Corrugated steel tube culvert filling structure and filling method thereof

A corrugated steel pipe and corrugated pipe technology is applied to the corrugated steel pipe culvert filling structure and the corrugated steel pipe culvert filling field, to achieve the effects of shortening the filling time, uniform stress and improving adverse effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

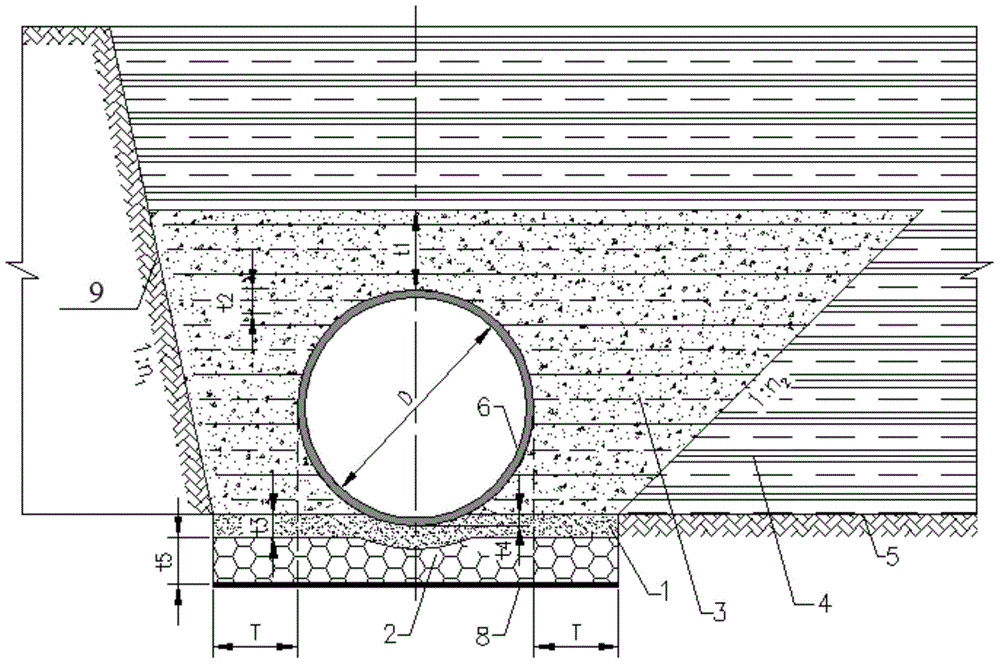

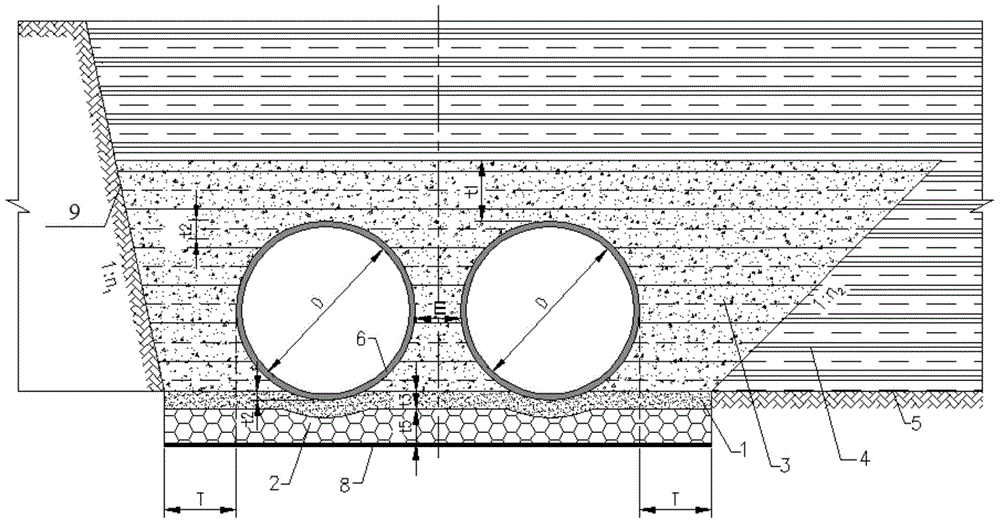

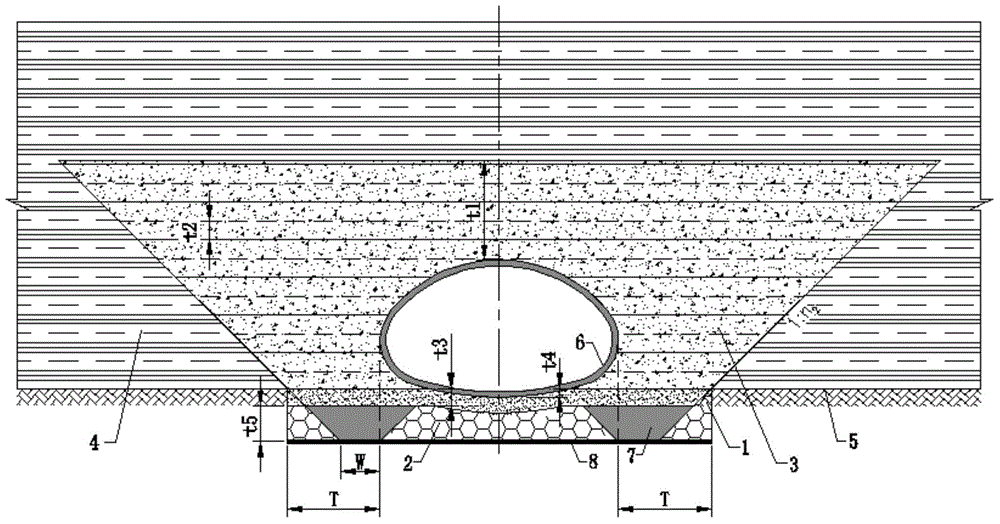

[0045] A corrugated steel pipe culvert filling structure, including a roadside backfill area 4 arranged on the ground 5, a structural backfill area 3 arranged in the roadside backfill area 4, and corrugated steel pipes arranged in the structural backfill area 3 6, and the corrugated steel pipe 6 is arranged on the sand cushion layer 1, the upper surface of the sand cushion layer 1 is flush with the ground, and the sand cushion layer 1 is provided with a depression matching the shape of the lower part of the corrugated steel pipe 6, and the sand cushion layer 1 is arranged on Substrate 2 on top.

[0046]The structural backfill area 3 includes backfill layers stacked in sequence, and the thickness of each backfill layer is 20-50 cm.

[0047] The bottom surface of the sub-base 2 is provided with a geotextile 8 .

[0048] The distance T that the sub-base layer 2 extends outward from the outermost side of the corrugated steel pipe is greater than 2m.

[0049] The corrugated steel...

Embodiment 2

[0055] When the substratum of the culvert is rock, the corrugated steel pipe is a round pipe, and the diameter is D=2m:

