Patents

Literature

245results about How to "Shorten filling time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

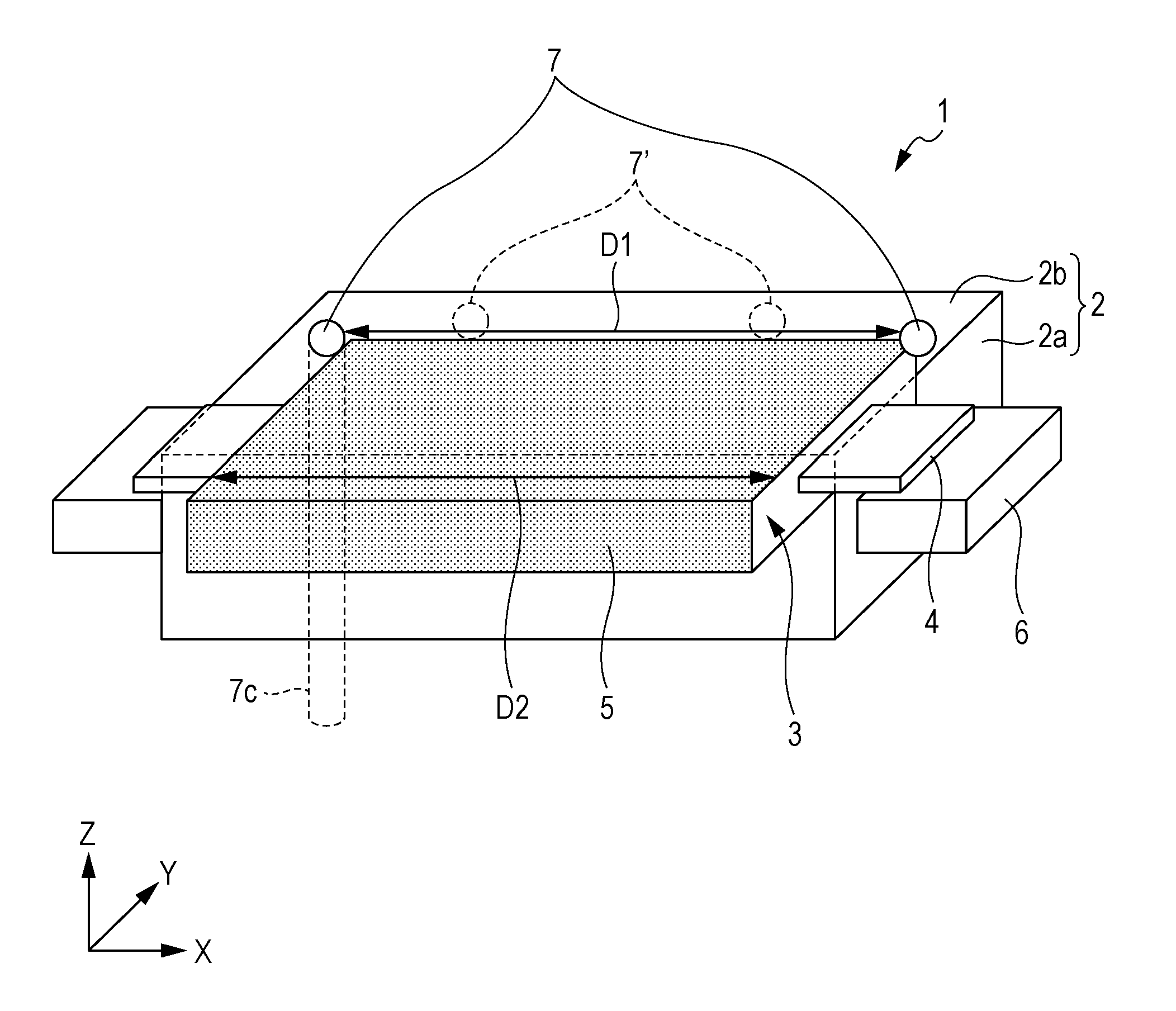

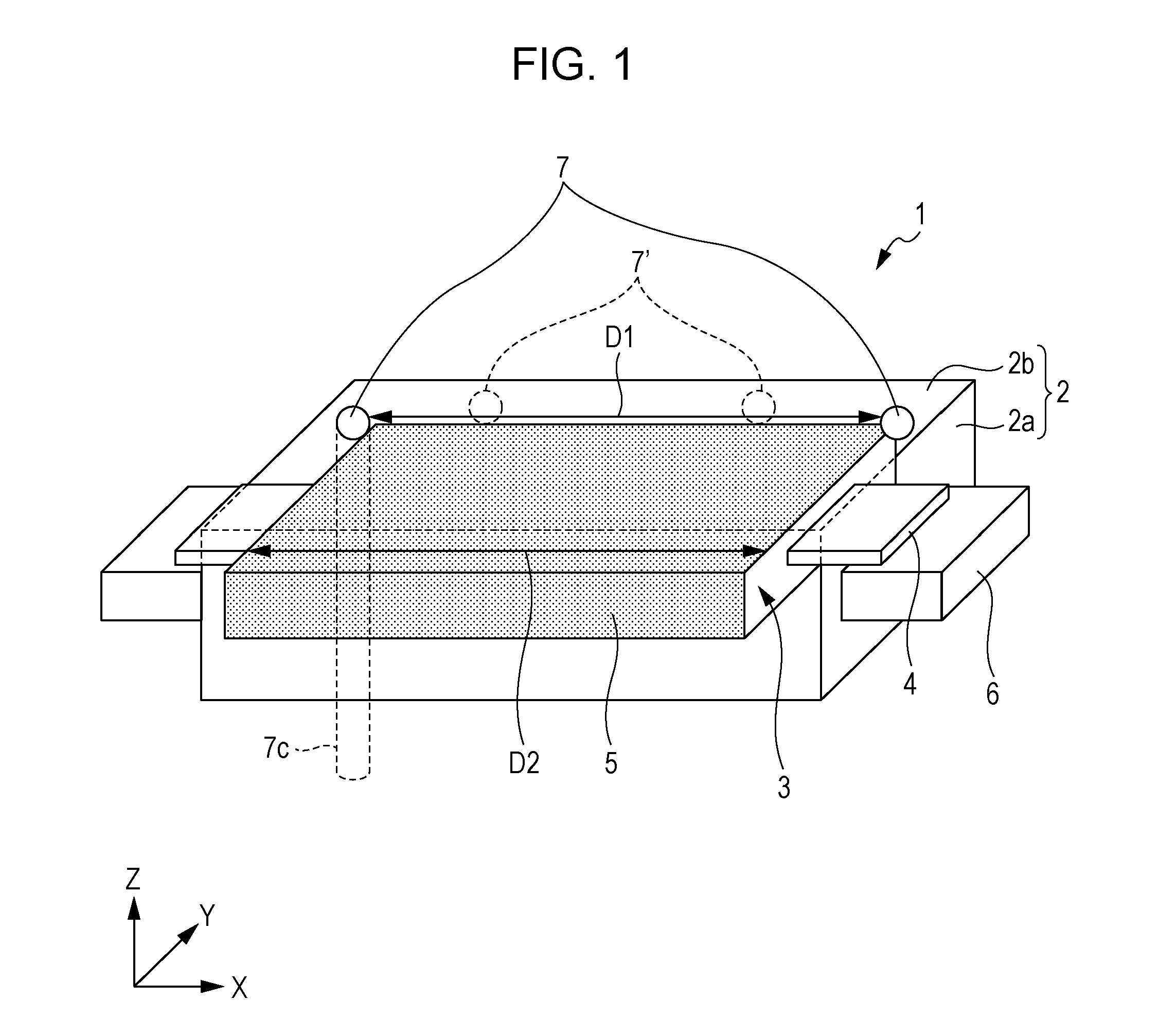

Electrodeposition display panel manufacturing method, electrodeposition display panel and electrodeposition display device

InactiveUS20060152474A1Short timeHigh viscosityStatic indicating devicesNon-linear opticsDisplay deviceAir bubble

