Micro-structural optical fibre selectively filling method and judge aligning system

A technology of micro-structured fiber and filling method, applied in the direction of cladding fiber, optical waveguide light guide, optical waveguide coupling, etc., can solve the problems of limited application and large gap of discharge parameters, and achieve the effect of reducing filling time and length.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

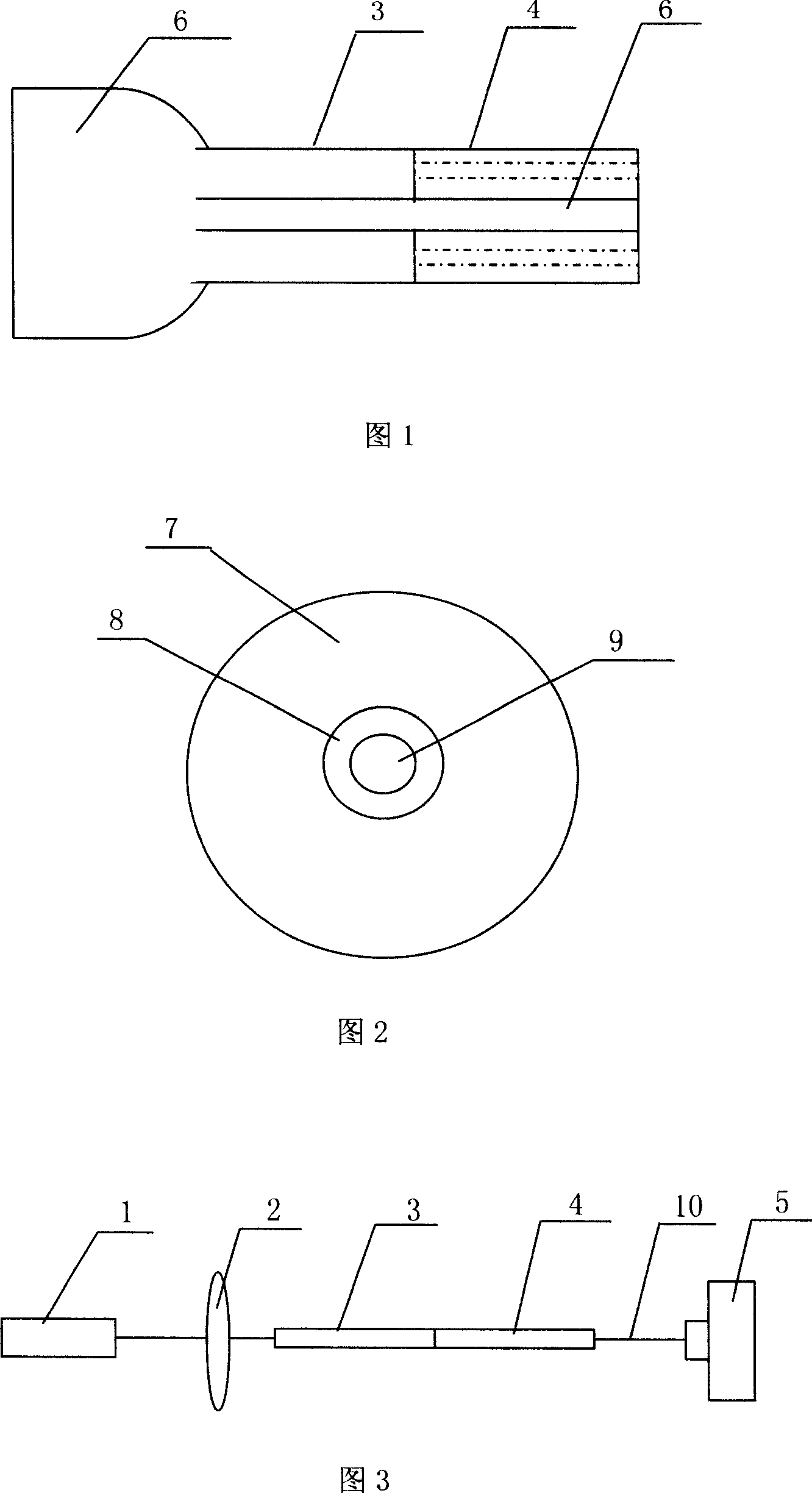

[0027] The method for selectively filling microstructured optical fibers and the judging and aligning system of the present invention will be described in detail below in conjunction with the embodiments.

[0028] As shown in Figure 1, the principle of the microstructure optical fiber selective filling method of the present invention is: draw a small section of single-hole optical fiber 3, make its core hole diameter be less than or equal to photonic crystal fiber 4 center hole diameters, combine it with photonic crystal fiber 4 Tight docking, to ensure that the center holes of the two are in a straight line. Then insert one end of the single-hole optical fiber 3 into the liquid to be filled, and use the capillary phenomenon to make the liquid 6 enter the core of the crystal fiber 4 along the core of the single-hole optical fiber 3 .

[0029] The selective filling method of microstructure optical fiber of the present invention is specifically completed by the following steps: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com