Urea filling system for vehicle

A filling system and vehicle urea technology, which is applied in packaging, bottle filling, liquid bottling, etc., can solve the problems of unsuitable filling speed and affecting filling efficiency, so as to avoid excessive filling speed and improve filling efficiency. The effect of improving filling efficiency and improving filling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

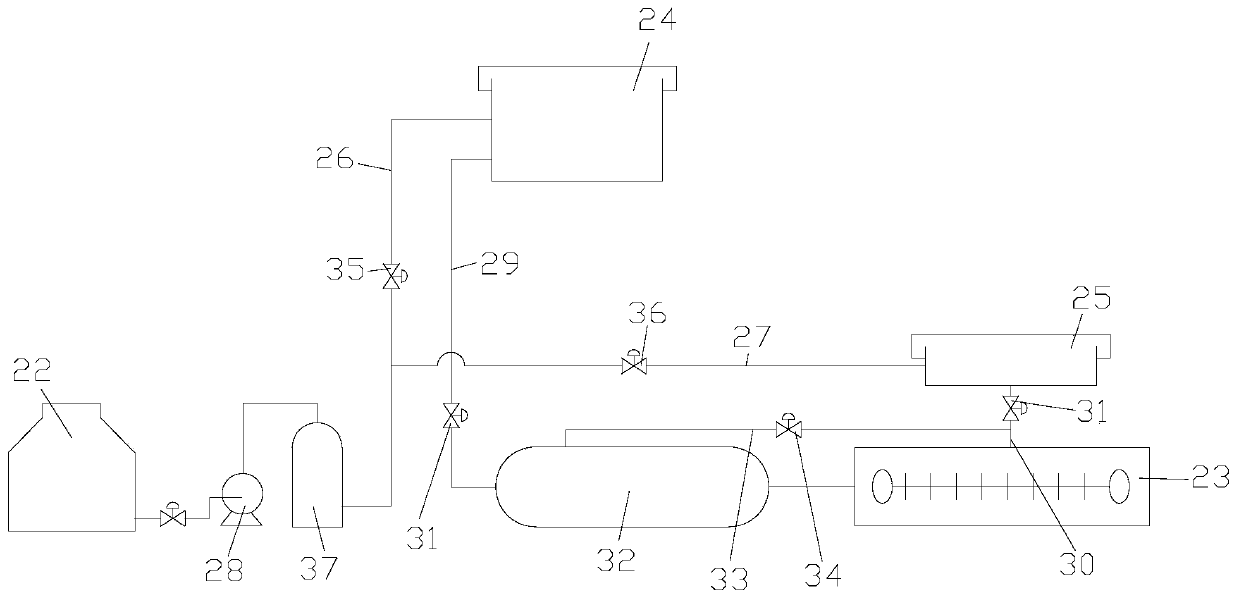

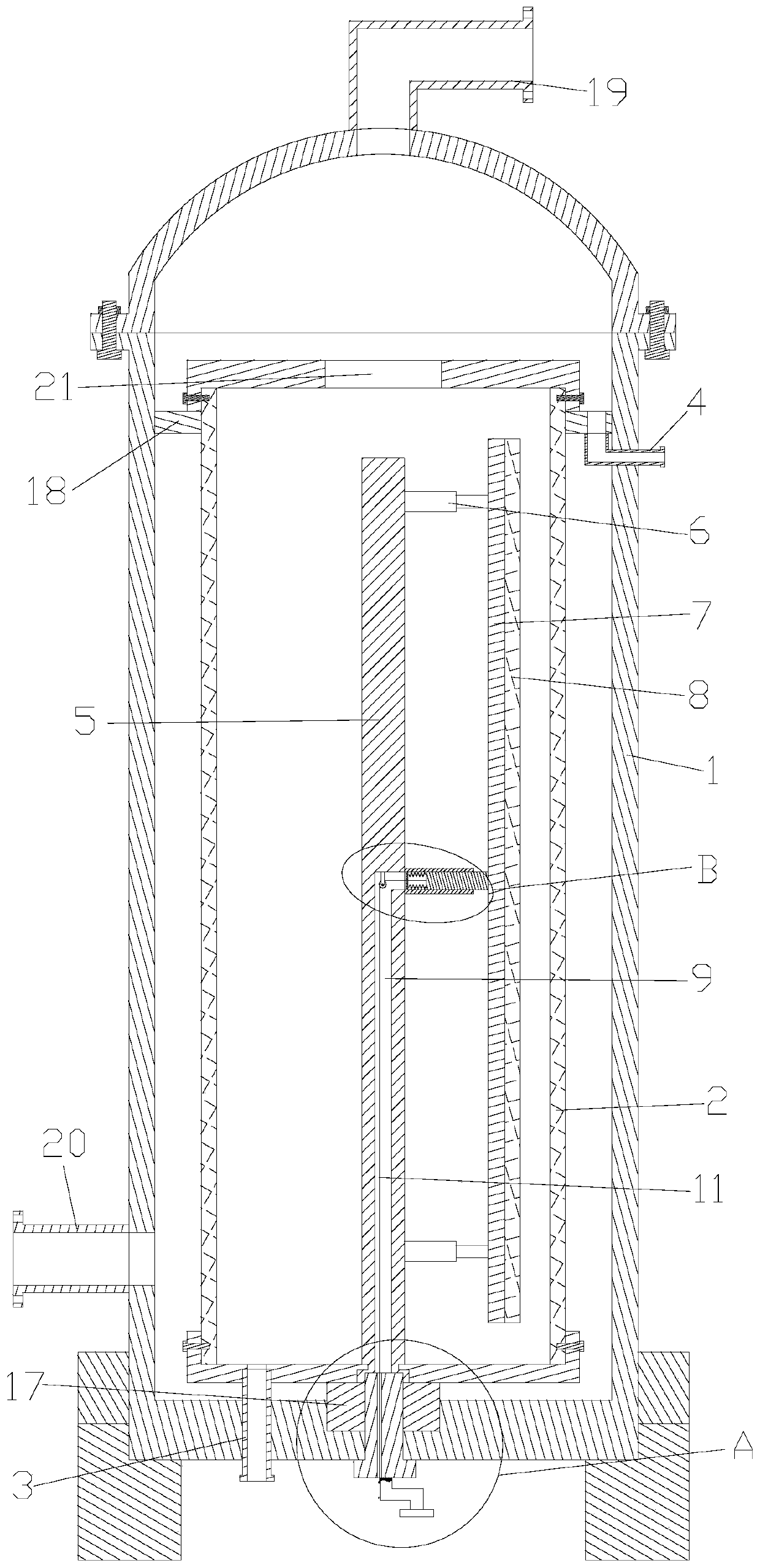

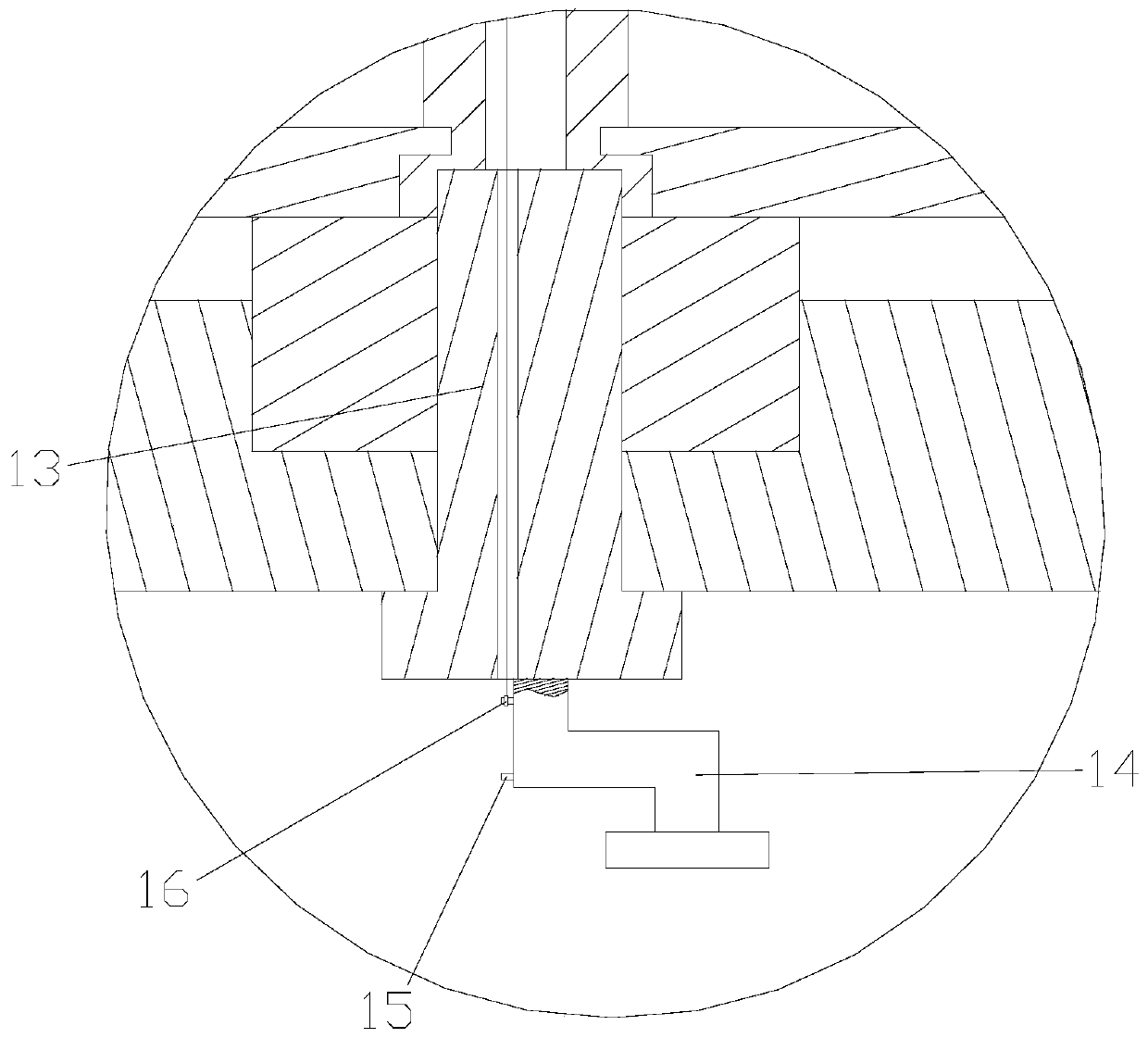

[0016] refer to Figure 1 ~ Figure 4 Shown: a kind of urea filling system for vehicles, raw material storage tank 22 and multi-head filling machine 23, high-position tank 24 and low-position tank 25 arranged from top to bottom, multi-head filling machine 23 can be 8-16 in the present embodiment Head filling machine, generally adopts 12 filling machines, the low slot 25 is positioned at about one meter above the multi-head filling machine 23, and the high slot 24 is positioned at about five meters above the multi-head filling machine 23; the raw material storage tank 22 and the high slot 24 is provided with the communication through the first pipeline 26, and the middle part of the first pipeline 26 communicates with the lower tank 25 through the second pipeline 27. The pump 28, the upper tank 24 communicate with the liquid inlet of the multi-head filling machine 23 through the third pipeline 29, the lower tank 25 communicates with the liquid inlet of the multi-head filling mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com