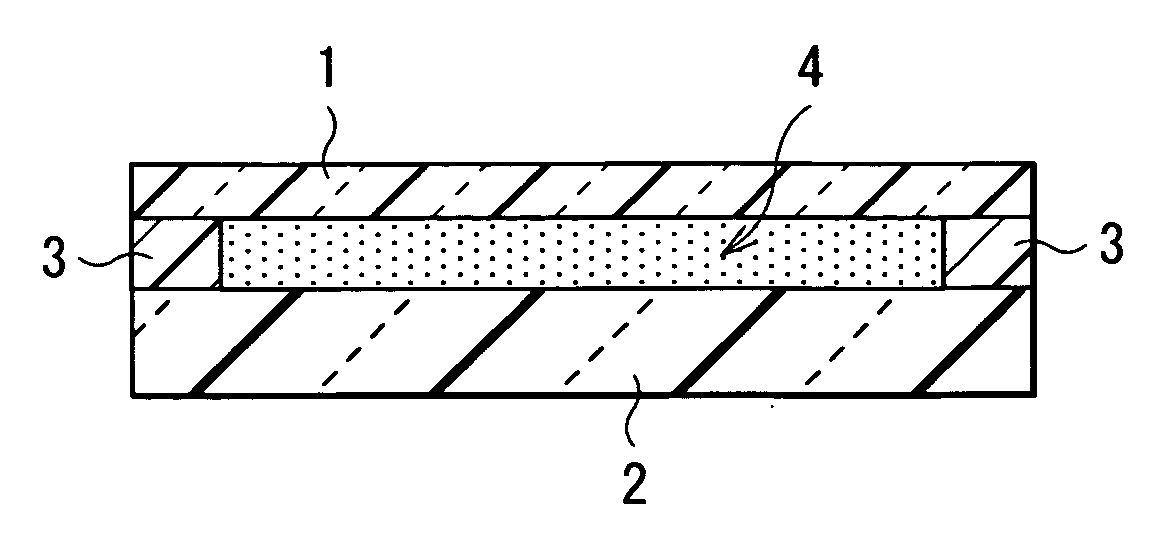

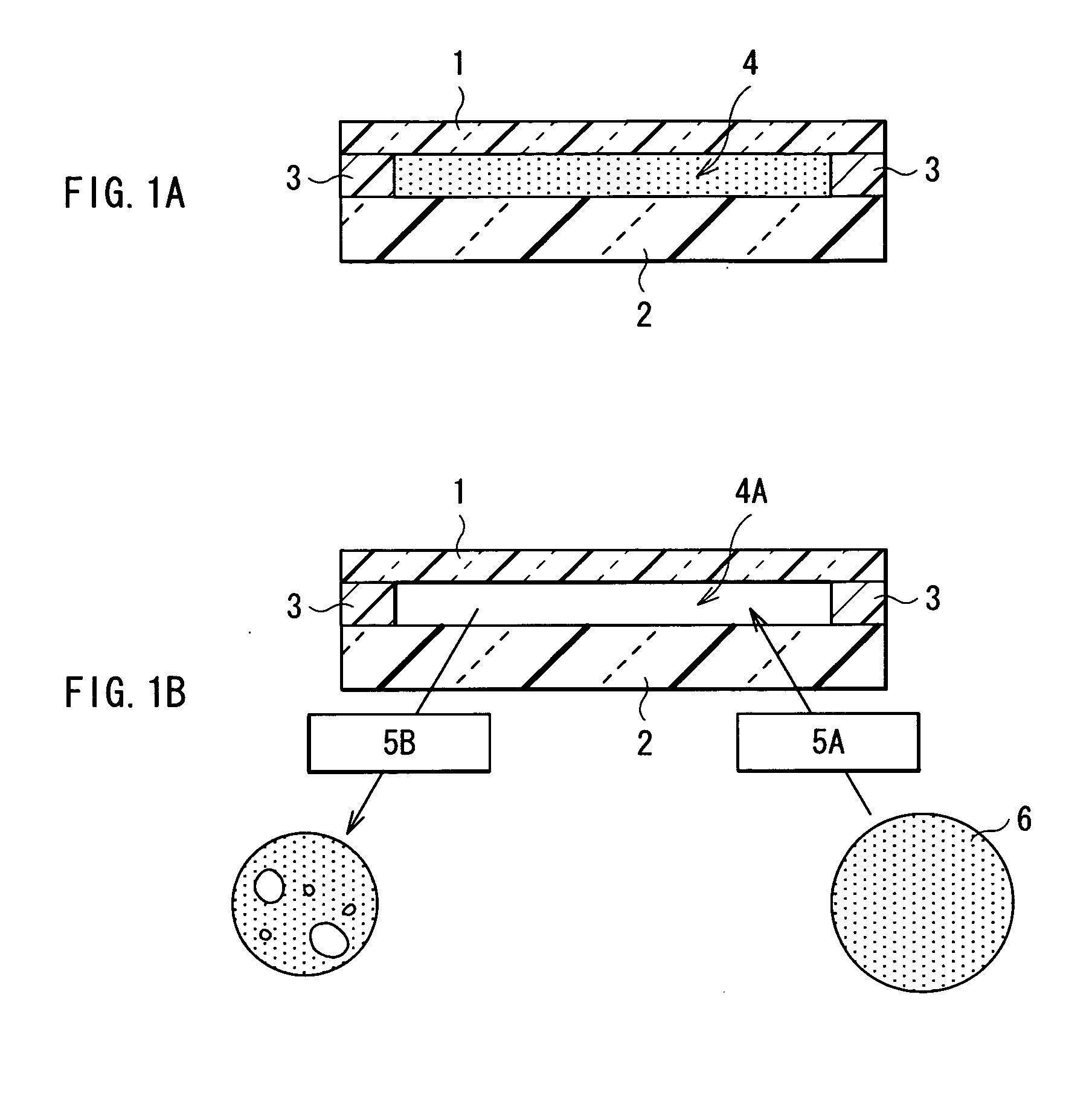

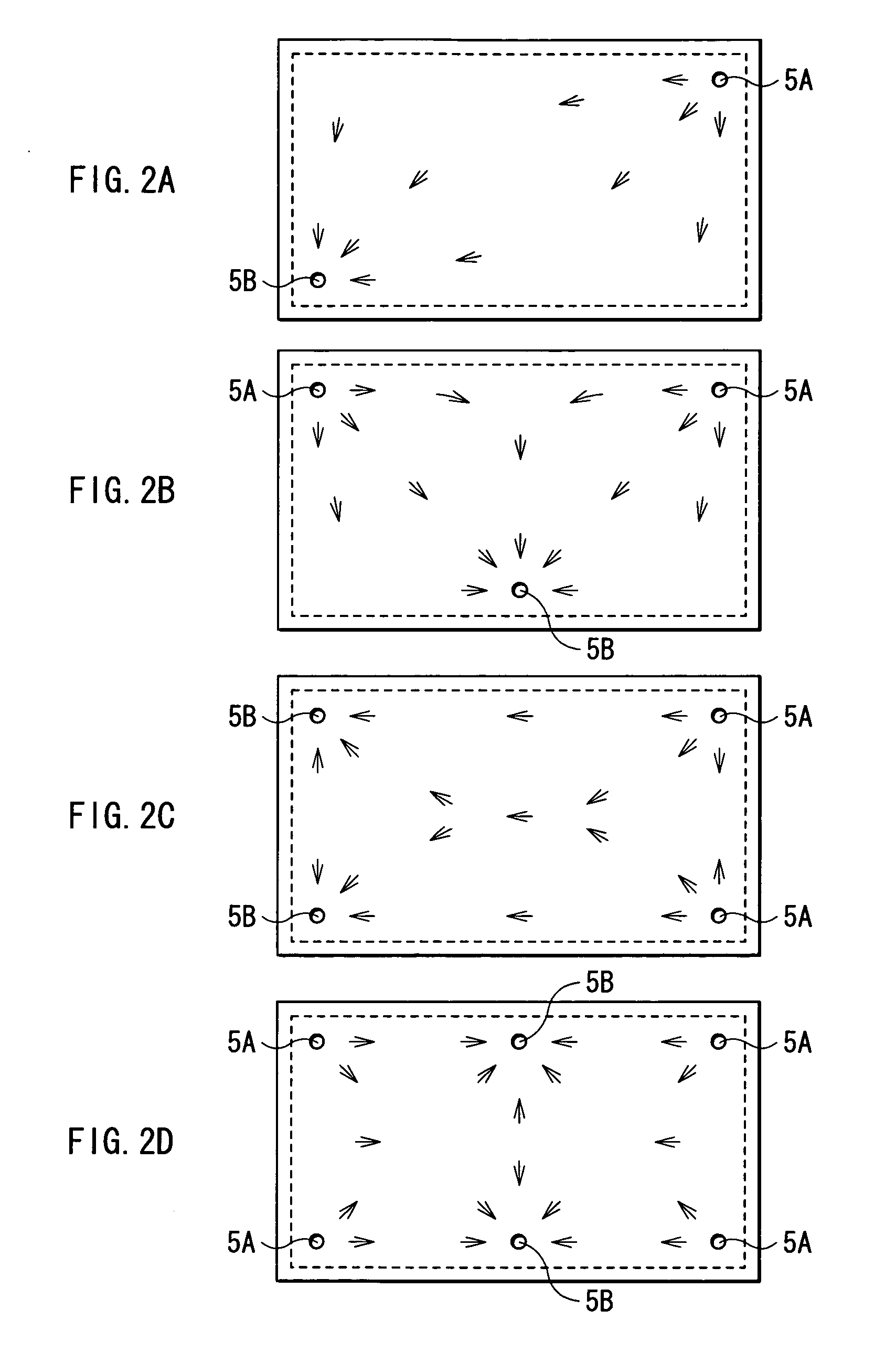

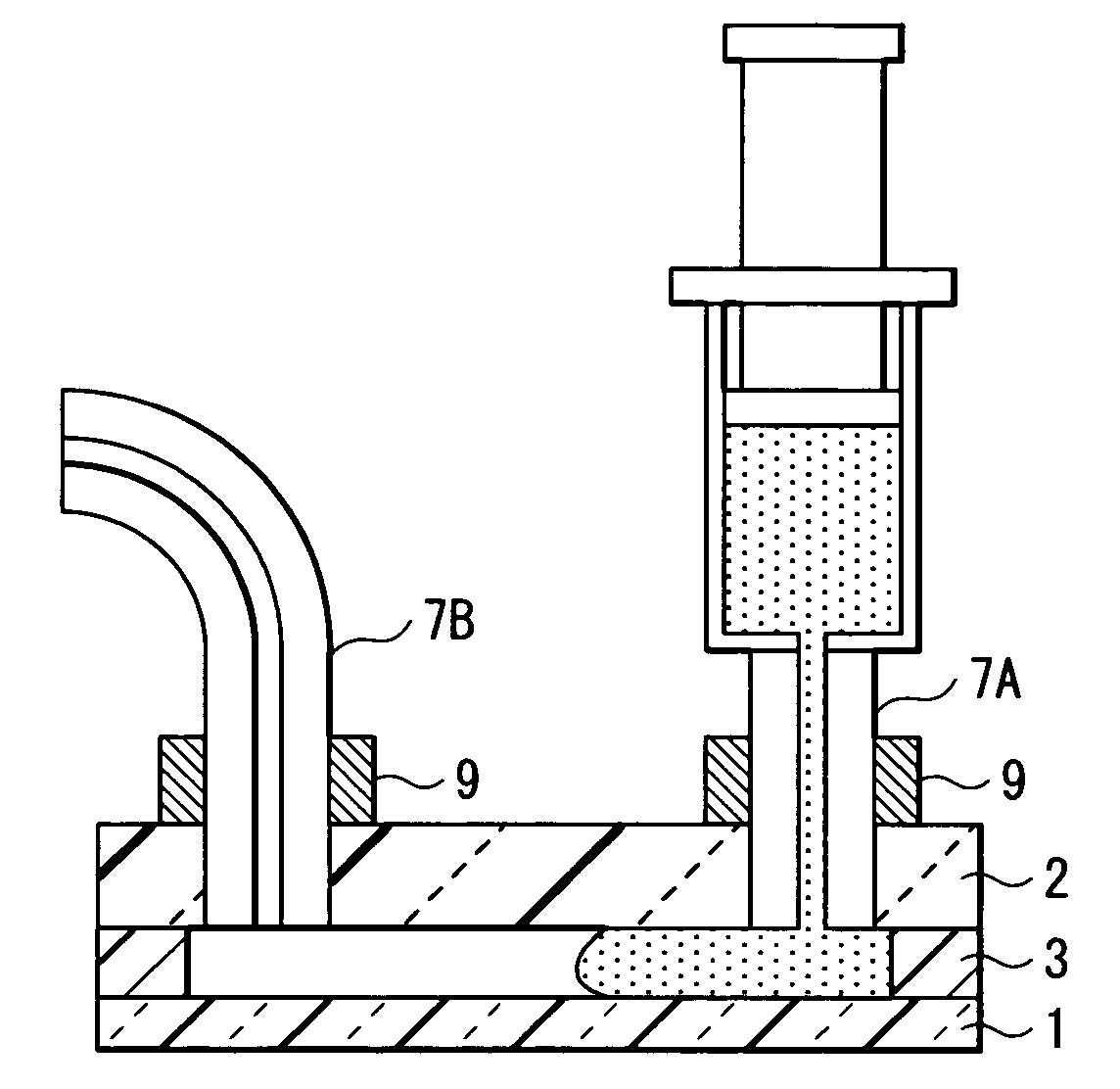

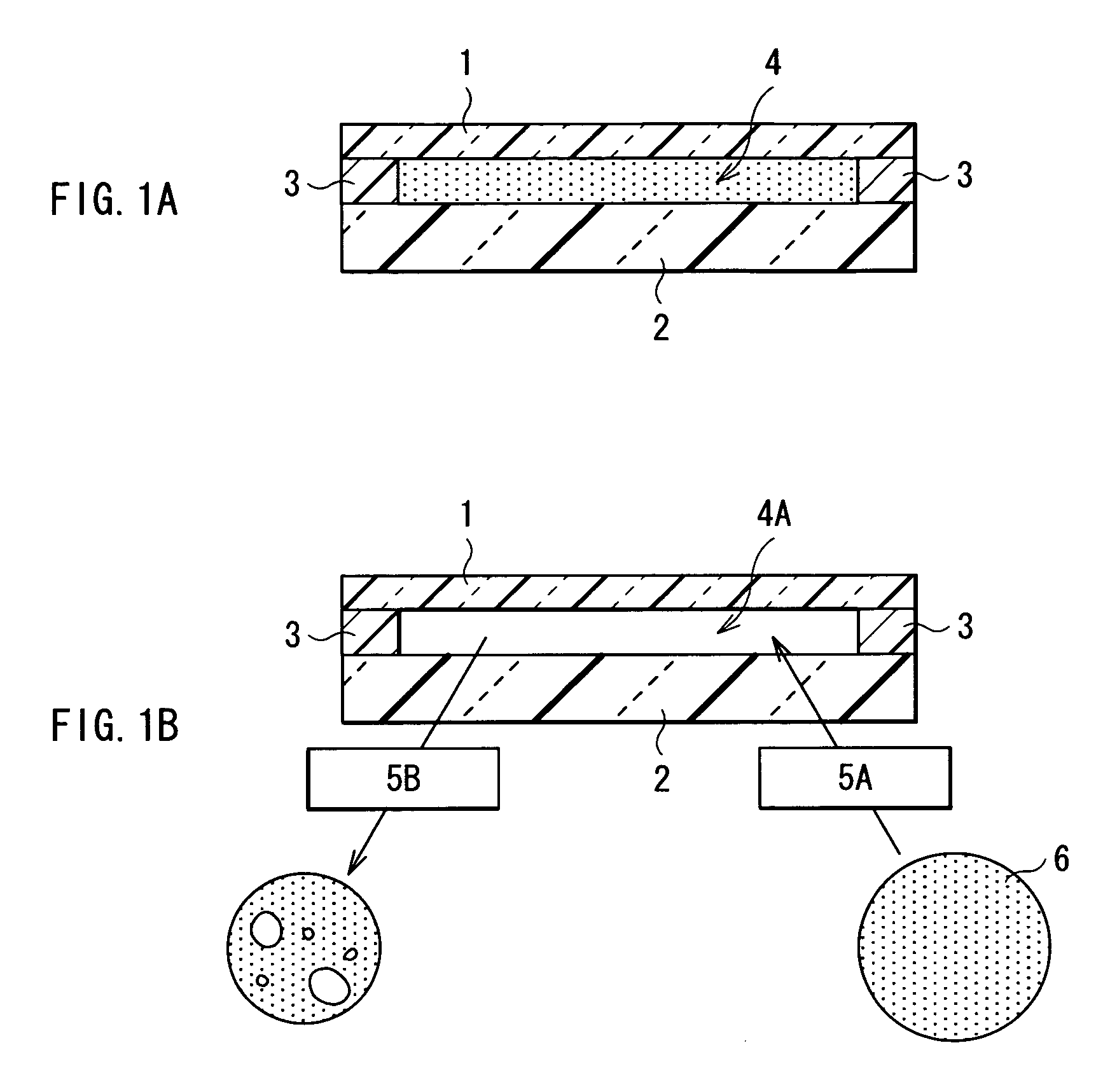

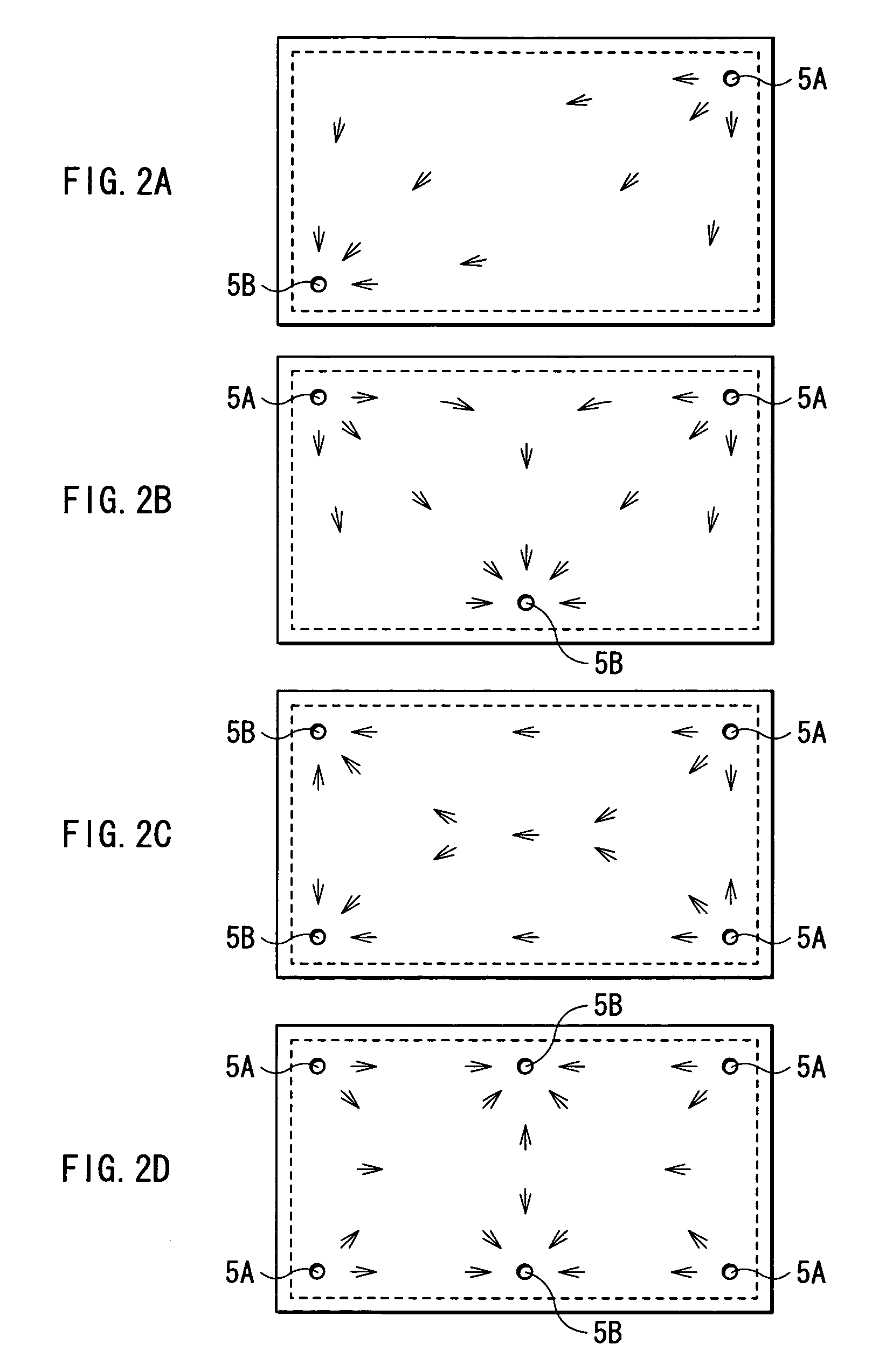

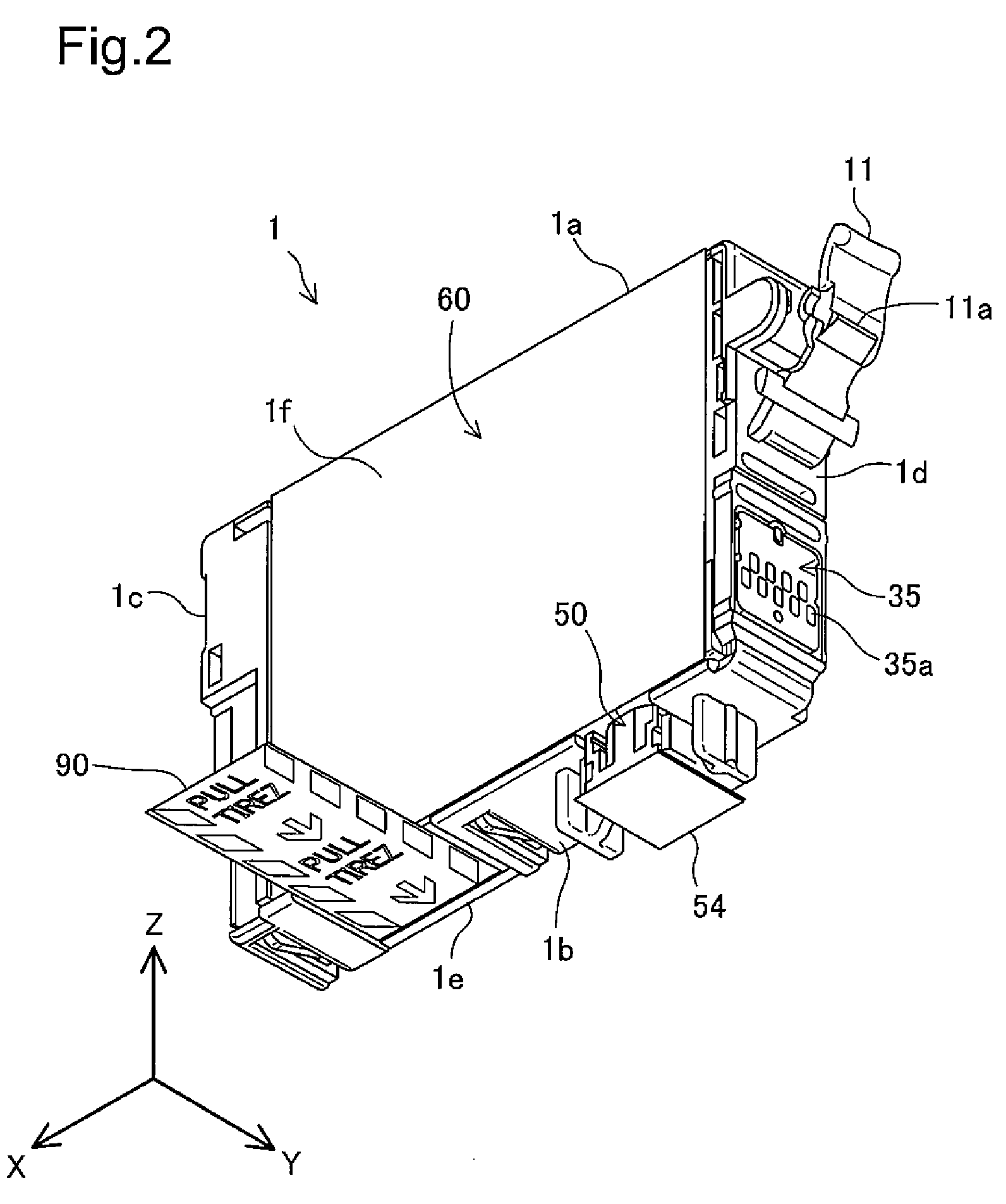

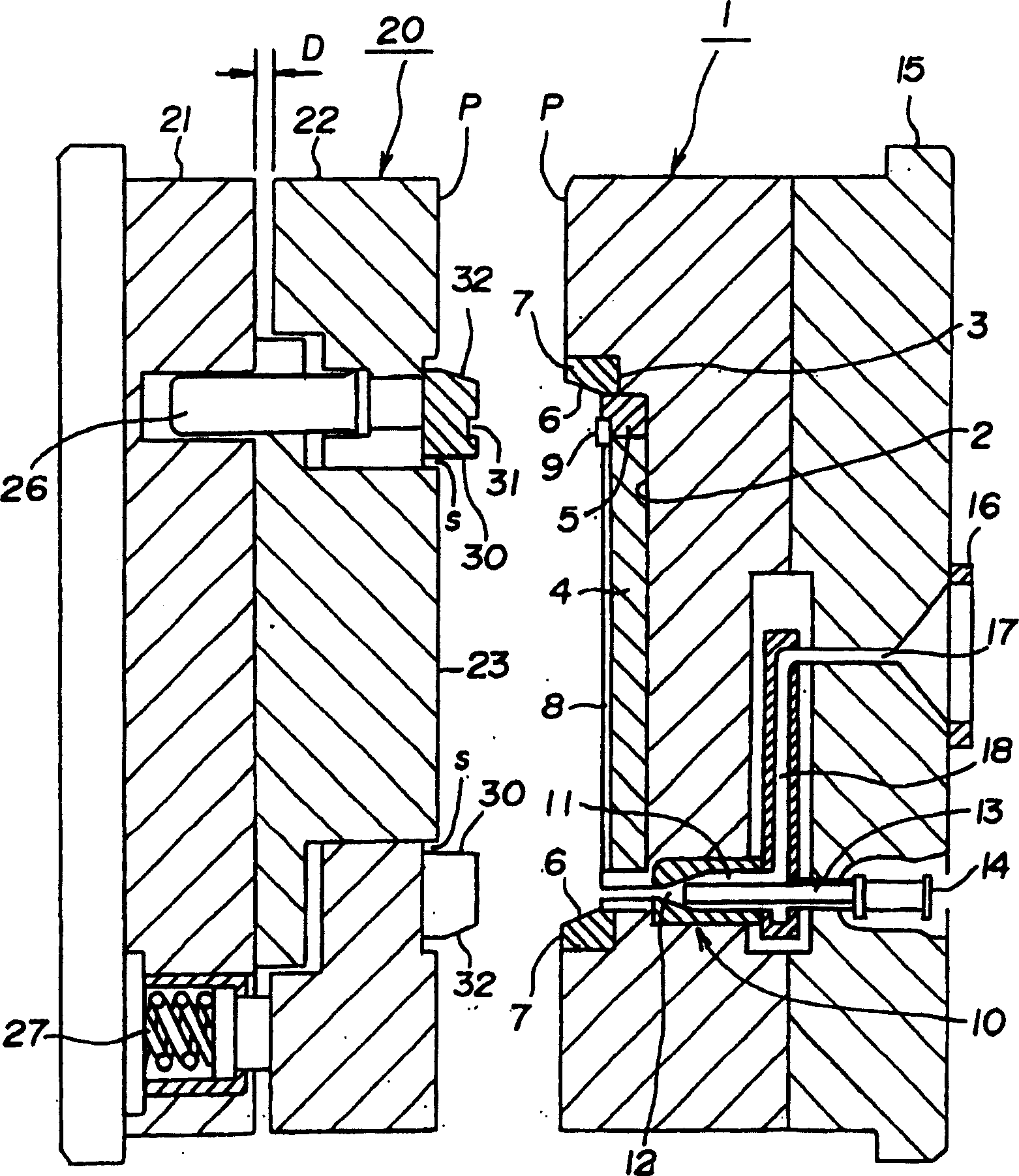

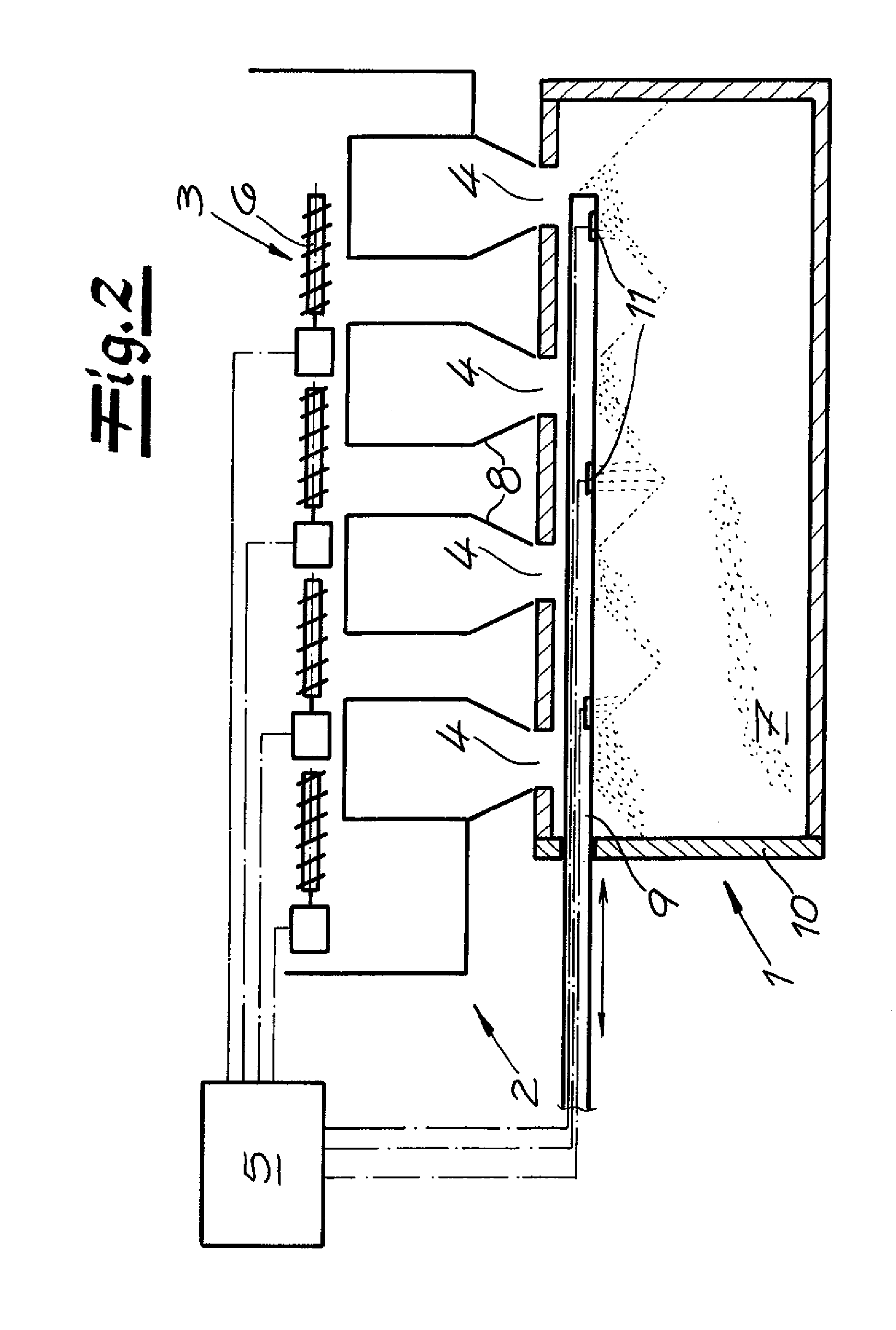

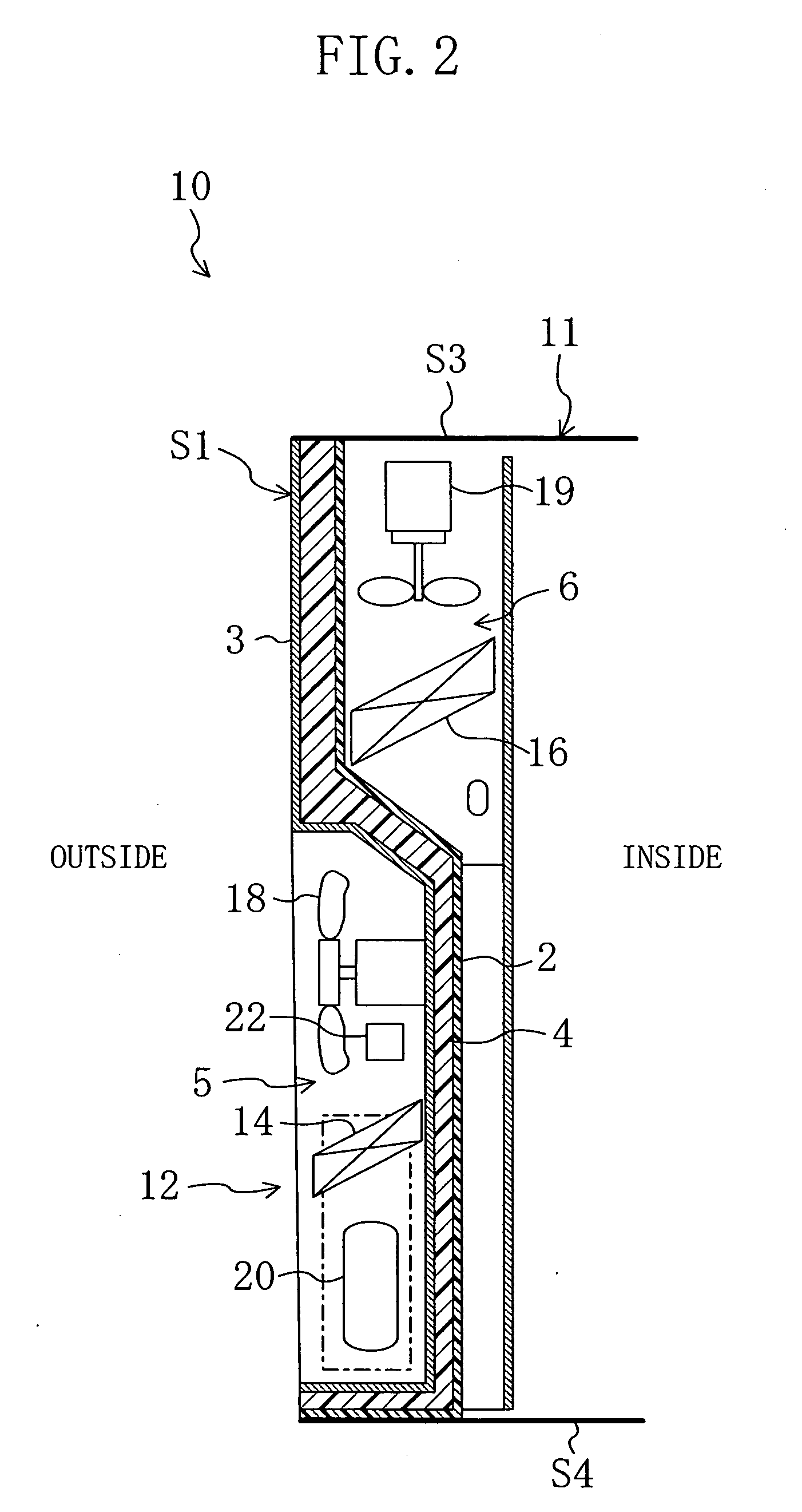

An electrodeposition display panel manufacturing method capable of manufacturing a highly reliable display panel in a short time and effectively, an electrodeposition display panel, and an electrodeposition display device are provided. Openings (5A), (5B) are provided in a rear substrate (2) of the cell. A nozzle (7A) to which an injector (8) is connected on the other side is inserted into the opening (5A), and a nozzle (7B) is inserted into the opening (5B). On the other end side of the nozzle (7B), a container for recovering a spilled display material (6) and a decompressor are arranged. While the display material (6) is pressure-injected from the opening (5A), evacuation and discharging air bubbles and the like are performed from the opening (5B). Thereby, the display material (6) is filled in the cell.

Owner:SONY CORP

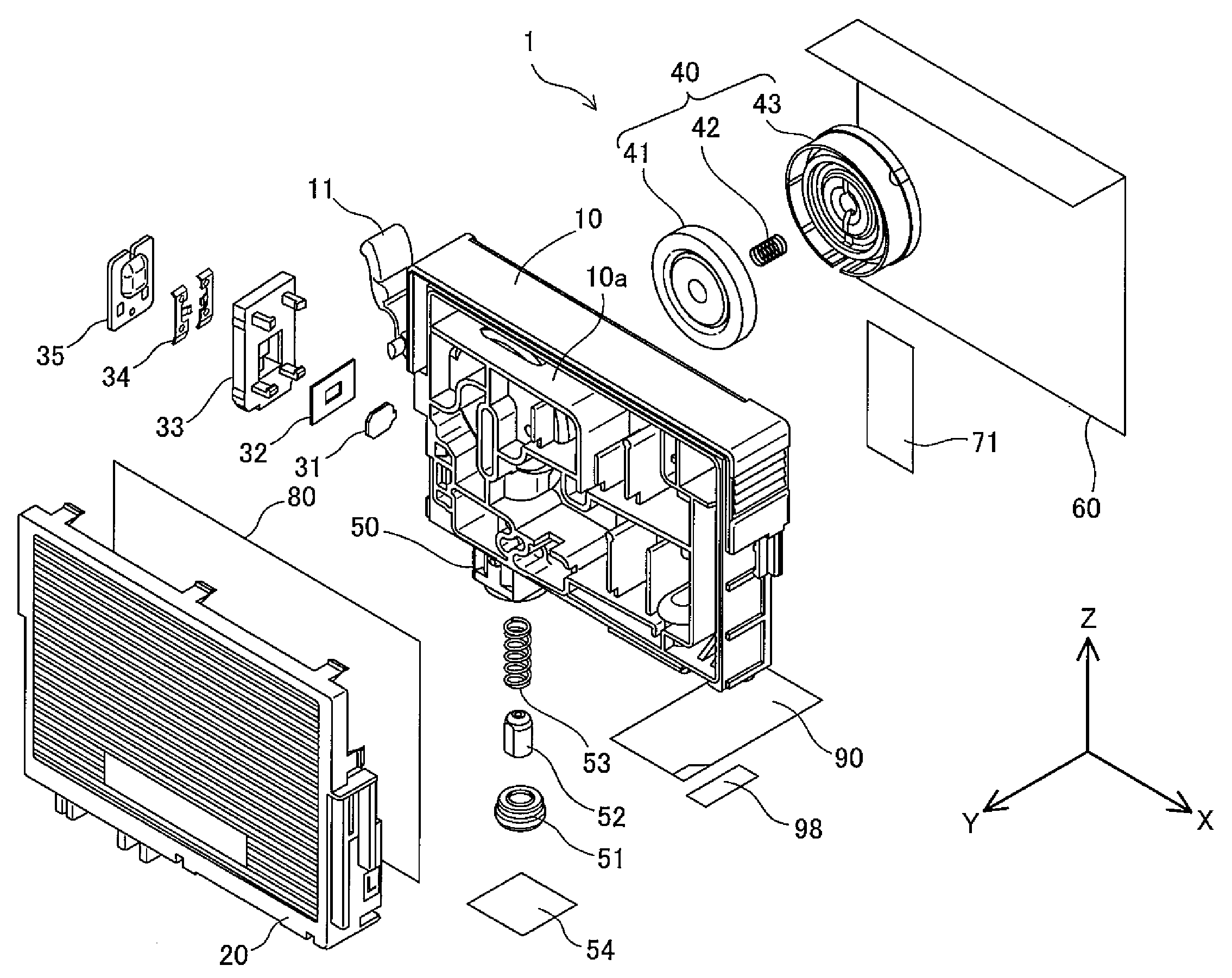

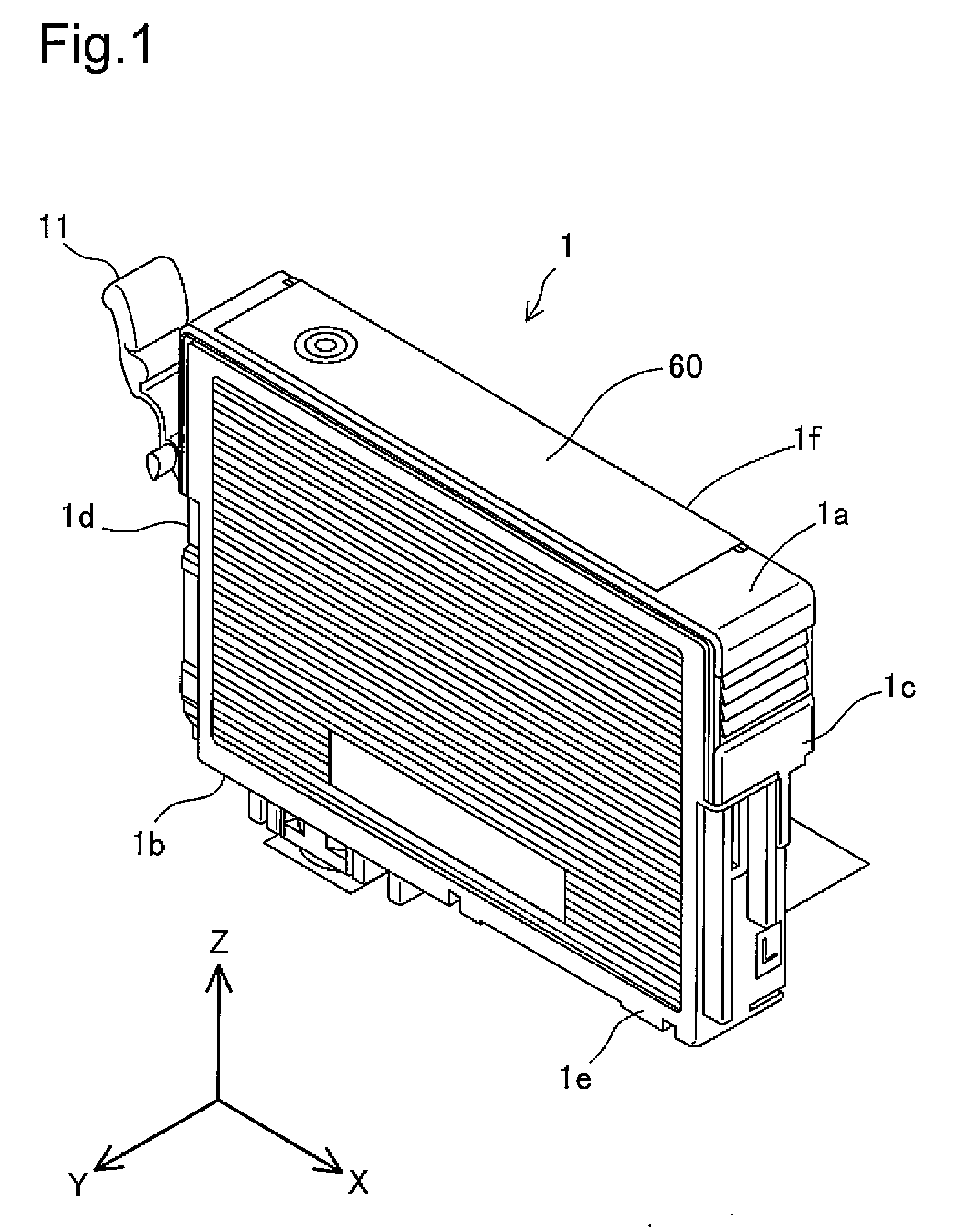

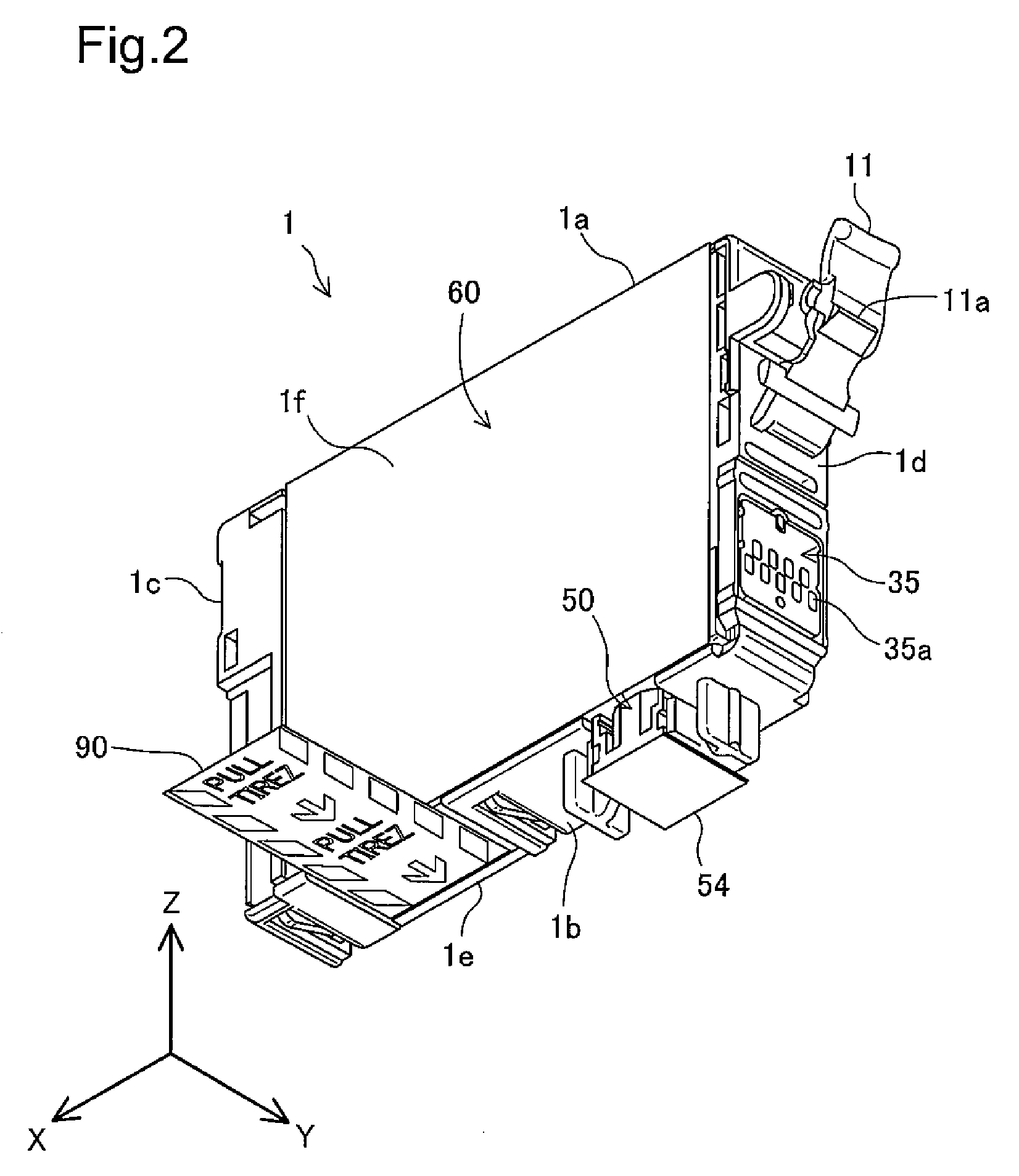

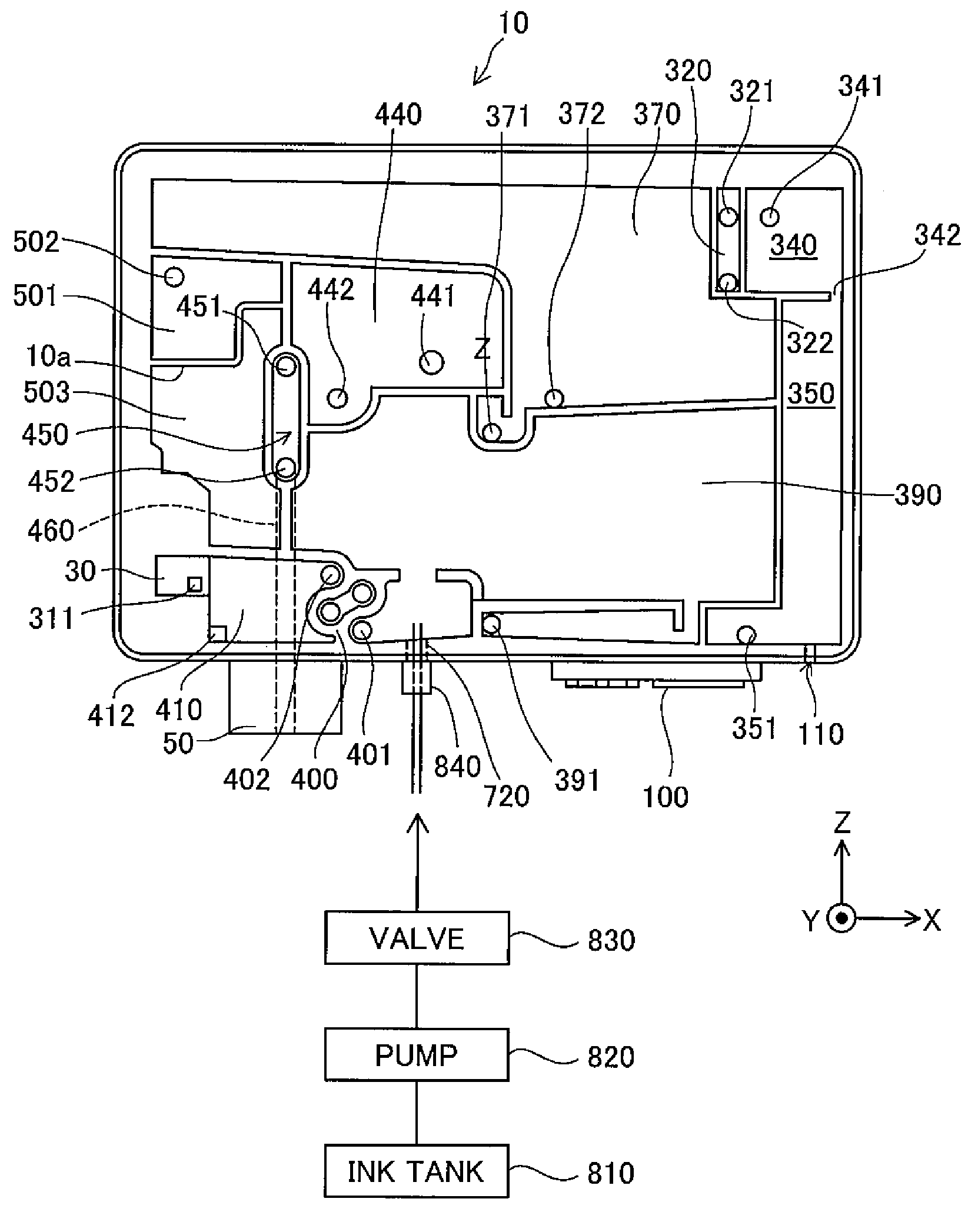

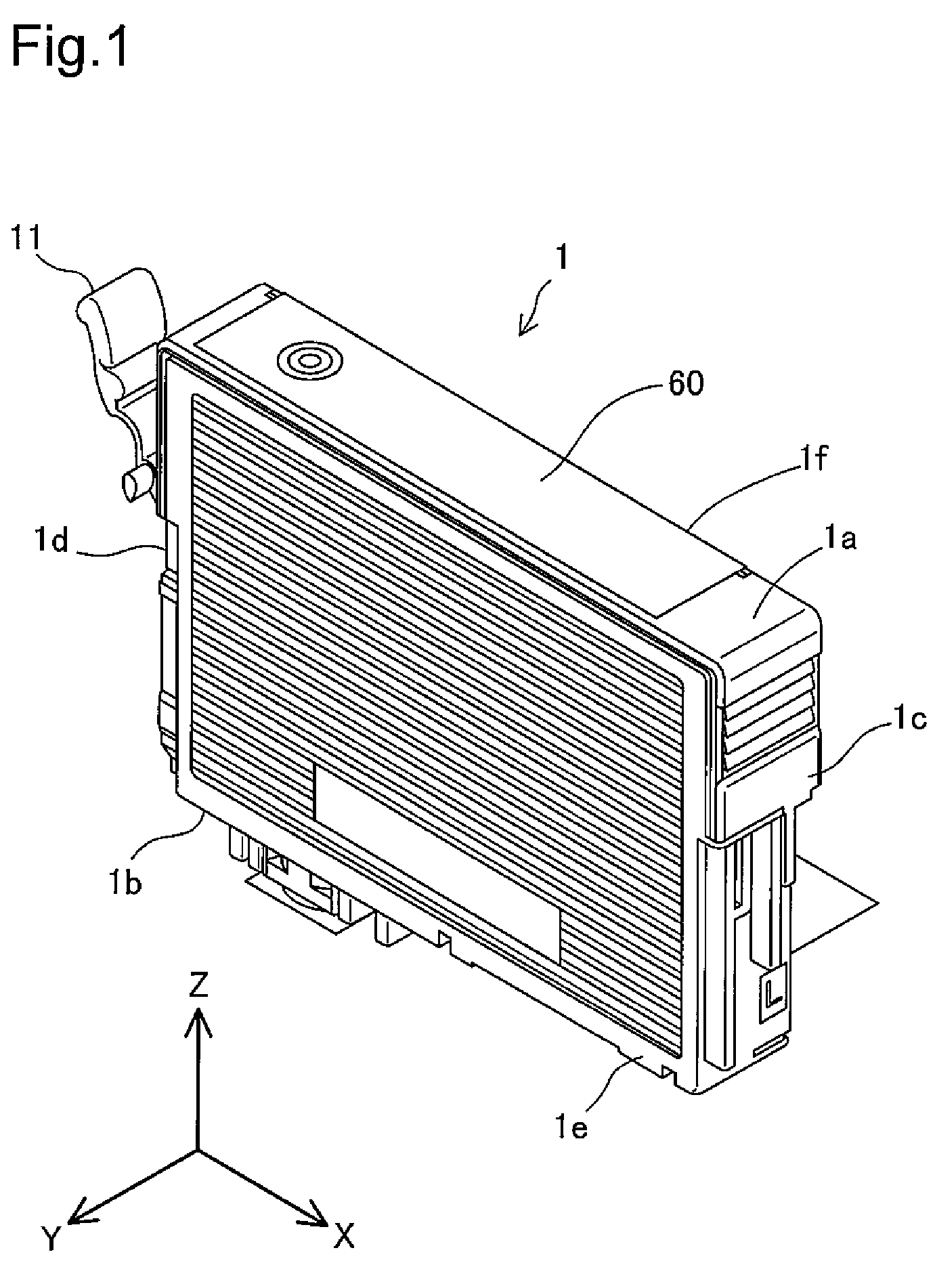

Liquid container and remanufacturing method of liquid container

ActiveUS20090322838A1Increase resistanceIncrease capacityWriting implementsMetal-working apparatusOpen structure

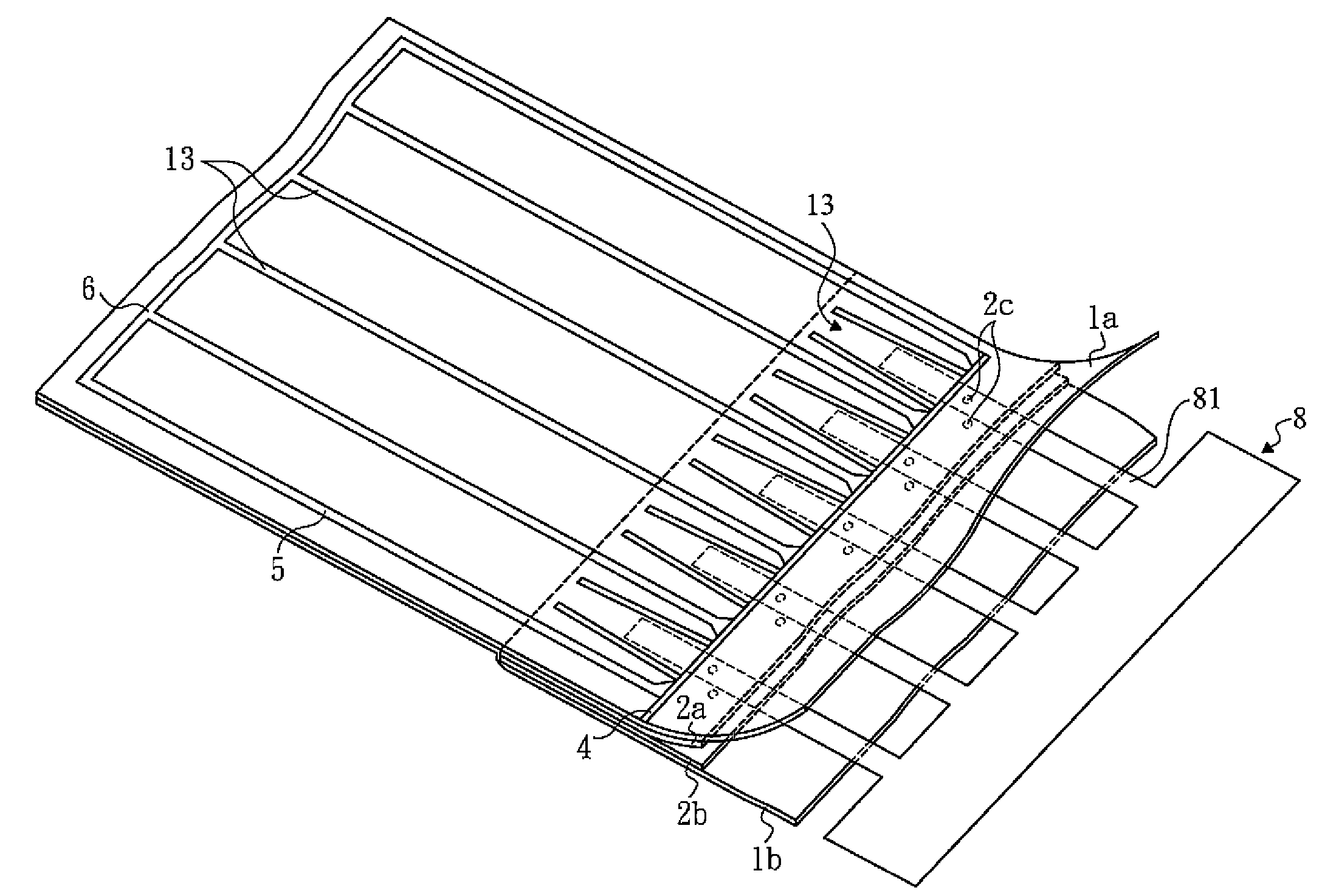

According to one aspect of the invention, a remanufacturing method of a liquid container forms an inlet in a downstream wall surface of a second chamber, which defines part of a bottom face of the liquid container. In the state of closing a liquid feeder and opening an air open structure, the remanufacturing method injects a liquid through the inlet to fill the second chamber with the liquid. In the state of opening the liquid feeder and closing the air open structure, the remanufacturing method injects the liquid through the inlet to fill a space from the second chamber to the liquid feeder with the liquid. The remanufacturing process seals the inlet after completion of the injection of the liquid. This arrangement enables the liquid to be efficiently refilled into the liquid container without damaging the functions of the liquid container.

