Reactor filled with solid particle and gas-phase catalytic oxidation with the reactor

a gas-phase catalytic oxidation and reactor technology, which is applied in the direction of indirect heat exchangers, lighting and heating apparatus, carboxylic compound preparation, etc., can solve the problems of difficult to coincide the pressure drop of the measuring reaction tube with that of the non-measuring reaction tube, and the heat-efficiency is not reduced to achieve cooling or heating,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

referential example 1

Production of Upstream Catalyst

[0106] In 150 liters of purified water kept heated and stirred, 100 kg of ammonium molybdate, 6.3 kg of ammonium paratungstate, and 13.7 kg of nickel nitrate were dissolved. To the resultant solution, an aqueous nitrate solution prepared by mixing a solution of 68.7 kg of cobalt nitrate in 100 liters of purified water, a solution of 19 kg of ferric nitrate in 30 liters of purified water, and a solution of 27.5 kg of bismuth nitrate in 30 liters of purified water incorporating therein 6 liters of concentrated nitric acid was added dropwise. Then, a solution of 14.2 kg of an aqueous 20 wt. % silica sol solution and 0.29 kg of potassium nitrate in 15 liters of purified water was added. The suspension thus obtained was heated and stirred till vaporization to dryness and then dried and pulverized. The produced powder was molded into cylinders 5 mm.+-.10% in diameter and 7 mm.+-.10% in length and calcined as swept with air at 460.degree. C. for six hours to ...

referential example 2

Production of Downstream Catalyst

[0107] In 500 liters of purified water kept heated and stirred, 100 kg of ammonium molybdate, 12.7 kg of ammonium paratungstate, and 27.6 kg of ammonium metavanadate were dissolved. To the resultant solution, a solution of 20.5 kg of copper nitrate and 1.4 kg of antimony trioxide in 50 liters of purified water were added. This mixed solution and 350 kg of a silica-alumina carrier having an average particle diameter of 5 mm .+-.10% were evaporated together to dryness to have a catalytic component deposited on the carrier and then calcined at 400.degree. C. for six hours to afford a catalyst. The catalyst in a required amount was obtained by repeating this process. This catalyst had this molar composition: Mo 12, V 5.0, W 1.0, Cu 2.2, Sb 0.2.

Inert Particle

[0108] Raschig rings of stainless steel having 6 mm.+-.0.5 mm in outer diameter, and 6 mm.+-.0.5 mm in length (available from IWAO JIKI K.K. in Japan) are used as the inert particle.

