Patents

Literature

32results about How to "Reduce filling pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

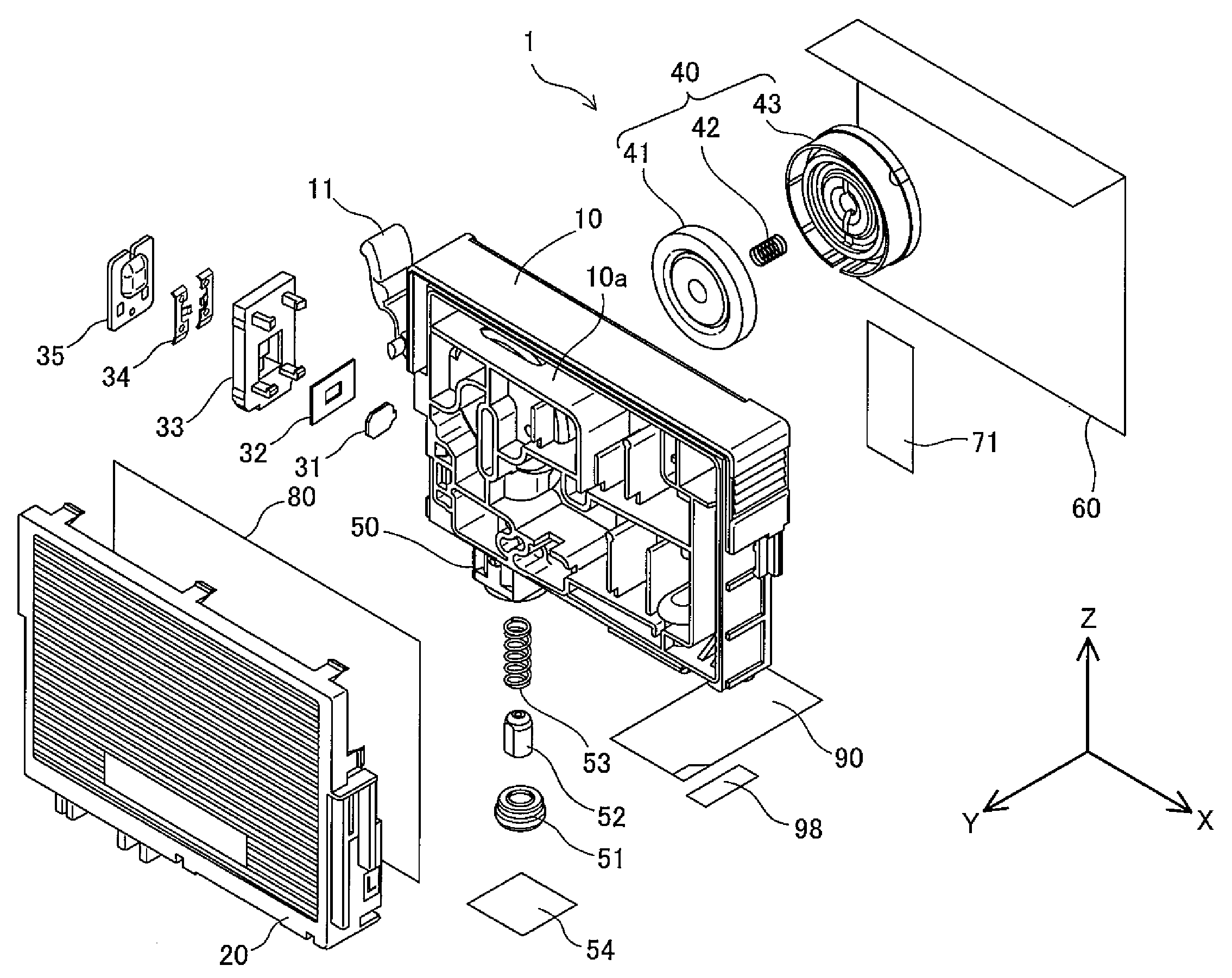

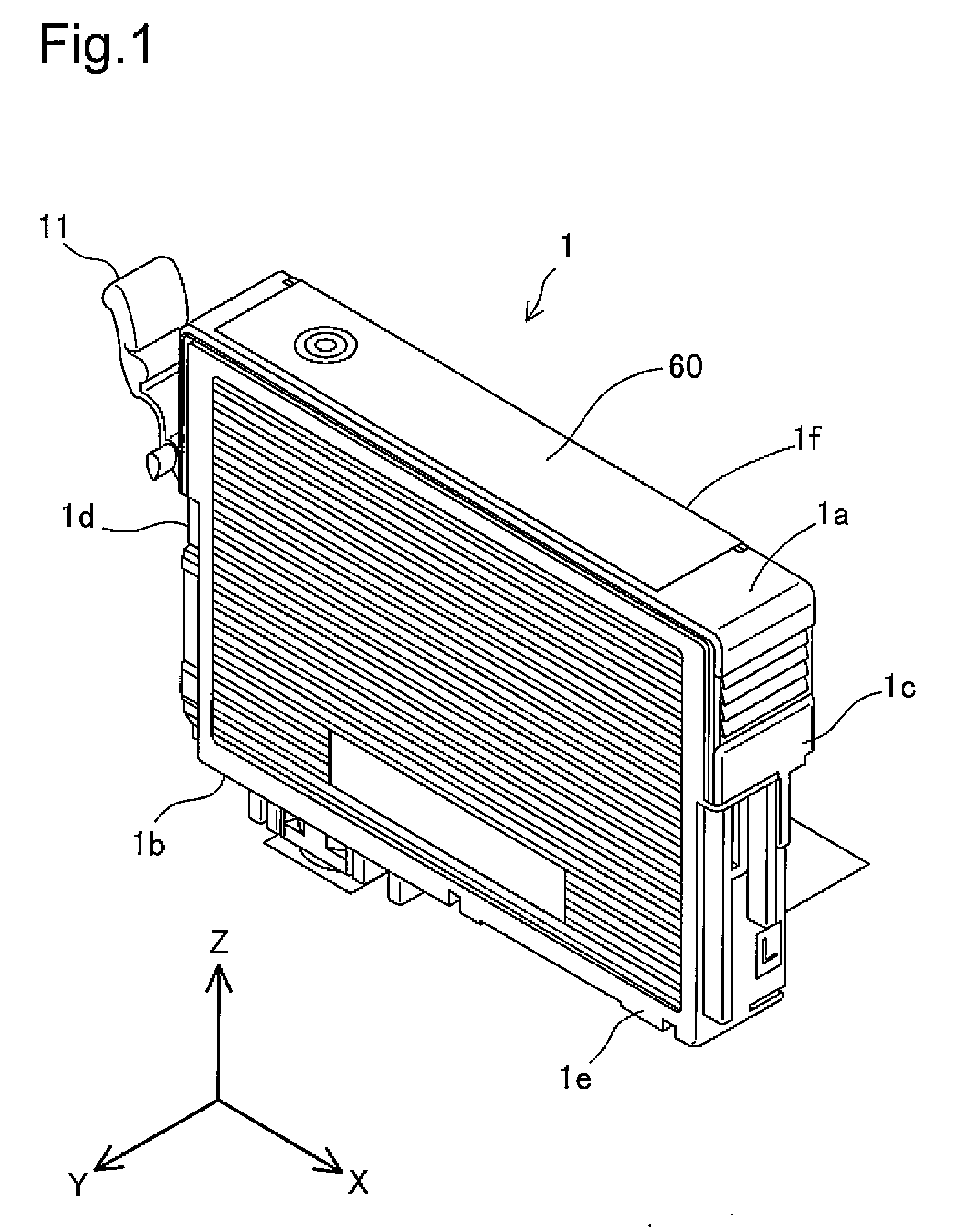

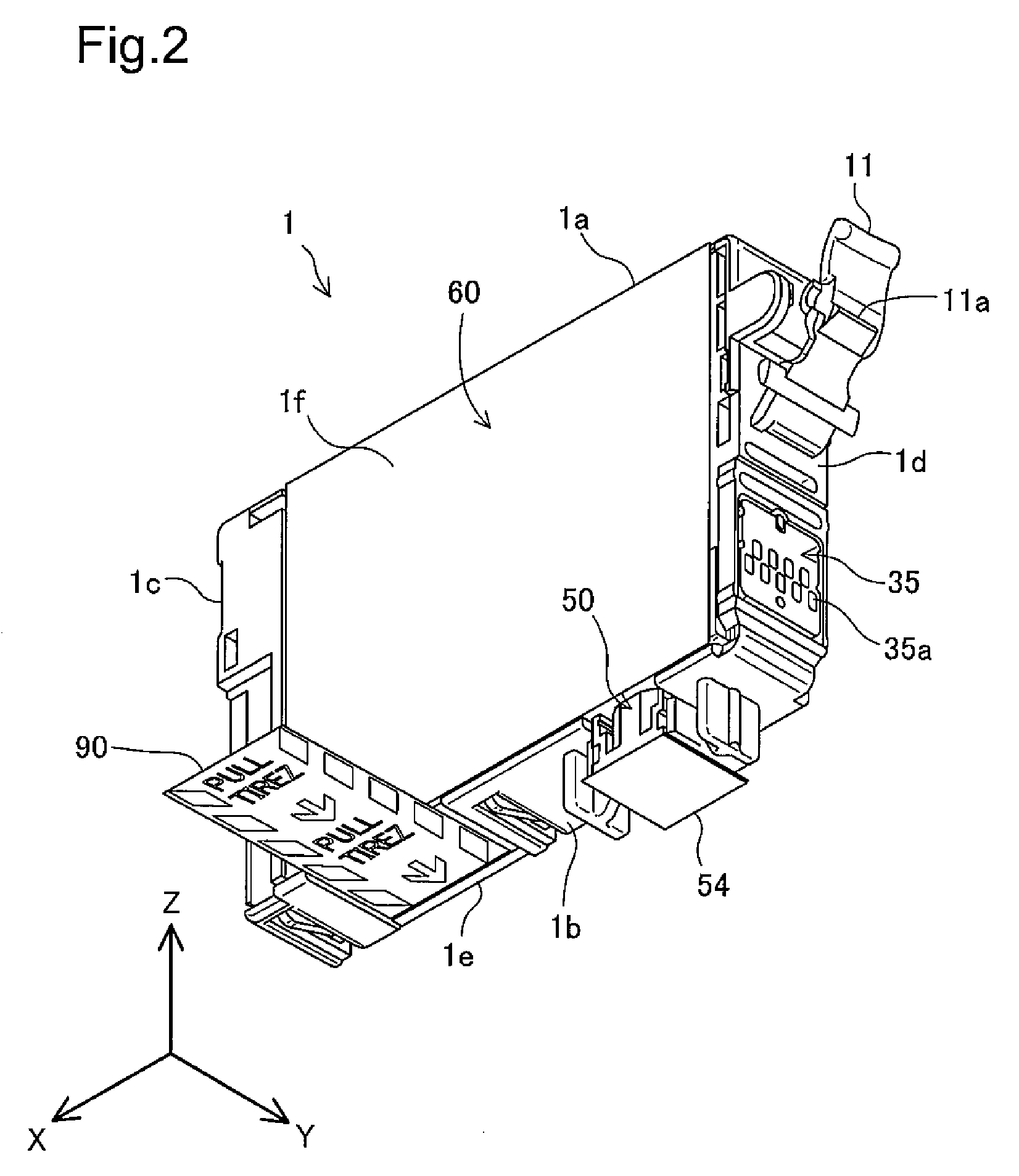

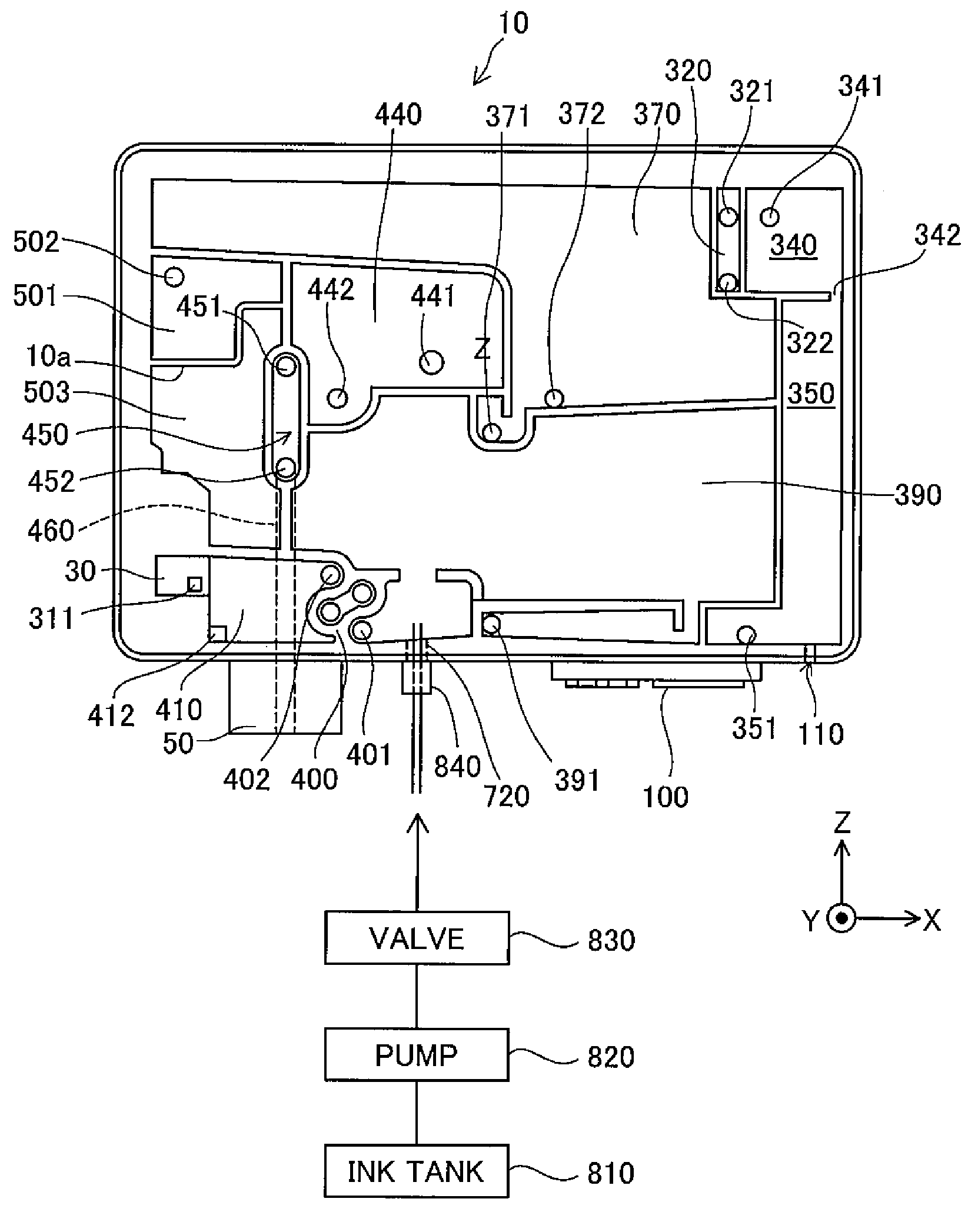

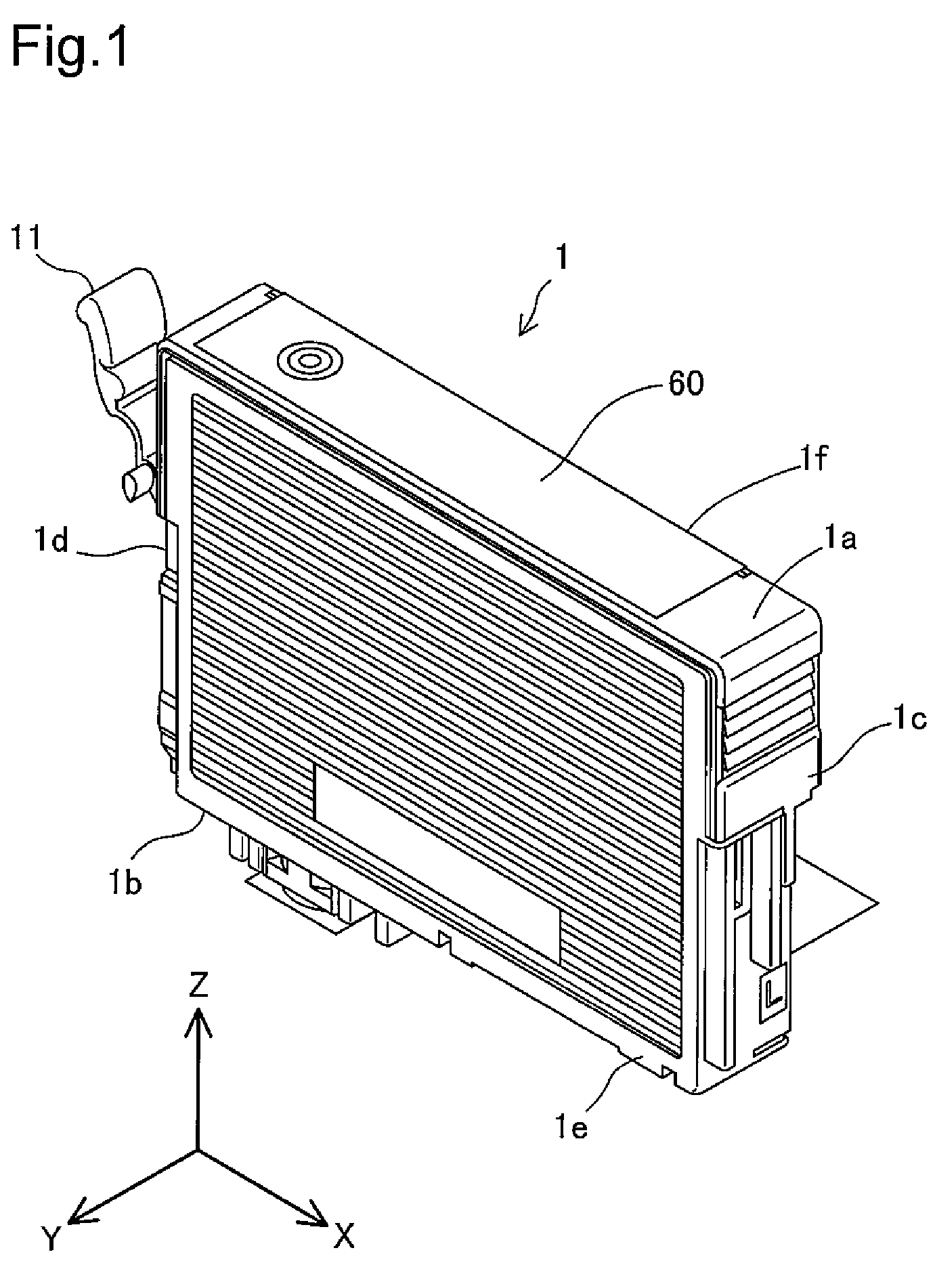