Owner:SEIKO EPSON CORP

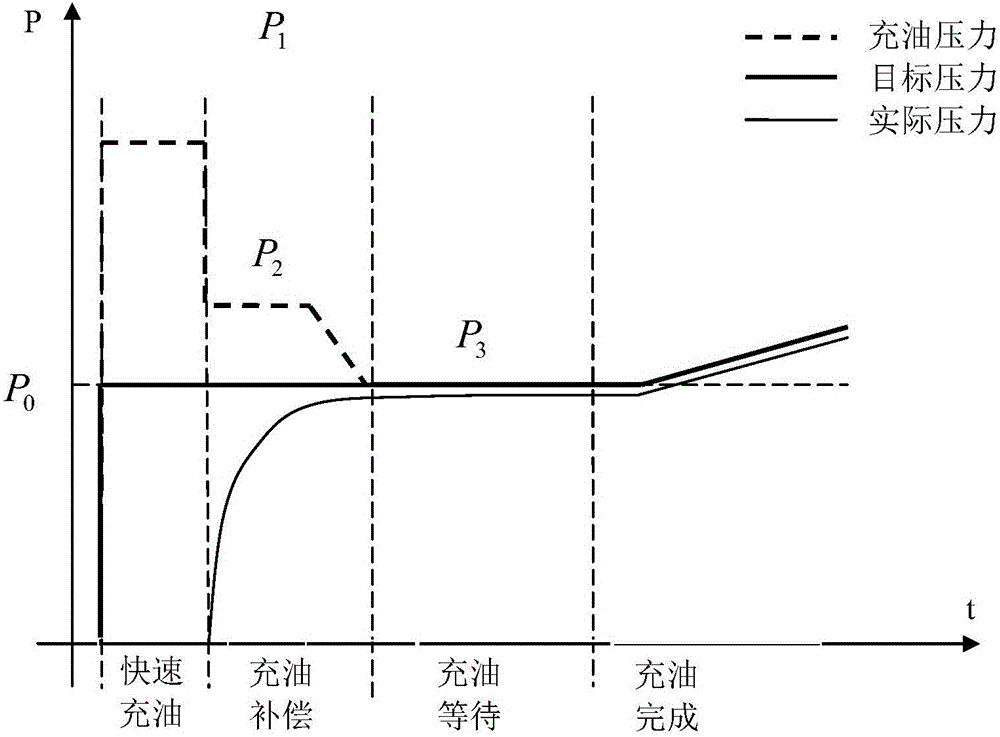

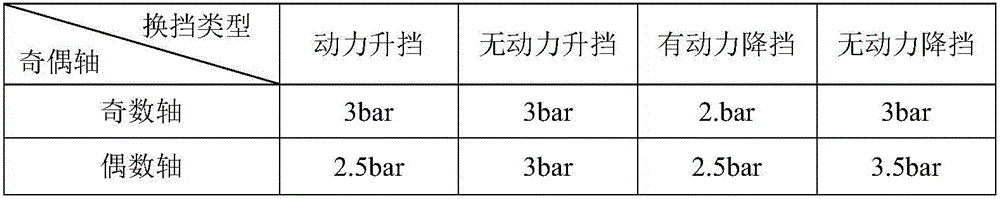

Oil charging accurate control method for wet clutch

ActiveCN105805186AQuick responseShorten filling timeClutchesGearing controlSystem pressureOil temperature

The invention relates to an oil charging accurate control method for a clutch in the gear shifting process of a wet double-clutch automatic transmission. The oil charging process of the clutch is divided into four stages. In the first stage, oil is rapidly charged into the clutch, the oil charging pressure satisfies the equation that P1=P0+delta P1, P0 is the target pressure, and the most appropriate delta P1 value under each oil temperature and gear shifting type is found out through an experiment mode by considering the influences of the oil temperature of a gear box and the gear shifting type. In the second stage, oil charging compensation is carried out on the clutch subjected to rapid oil charging, the oil charging pressure satisfies the equation that P2=P0+delta P2, and the most appropriate delta P2 value under each gear shifting type and system pressure is found out through an experiment mode by considering the influences of the gear shifting type and system pressure. In the third stage, oil charging waiting is carried out on the clutch, the oil charging pressure satisfies the equation that P3=P0, and the third stage is ended when the pressure of the clutch reaches 95% of the target pressure. In the fourth stage, oil charging is finished. By controlling the pressure of each stage, rapid and accurate response of the pressure of the oil charging process of the clutch can be realized, and impact caused by pressure overshoot of the clutch is avoided.

Owner:CHINA FIRST AUTOMOBILE

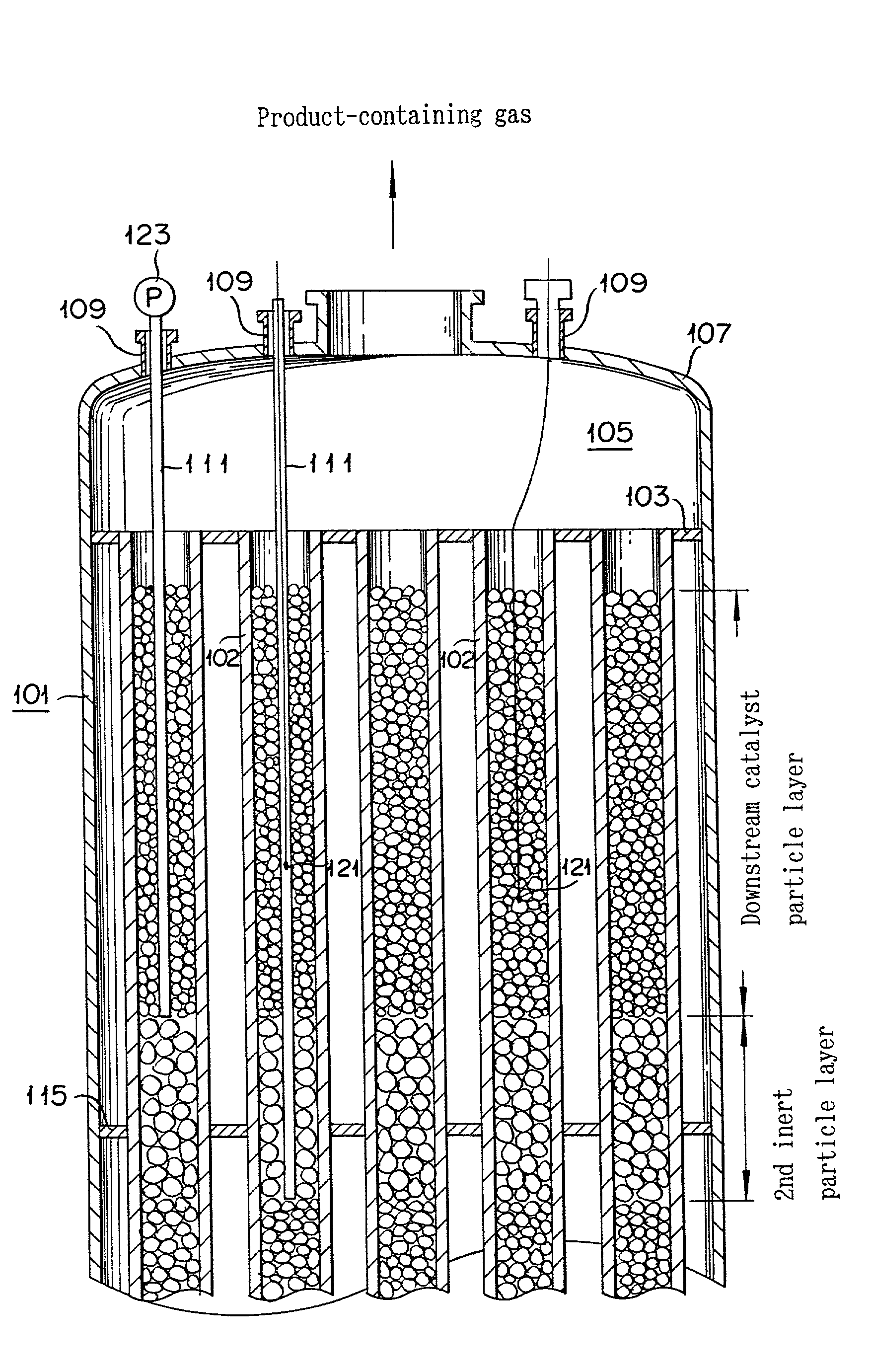

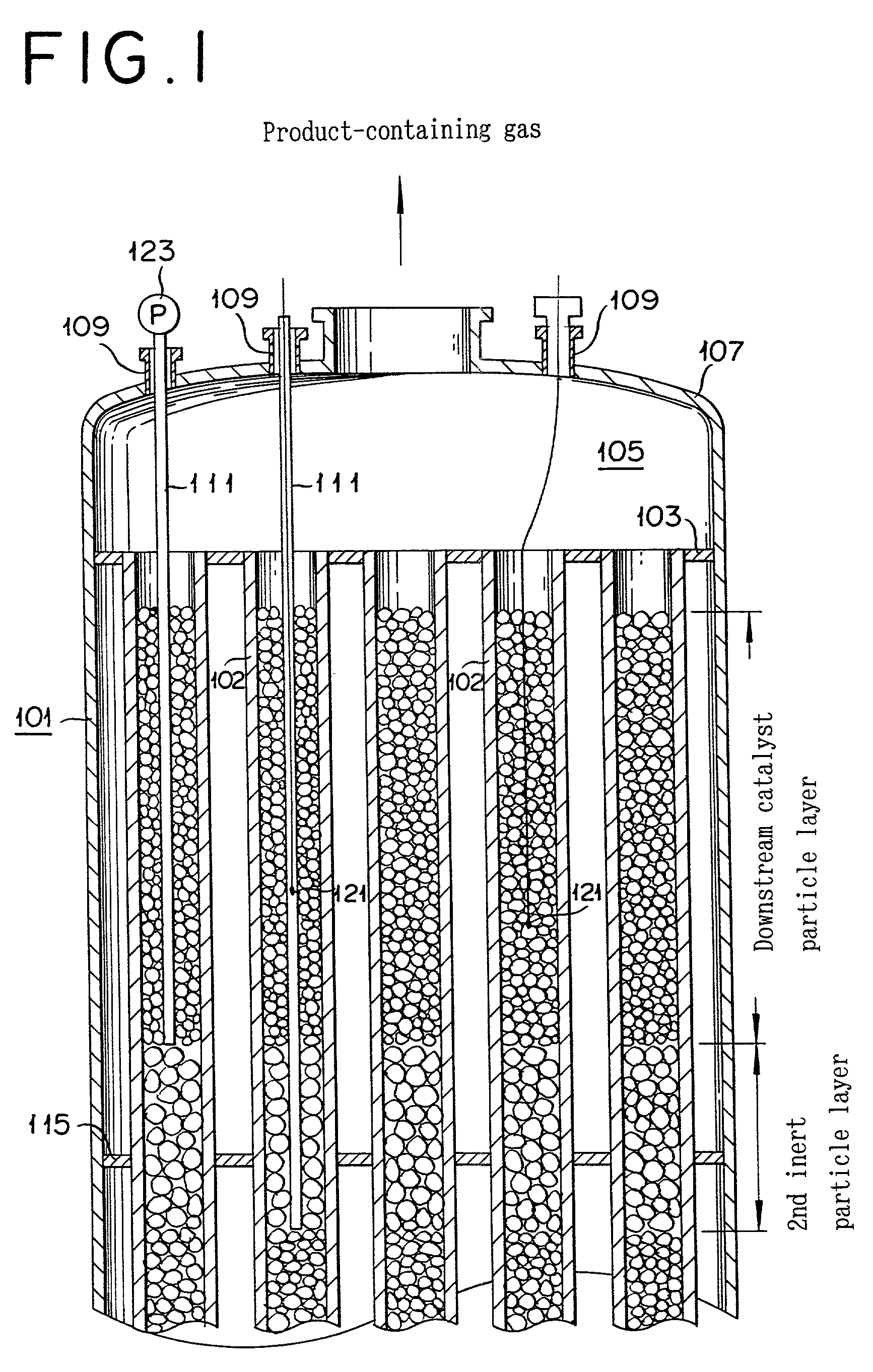

Reactor filled with solid particle and gas-phase catalytic oxidation with the reactor

InactiveUS20030006026A1Accurate pressureAccurate temperatureOrganic compound preparationOrganic chemistry methodsGas phaseCatalytic oxidation

A shell-and tube reactor including at least one reaction tube with a measuring means, substantially same solid particles being filled in the reaction tubes with or without the measuring means, a length of the filled solid particle layer, and a pressure drop thereof while passing a gas through the reaction tube, per each reaction tube, being substantially the same, respectively. By measuring the temperature of the catalyst particle layer, such a temperature as a representative can be gasped.

Owner:NIPPON SHOKUBAI CO LTD

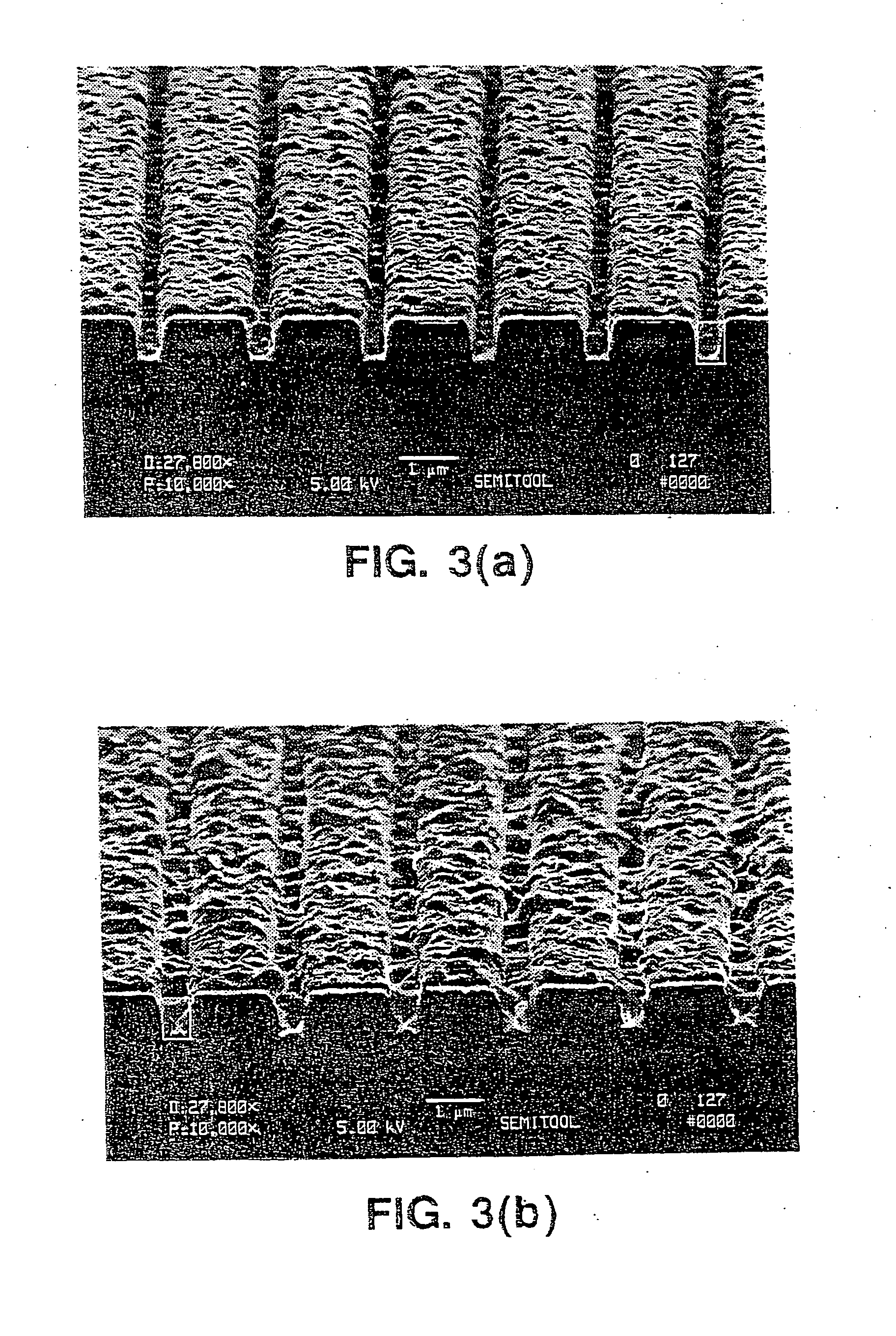

Micro-pore electroplated copper filling method for three-dimensional (3D) copper interconnection high aspect ratio through-silicon-via technology

InactiveCN103361694ALow costFast hole fillingCellsSemiconductor/solid-state device manufacturingMethane sulfonateInterconnection

The invention discloses a micro-pore electroplated copper filling method for a three-dimensional (3D) copper interconnection high aspect ratio through-silicon-via technology. The micro-pore electroplated copper filling method comprises the following steps of: 1, preparing an electroplating solution of a copper methane sulfonate system; 2, wetting micro pores of the through-silicon-via technology through electroplating pretreatment; 3, electrifying and slotting, and increasing the ultralow current diffusion step, so that the copper ion and additives are reasonably distributed on the surfaces and inside the micro pores through the through-silicon-via technology; 4, connecting a silicon wafer where the through-silicon-via technology is positioned with a cathode of a power supply, so that the electroplating surface of the wafer is completely soaked in the electroplating solution, step-by-step current electroplating is performed under the condition that the cathode is rotated or stirred, and the electroplating conditions comprise the current density of 0.01-10A / dm<2> and the temperature of 15-30 DEG C; and 5, completely and thoroughly washing the wafer by using deionized water, performing spin-dry or blow-dry. The provided micro-pore electroplated copper filling method for the 3D copper interconnection high aspect ratio through-silicon-via technology is high in pore filling speed and thin in surface copper, hole and crack risks are avoided, and complete filling of high-difficulty hole with the depth-to-width ratio of more than 10:1 can be realized.

Owner:SHANGHAI SINYANG SEMICON MATERIALS

Electrodeposition display panel manufacturing method, electrodeposition display panel, and electrodeposition display device

An electrodeposition display panel manufacturing method capable of manufacturing a highly reliable display panel in a short time and effectively, an electrodeposition display panel, and an electrodeposition display device are provided. Openings (5A), (5B) are provided in a rear substrate (2) of the cell. A nozzle (7A) to which an injector (8) is connected on the other side is inserted into the opening (5A), and a nozzle (7B) is inserted into the opening (5B). On the other end side of the nozzle (7B), a container for recovering a spilled display material (6) and a decompressor are arranged. While the display material (6) is pressure-injected from the opening (5A), evacuation and discharging air bubbles and the like are performed from the opening (5B). Thereby, the display material (6) is filled in the cell.

Owner:SONY CORP

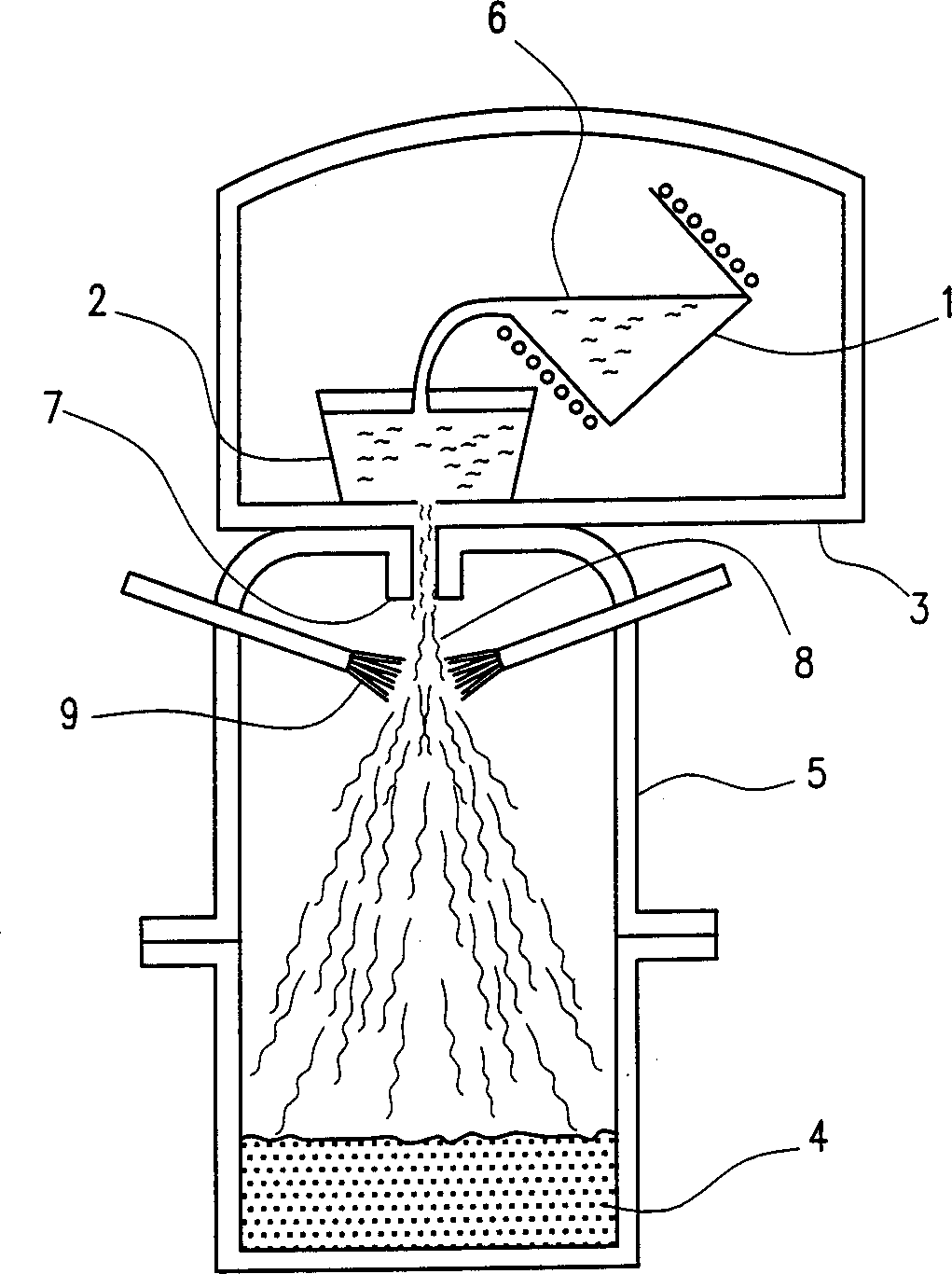

Evanescent mode pouring system of speed changing box body

The invention discloses an evanescent mode pouring system of a speed changing box body. The evanescent mode pouring system is provided with a sprue, wherein the sprue is sequentially communicated with a pouring cup, a first cross gate and a second cross gate from top to bottom, and the first cross gate and the second cross gate are respectively communicated onto the sprue along the radial direction of the sprue; the end part, away from of the sprue, of each of the first cross gate and the second cross gate is respectively provided with a first inner gate pouring port and a second inner gate pouring port. The pouring system is adopted for pouring a casting, so that the mold filling time is shortened, and the heat loss is reduced; moreover, the shrinkage porosity and cavity weakness can be greatly reduced, and the casting quality can be effectively improved.

