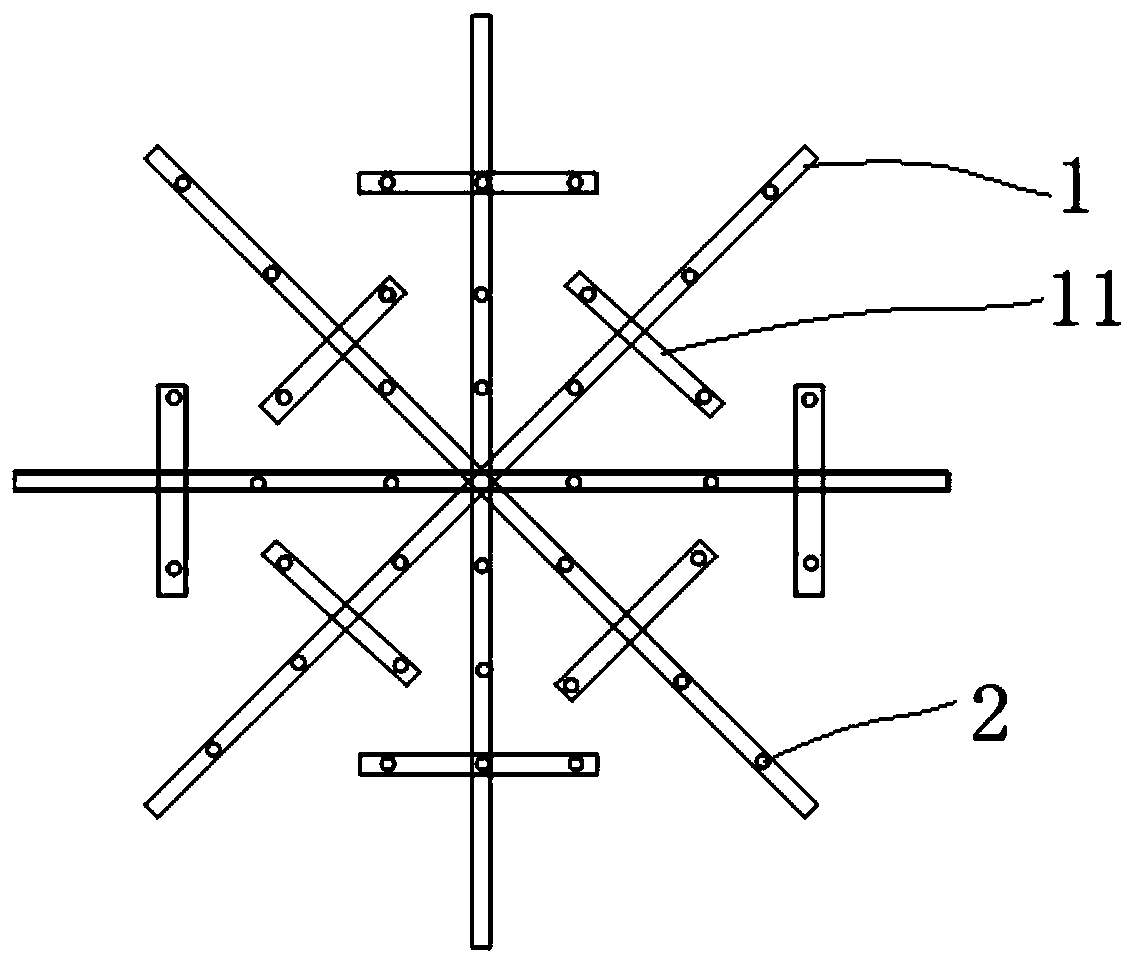

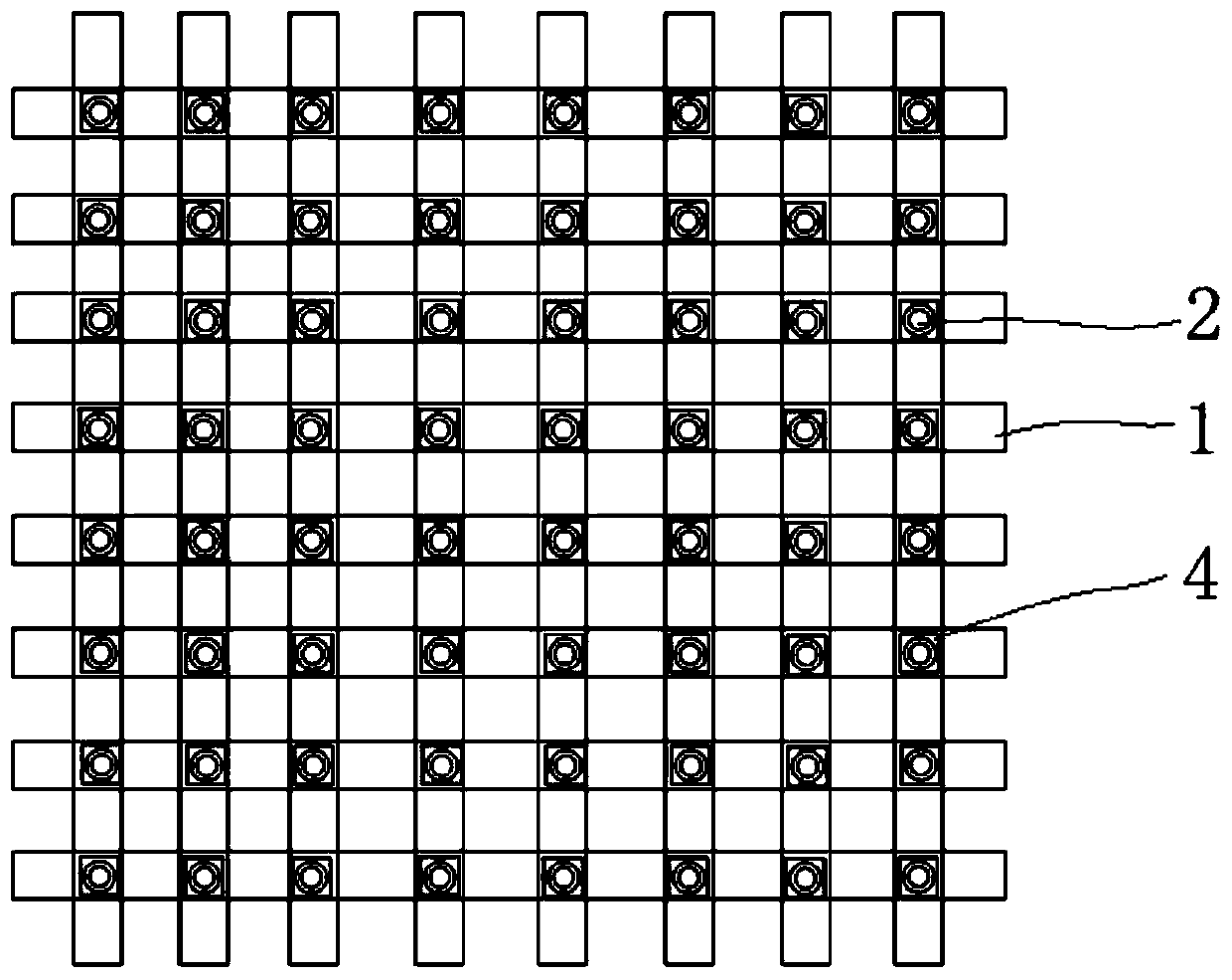

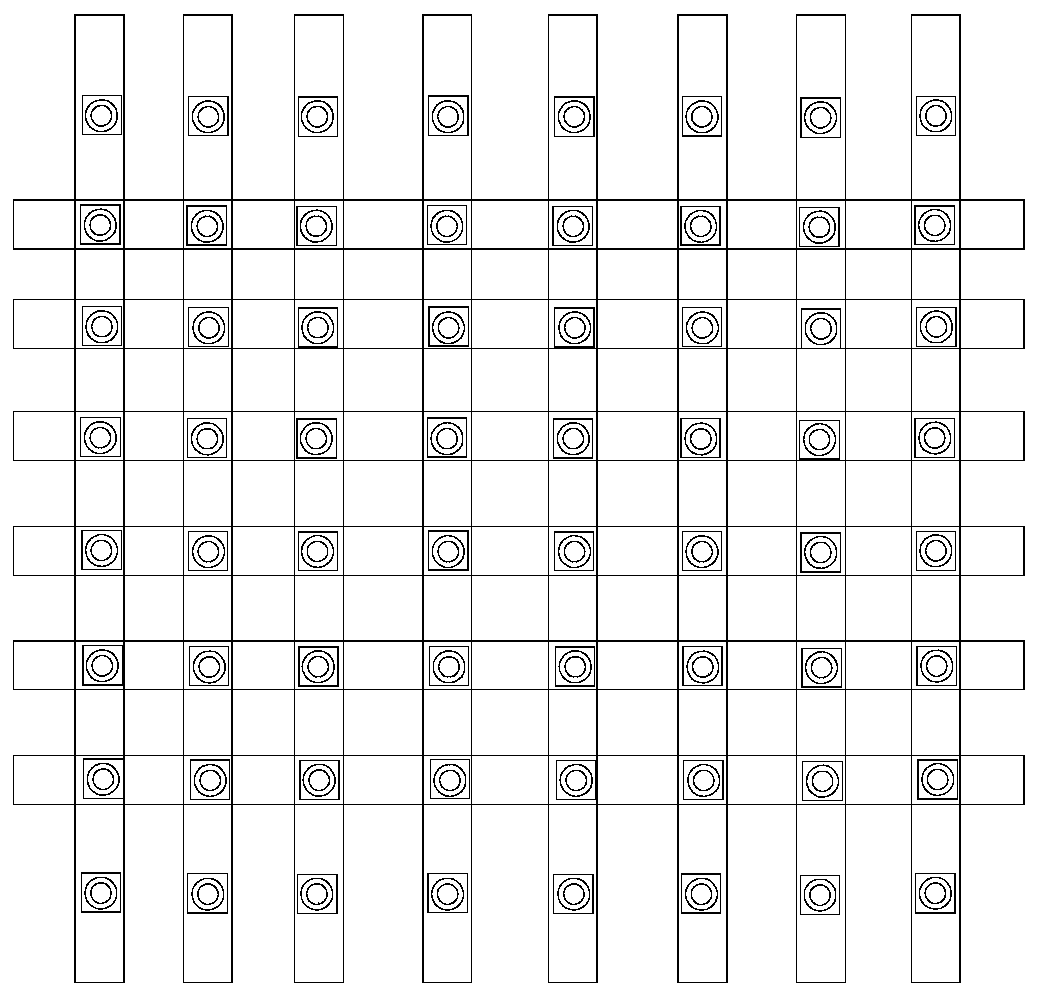

Quick conductive paste filling device based on electrode cap

PendingCN110559090AImprove work efficiencyAccurate data recordingSurgeryDiagnostic recording/measuringBiomedical engineeringData recording

The present invention discloses a quick conductive paste filling device based on an electrode cap. The device comprises a plurality of flexible elastic belts and a plurality of suction injection ballsarranged on the elastic belts, and when the elastic belts are bent to have the same radian as the electrode cap, and the suction injection balls on the elastic belts are correspondingly inserted intoelectrode cavities in the electrode cap one by one. The plurality of the suction injection balls are arranged on the plurality of the flexible elastic belts, distribution of the suction injection balls on the whole filling device is consistent with distribution of electrodes on the electrode cap to be injected, as the elastic belts have certain elasticity, certain elastic belts can be bent to beattached to the electrode cap, suction ports of the plurality of the suction injection balls are inserted into the cavities of the electrode cap, by manually pressing the injection balls, conductive paste filling of the plurality of the electrode cavities is completed at one time, whole filling time can be shortened to 5 minutes, working efficiency is greatly improved, and data recording of brainelectrical activities is more accurate.

Owner:INST OF PSYCHOLOGY CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com