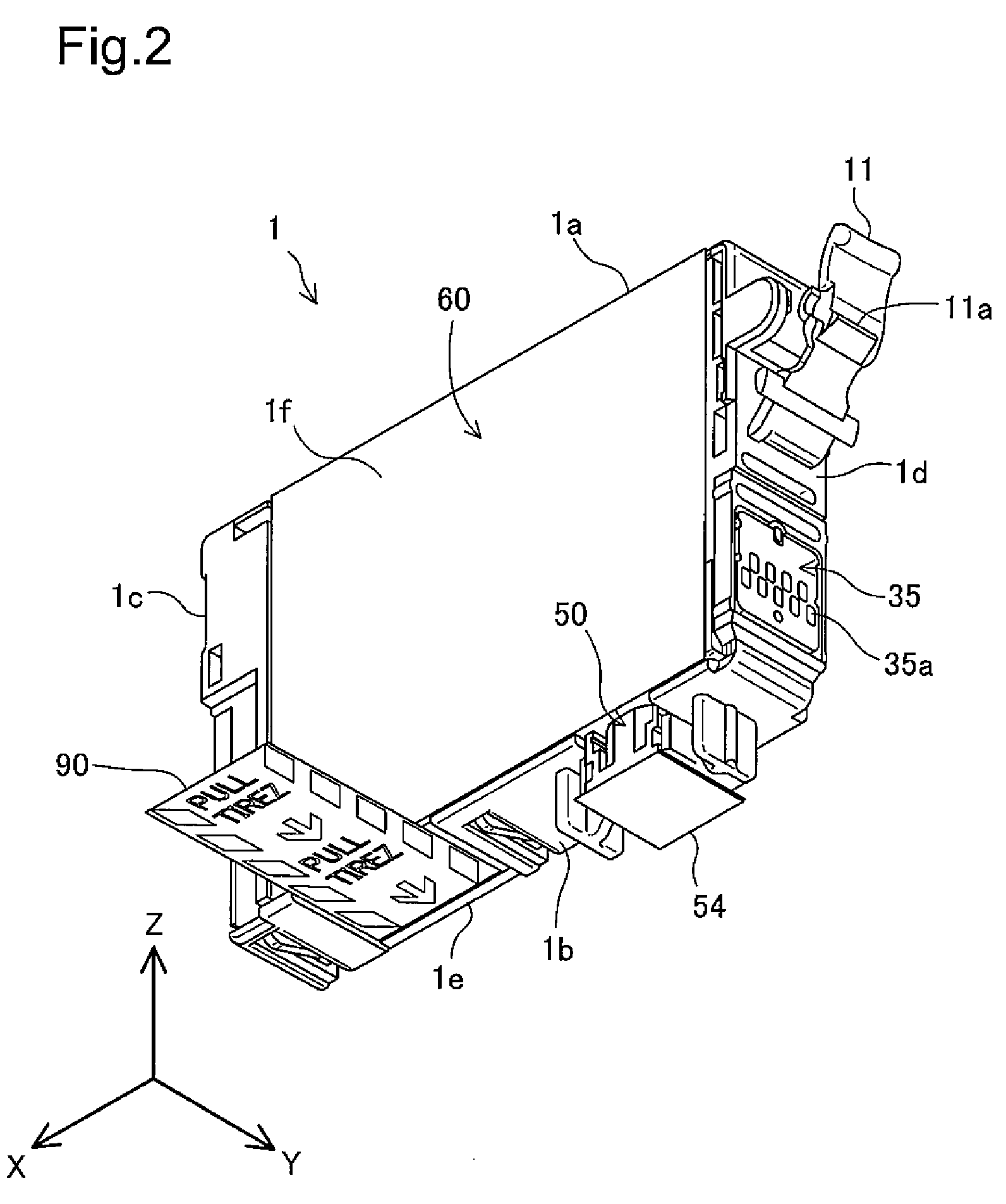

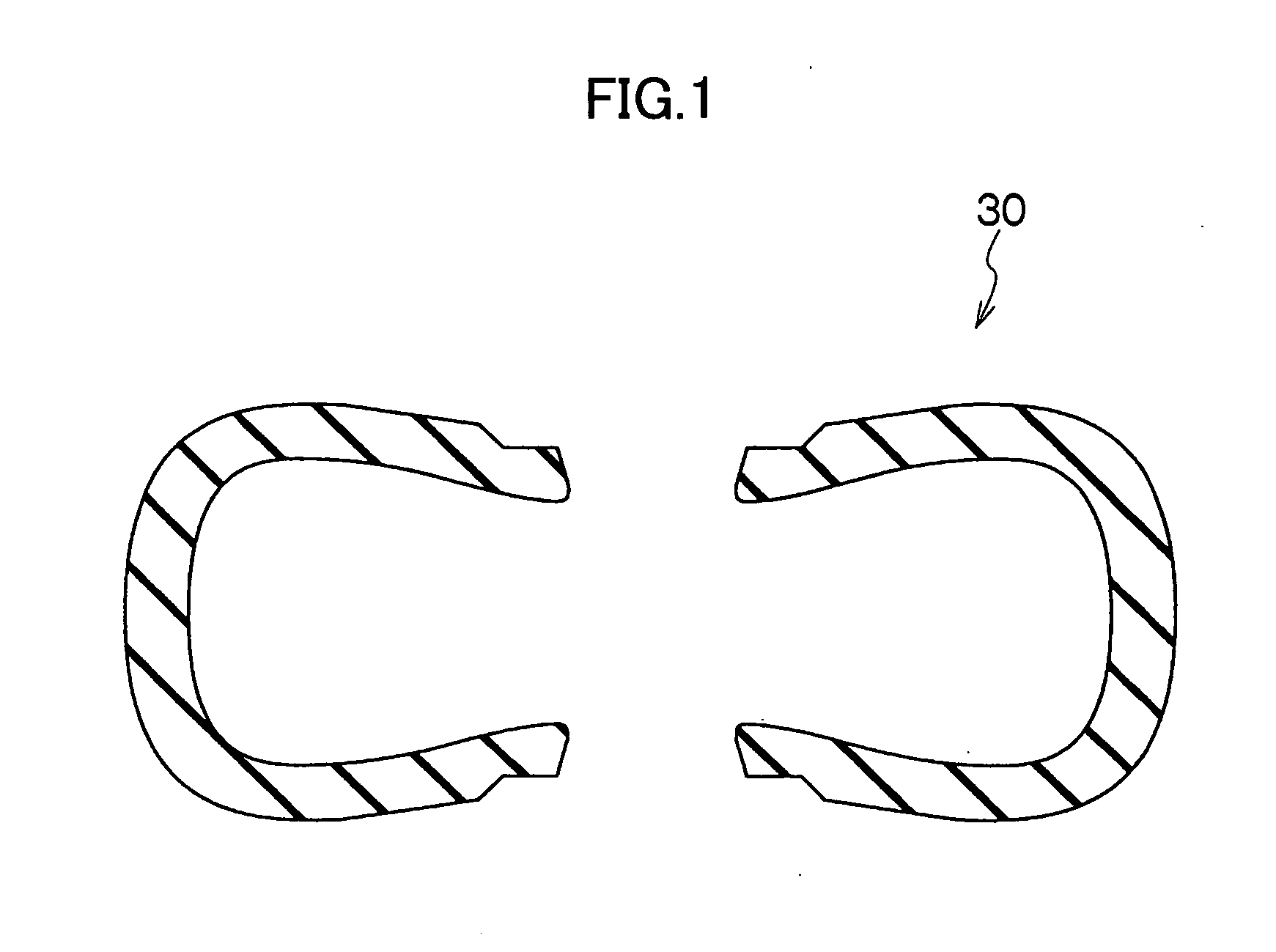

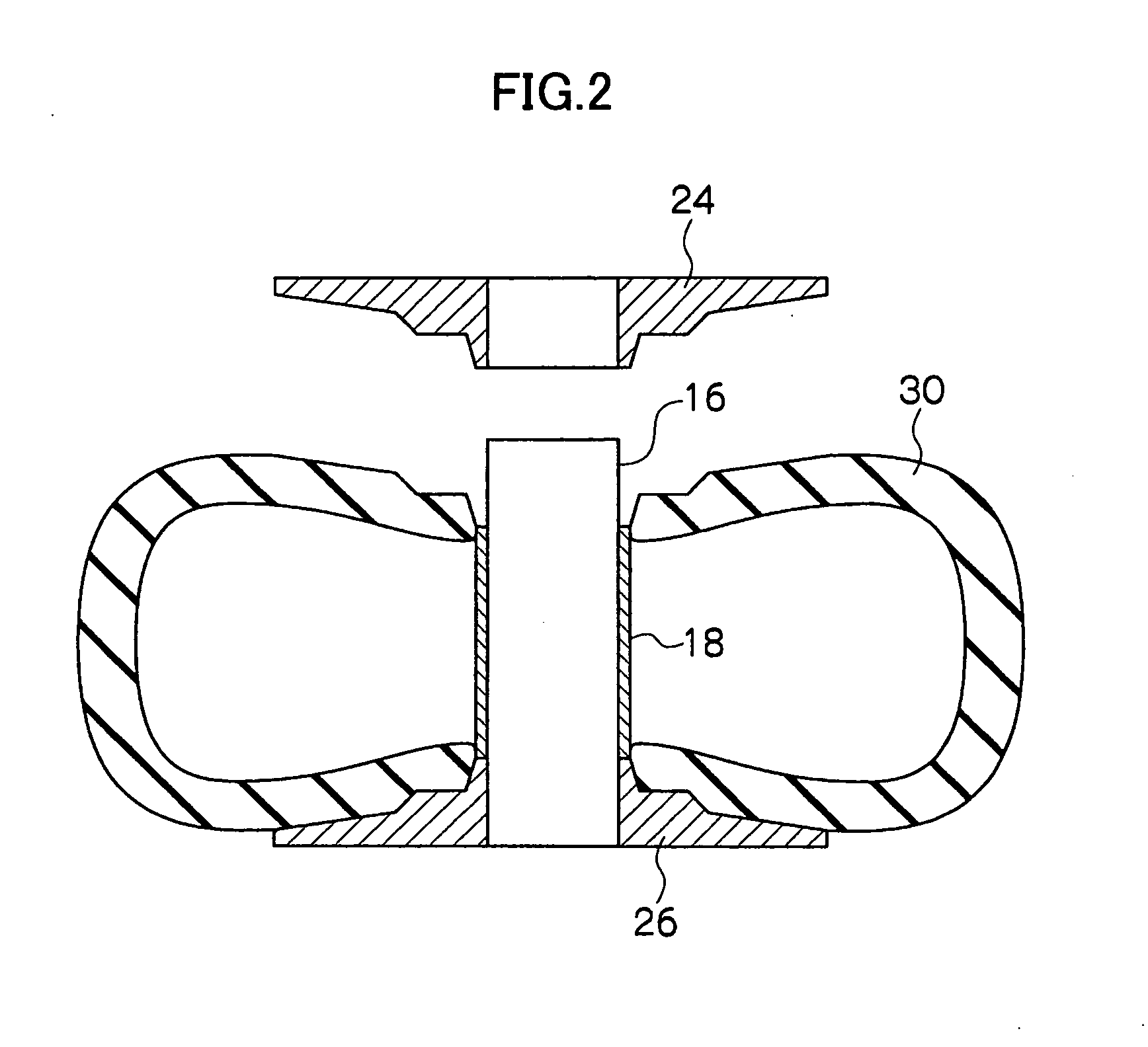

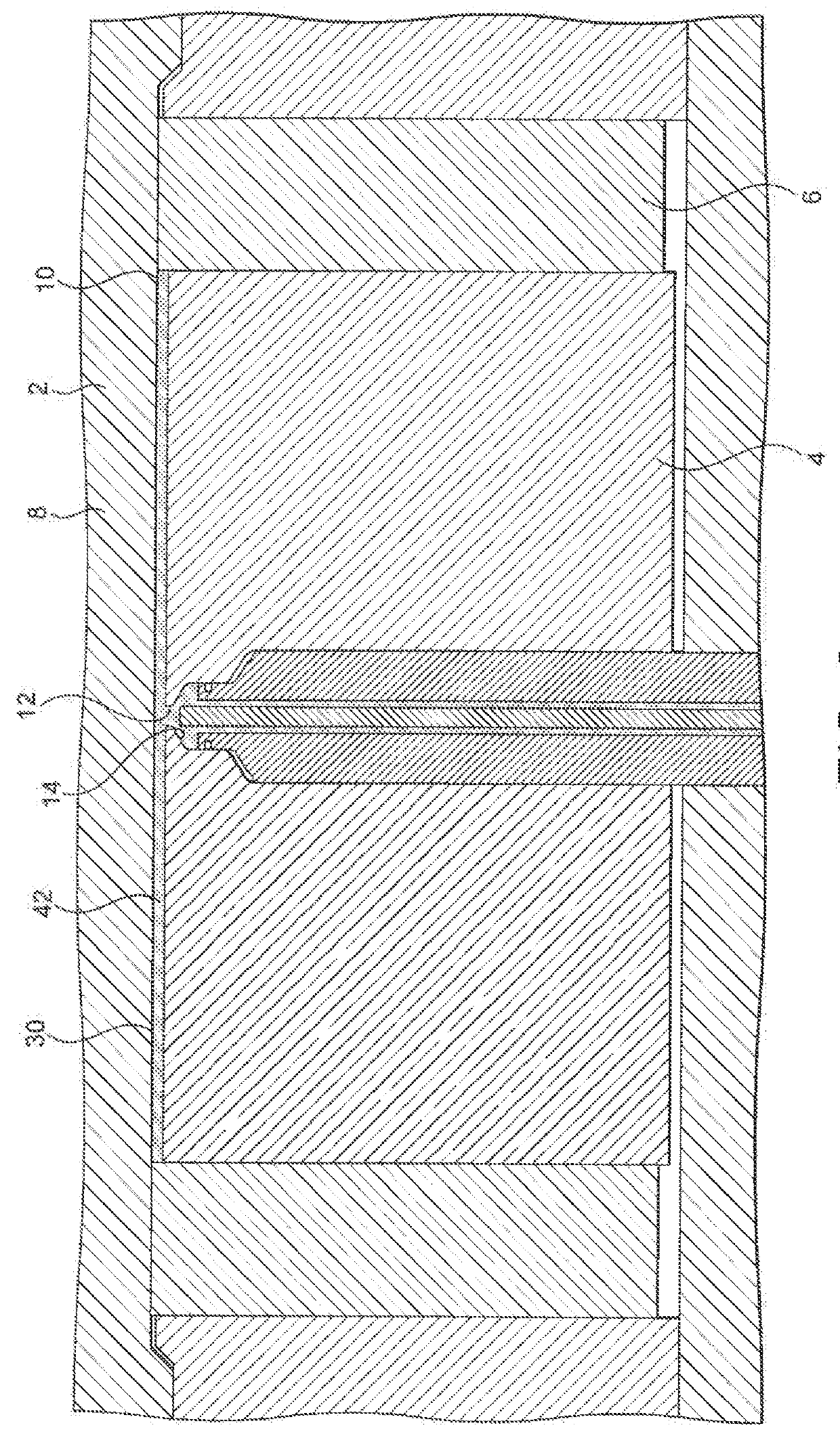

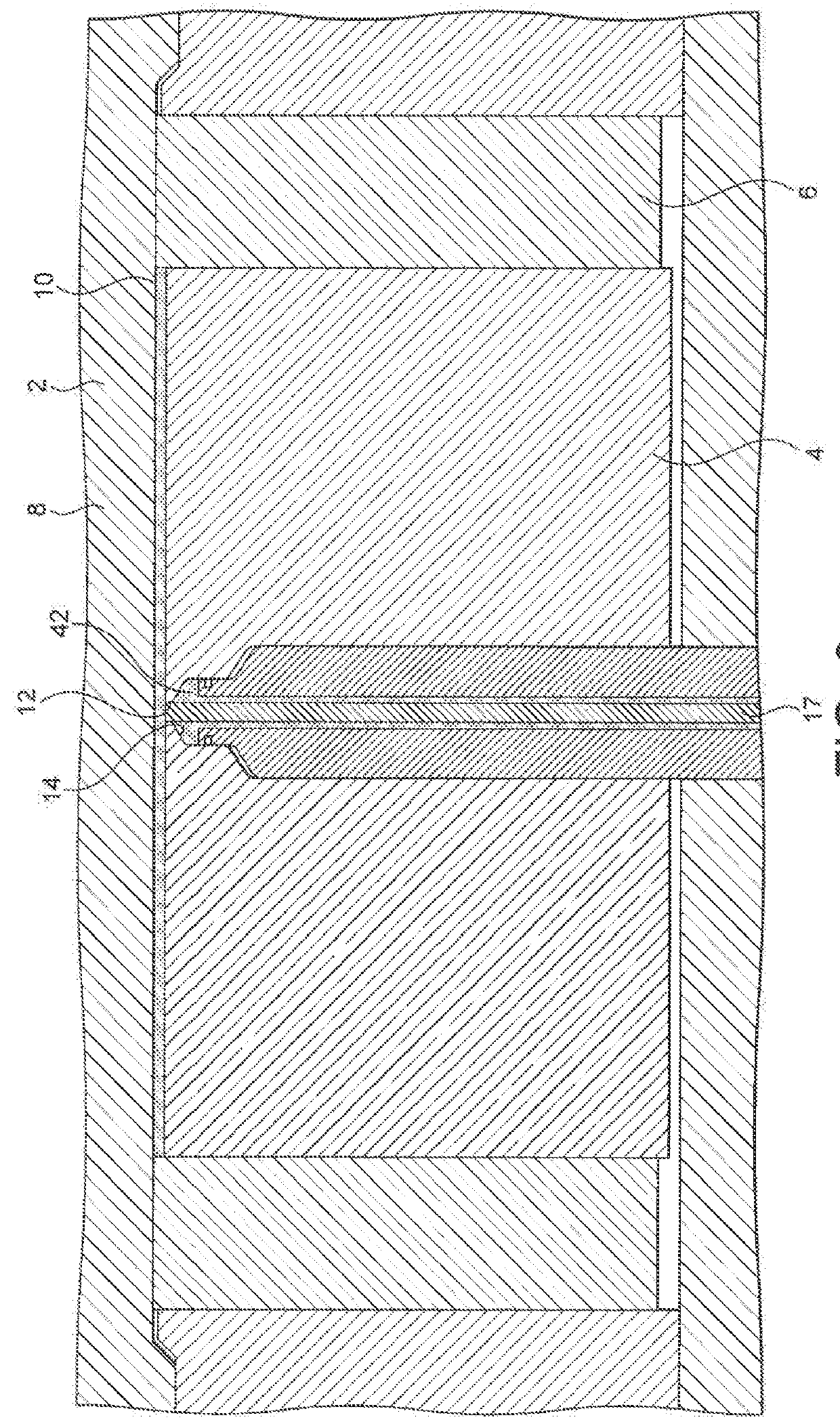

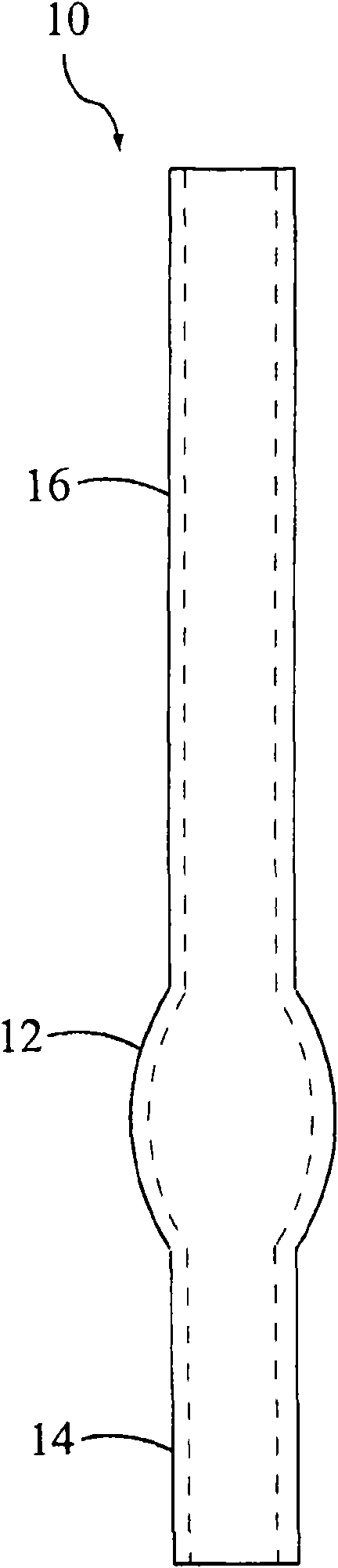

Liquid container and remanufacturing method of liquid container