Owner:HEFEI UNIV OF TECH

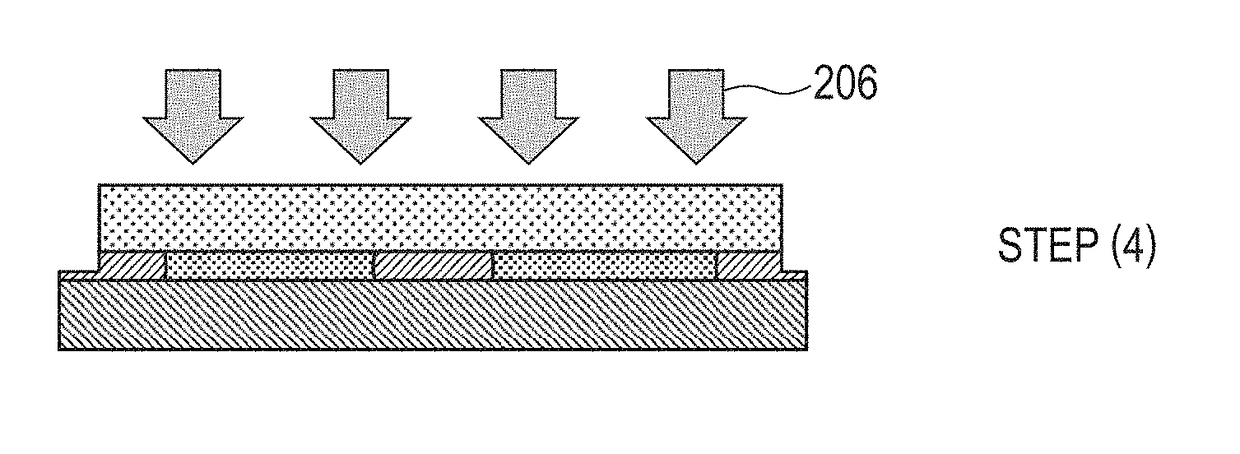

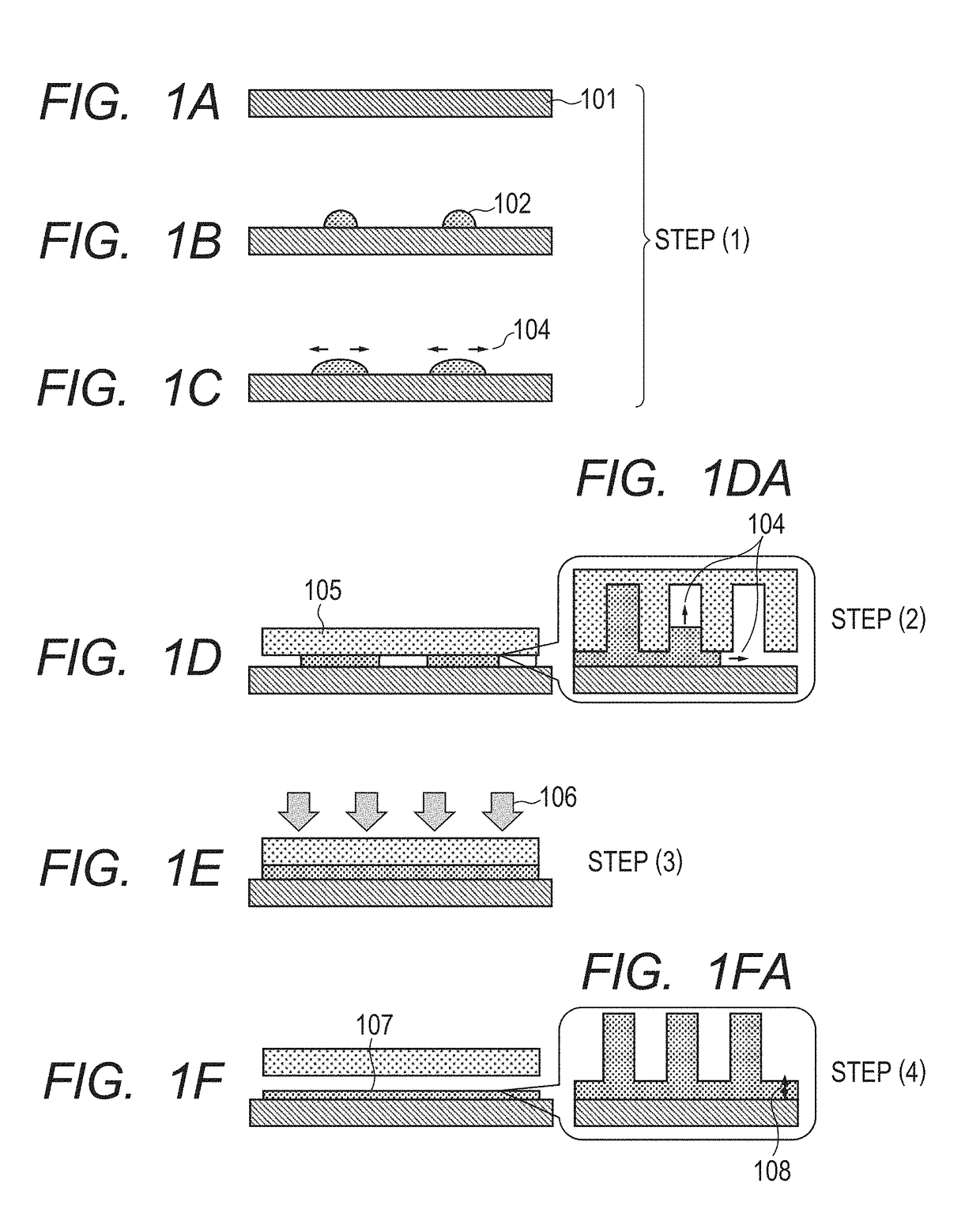

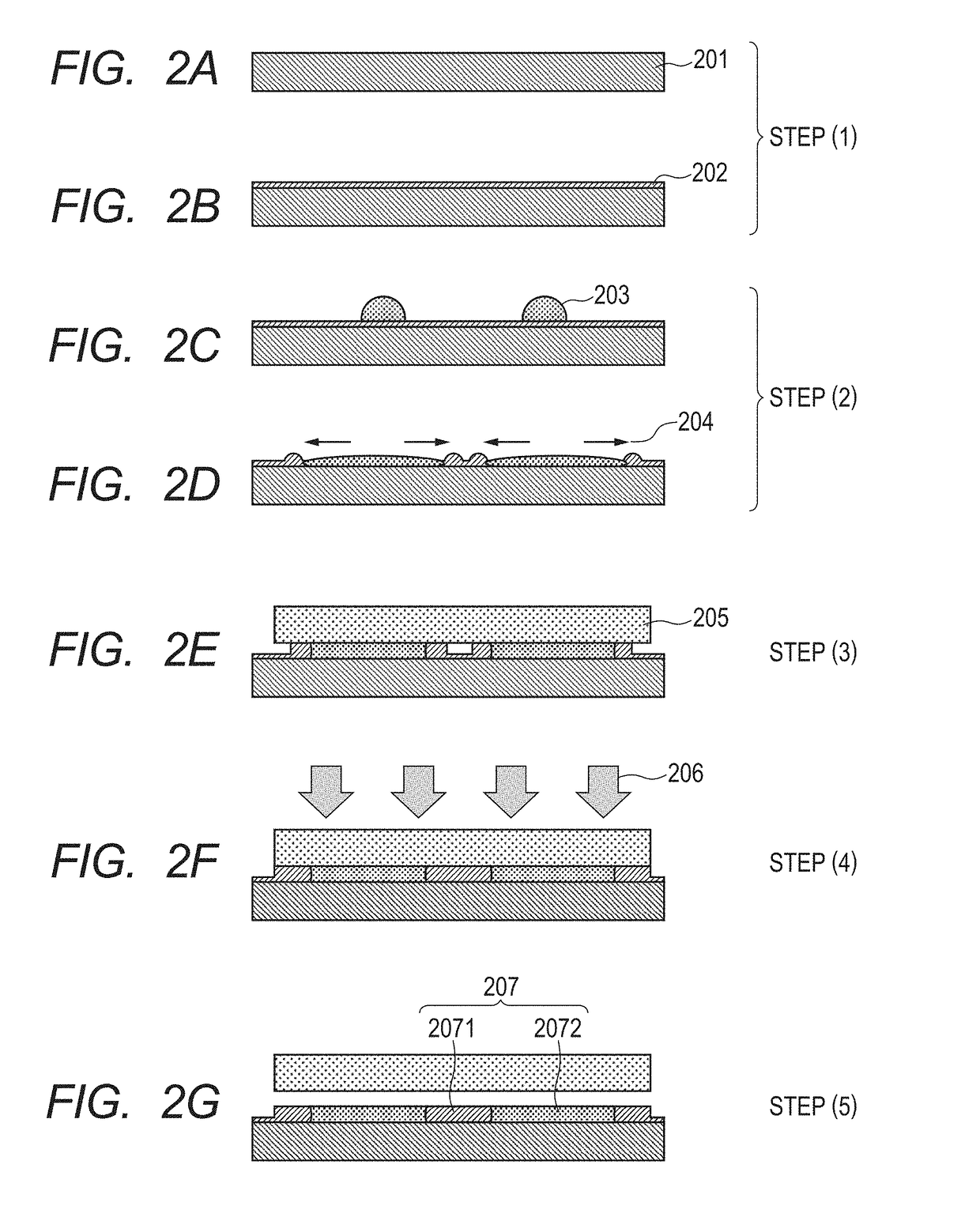

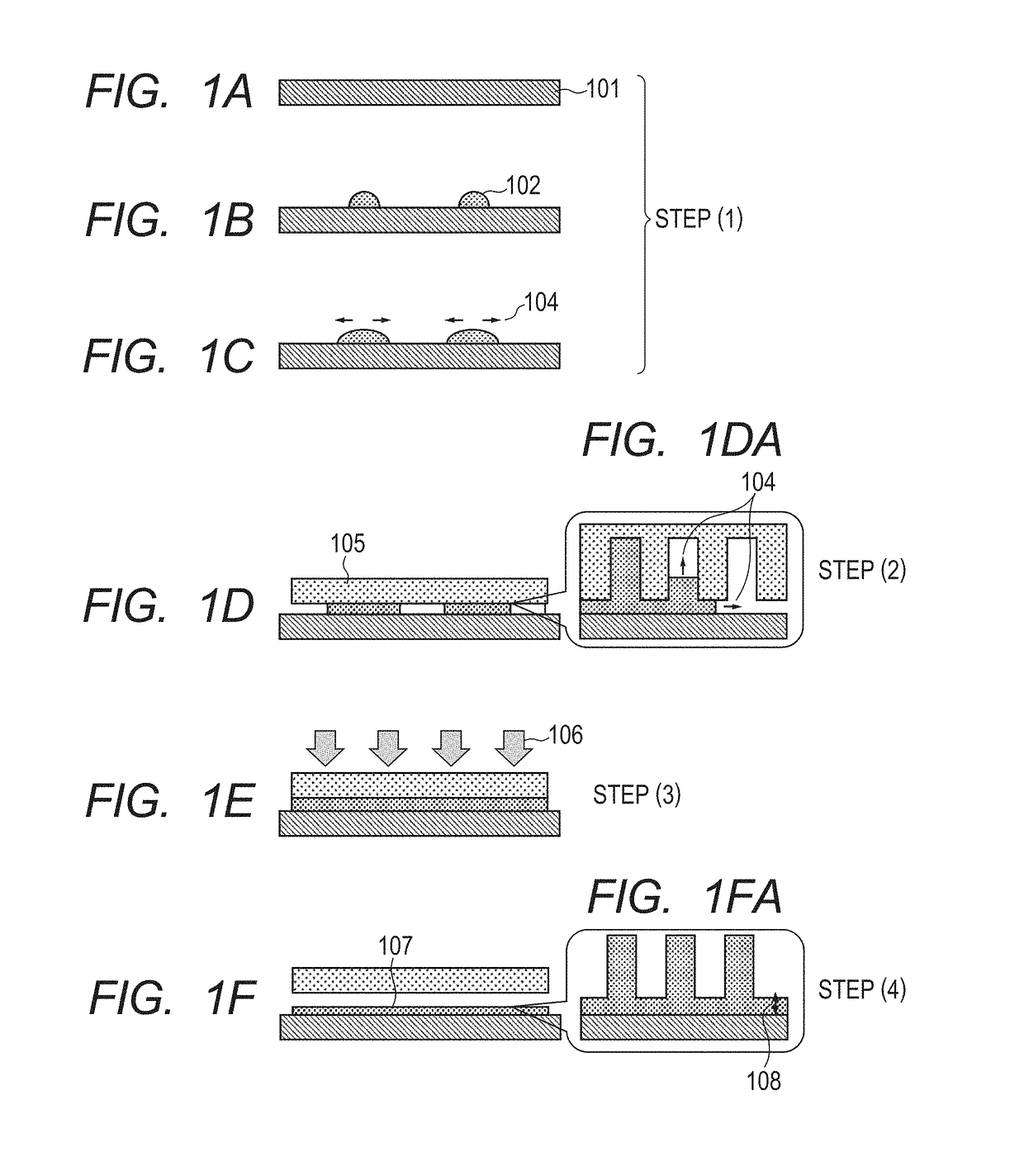

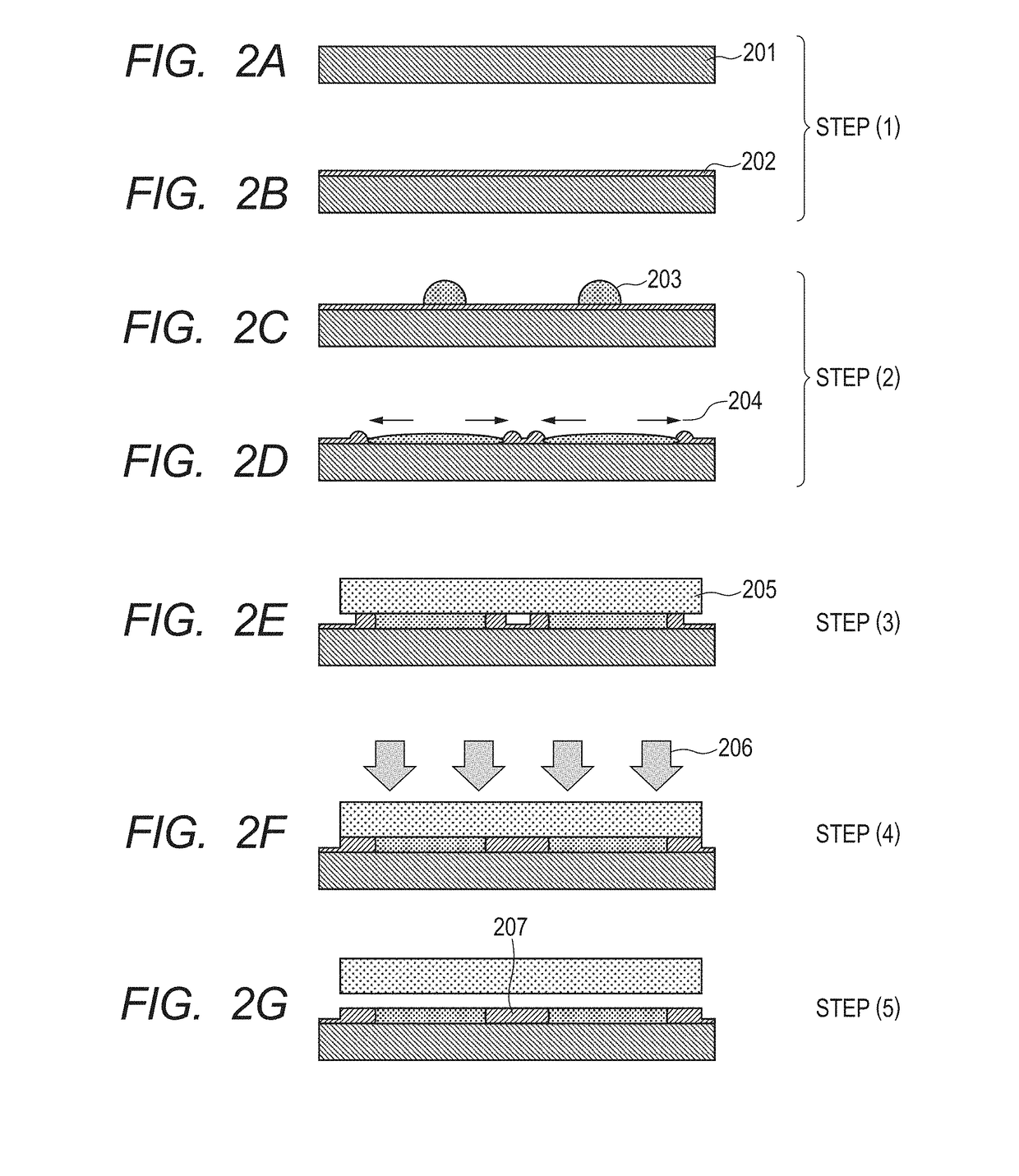

Pattern forming method as well as production methods for processed substrate, optical component, circuit board, electronic component and imprint mold

ActiveUS20170285466A1Reduce surface tensionImprove throughputPhotomechanical apparatusOptical articlesElectronic componentSURFACTANT BLEND

Owner:CANON KK

Pattern forming method as well as production methods for processed substrate, optical component, circuit board, electronic component and imprint mold

ActiveUS20170283620A1Improve throughputShorten filling timeInksPhotomechanical coating apparatusSolventElectronic component

A pattern is formed on a substrate with forming a layer of a curable composition (A1) containing a component (a1) serving as a polymerizable compound and a component (e1) on a surface of the substrate, then dispensing droplets of a curable composition (A2) containing at least a component (a2) serving as a polymerizable compound dropwise discretely onto the layer of the curable composition (A1), subsequently sandwiching a mixture layer of the curable composition (A1) and the curable composition (A2) between a mold and the substrate, then irradiating the mixture layer with light to cure the layer, and releasing the mold from the mixture layer after the curing, a surface tension of a composition of components of the curable composition (A1) except a solvent being higher than a surface tension a composition of components of the curable composition (A2) except a solvent.

Owner:CANON KK

Liquid container and remanufacturing method of liquid container

ActiveUS8177342B2Increase resistanceIncrease capacityWriting implementsMetal-working apparatusEngineeringMechanical engineering

According to one aspect of the invention, a remanufacturing method of a liquid container forms an inlet in a downstream wall surface of a second chamber, which defines part of a bottom face of the liquid container. In the state of closing a liquid feeder and opening an air open structure, the remanufacturing method injects a liquid through the inlet to fill the second chamber with the liquid. In the state of opening the liquid feeder and closing the air open structure, the remanufacturing method injects the liquid through the inlet to fill a space from the second chamber to the liquid feeder with the liquid. The remanufacturing process seals the inlet after completion of the injection of the liquid. This arrangement enables the liquid to be efficiently refilled into the liquid container without damaging the functions of the liquid container.

Owner:SEIKO EPSON CORP

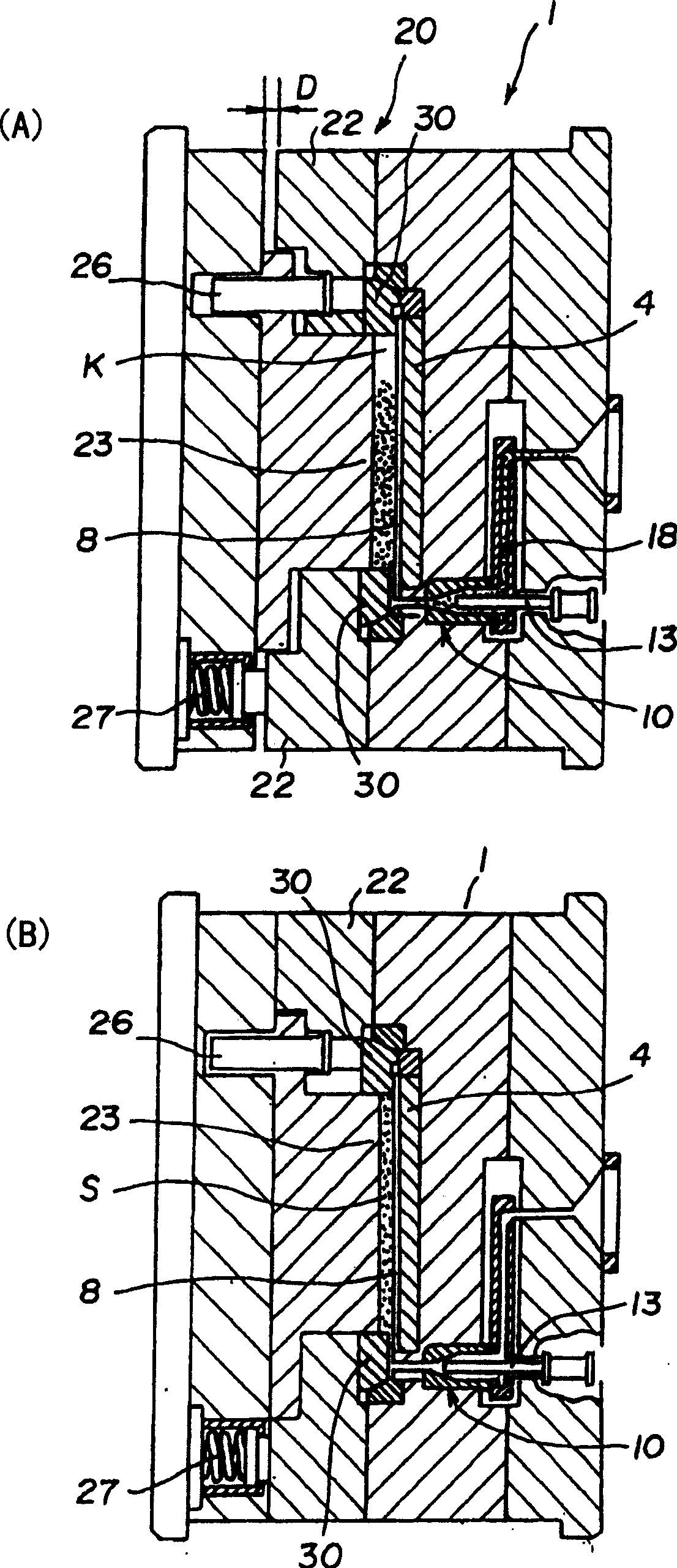

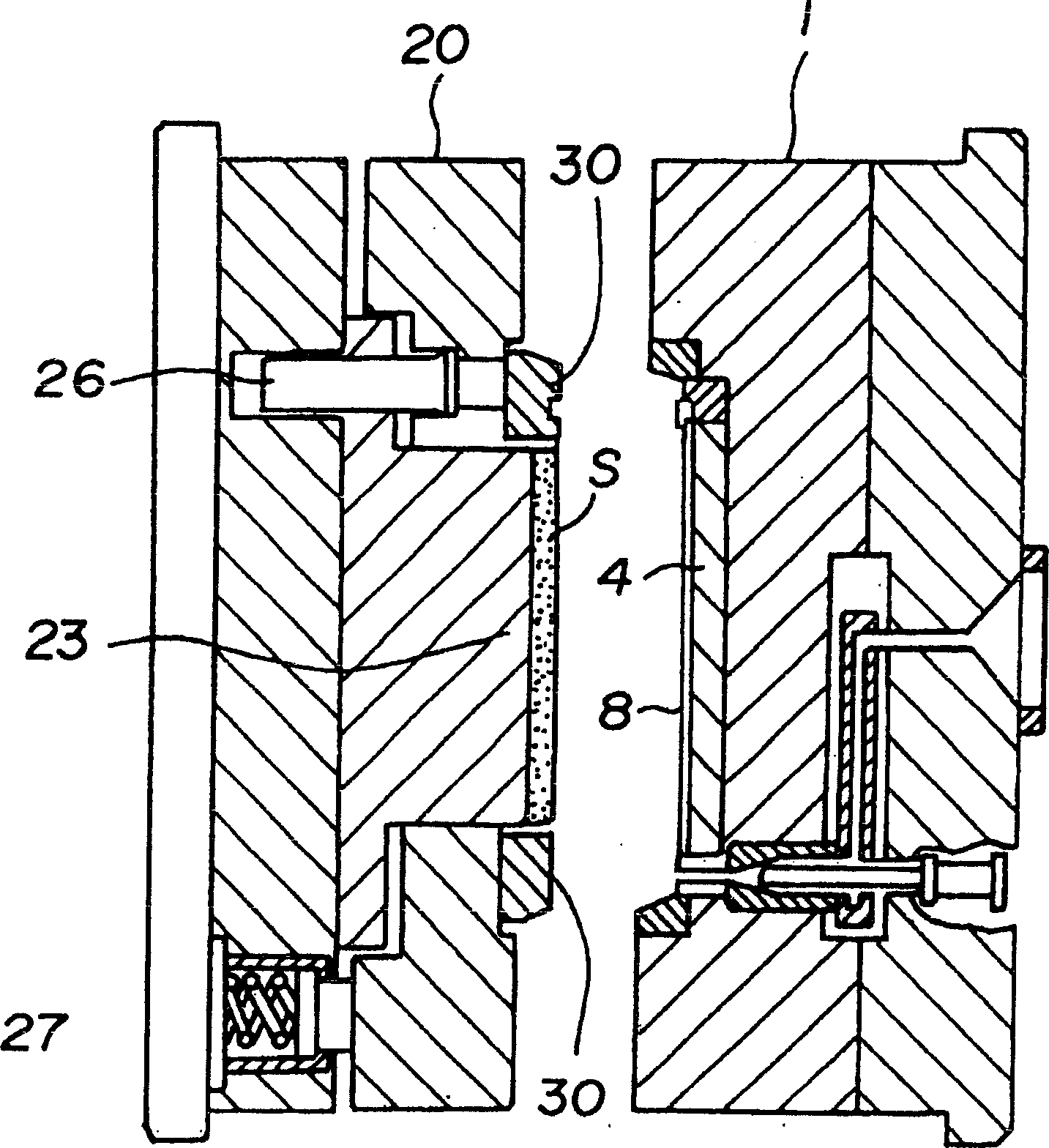

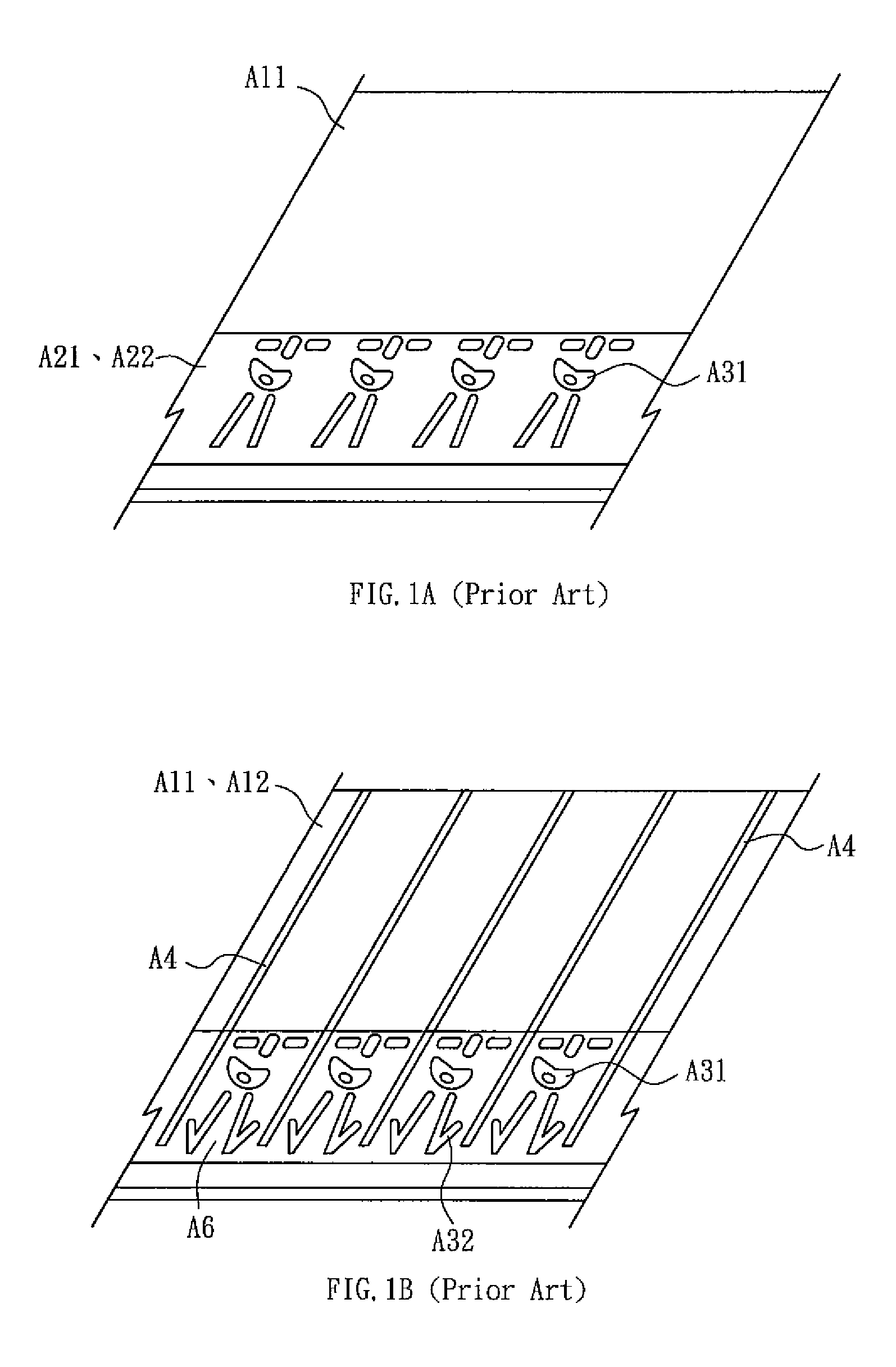

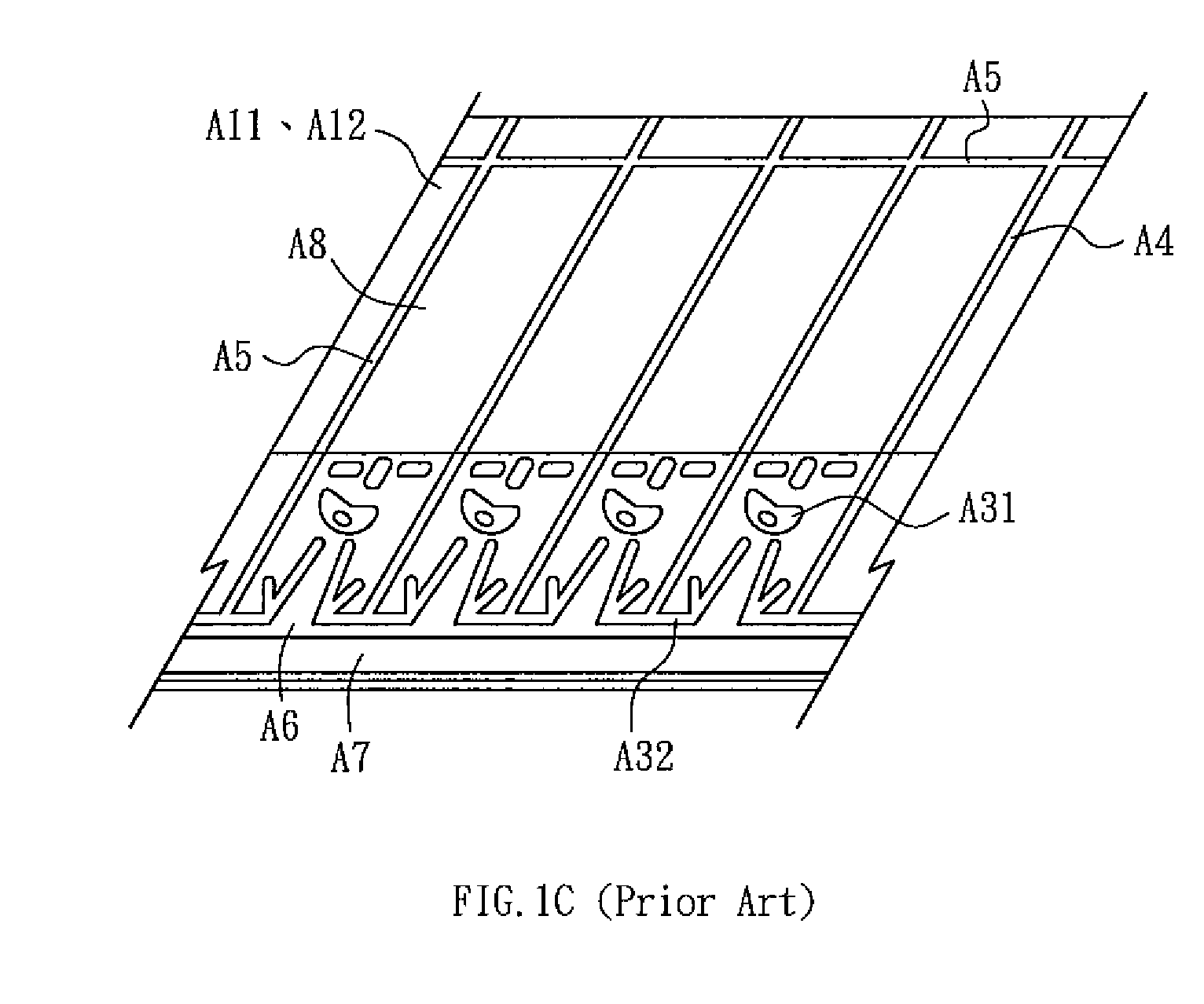

Shaping method of thick light guiding plate and its mould

InactiveCN1727169AShorten filling timeShorten molding cycleOptical articlesOptical light guidesLight guideCooling speed

The present invention provides a molding method capable of molding a thick-walled light guide plate of high quality by a short molding cycle. A predetermined amount of a molten resin is charged in the shaping space K constituted of the stamper (8) provided to the core (4) on the cavity side of a fixed mold, the core 23 on the core side of a movable mold and cores 30 and 30 on the peripheral wall side of the movable mold. Then, a valve gate is closed to compress the molten resin by the core 23 on the core side. Transfer properties are enhanced by compression and the molding cycle is shortened. At the time of compression, the temperature of the cores (30 and 30) on the peripheral wall side is made higher than the temperature of the core (4) on the cavity side and the core (23) on the core side. By this constitution, the cooling speed of the cores (30 and 30) on the peripheral wall side becomes slow to enhance a compression effect and the occurrence of a sink is suppressed.

Owner:JAPAN STEEL WORKS LTD +2

Ammonia Storage Cartridge With Optimized Filling Time, in Particular for a Motor Vehicle Gas Exhaust system

ActiveCN104234796AShorten filling timeExhaust apparatusSilencing apparatusMobile vehicleAmmonia storage

An ammonia storage cartridge includes_an ammonia storage member having a storage material capable of absorbing or adsorbing ammonia. The storage member extends along a longitudinal axis. A heating element heats the storage member, and a hermetic tank houses the storage member. A tubular ammonia circulation element is arranged coaxially to the storage member, and includes_a first surface at least partially delimiting, with an element chosen from among the heating element and the hermetic tank, a circulation duct for the fluid ammonia. A second surface is arranged at least partially in contact with the storage member, and-at least one orifice passes radially through, allowing the circulation of fluid between the circulation duct and the storage member.

Owner:FAURECIA SYST DECHAPPEMENT

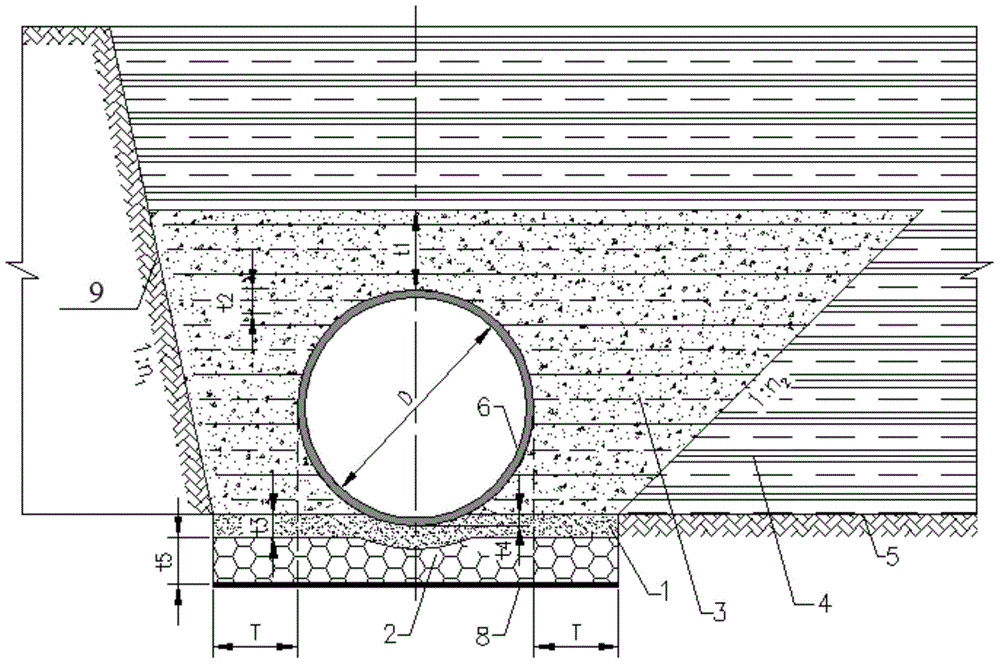

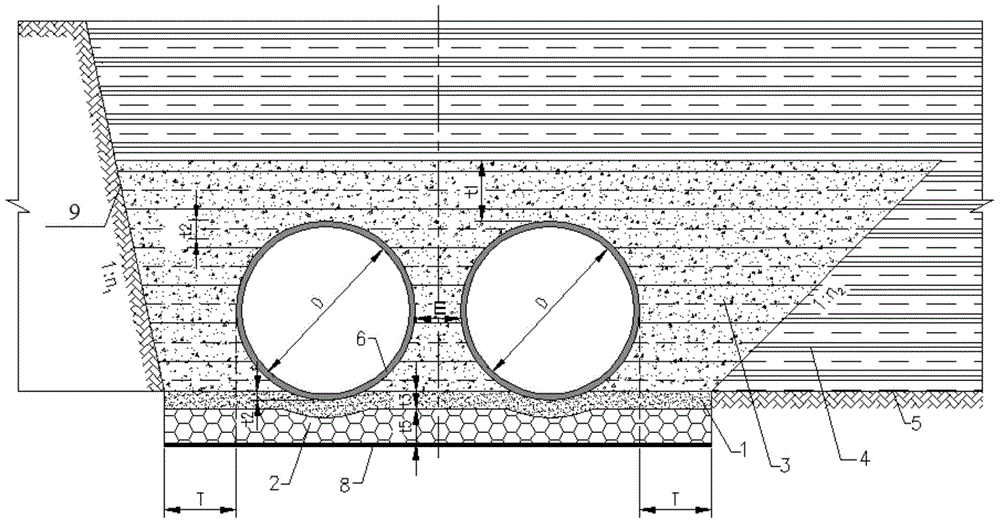

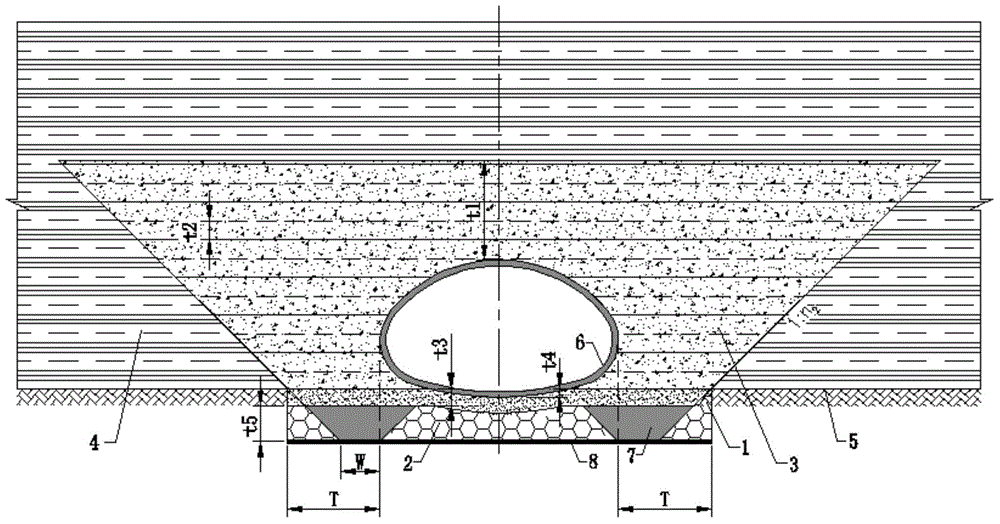

Corrugated steel tube culvert filling structure and filling method thereof

The invention discloses a corrugated steel tube culvert filling structure and further discloses a filling method of the corrugated steel tube culvert filling structure. The filling structure overcomes the defect that the walls of corrugated steel tubes can be easily damaged due to an original masonry culvert rigid foundation, a flexible foundation with a sand cushion and a subbase is adopted for filling, geotextile is adopted under weak geological conditions, and thus the corrugated steel tubes can be prevented from settling unevenly. The whole tube bodies are placed under the protection of a structural backfill area, the tube bodies of the corrugated steel tubes can be effectively protected, and the characteristic of the flexible material of the corrugated steel tubes can be matched better. The filling structure is suitable for corrugated steel tubes in various shapes such as a circle, an oval and a tube arch and is also suitable for construction with a tube ditch method or an embankment building method.