[0056] The thickness of the sand cushion layer 1 is t3=30cm, the thickness of the subbase layer 2 is t5=60cm, the top width of the subbase layer 2 is T=5m, and the height of the structural backfill area 3 above the top of the corrugated steel pipe 6 is t1=100cm. The particle size of the sand cushion layer 1 is not greater than 12 mm. The sub-base 2 is gravel, the particle size is not more than 37.5mm, the sub-base 2 should not be over-compacted, the compaction degree is between 85-90%, and the extension distance T of the sub-base is 2m. The structural backfill area 3 is filled in layers with a thickness of 20 cm for each layer, and the compaction degree is between 93% and 95%. Within the height of the structural backfill area, the road roller can run parallel to the culvert, and must not run within 150cm of the pipe side; above the height of the structural...

Embodiment 3

[0058] When the substratum of the culvert is a swamp, the corrugated steel pipe is a round pipe, and the diameter is D=6m:

[0059] The thickness of sand cushion layer 1 is t3=30cm, the thickness of subbase layer 2 is t5=80cm, the top width of subbase layer 2 is T=10m, the height of structural backfill area 3 above the top of corrugated steel pipe 6 is t1=100cm, and the particle size of sand cushion layer 1 is different. greater than 12mm. The sub-base 2 is gravel, the particle size is not more than 37.5mm, the sub-base 2 should not be over-compacted, and the compaction degree is between 85-90%. Geotextiles are laid within the range of the lower surface D of the sub-base 2, and the extension distance T of the sub-base is 2m. . Structural backfill area 3 is sand and gravel, and the thickness of each layer is 40cm. The compaction degree is between 93 and 95%. Within the height range of the structural backfill area 3, the road roller can run parallel to the culvert, and shall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com