ActiveUS20090322838A1Increase resistanceIncrease capacityWriting implementsMetal-working apparatusOpen structure

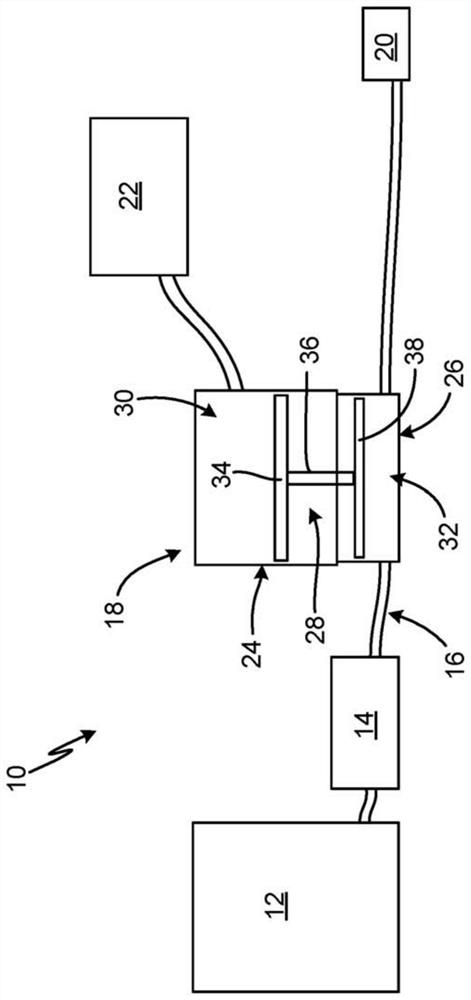

According to one aspect of the invention, a remanufacturing method of a liquid container forms an inlet in a downstream wall surface of a second chamber, which defines part of a bottom face of the liquid container. In the state of closing a liquid feeder and opening an air open structure, the remanufacturing method injects a liquid through the inlet to fill the second chamber with the liquid. In the state of opening the liquid feeder and closing the air open structure, the remanufacturing method injects the liquid through the inlet to fill a space from the second chamber to the liquid feeder with the liquid. The remanufacturing process seals the inlet after completion of the injection of the liquid. This arrangement enables the liquid to be efficiently refilled into the liquid container without damaging the functions of the liquid container.