Owner:CCCC SECOND HIGHWAY CONSULTANTS CO LTD

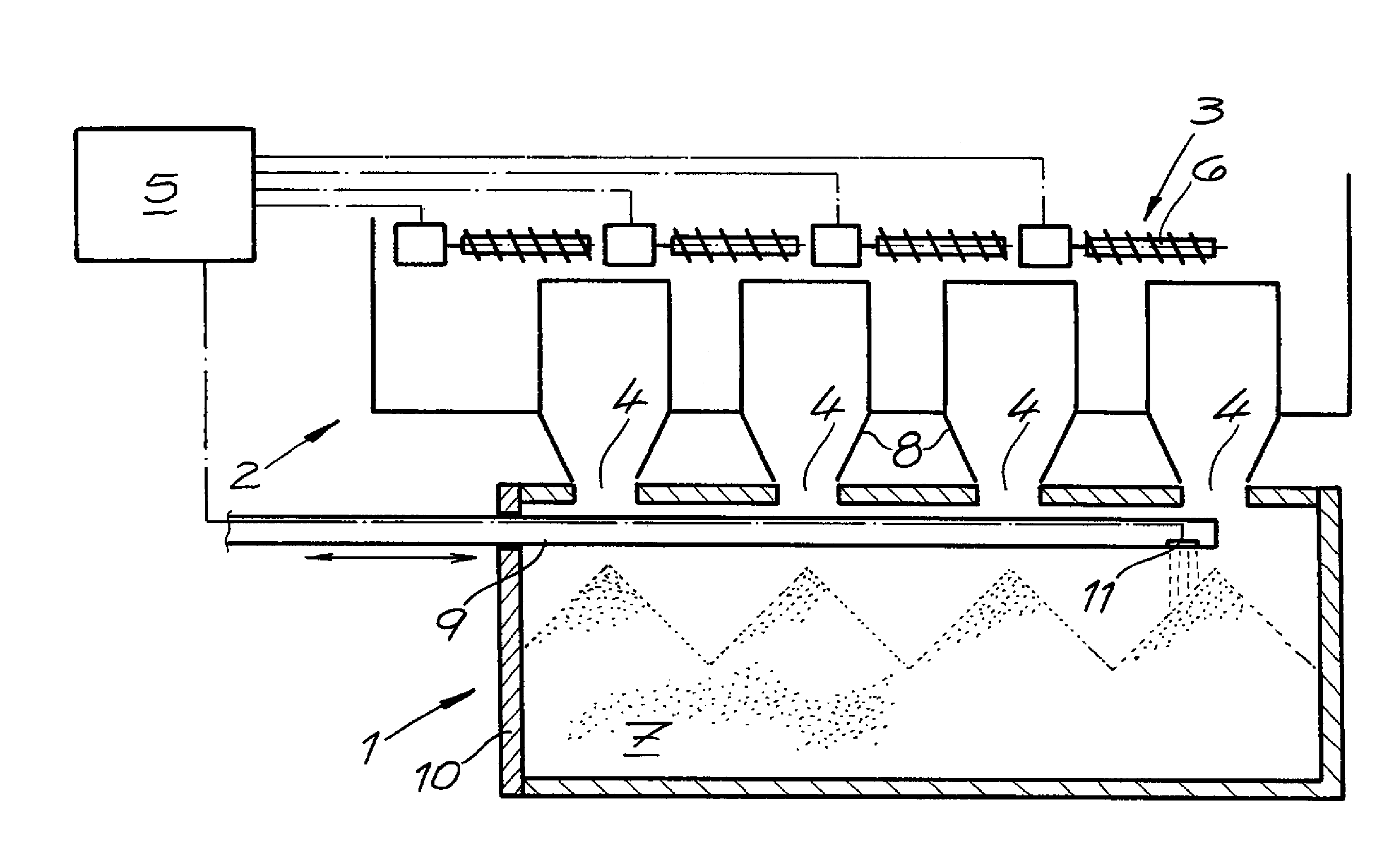

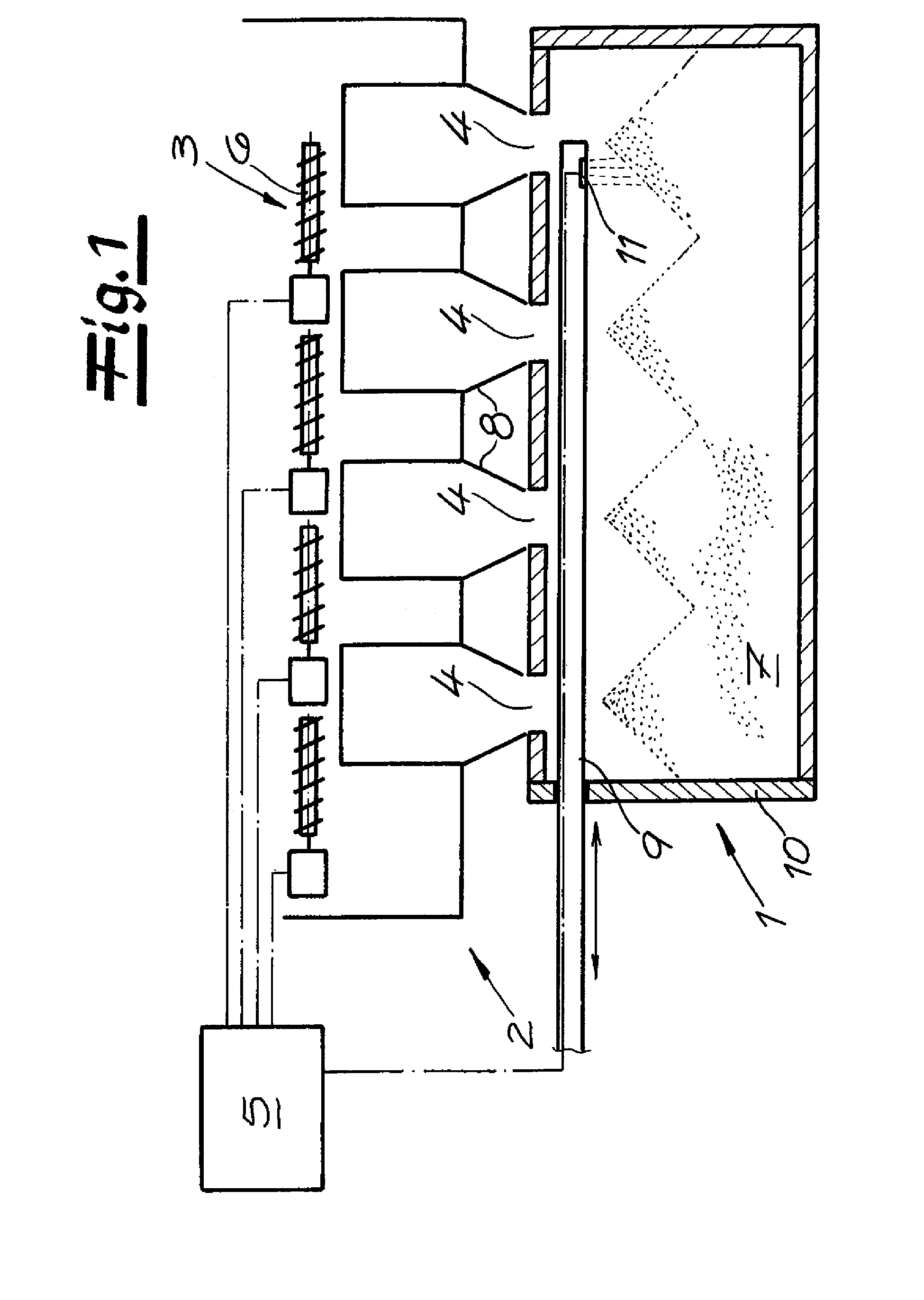

Leveling apparatus for and method of filling an oven chamber of a coke-oven battery

InactiveUS8568568B2Shorten filling timeImproved resultCoke oven safety devicesCharging-discharging device combinationsEngineeringBiomedical engineering

A coking oven has a battery of longitudinally extending and transversely spaced coking chambers each provided with a plurality of downwardly open and longitudinally spaced filling holes. Coal is charged into the chambers through the respective filling holes. A respective longitudinally movable leveling rod in each of the chambers can level coal charged by the filling equipment into the chambers. Sensors provided on the leveling rods scan from above transversely and longitudinally spaced points on a surface of the coal charged through the holes into the respective chambers. A controller connected to the sensors records a respective measurement corresponding to a vertical position of the surface at each the points and determines from the measurements thereof a three-dimensional filling-level profile of the surface of the charged coal for controlling operation of the filling equipment and filling of the chambers with the coal.

Owner:UHDE GMBH

Air enclosure without heat resistant material and manufacturing of same

InactiveUS20090239006A1Save air filling timeLow costEnvelopes/bags making machinerySynthetic resin layered productsEngineeringAir compression

An air enclosure without a heat resistant material is formed by stacking two outer films and two inner films, allowing the two inner films to be lain in between the two outer films, placing a heat resistant pad between the two inner films, adhering the two outer films and the two inner films to each other to form at least one air inlet between the two inner films and at least one air cylinder between the two outer films, and thereafter, taking out the heat resistant pad, and filling air into the air cylinder via the air inlet to cause the air cylinder to be filled with air and expanded, where the air in the air cylinder compresses the two inner films to cover the air inlet to shield the air cylinder.

Owner:LIAO CHIEH HUA

Fast directional multilevel simulation method for planar microstrip circuit

InactiveCN102054094AReduce complexityGood low-rank propertiesSpecial data processing applicationsInternal memoryComputation complexity

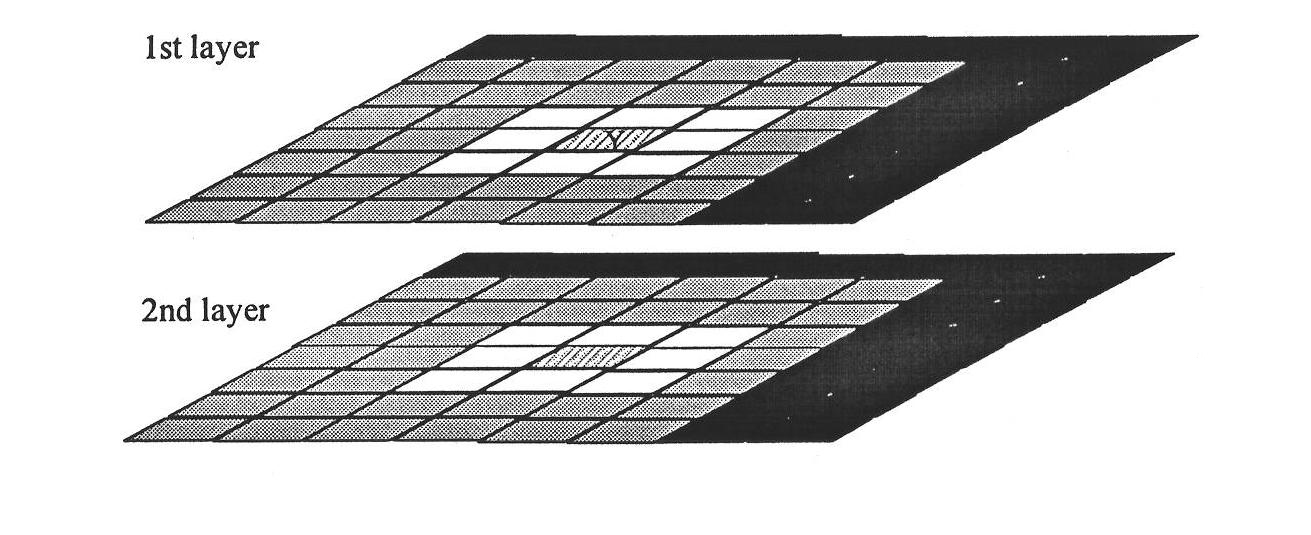

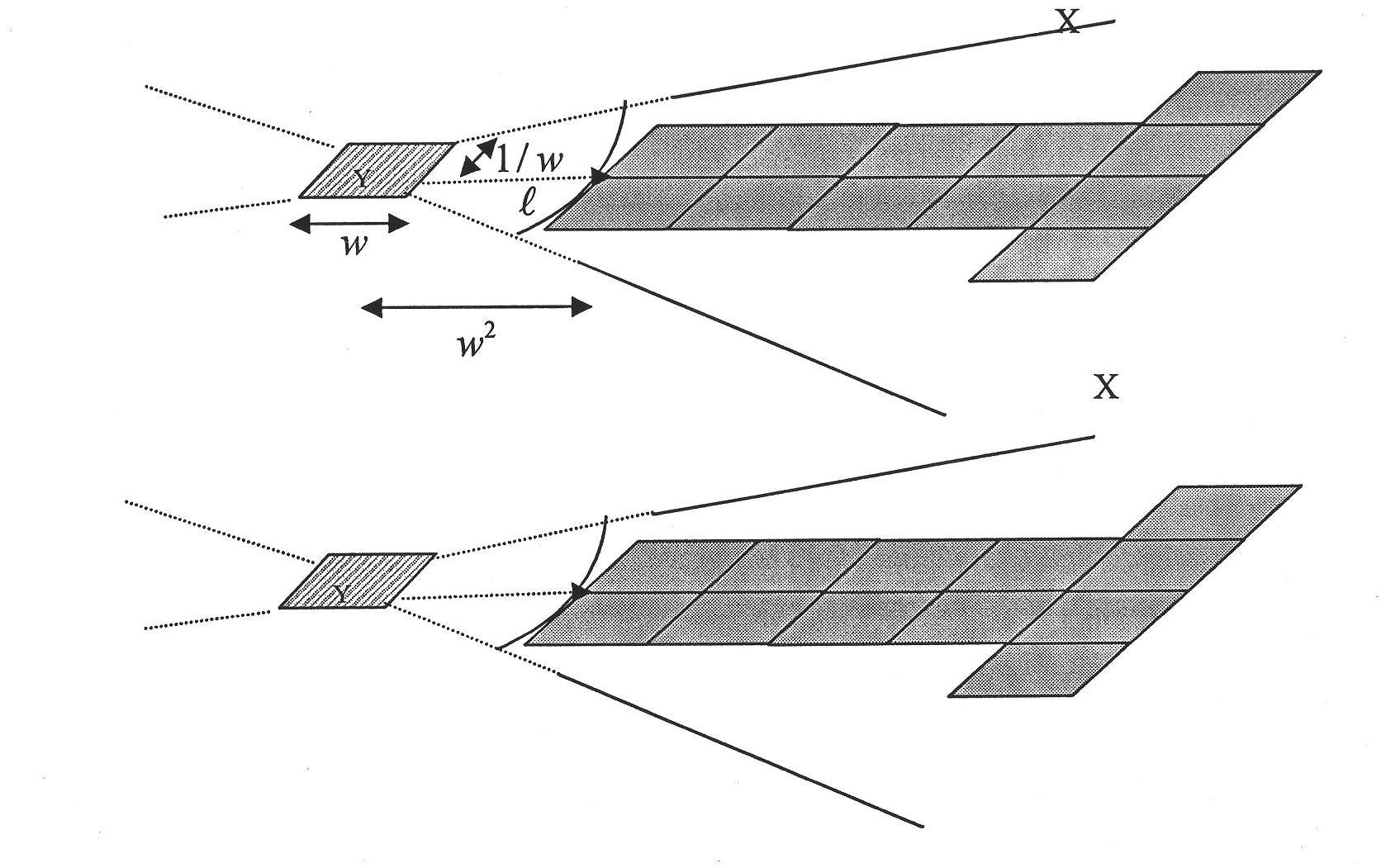

The invention discloses a fast directional multilevel algorithm for analyzing a planar microstrip circuit. The planar microstrip circuit structure is analyzed based on the fast directional multilevel algorithm. In the algorithm, a complex circuit is divided by a planar triangular surface element, and the fast directional multilevel algorithm is combined with a Rao-Wilton-Glisson (RWG) function to be applied to an electric field integral equation to ensure the calculating accuracy of a model; and by utilizing a principle that an impedance matrix formed by a moment method when the field-to-source point distance is long enough has good low-rank characteristic, fast directional multilevel calculation is adopted for a far field area, a Green function is unfolded by a low-rank expression, the expansion is only related to calculation of a kernel function so as to greatly reduce the calculating complexity of the multilayer microstrip circuit, and the calculating complicity and internal memory demand are reduced to O(NlogN) magnitude. A quadtree form is also adopted for grouping analysis of the planar microstrip multilayer circuit, the consumption of the internal memory is effectively reduced, the calculation result is accurate, the testing cost is low, and the fast directional multilevel algorithm can be widely applied to simulation analysis of complex circuits.

Owner:NANJING UNIV OF SCI & TECH

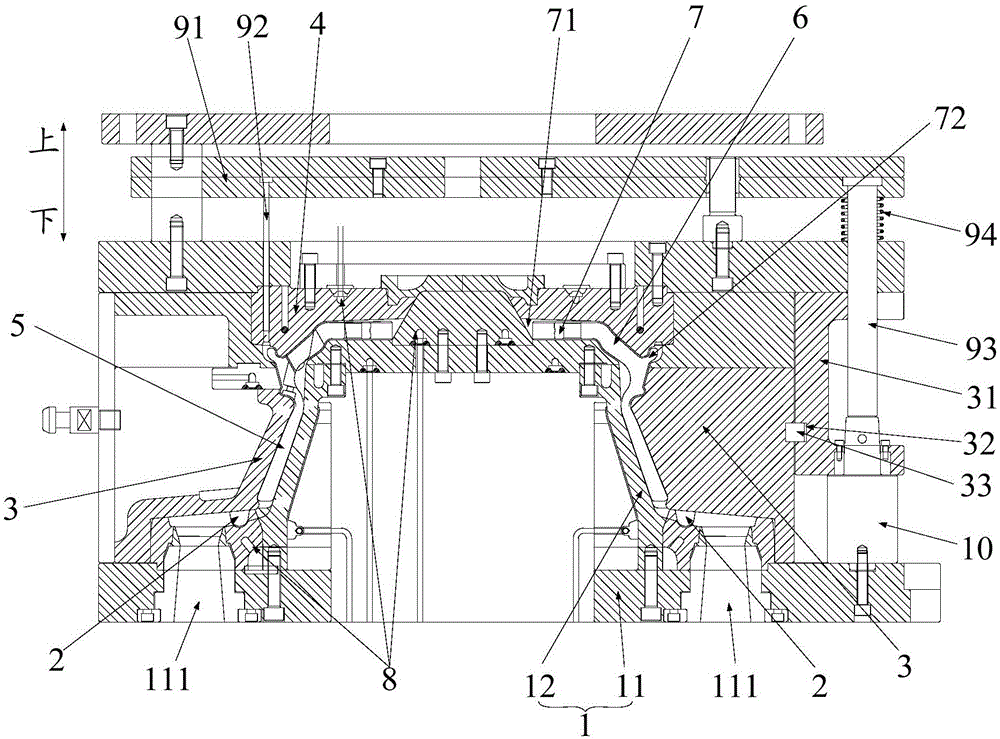

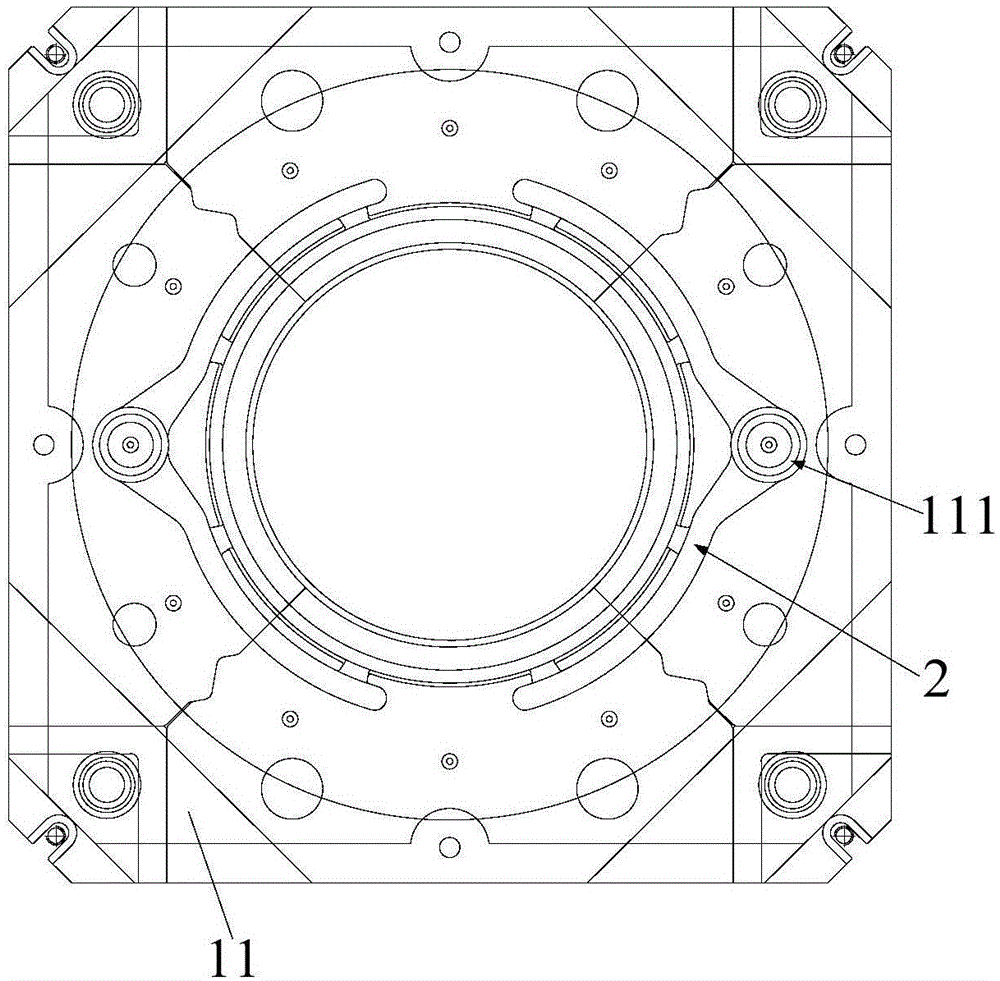

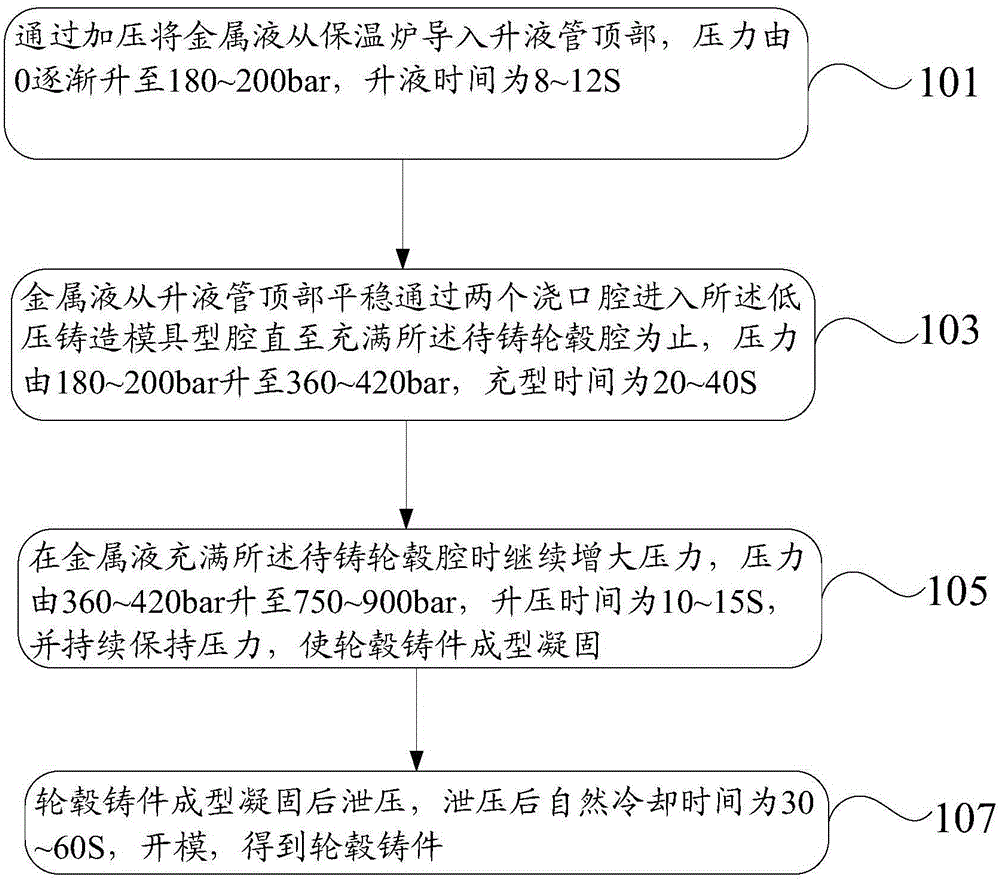

Low-pressure casting mould and method for casting hub

The invention provides a low-pressure casting mould and a method for casting a hub. The low-pressure casting mould comprises a lower mould body, multiple side mould bodies, an upper mould body and a control device. The multiple side mould bodies are matched with the lower mould body to form a rim cavity and a flow pass cavity corresponding to a rim of the hub to be cast. The upper mould body is matched with the lower mould body and the side mould bodies to form a spoke cavity corresponding to a spoke of the hub to be cast, an installing cavity corresponding to an installing plate of the hub to be cast, and an upper wheel edge cavity corresponding to an upper wheel lip of the hub to be cast. Two sprue cavities are formed in a bottom plate. The flow pass cavity, the upper wheel edge cavity, the spoke cavity, the rim cavity and the installing cavity are communicated mutually to form a cavity of the hub to be cast. The cavity of the hub to be cast is communicated with the two sprue cavities. According to the low-pressure casting mould, materials are fed from the two sprue cavities, casting to the top is carried out, mould filling time is shortened, stability is good, low-pressure casting is adopted for replacing forging to obtain a rotary extruded workblank, compared with forging equipment, precision is higher, manufacturing cost is lower, the mechanical performance of products is improved, and the production cost is reduced, which is beneficial for market competitiveness of the products.

Owner:ZHEJIANG JINFEI KAIDA WHEEL

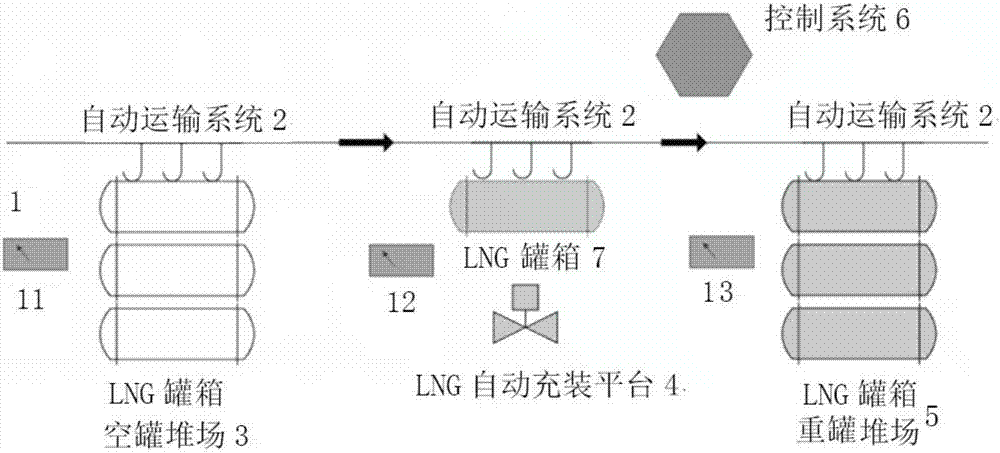

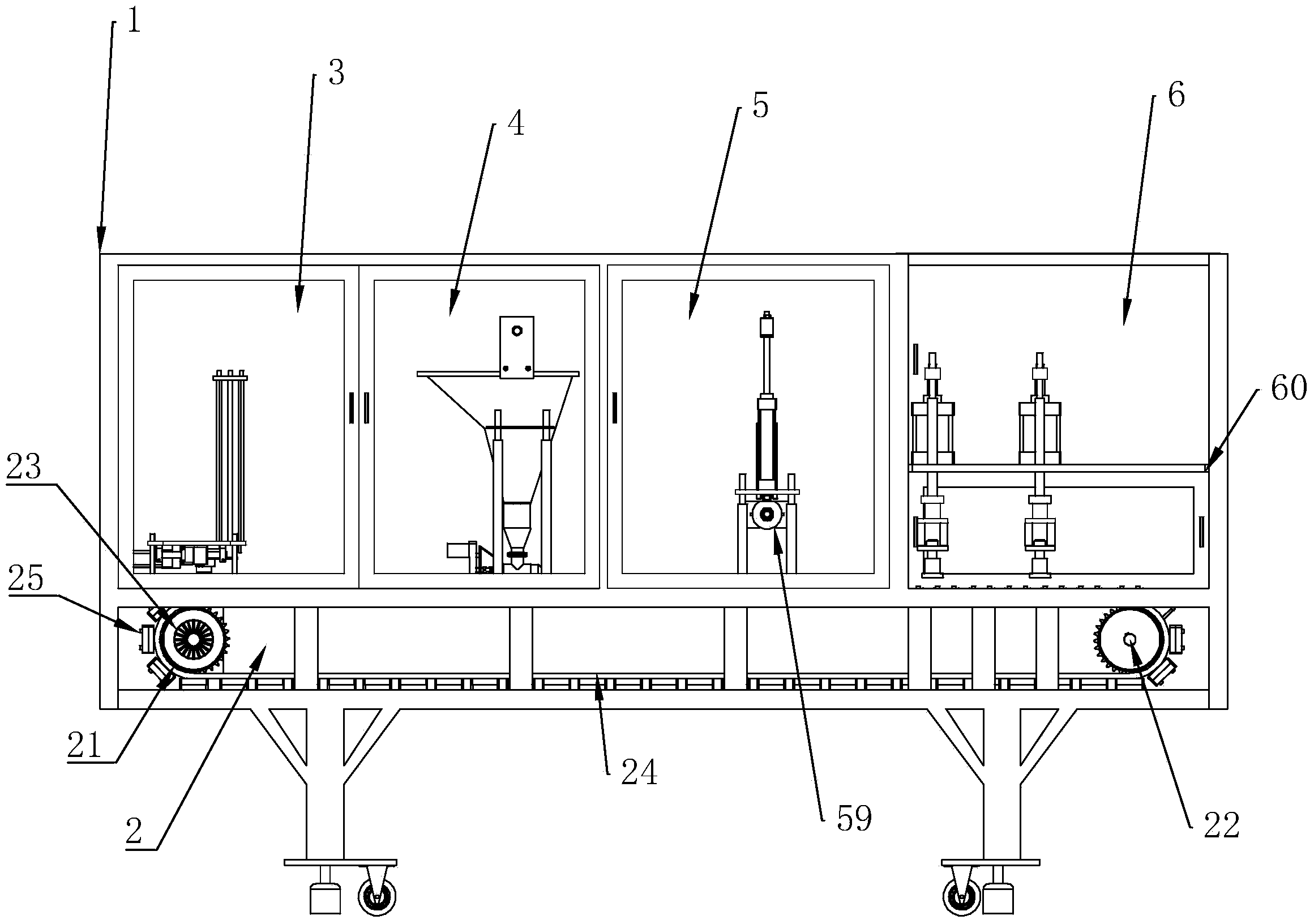

LNG tank box assembly line filling system

ActiveCN107479424AShorten filling timeRemove uncertaintyProgramme control in sequence/logic controllersMarine engineeringControl system

The invention relates to an LNG tank box assembly line filling system, and the system is characterized in that the system comprises a scanning and information recorder, an LNG tank box empty tank storage yard, an automatic conveying system, an LNG automatic filling platform, a control system and an LNG tank box refilling storage yard. The scanning and information recorder is used for obtaining the recognition information of an LNG tank box before filling, during filling and after filling. The automatic conveying system is connected with the LNG tank box empty tank storage yard, the LNG automatic filling platform and the LNG tank box refilling storage yard, and is used for conveying a to-be-filled LNG tank box to sequentially pass through the LNG tank box empty tank storage yard, the LNG automatic filling platform and the LNG tank box refilling storage yard. The LNG automatic filling platform is used for completing the filling of the LNG tank box. The control system is connected with the scanning and information recorder, the automatic conveying system and the LNG automatic filling platform. The system can achieve the automatic filling of the LNG tank box, and improves the filling efficiency and safety.

