Method of charging low temperature liquified gas

A low-temperature liquefied gas and liquid technology, applied in container filling methods, liquid variable capacity machinery, gas/liquid distribution and storage, etc., can solve the problems of high energy, gas deterioration, etc., achieve less heat generation, shorten filling time, The effect of minimizing power costs or operating and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

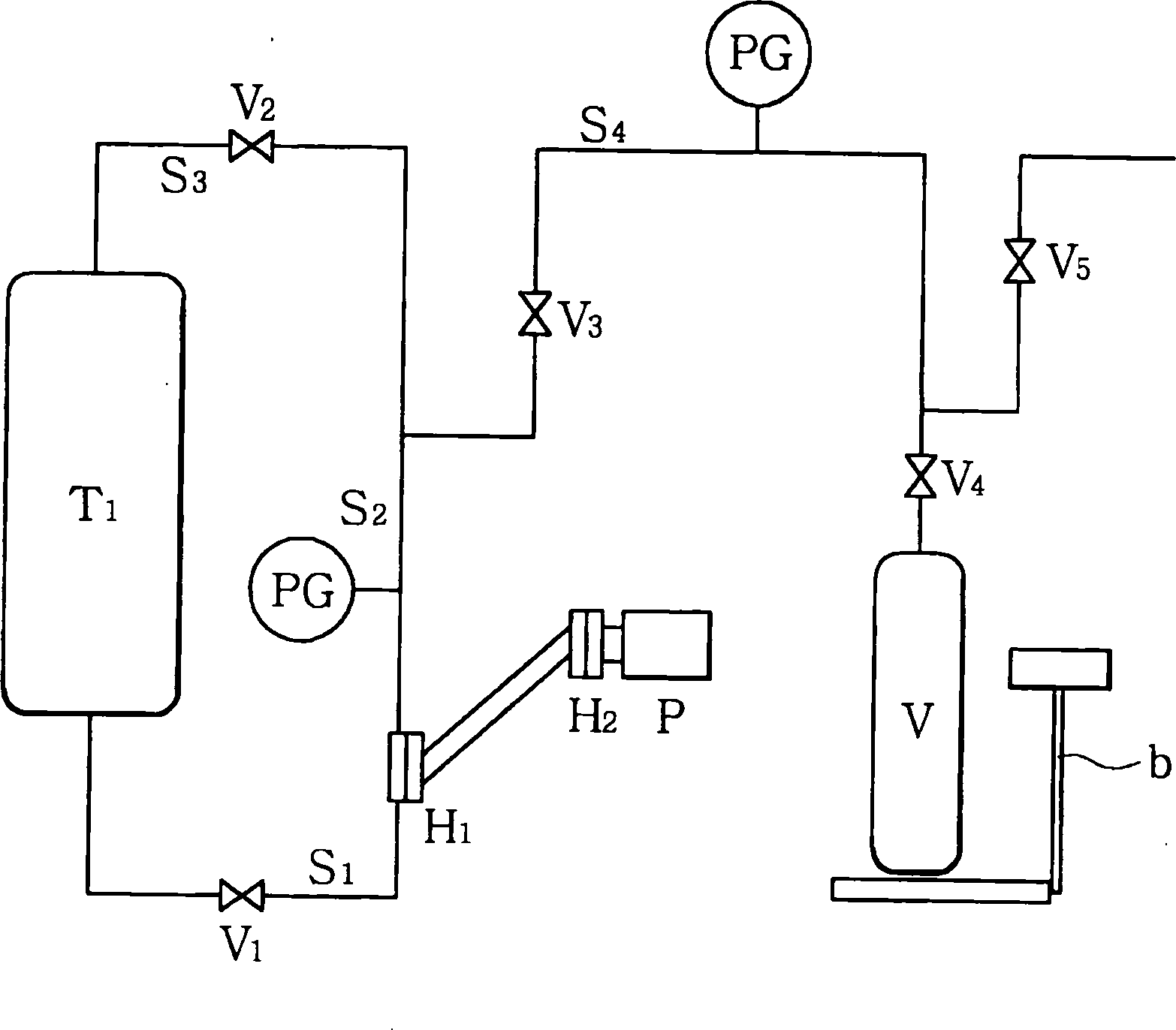

[0034] according to figure 1 The filling method of the present invention will be specifically described. The liquefied gas used in the filling test is a liquid high-purity NF condensed at low temperature 3 gas. Tank T 1 Using piping and NF 3 Manufacturing process connection, for thermal insulation, storage tank T 1 The exterior is made of a double vacuum jacket. NF stored in tanks 3 Gas, through suction piping S 1 Delivery to diaphragm pump suction port, suction piping S 1 It is also made into double-layer tubular vacuum insulated piping, and the pressure head H at the remote end of the pump is 2 A coil was installed to maintain the temperature of the remote head at -90°C by passage of a cryogenic fluid (liquid nitrogen, liquid air, etc.). The pump pressure head and the oil storage tank are filled with oil by a diaphragm pump, and the pump pressure head H 1 with remote indenter H2 Fill with dehydrated and degassed ethanol in between. Install a pressure gauge on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com