Owner:SEIKO EPSON CORP

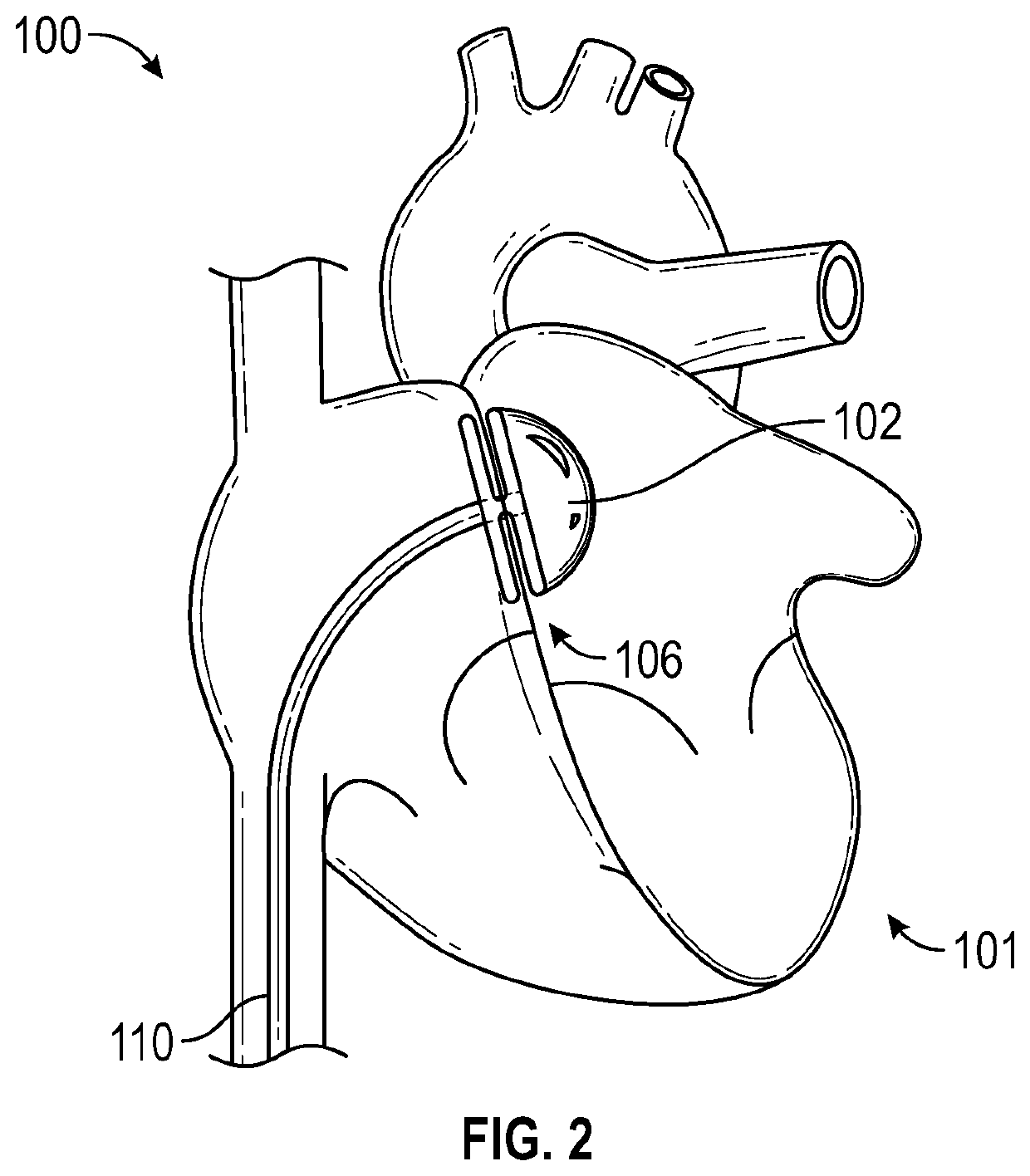

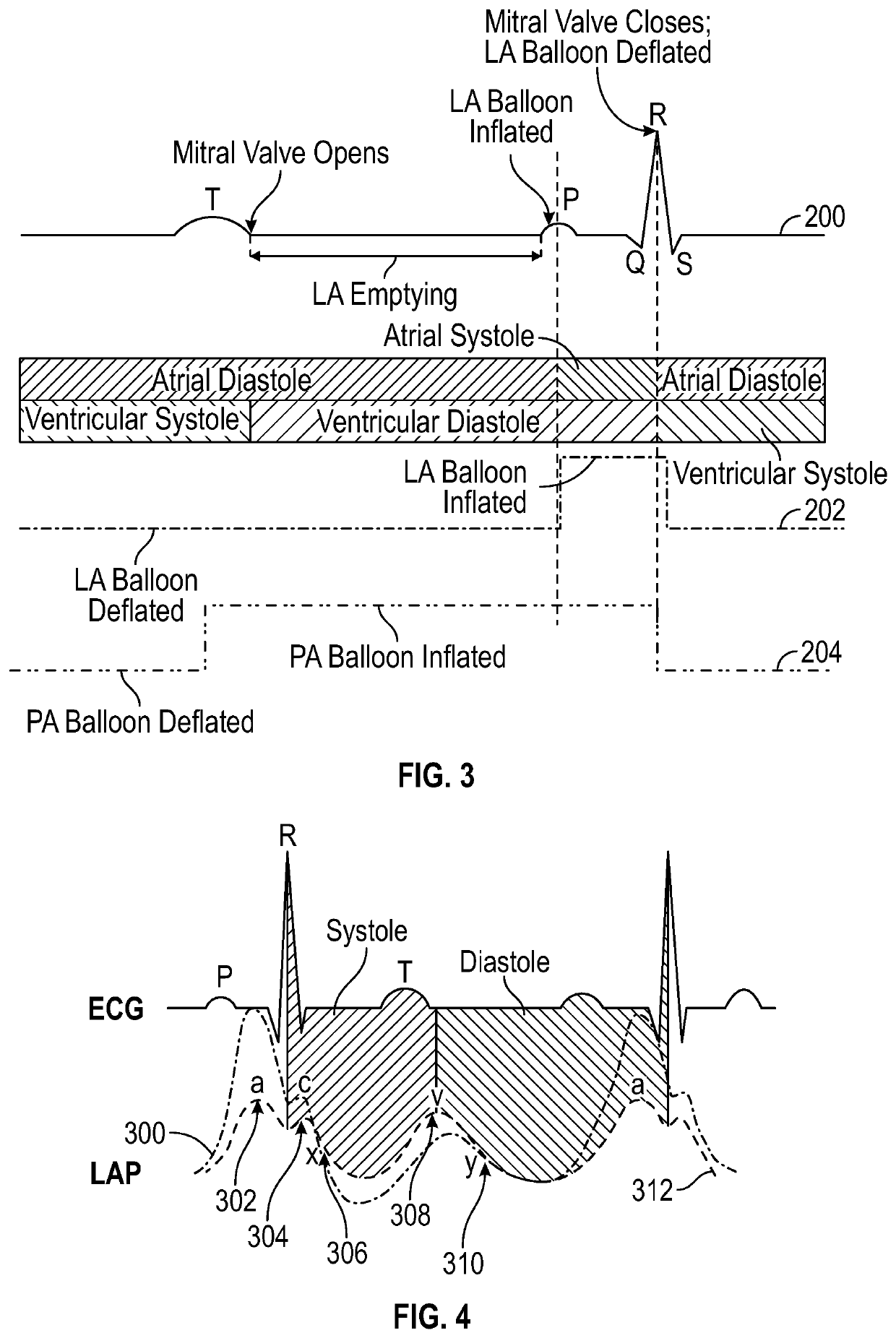

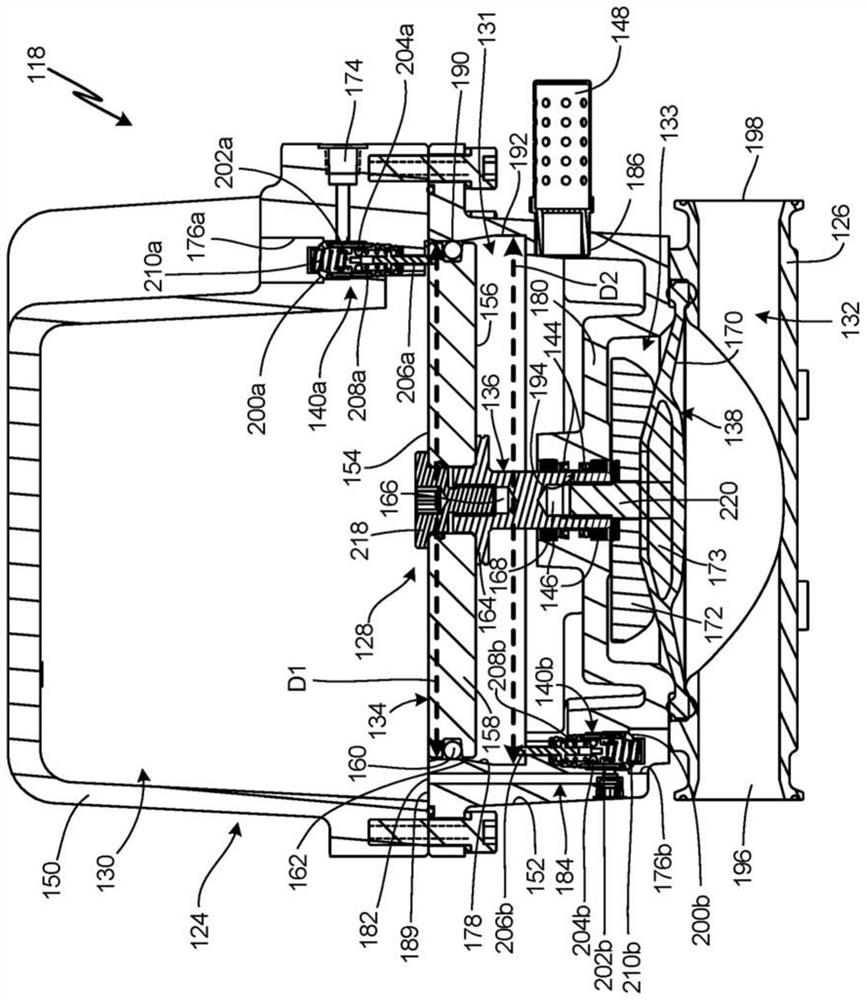

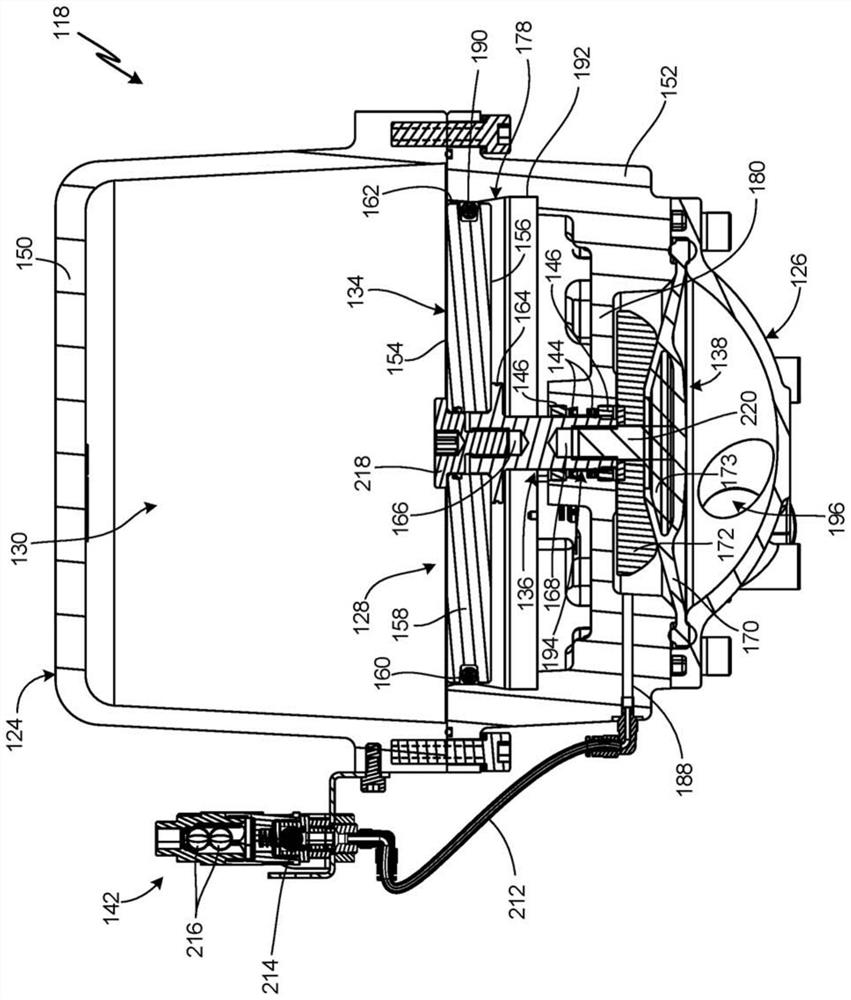