Owner:CHINA NAT OFFSHORE OIL CORP +1

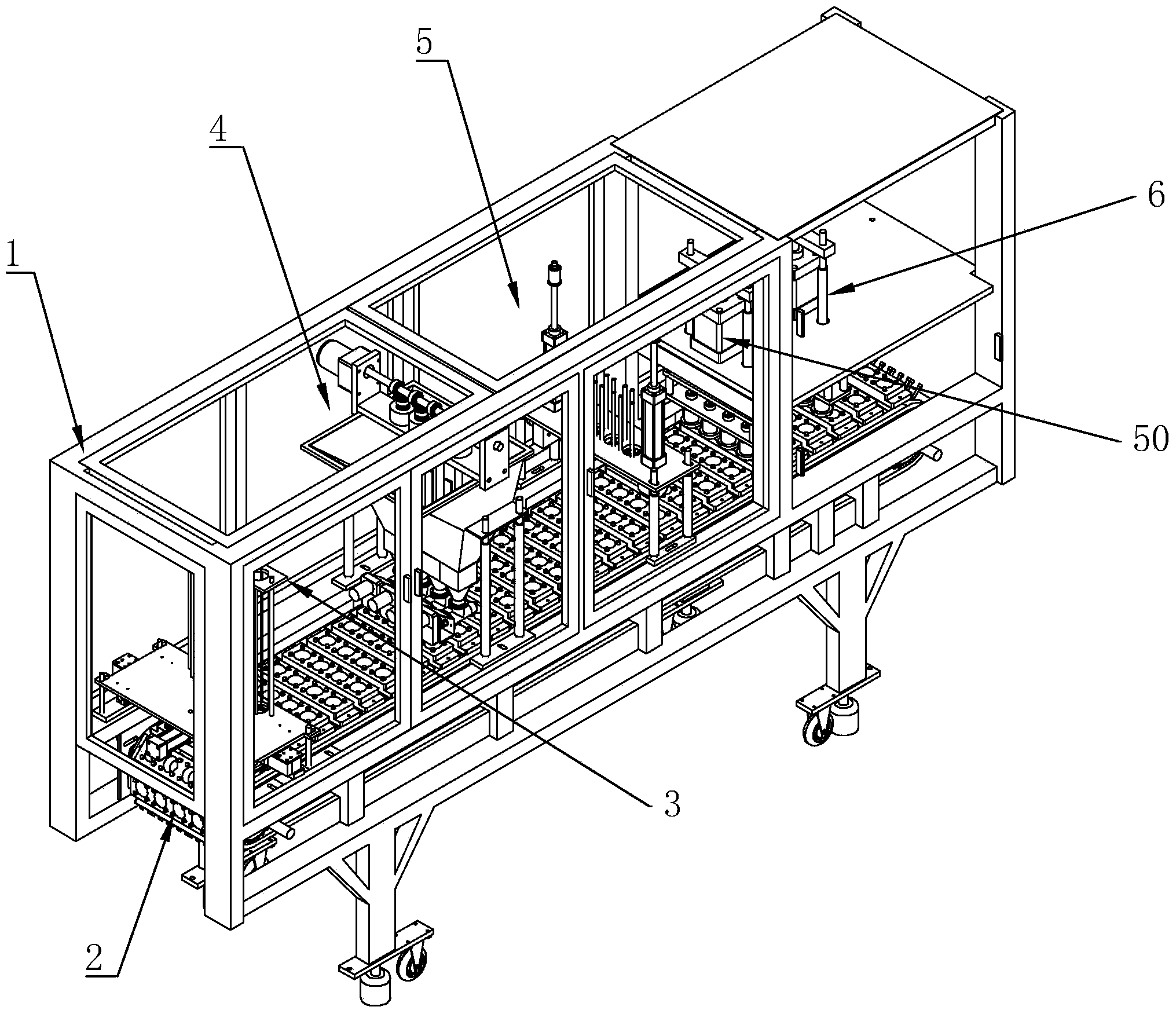

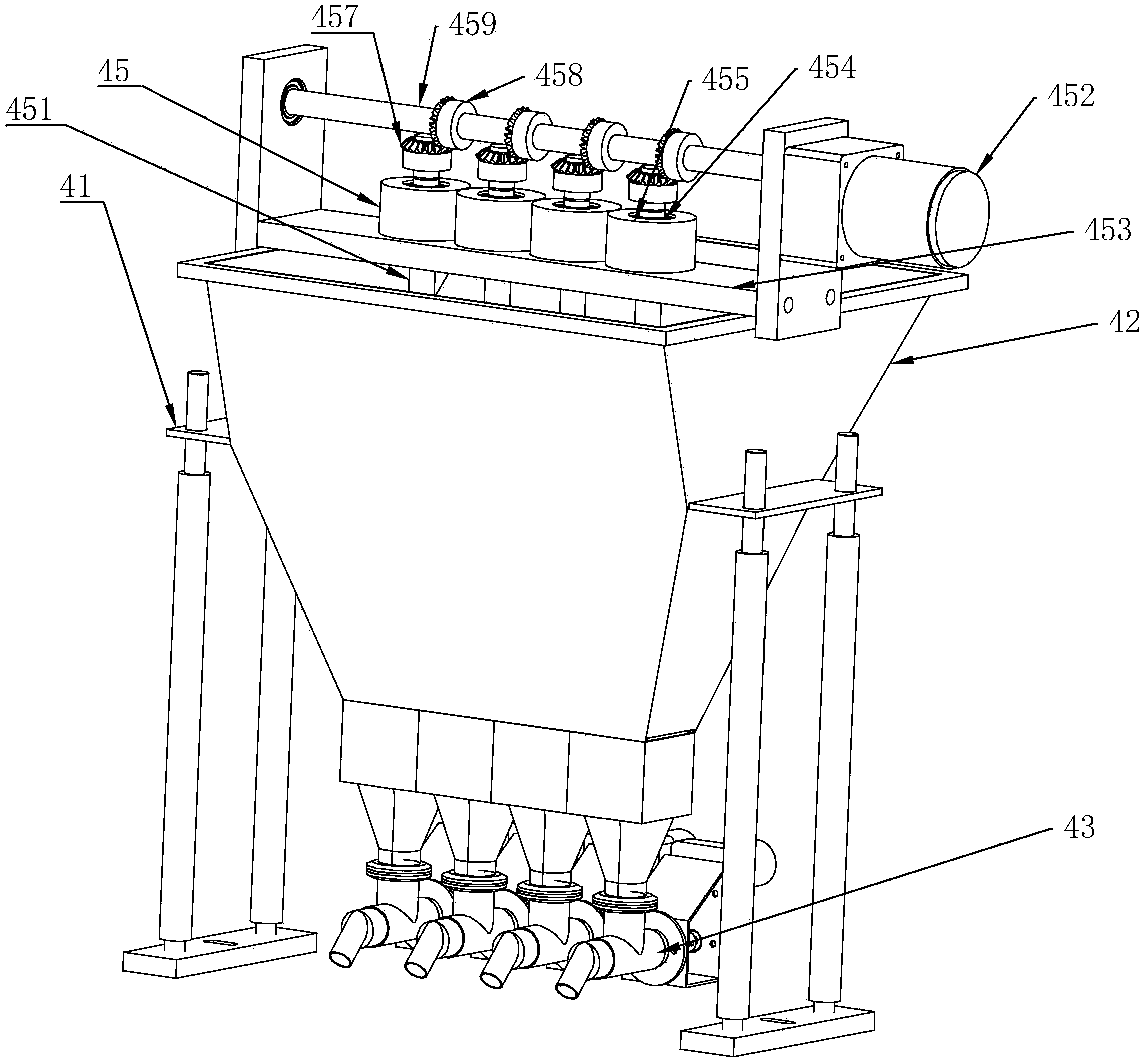

Full-automatic coffee capsule filling machine suitable for coarse coffee powder

InactiveCN104386269AShorten filling timeReduce wasteSolid materialElectric machineryMaterial resources

The invention discloses a full-automatic coffee capsule filling machine suitable for coarse coffee powder. The full-automatic coffee capsule filling machine comprises a main support and a transmission device, wherein the transmission device is arranged on the main support and is sequentially provided with a cup placing device, a feeding device, a film absorbing device and a film sealing device, the feeding device comprises a feeding support, the feeding support is provided with a raw material storage box, the bottom part of the raw material storage box is funnel-shaped and is connected with a material conveying device, the material conveying device comprises a three-way pipe, the three-way pipe comprises a material inlet pipe, a material storage through pipe and a material outlet pipe, the material inlet pipe is connected with the raw material storage box, the material storage pipe is internally provided with a worm rod, the other end, which is opposite to the material outlet pipe, of the worm rod is connected with a material conveying motor in an linkage mode, and a universal joint is connected between the material conveying motor and the worm rod. According to the full-automatic coffee capsule filling machine suitable for the coarse coffee powder, disclosed by the invention, the full-automatic coffee capsule filling machine is suitable for the filling of the coarse coffee powder, the filling efficiency is increased, the waste of human and material resources is reduced, and the whole filling process can be fully automated.

Owner:温州市沪华机械电器有限公司

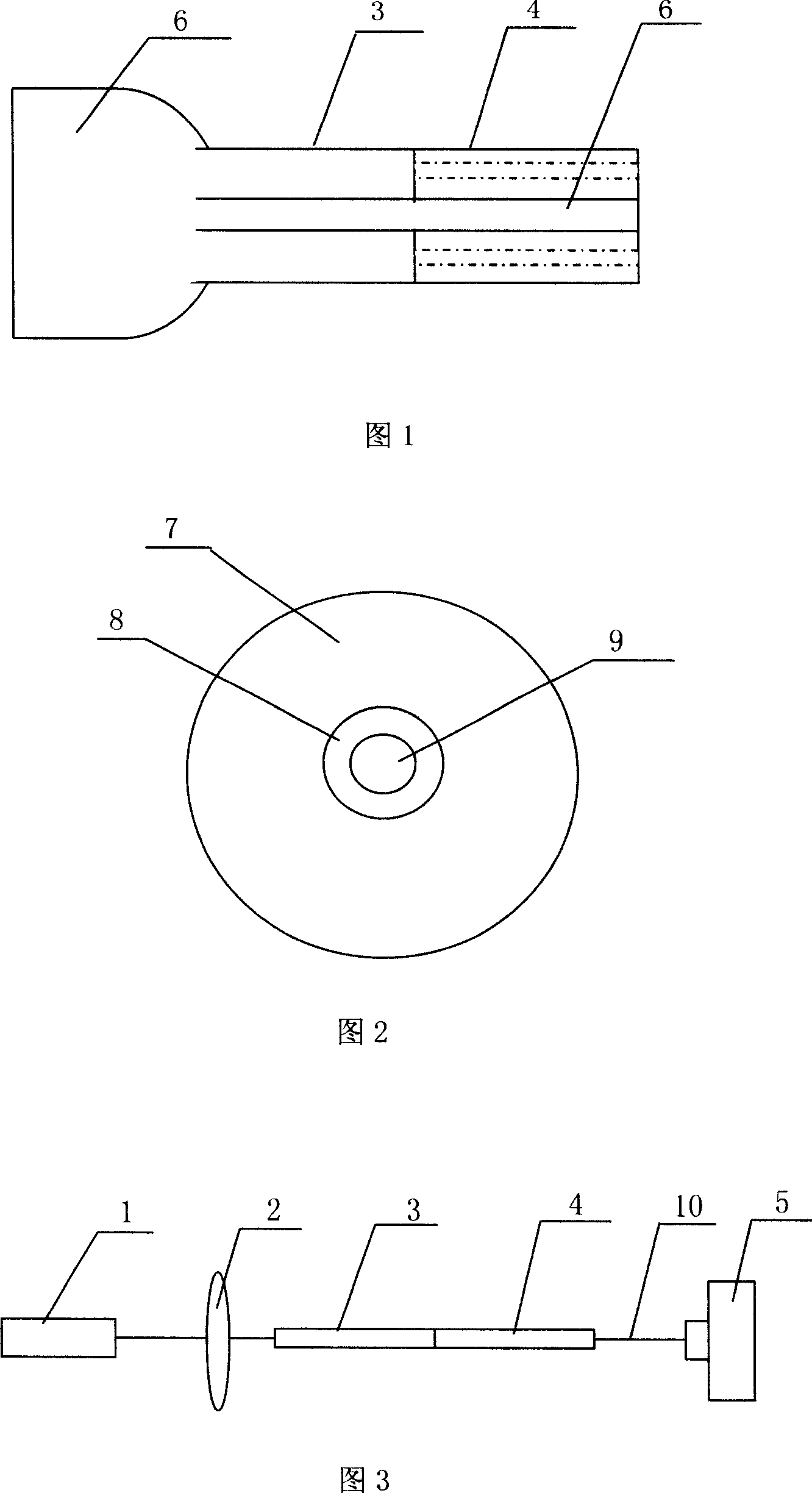

Micro-structural optical fibre selectively filling method and judge aligning system

InactiveCN101013182AShorten the lengthShorten filling timeCladded optical fibreCoupling light guidesSingle holeEngineering

It is a microstructure fiber selective filling method and judgment aiming system, the filling system completed by the following steps: 1) pulling to produce single-hole fiber; 2) pre-aligning, processing the produced single-hole fiber and the filling photonic crystal fiber with end-cutting and aiming at the center hole heart; 3) accurate alignment, using the judgment aiming system precisely aiming at the center hole heart of the single hole fiber and photonic crystal fiber; 4) completing filling. The said judgment aiming system comprises laser, coupler, and power meter in serial, and during the measurement, the closely docking single-hole fiber and photonic crystal fiber is placed between the coupler and the power meter. The invention applies to all center hole selective filling of the prohibit-belt fibers that the fiber core hole size is greater than or equal to the single-hole fiber. Requiring only a small section of single-hole fiber, the invention can process a fiber core hole filling of different structures prohibit-belt fibers. Meanwhile, it reduces the length of single-hole fiber and increases the air hole size, and it can appropriately reduce the filling time.

Owner:NANKAI UNIV

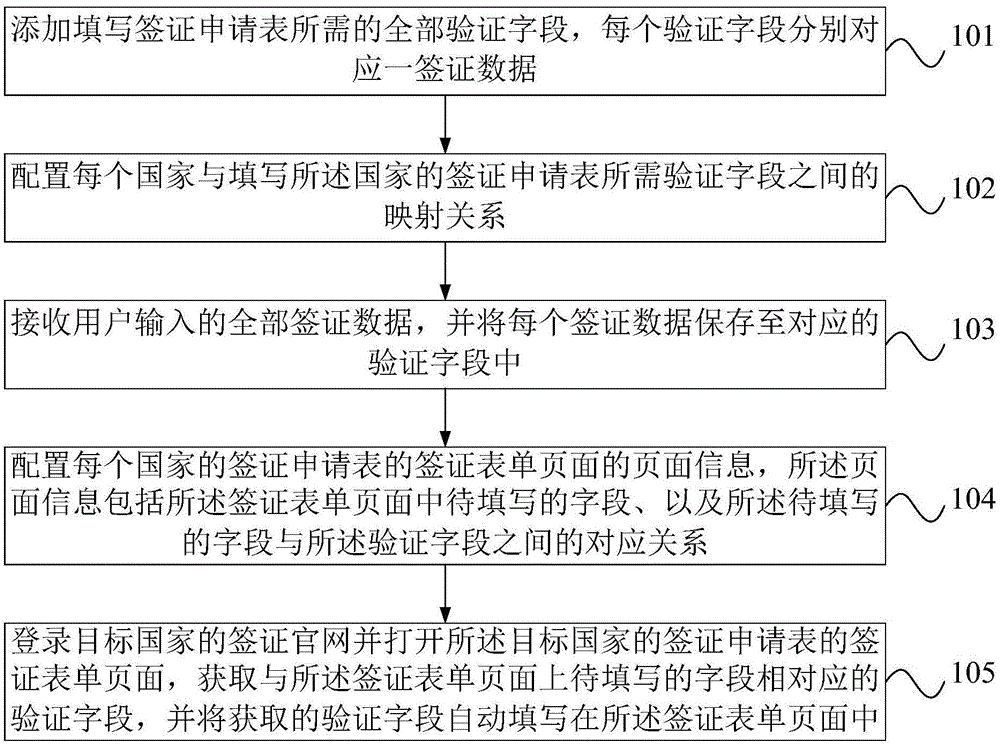

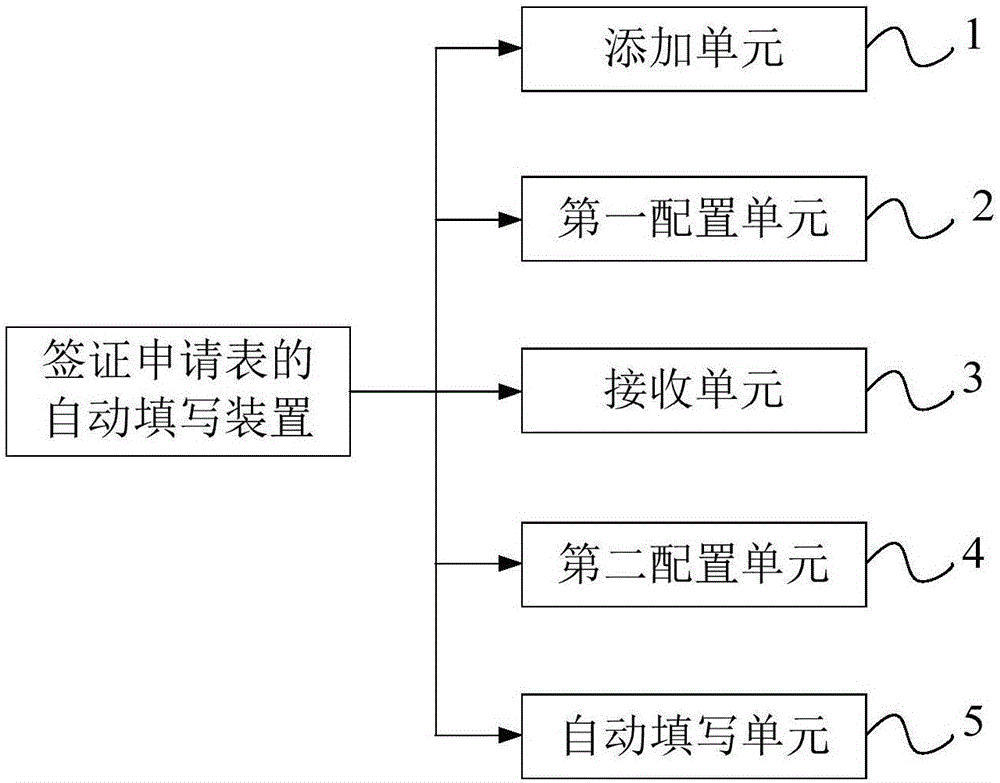

Automatic writing device and automatic writing device of visa application form

ActiveCN105138505AImplement autofillEasy to operateSpecial data processing applicationsUser inputSoftware engineering

The invention discloses an automatic writing device and an automatic writing device of a visa application form. The method comprises the steps of S1. adding all verification fields needed writing the application form, wherein each verification field corresponds to visa data; S2. configuring the mapping relationship between each country and the verification fields needed for writing the visa application form of the country; S3. receiving all the visa data input by a user, and storing each visa data into the corresponding verification field; S4. configuring the page information of the page of the visa form of the visa application form of each country; and S5. register the visa official website of the target country, and opening the visa form page of the visa application form of the target country so as to acquire the verification fields corresponding to fields to be written on the visa form page, and automatically writing the acquired verification fields onto the visa form page. According to the method, the automatic writing of the visa application form can be realized, the writing accuracy and the writing efficiency can be improved, and the user operation is simplified.

Owner:CTRIP COMP TECH SHANGHAI

Production method of interconnection structure with materials containing polymer and metal through holes

InactiveCN102956540AReduce manufacturing stepsEasy to processSemiconductor/solid-state device manufacturingPolymer scienceInterconnection

The invention discloses a production method of an interconnection structure with materials containing polymer and metal through holes. The production method includes: reserving blind holes or through holes on a substrate, and filling polymer in the blind holes or through holes; inserting metal blocks into the blind holes or through holes filled with polymer; solidifying polymer in the blind holes or the through holes; and grinding and polishing the front and the back of the substrate to expose the metal. By the production method, the multilayer stack structure adopted in three-dimensional packaging or MEMS (micro-electro-mechanical systems) packaging can be achieved effectively.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

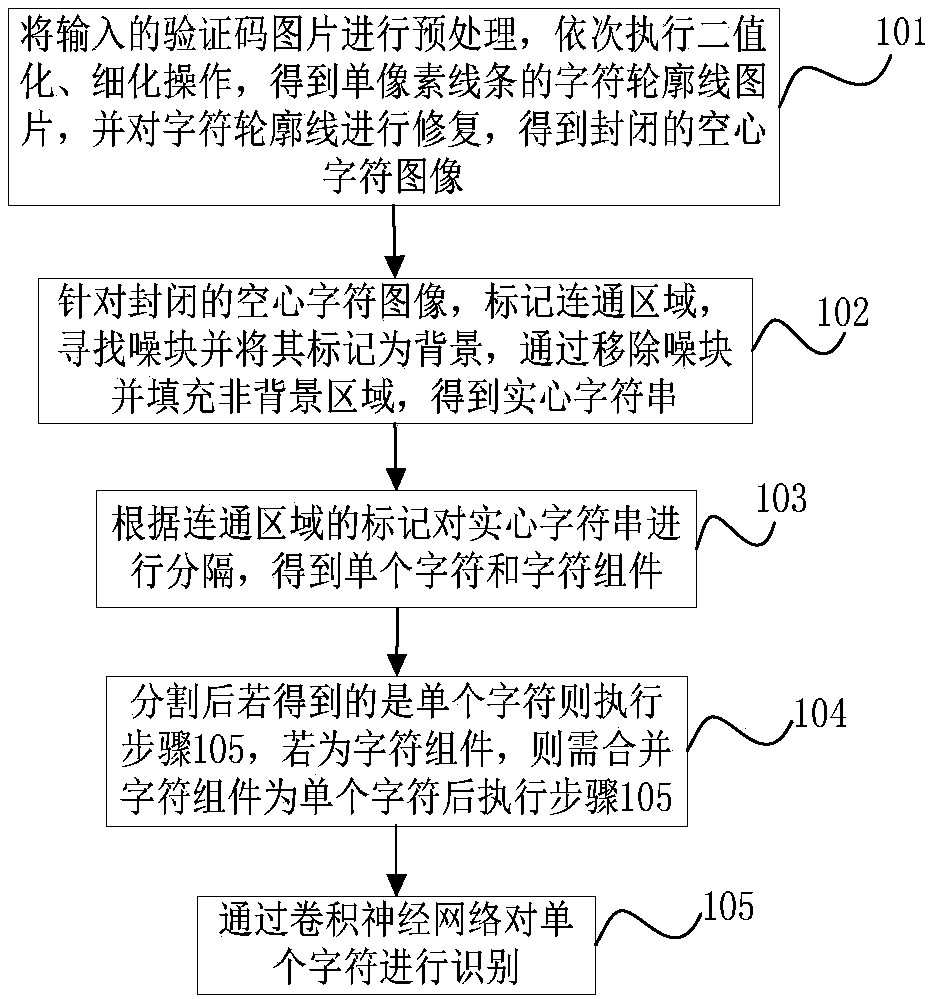

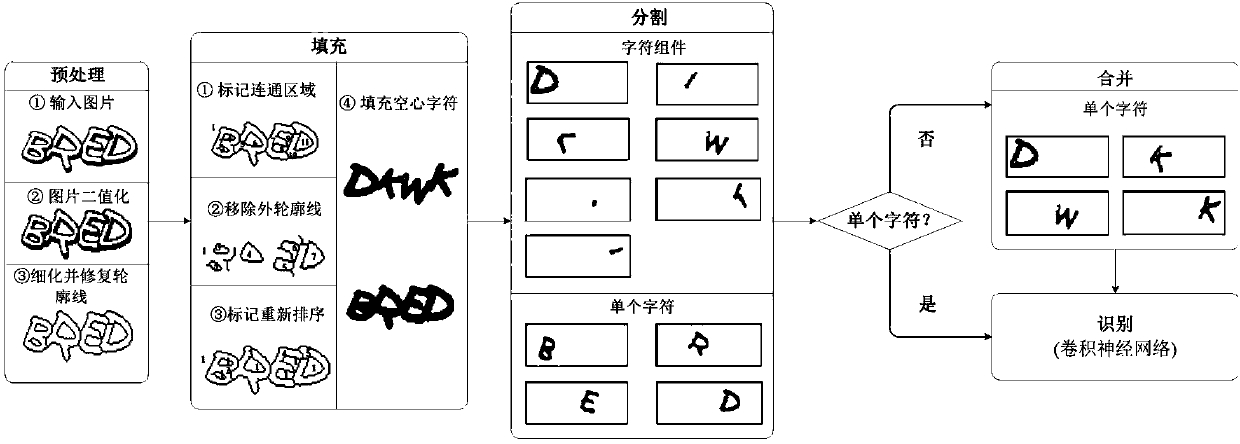

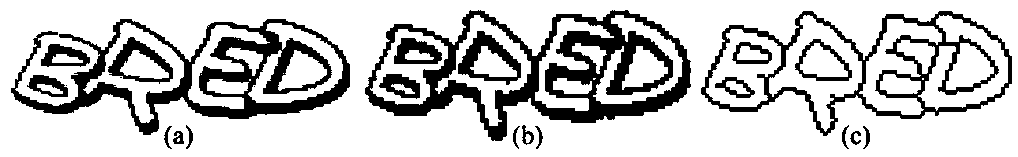

Method for rapidly identifying hollow verification code

ActiveCN108038484AQuick identificationAccurate identificationNeural architecturesNeural learning methodsRapid identificationNear neighbor

The invention belongs to the technical field of a verification code, and in particular relates to a method for rapidly identifying a hollow verification code. The method comprises the steps of firstly, thinning a character contour line of the verification code in a preprocessing stage; secondly, only filling a character block through inner and outer contour lines to obtain a solid character; thirdly, segmenting the solid character to obtain single characters and character components; fourthly, analyzing structural characteristics and order associations of the character components, and combining the character components by use of a minimum nearest neighbor algorithm to obtain the non-redundant single characters; and finally, identifying the single characters obtained after segmentation andcombination by use of a convolutional neural network to obtain a final deciphering result. According to the method for rapidly identifying the hollow verification code, compared with an existing identification method, not only is an original structure kept from being not damaged, but also breakages of the character contour lines are guaranteed to be accurately repaired, the filling time can be shortened, the filling precision can be improved, accurate acquisition and rapid identification of the hollow identification code are realized, the identification success rate is greatly improved, the applicability is high and better application values are provided.

Owner:PLA STRATEGIC SUPPORT FORCE INFORMATION ENG UNIV PLA SSF IEU

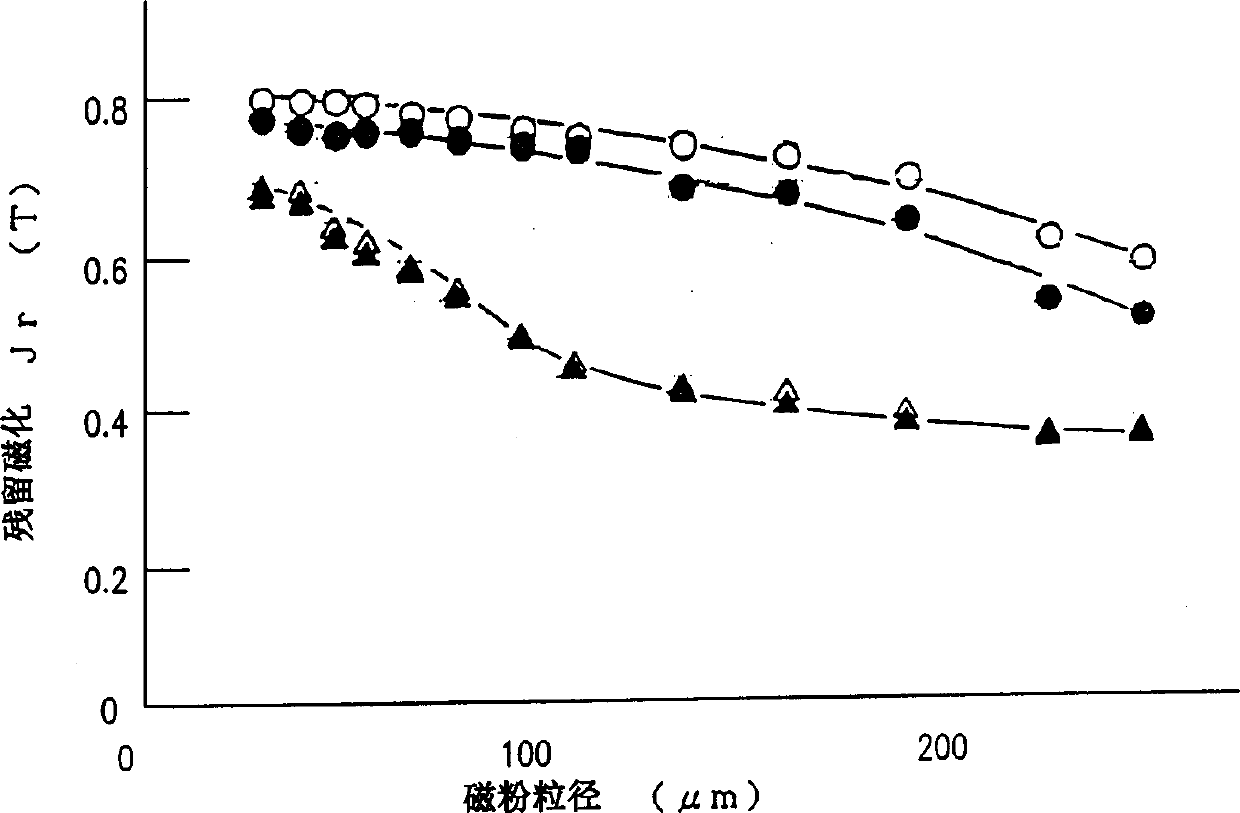

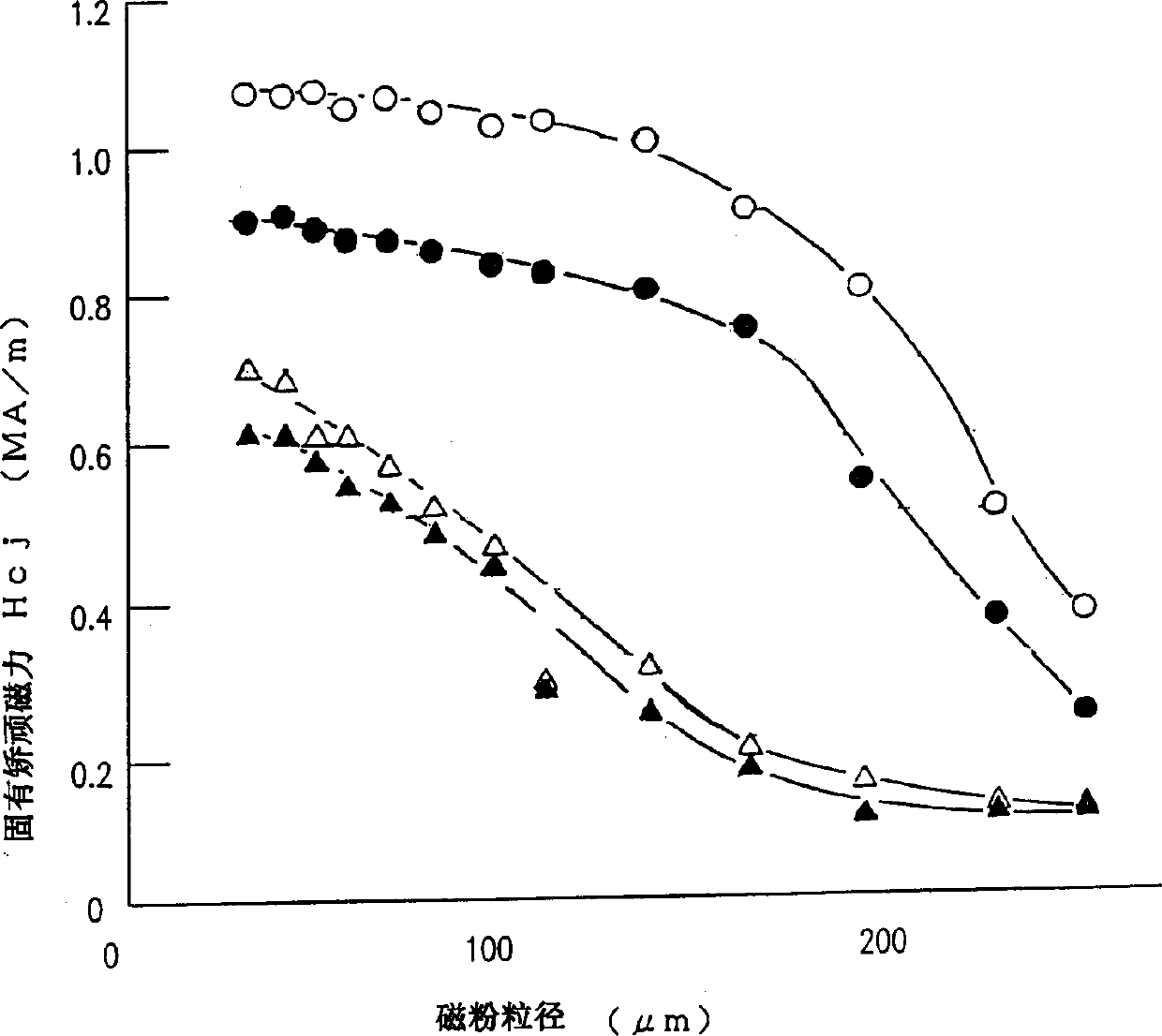

Magnetic alloy powder for permanent magnet and mfg. method thereof

InactiveCN1360316AImprove cooling effectImprove liquidityInorganic material magnetismRare-earth elementNon oxidative

To mass-produce alloyed rare-earth magnetic powder having high coercive force by using the gas atomization method. Spherical powder is formed by spraying molten alloyed pig iron containing R (R is at least one kind of rare-earth elements including Y.) of >=20 wt.% and <=40 wt.%, T (T is a transition metal including Fe as the main component.) of >=60 wt.% and <=79 wt.%, and Q (Q is an element including B (boron) and C (carbon)) of >=0.5 wt.% and <=2.0 wt.%, in the non-oxidative atmosphere, and the shape of particles of the powder is substantially spherical. After that, the spherical powder is heat-treated at a temperature of >=500 deg.C and <=800 deg.C.