example 1

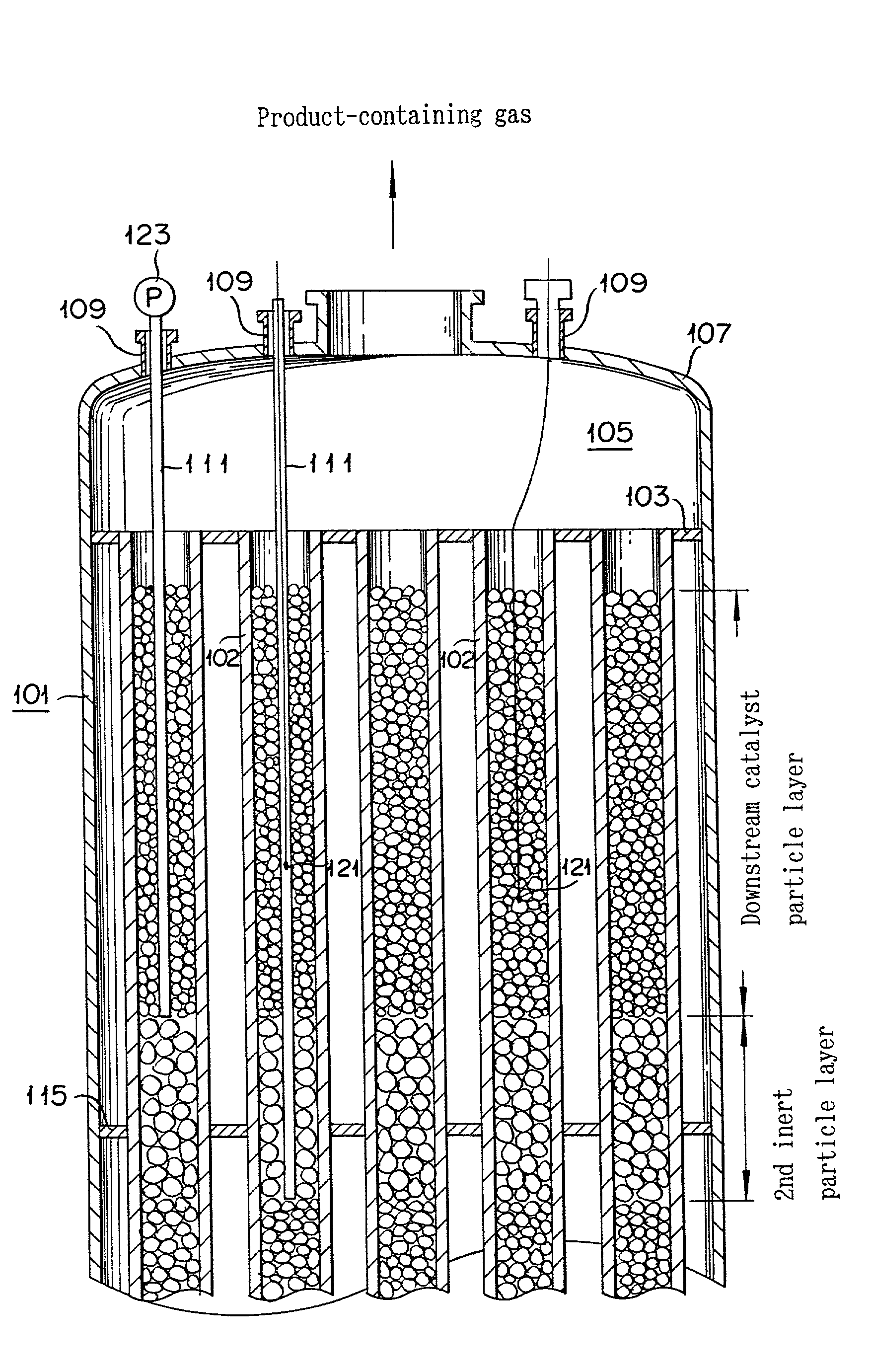

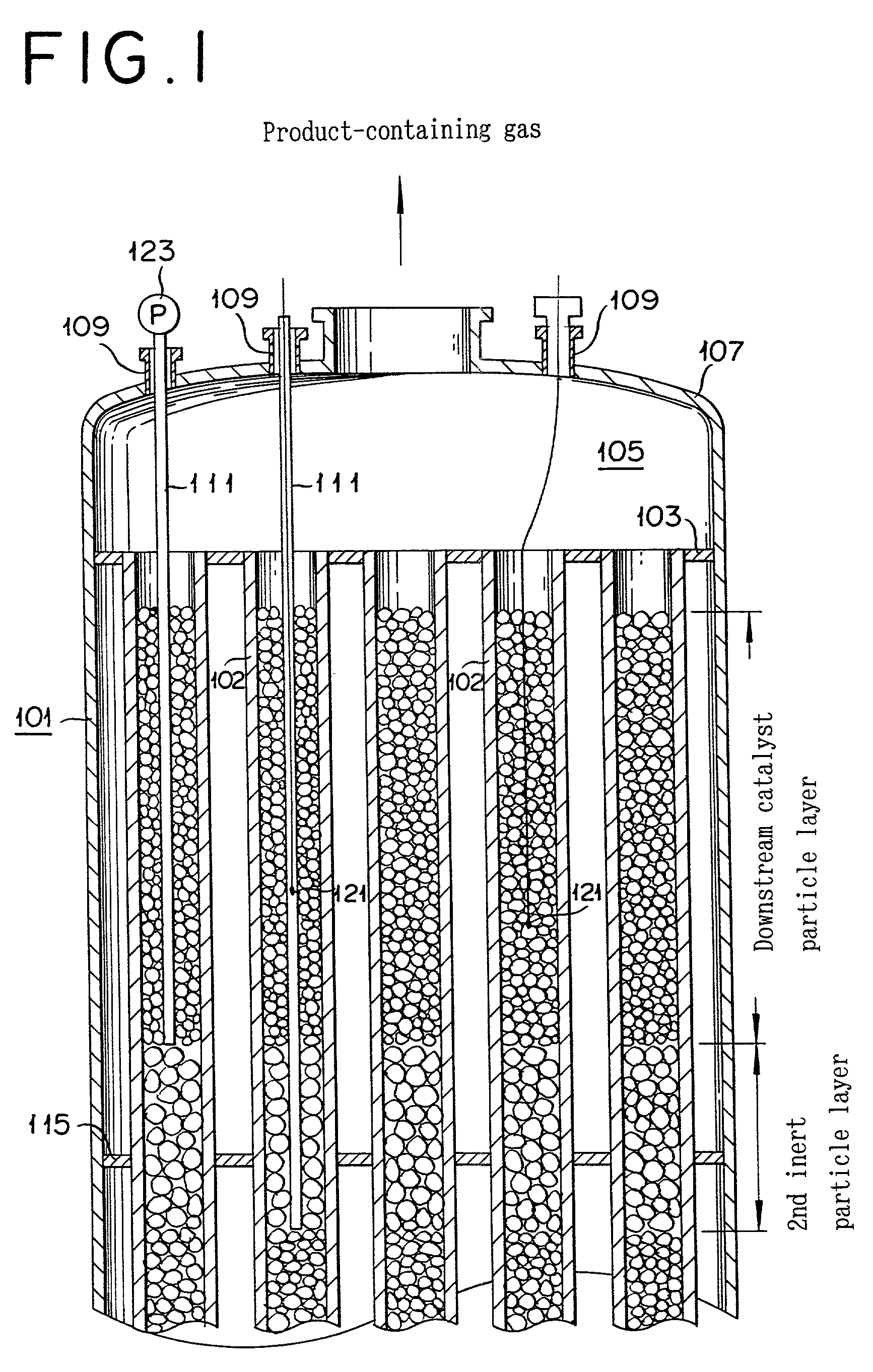

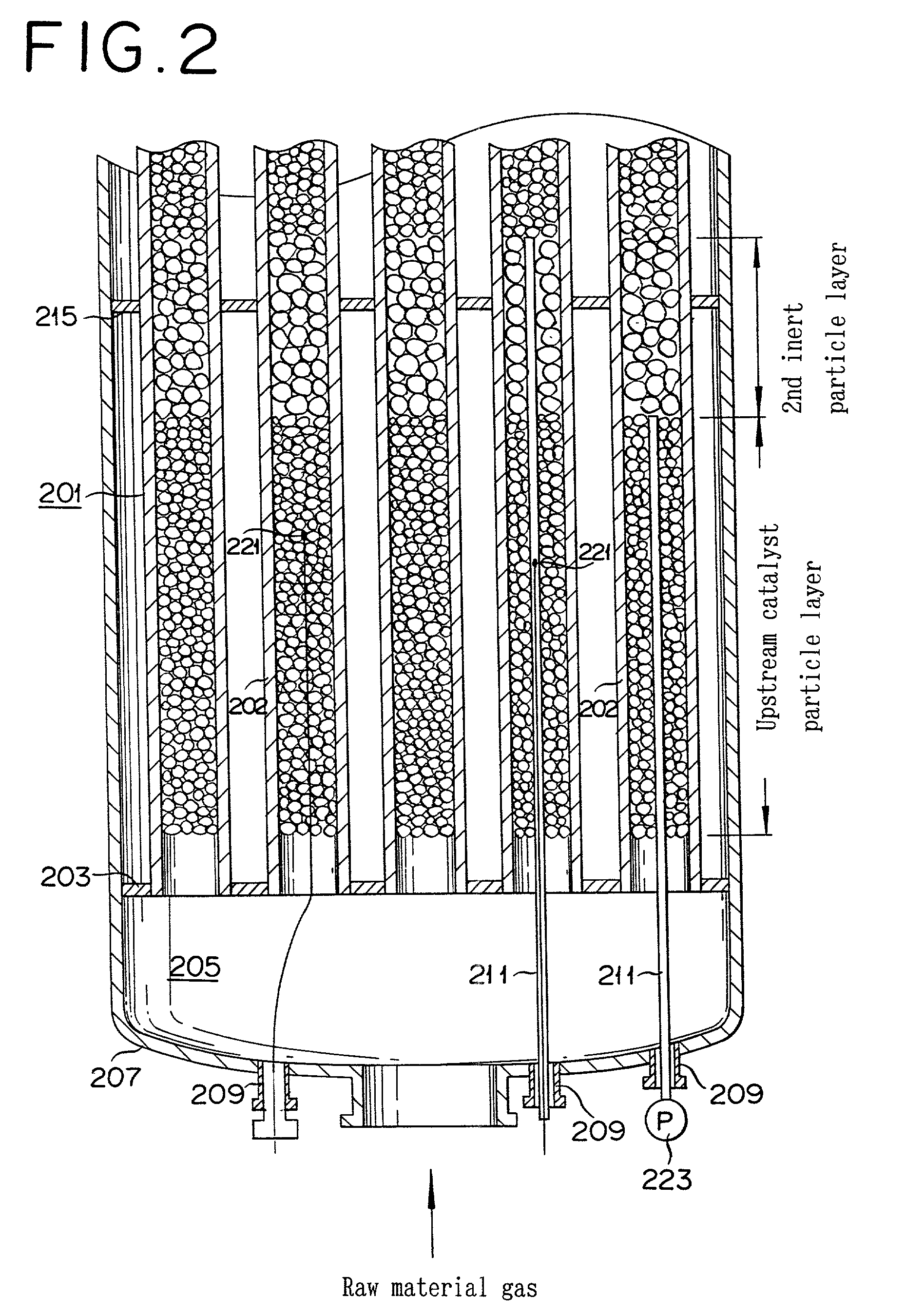

[0109] A vertical shell-and-tube reactor was adopted, having reaction tubes made of steel and of 6,500 mm in length and 25 mm in inside diameter, with an intermediate tube sheet equipped at the middle of the reactor. Upstream catalyst particles, inert particles, and downstream catalyst particles were sequentially filled on the bottom of reaction tubes per each reaction tube as follows:

[0110] Filling Manner

[0111] The upstream catalyst, inert, and downstream catalyst particles were divided into 14 pieces so as to be the same volume, respectively.

[0112] All of non-measuring reaction tubes were filled with the above particles, and then measuring reaction tubes filled therewith in a way that the length of filled layer was the same as the mean of the non-measuring reaction tubes. The volumetric measurement was performed by means of a plastic volumetric measuring vessel. The length of the layer was performed with a measure. The pressure drop of the solid particle layer was measured on a di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com