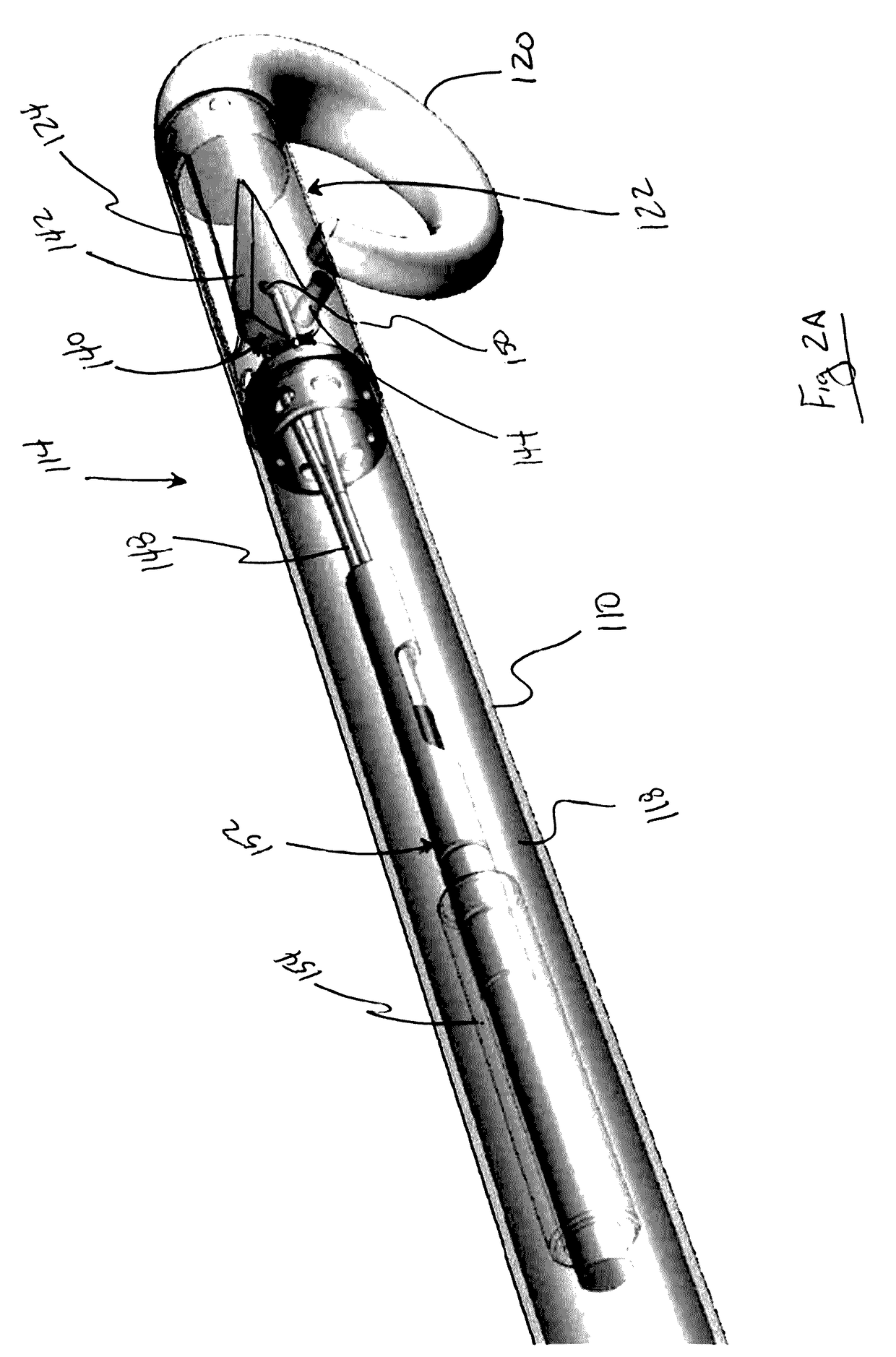

Intra-cardiac left atrial and dual support systems

ActiveUS10888644B2Improves diastolic fillingReduce pressureControl devicesBlood pumpsCardiac cycleEngineering