Owner:SUMITOMO SPECIAL METAL CO LTD

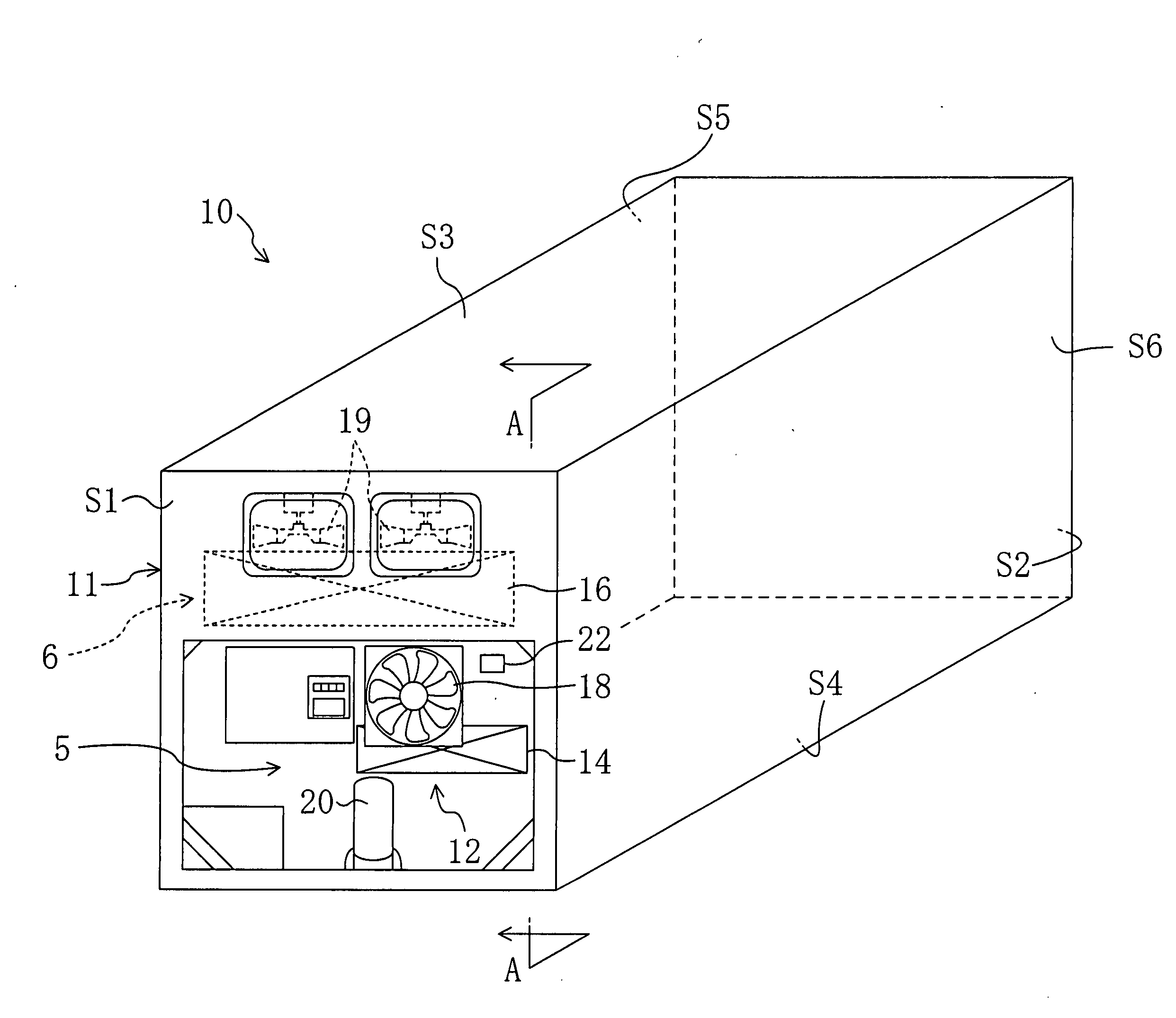

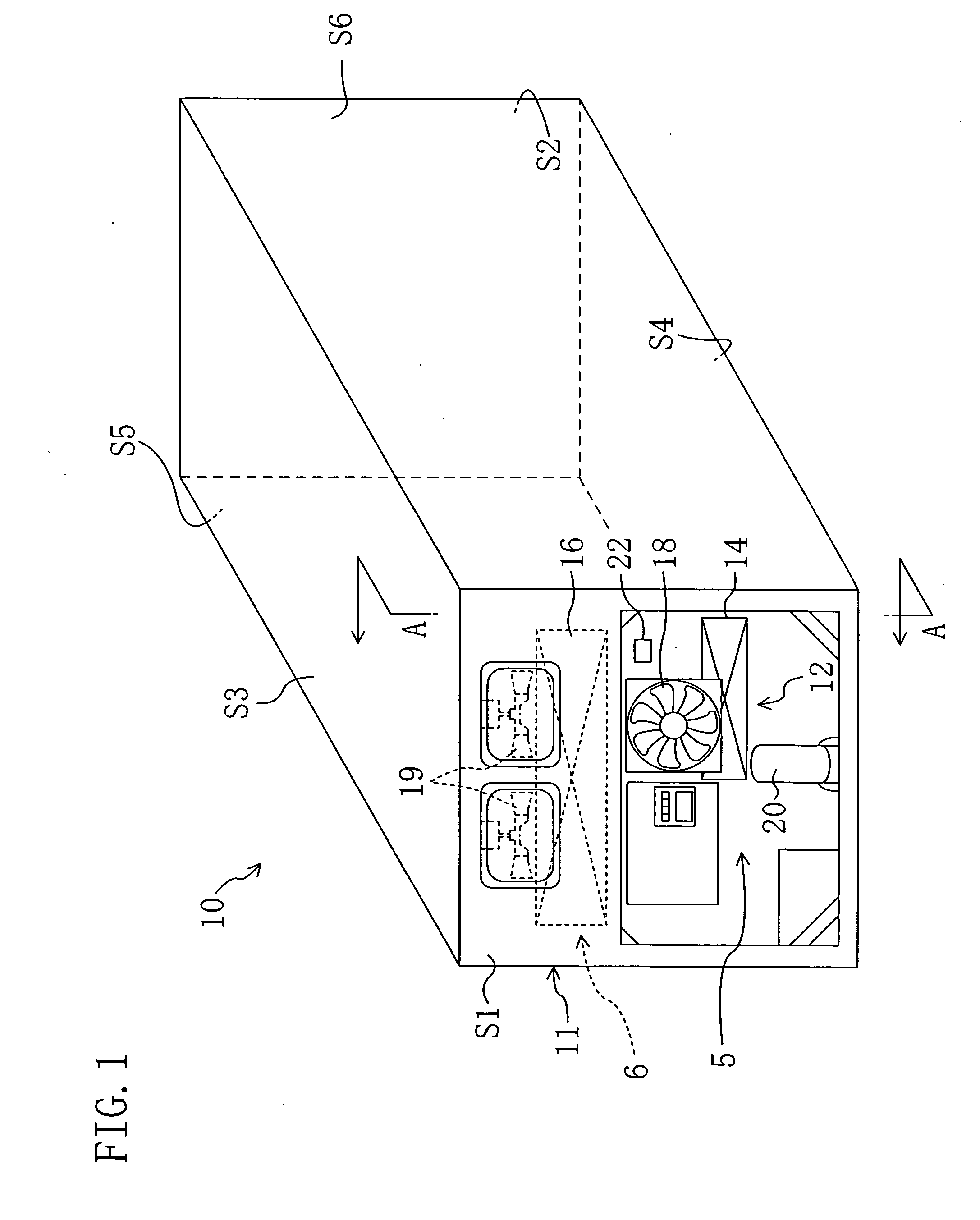

Casing Structure for Refrigeration System and Sealing Method for Refrigeration System Casing

InactiveUS20090133420A1Improve air tightnessPrevent materialPipesCompression machines with non-reversible cycleEngineeringSealant

A casing (11) for use in a freezing container is provided with a through hole (H) for insertion of the piping of a refrigerant circuit therethrough. Each opening end of the through hole (H) is covered over with a respective mesh sheet (31, 32). With each opening end of the through hole (H) covered over with the mesh sheet (31, 32), the tip end of a filling nozzle (33) is inserted until it reaches the middle of the through hole (H) and a sealant material is injected. The injected sealant material is held back within the through hole (H) by each mesh sheet (31, 32) and, with the progress of the injection of the sealant material, the air present in the through hole (H) is purged out through each mesh sheet (31, 32).

Owner:DAIKIN IND LTD

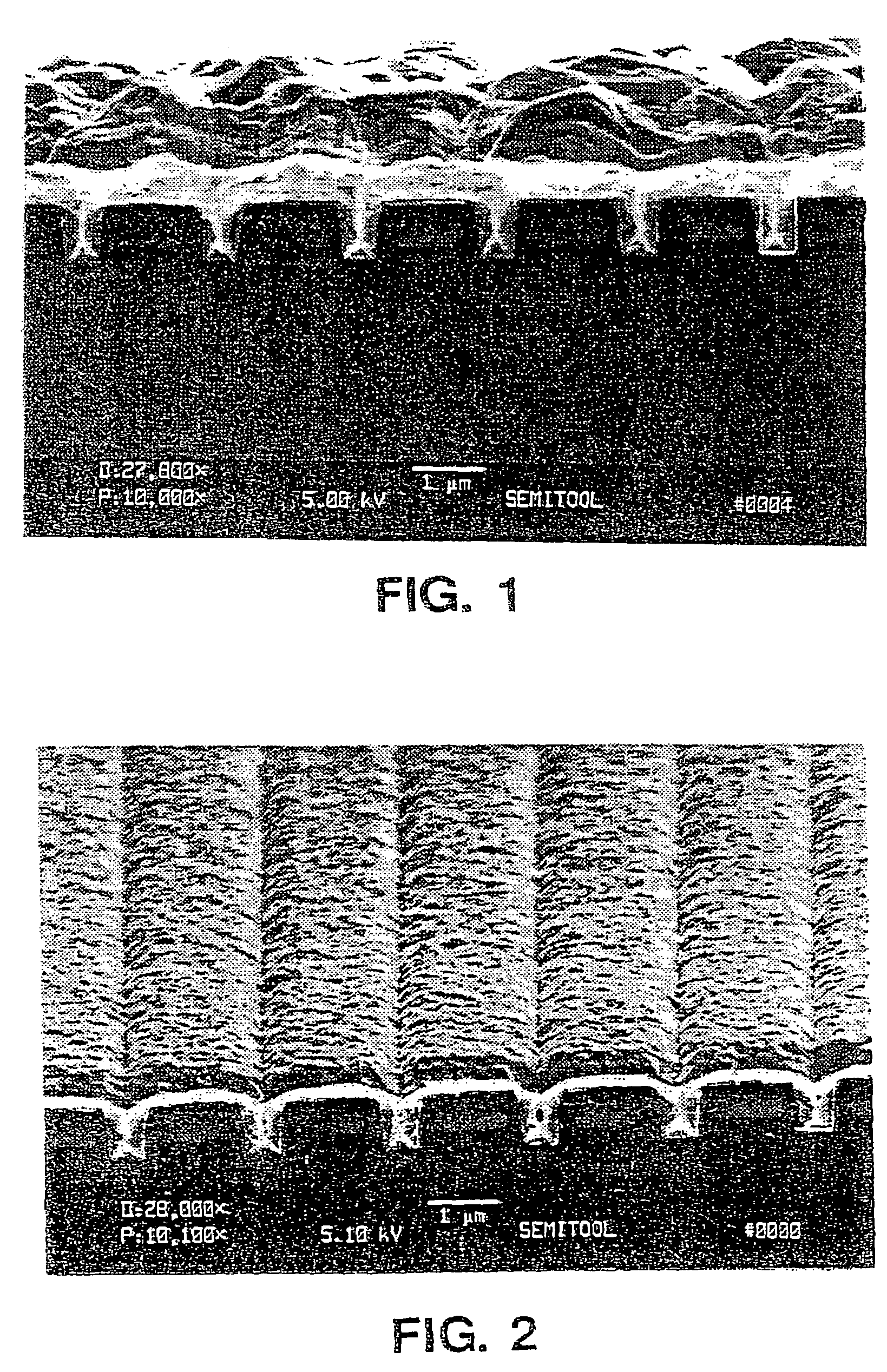

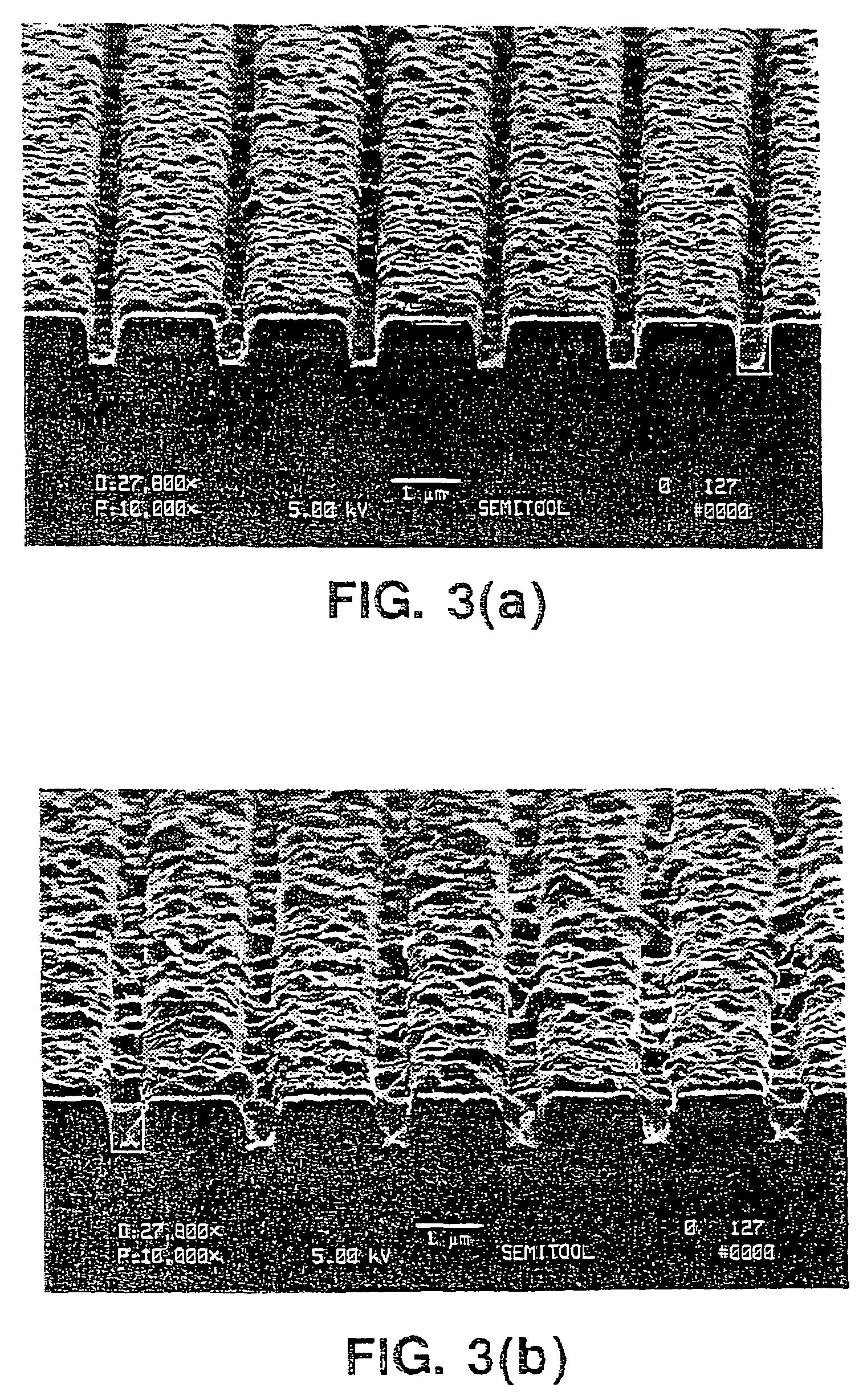

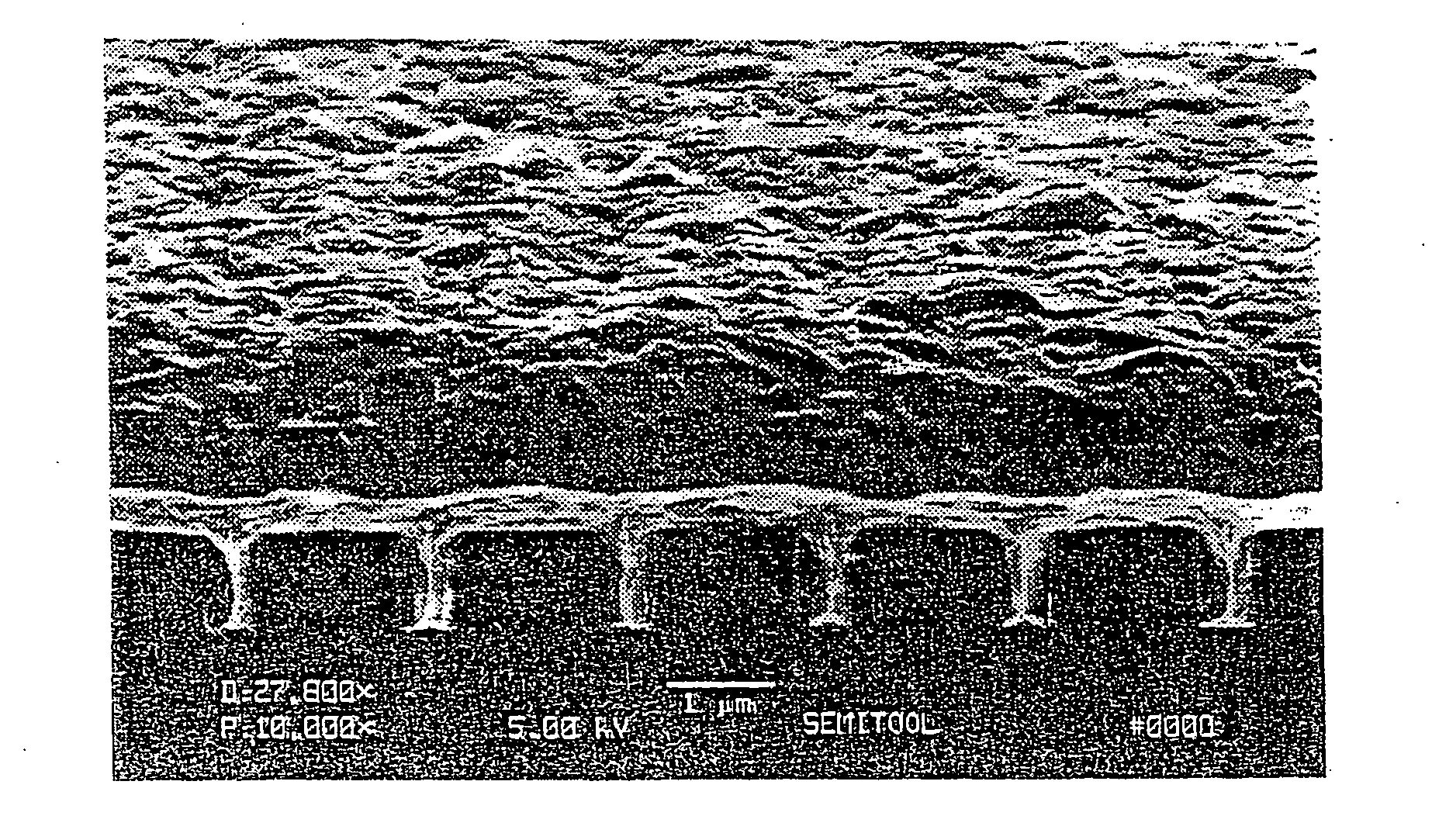

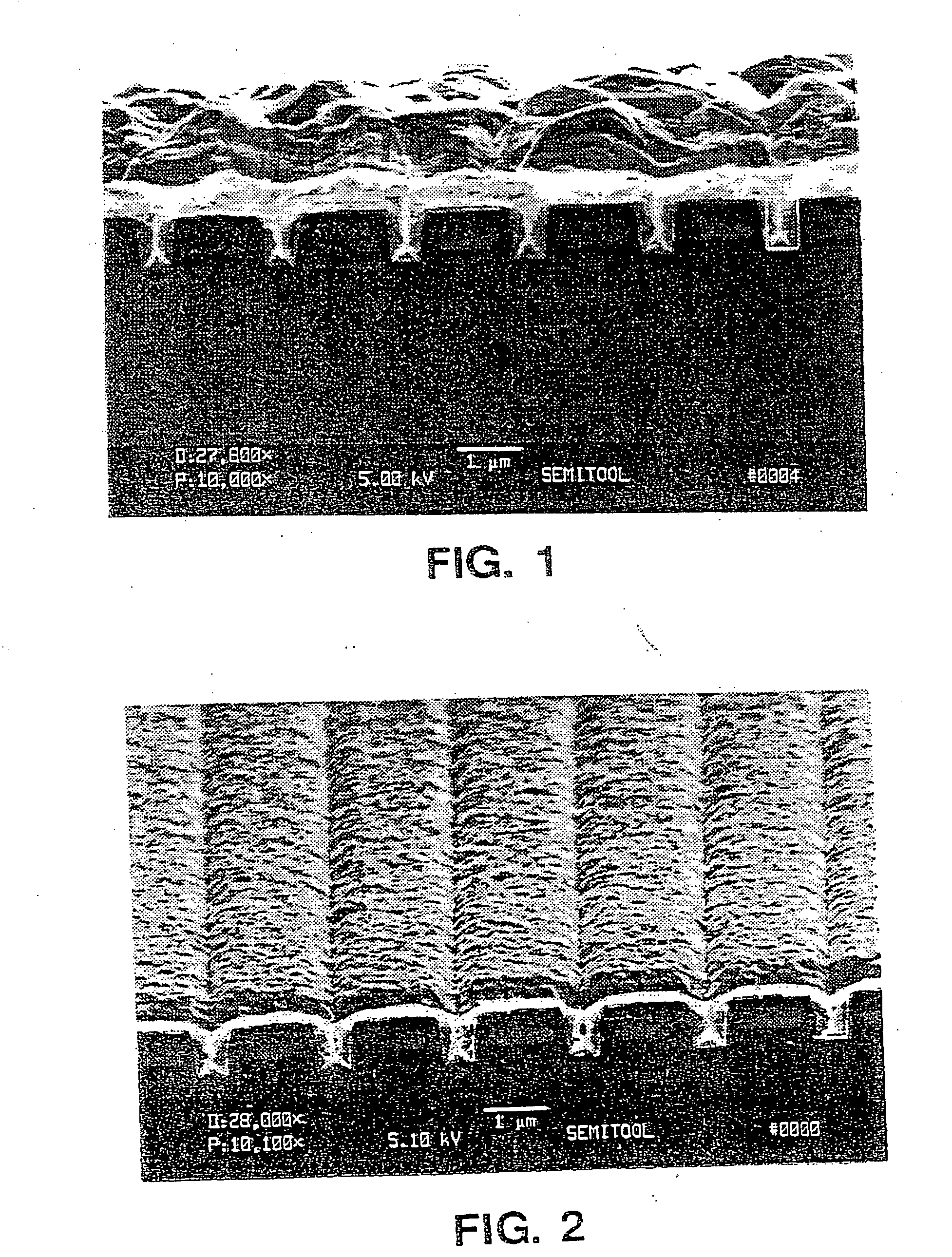

Method of submicron metallization using electrochemical deposition of recesses including a first deposition at a first current density and a second deposition at an increased current density

InactiveUS7144805B2Promote resultsShorten filling timeSemiconductor/solid-state device manufacturingPrinted circuit manufactureElectricityCombined use

Methods for depositing a metal into a micro-recessed structure in the surface of a microelectronic workpiece are disclosed. The methods are suitable for use in connection with additive free as well as additive containing electroplating solutions. In accordance with one embodiment, the method includes making contact between the surface of the microelectronic workpiece and an electroplating solution in an electroplating cell that includes a cathode formed by the surface of the microelectronic workpiece and an anode disposed in electrical contact with the electroplating solution. Next, an initial film of the metal is deposited into the micro-recessed structure using at least a first electroplating waveform having a first current density. The first current density of the first electroplating waveform is provided to enhance the deposition of the metal at a bottom of the micro-recessed structure. After this initial plating, deposition of the metal is continued using at least a second electroplating waveform having a second current density. The second current density of the second electroplating waveform is provided to assist in reducing the time required to substantially complete filling of the micro-recessed structure.

