Evanescent mode pouring system of speed changing box body

A pouring system and gearbox technology, applied in casting molding equipment, molds, cores, etc., can solve problems such as shrinkage, loosening and shrinkage, and achieve the effects of reducing heat loss, improving casting quality, and shortening filling time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

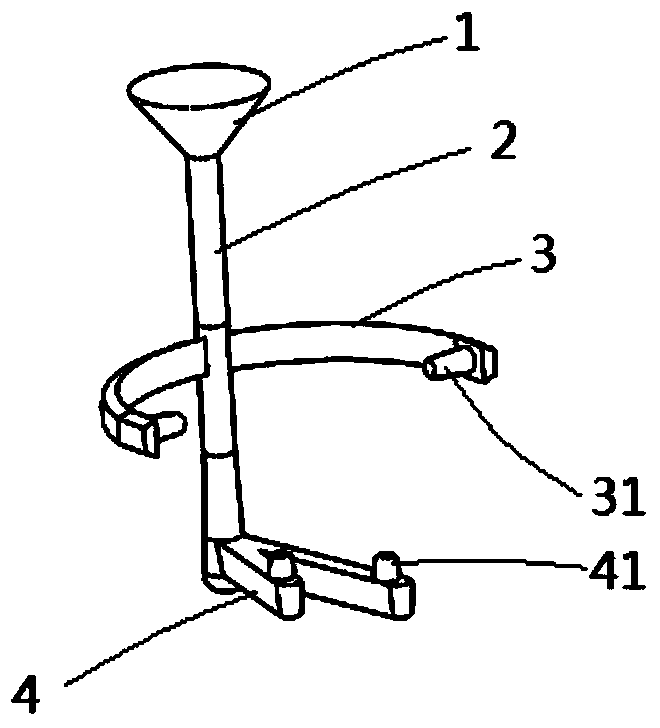

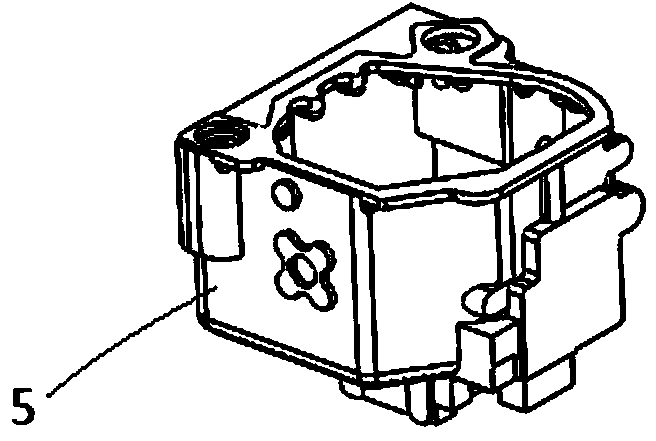

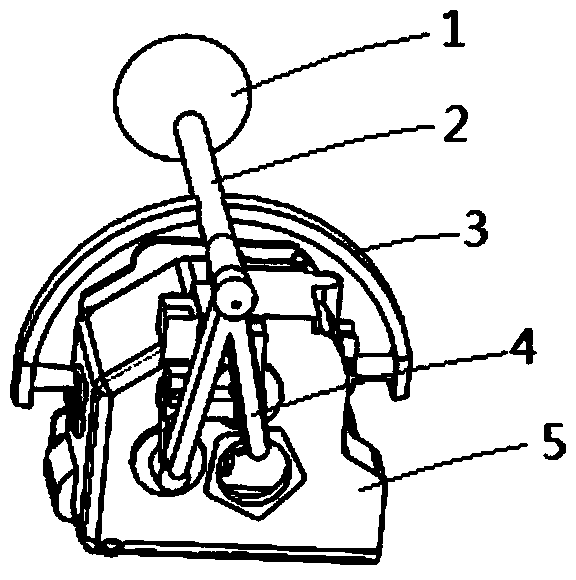

[0017] Example: Combine Figure 1-3 , the lost foam casting system of the gearbox case of the present invention, the sprue 2 is connected with the sprue cup 1, the first runner 3 and the second runner 4 successively from top to bottom on the sprue 2, and the first runner 3 and the second sprue 4 are respectively connected to the sprue 2 along the radial direction of the sprue; and, the ends of the first runner and the second runner away from the sprue are respectively provided with first Ingate sprue 31 , second ingate sprue 41 .

[0018] In the specific setting, the first runner 3 is generally semicircular, the sprue is in the middle of the semicircular first runner, and the two first inner runner gates 31 at the end of the first runner are in the Both sides of the upper half of the gearbox casing 5.

[0019] The second runners are two with different lengths and form a V shape, and the two second runner gates 41 at the ends of the second runners are located at the thick and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com