Owner:SEMITOOL INC

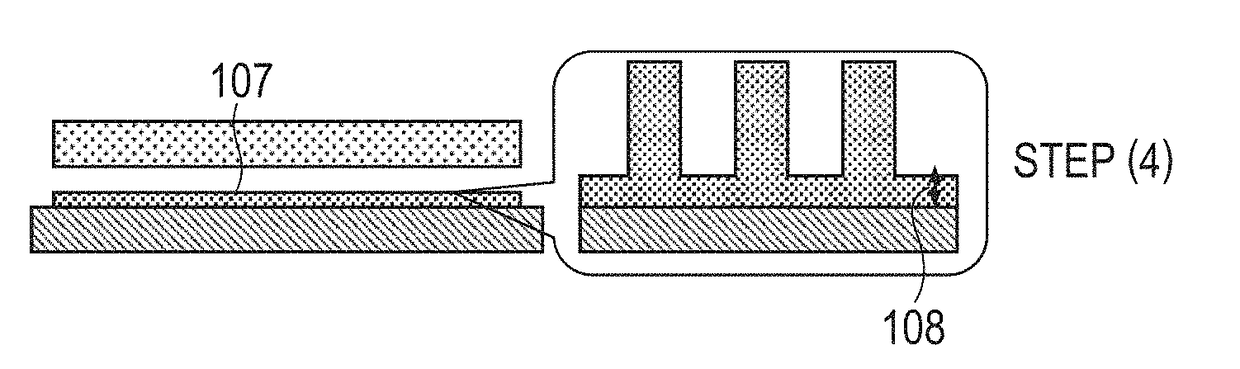

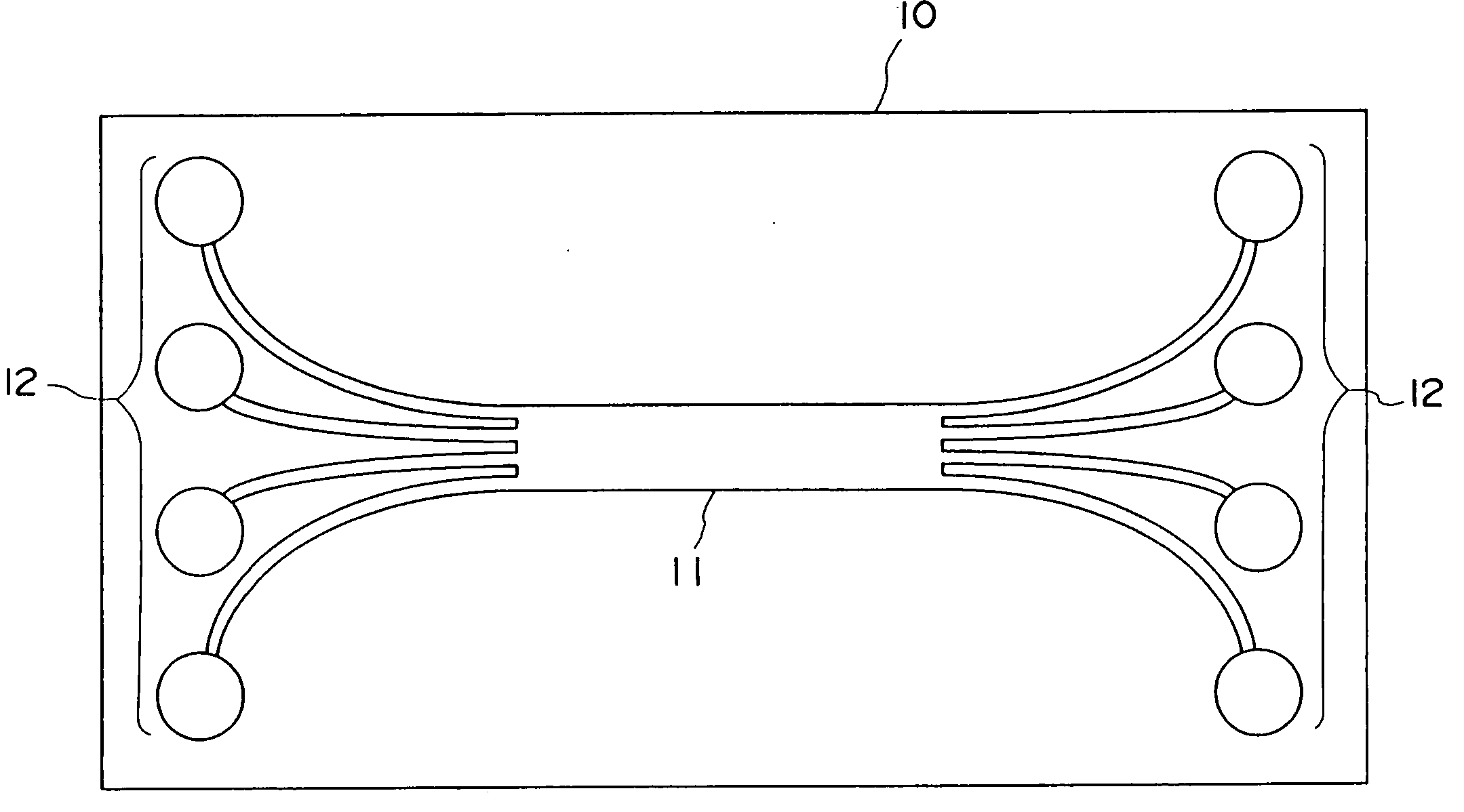

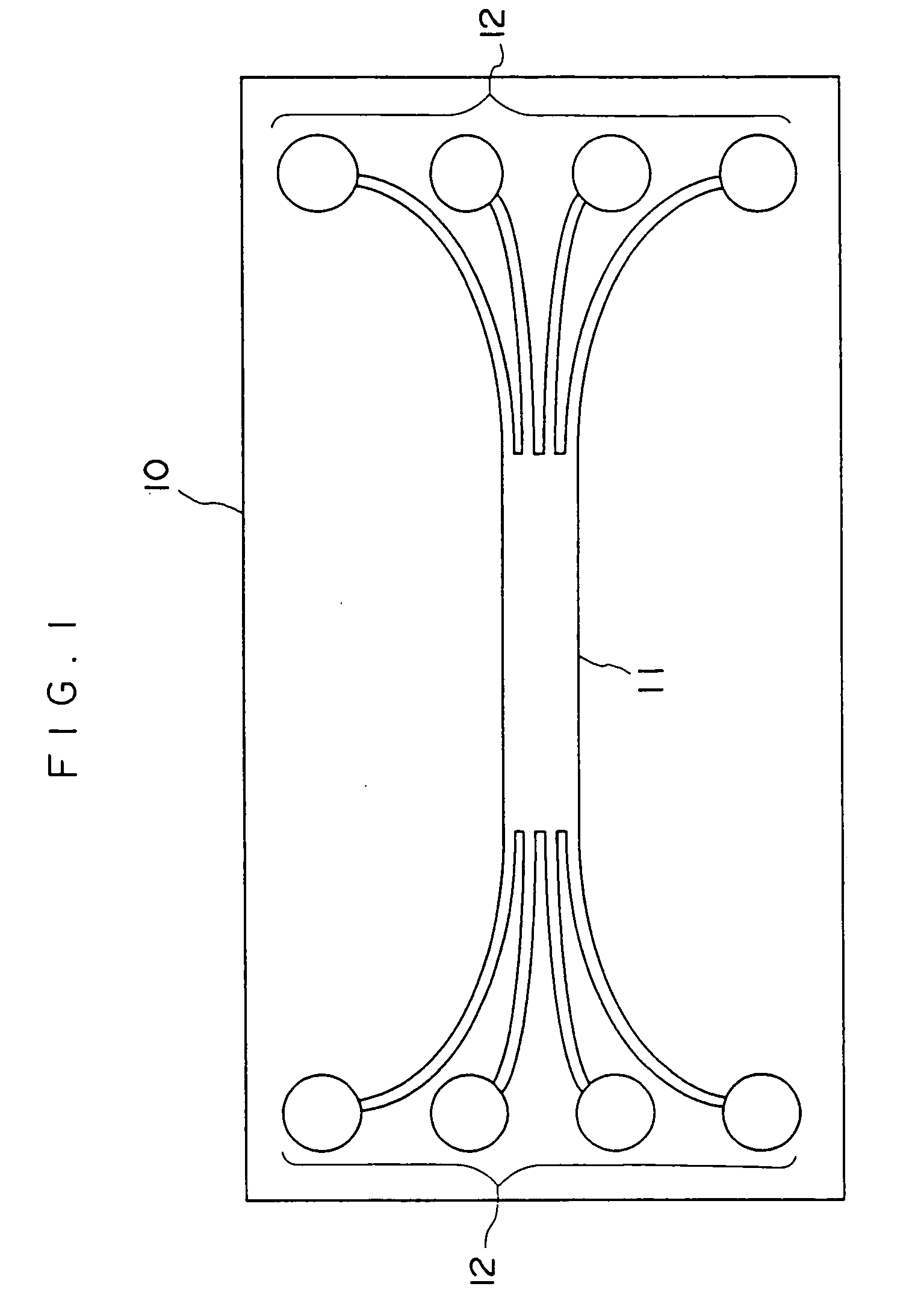

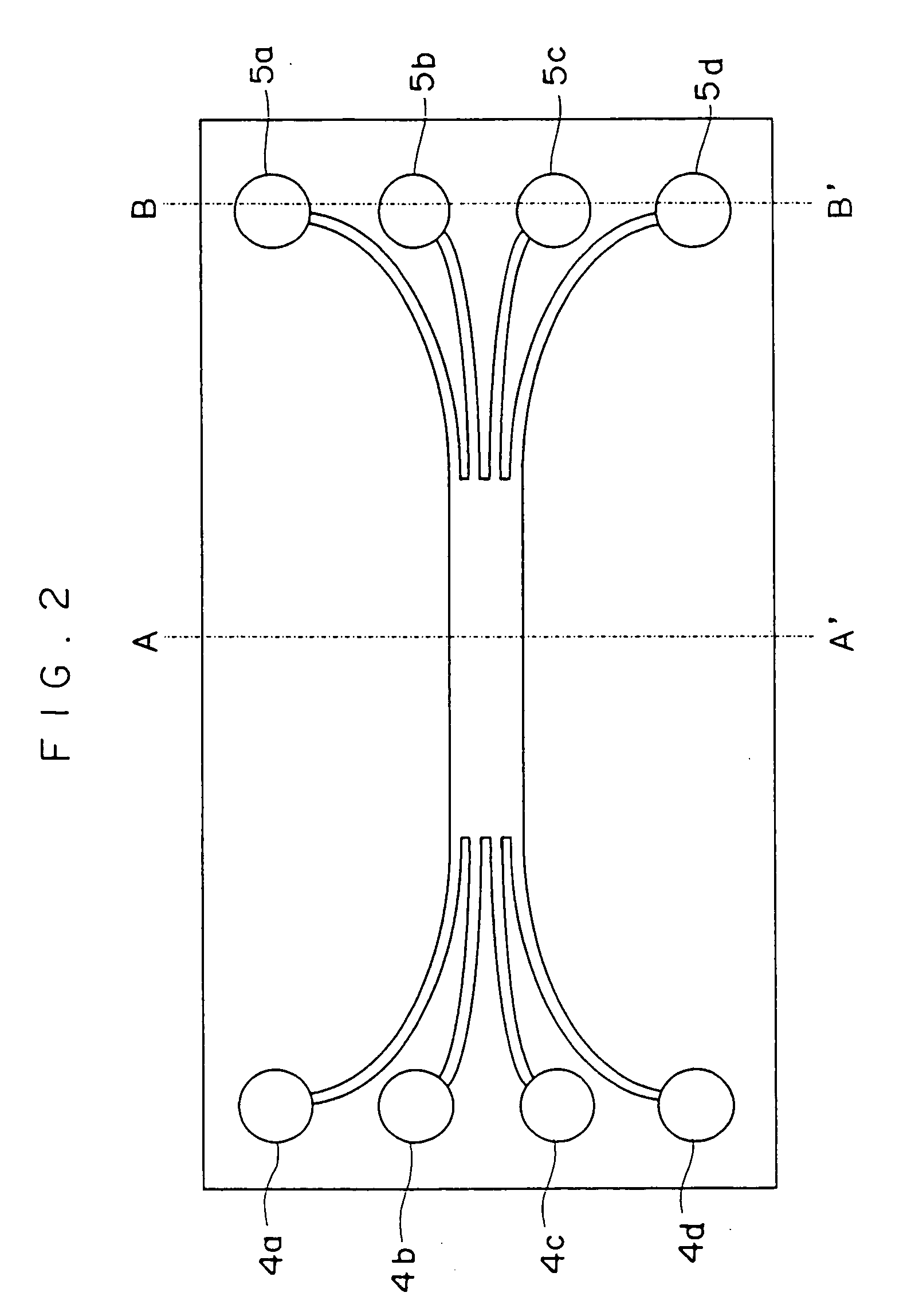

Method for producing polymeric optical waveguide and device for producing the same

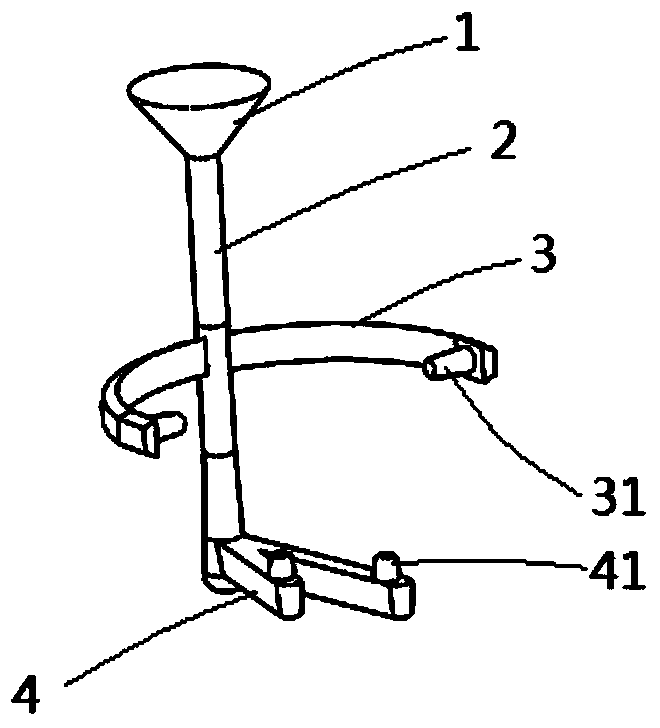

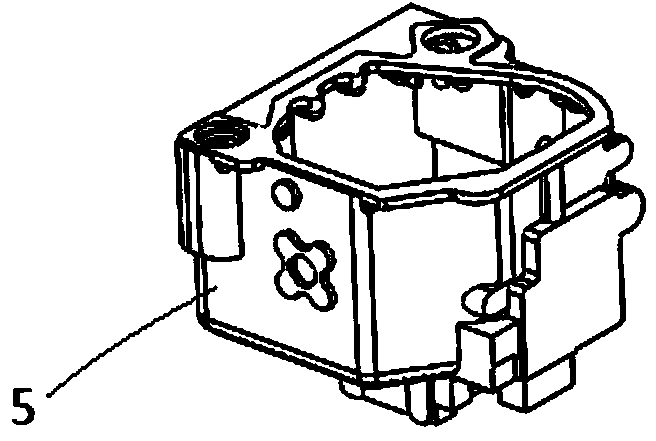

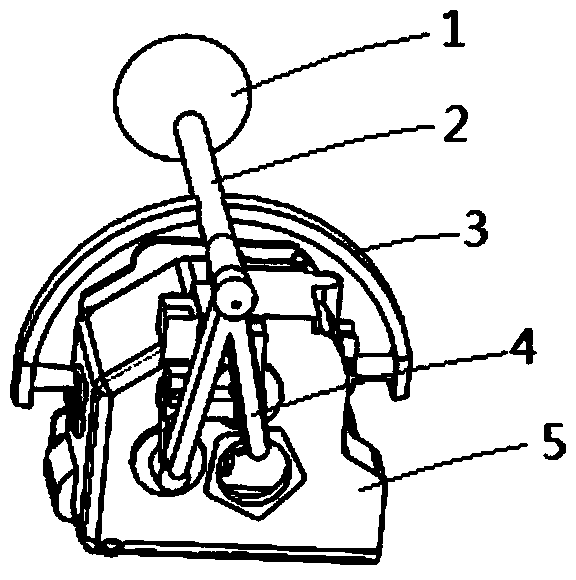

InactiveUS20050017383A1Reduced waveguide loss and insertion lossShorten filling timeConfectioneryOptical articlesWaveguidePolymer

The present invention relates to a method for producing a polymeric optical waveguide, comprising: preparing a mold having, on a surface thereof, a branched concave portion for forming a core; bringing a clad substrate into close contact with the surface of the mold having the branched concave portion; filling the branched concave portion with a core-forming curable resin by supplying and sucking the core-forming curable resin from one end of the branched concave portion into the branched concave portion toward another end of the branched concave portion which is provided opposite the one end while the remaining ends of the branched concave portion are closed, by opening the closed ends, and by sucking the core-forming curable resin into portions communicating with the opened ends; and curing the core-forming curable resin; and a production device used for the above method.

Owner:FUJIFILM BUSINESS INNOVATION CORP

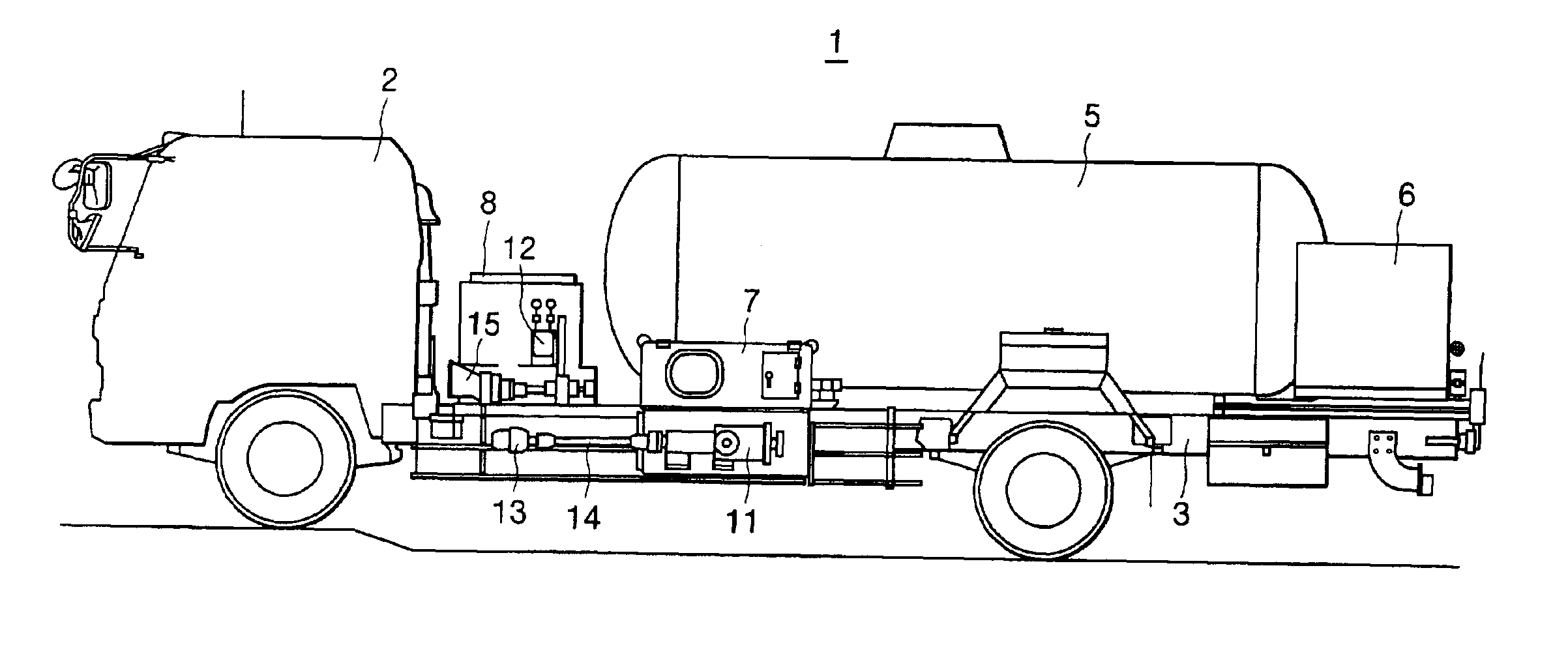

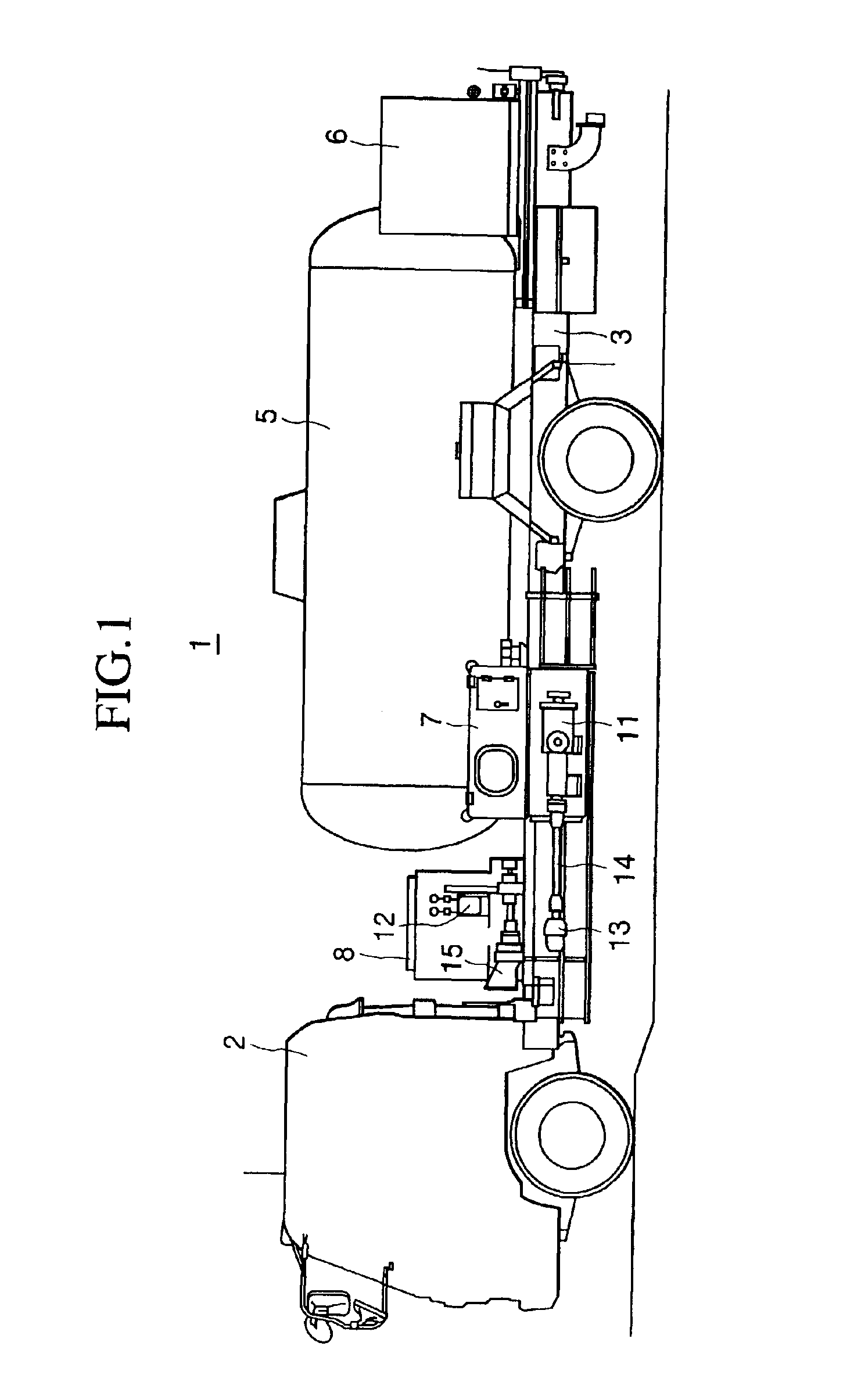

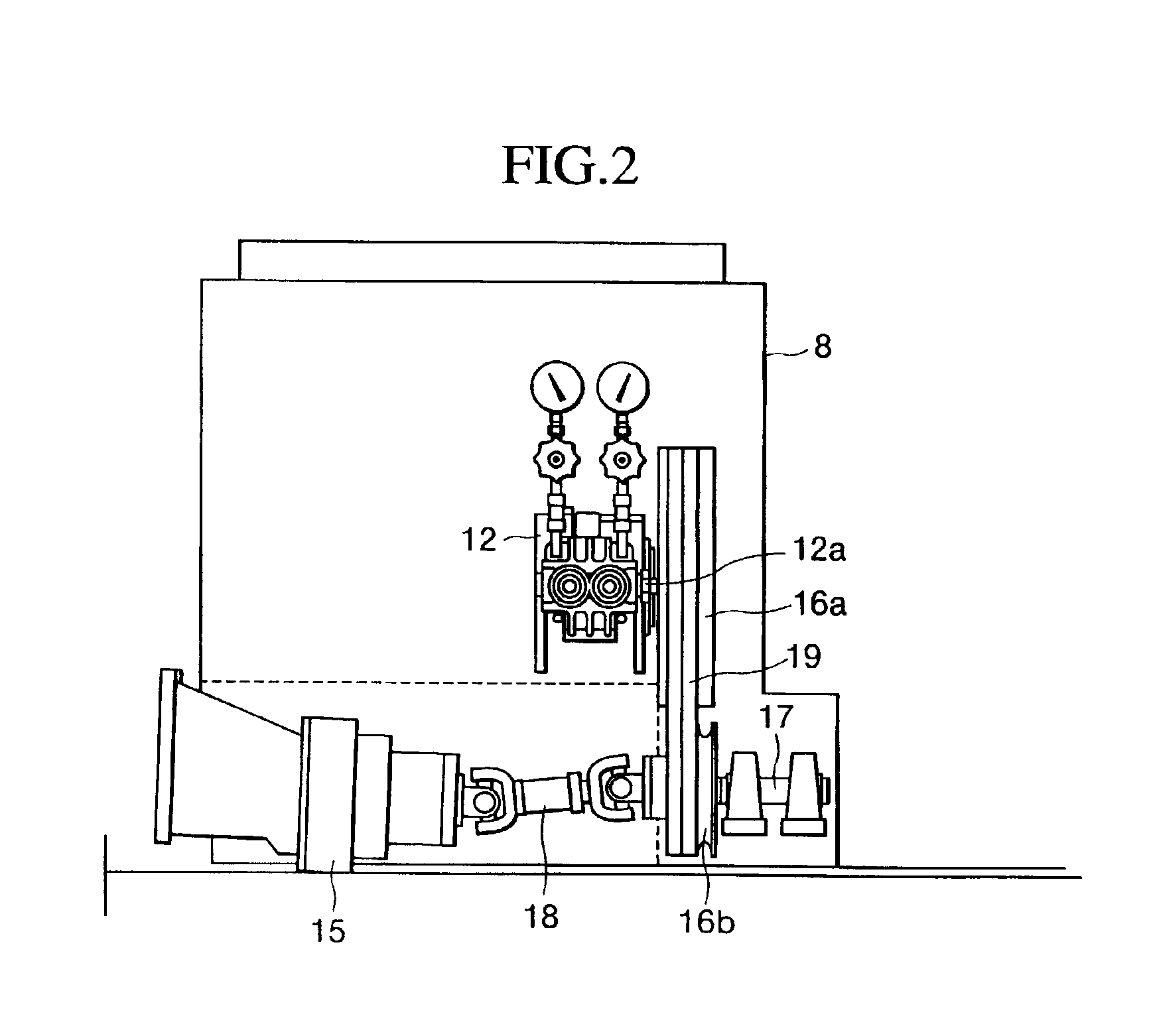

High-speed bulk filling tank truck

InactiveUS6889728B2Shorten filling timeSend efficientlyTank vehiclesPipeline systemsLiquid lineGas compressor

A high-speed bulk filling tank truck is provided, which permits reduction of the filling time. The high-speed bulk filling tank truck delivers a liquefied gas in a truck tank to a bulk storage tank, and recovers a gas-phase gas in the bulk storage tank into the truck tank, thereby filling the bulk storage tank with the liquefied gas. The high-speed bulk filling tank truck includes a liquid feed pump, provided on a liquid line through which the liquefied gas flows, for feeding the liquefied gas in the truck tank to the bulk storage tank, and a gas compressor, provided on the gas line through which a gas-phase gas flows, for compressing the gas-phase gas in the bulk storage tank and delivering the same into the truck tank.

Owner:KOOA GASU KAGOSHIMA

Method of submicron metallization using electrochemical deposition of recesses including a first deposition at a first current density and a second deposition at an increased current density

InactiveUS20050051436A1Promote resultsShorten filling timeSemiconductor/solid-state device manufacturingPrinted circuit manufactureElectricityCombined use

Methods for depositing a metal into a micro-recessed structure in the surface of a microelectronic workpiece are disclosed. The methods are suitable for use in connection with additive free as well as additive containing electroplating solutions. In accordance with one embodiment, the method includes making contact between the surface of the microelectronic workpiece and an electroplating solution in an electroplating cell that includes a cathode formed by the surface of the microelectronic workpiece and an anode disposed in electrical contact with the electroplating solution. Next, an initial film of the metal is deposited into the micro-recessed structure using at least a first electroplating waveform having a first current density. The first current density of the first electroplating waveform is provided to enhance the deposition of the metal at a bottom of the micro-recessed structure. After this initial plating, deposition of the metal is continued using at least a second electroplating waveform having a second current density. The second current density of the second electroplating waveform is provided to assist in reducing the time required to substantially complete filling of the micro-recessed structure.

Owner:SEMITOOL INC

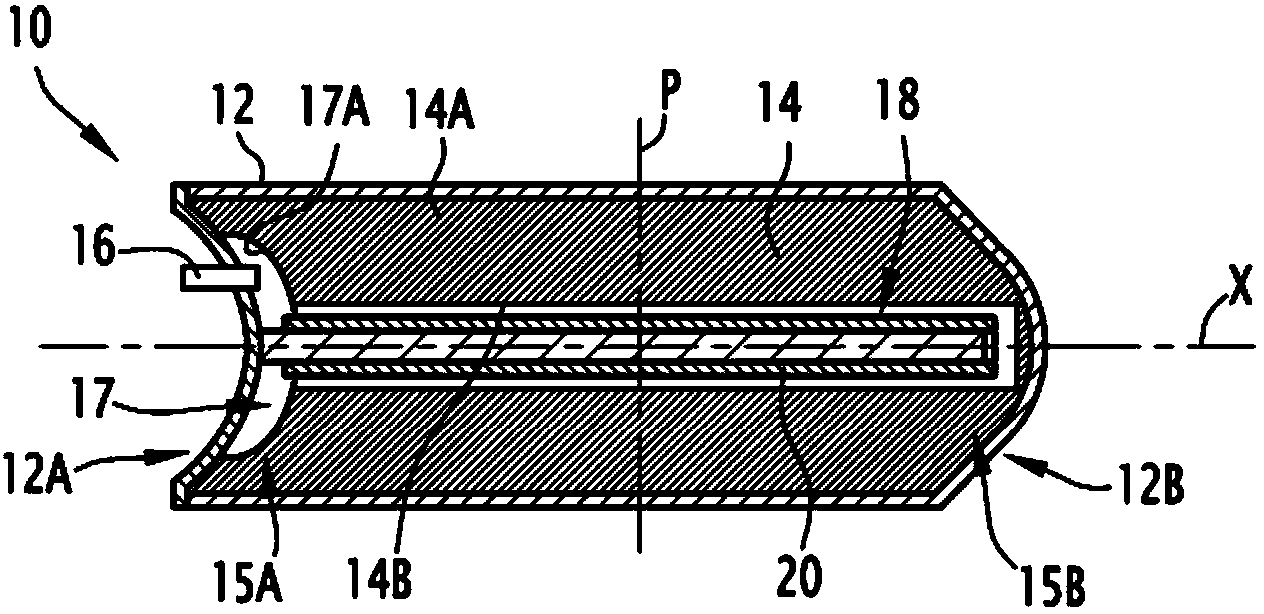

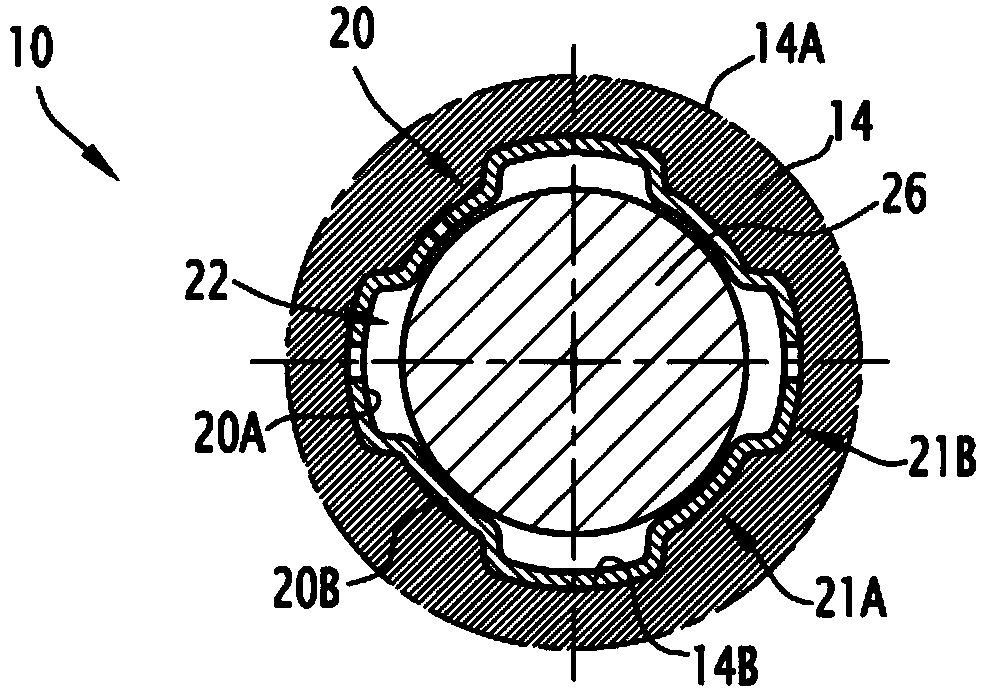

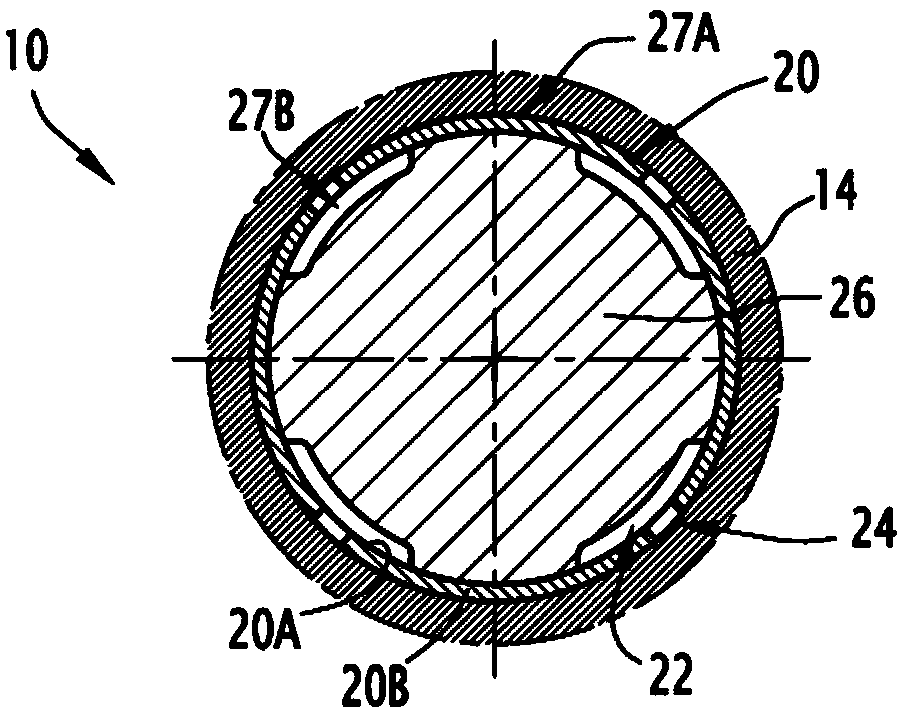

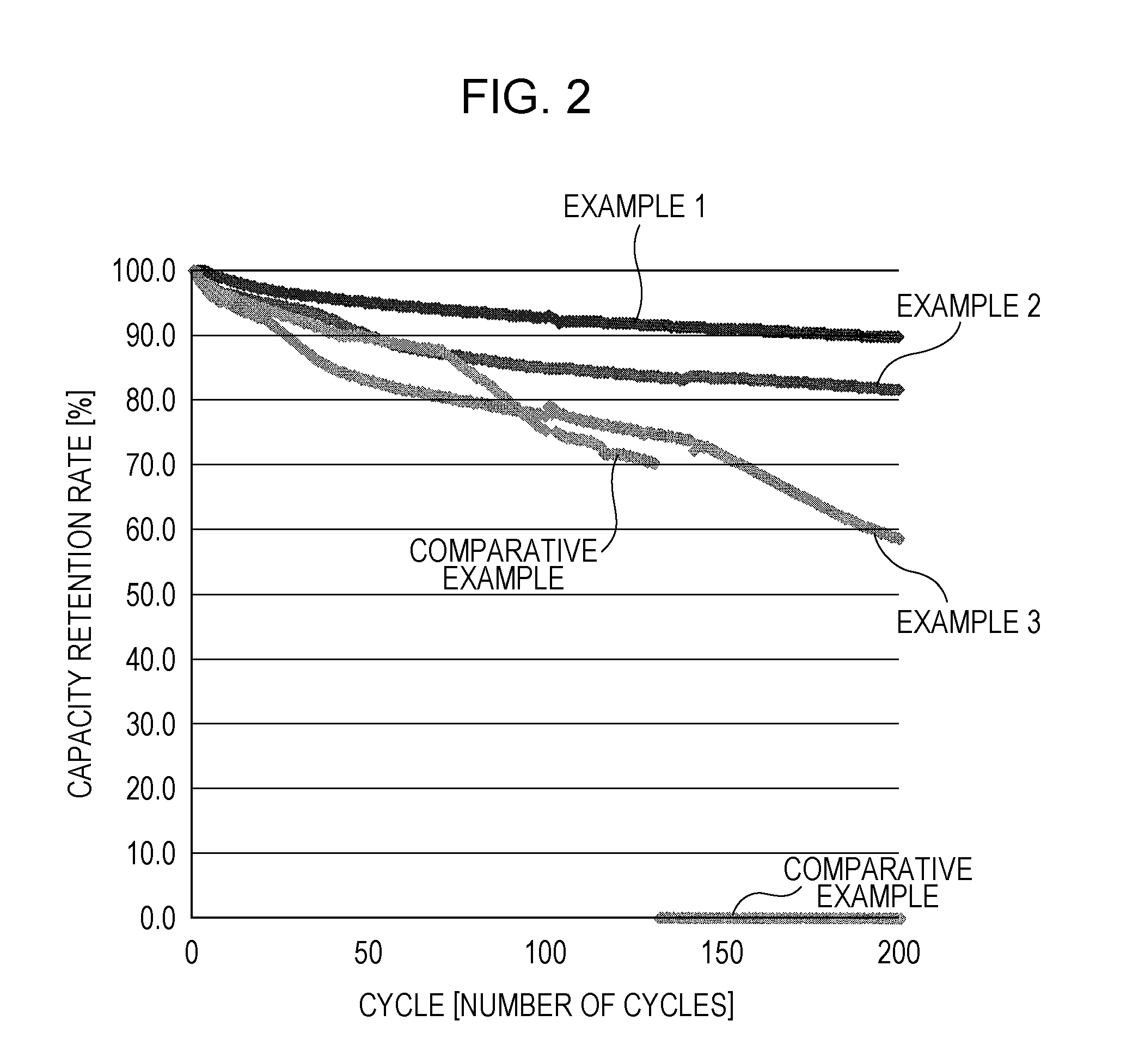

Nonaqueous secondary battery and filling method for same

InactiveUS20140023912A1Shorten filling timeReduce capacityFinal product manufactureElectrode carriers/collectorsEngineeringElectrolyte

At least one of holes is formed at a position that is at a higher level than a surface of an electrolyte in use of a nonaqueous secondary battery, and that is not overlapped with an electrode laminate.

Owner:SHARP KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com