Owner:INQB8 MEDICAL TECH LLC

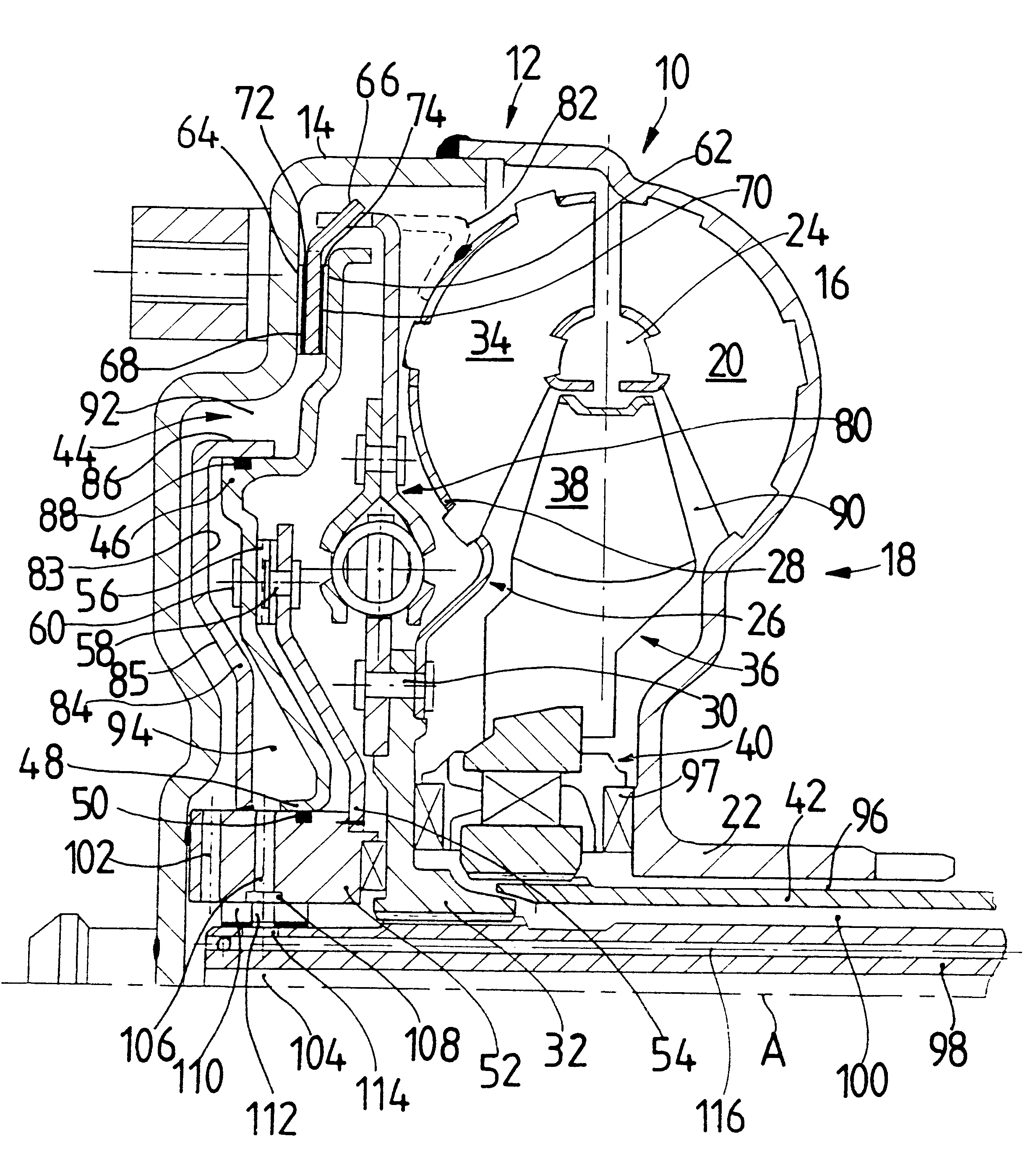

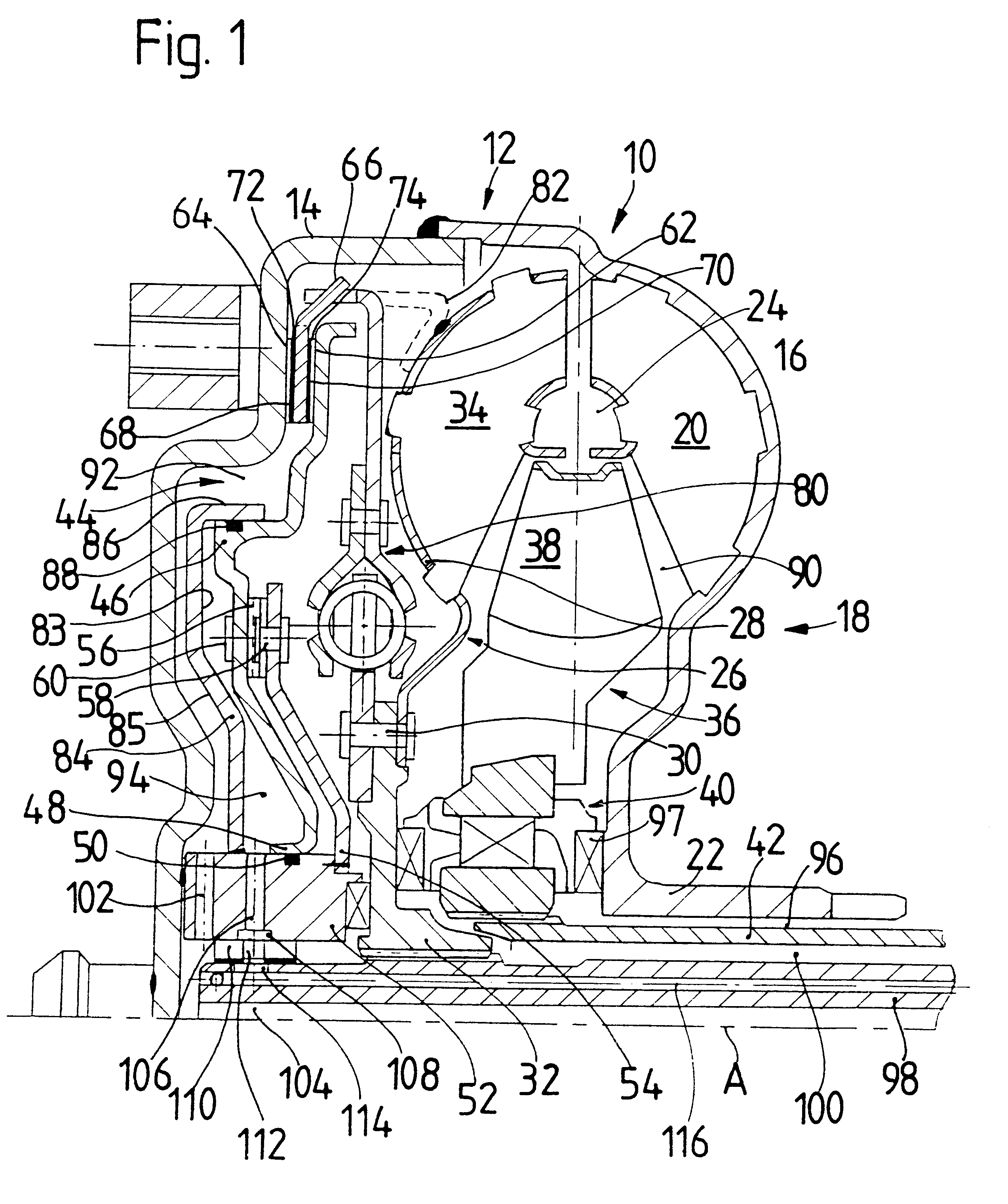

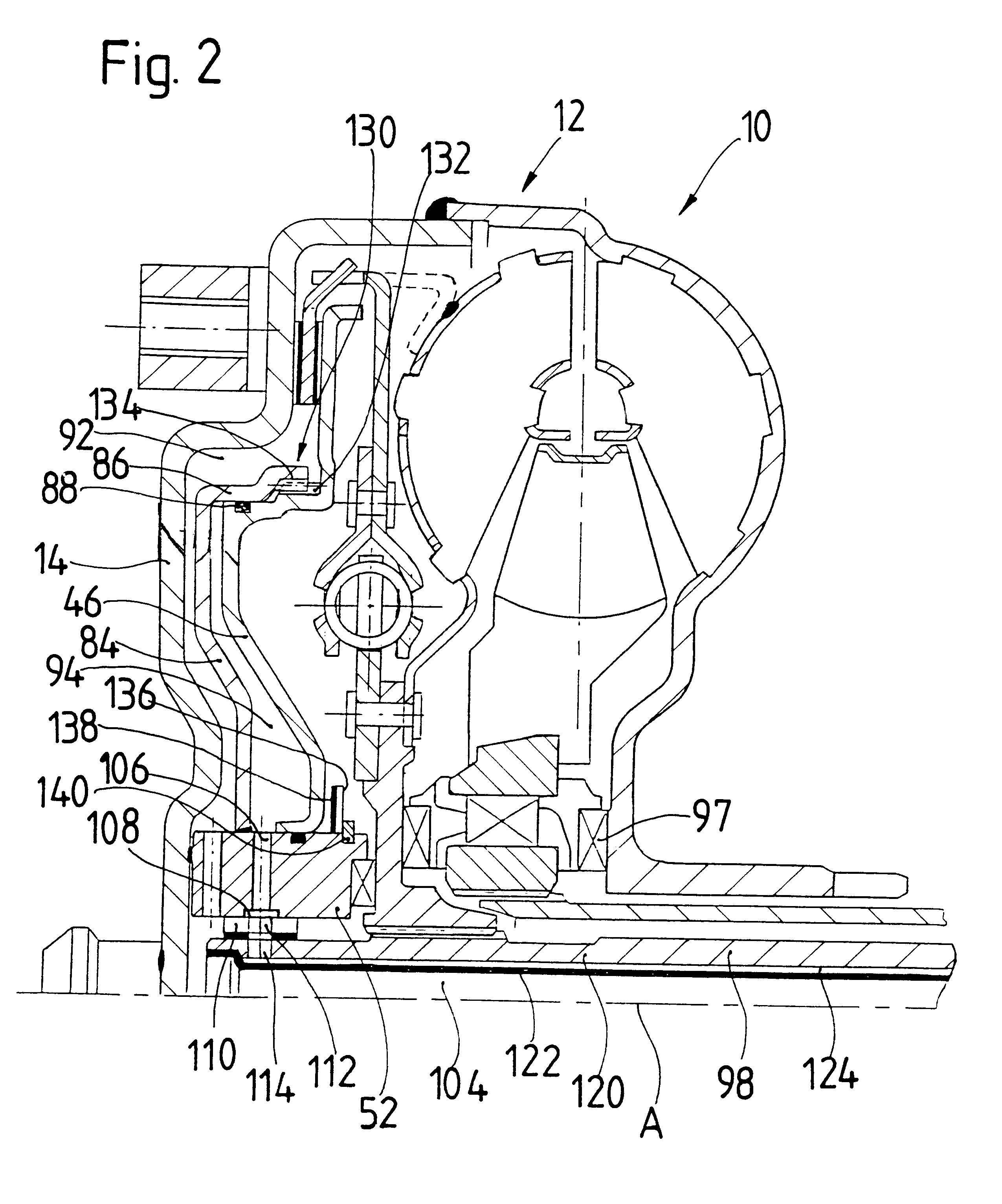

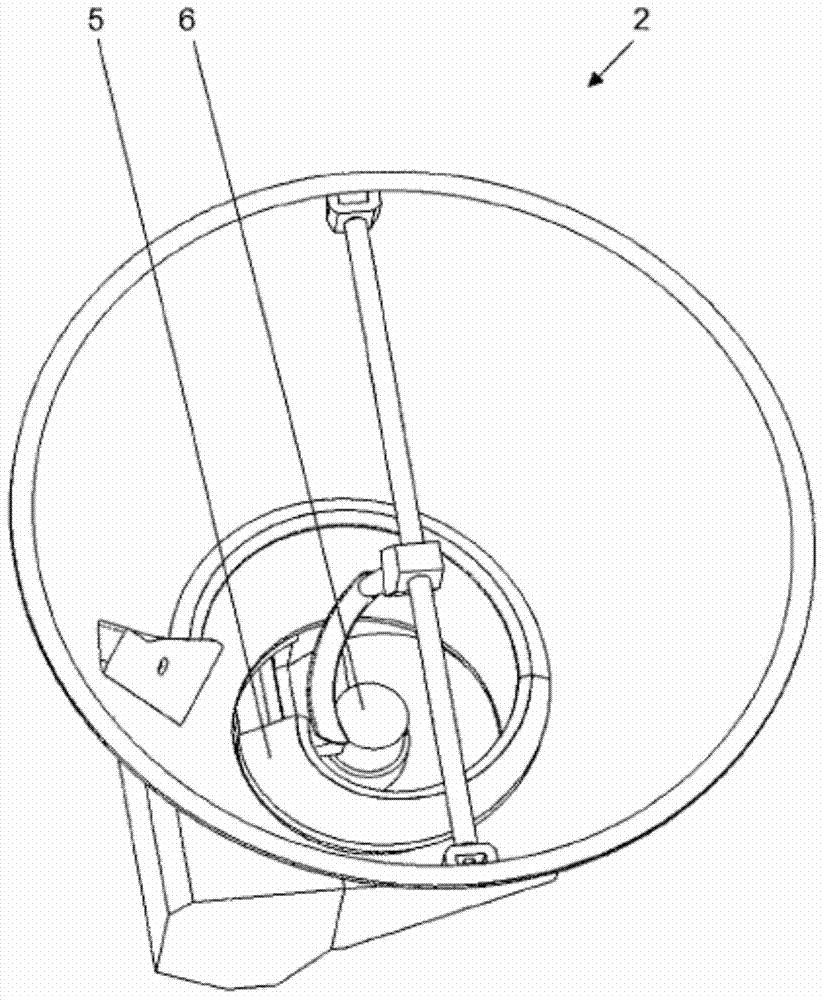

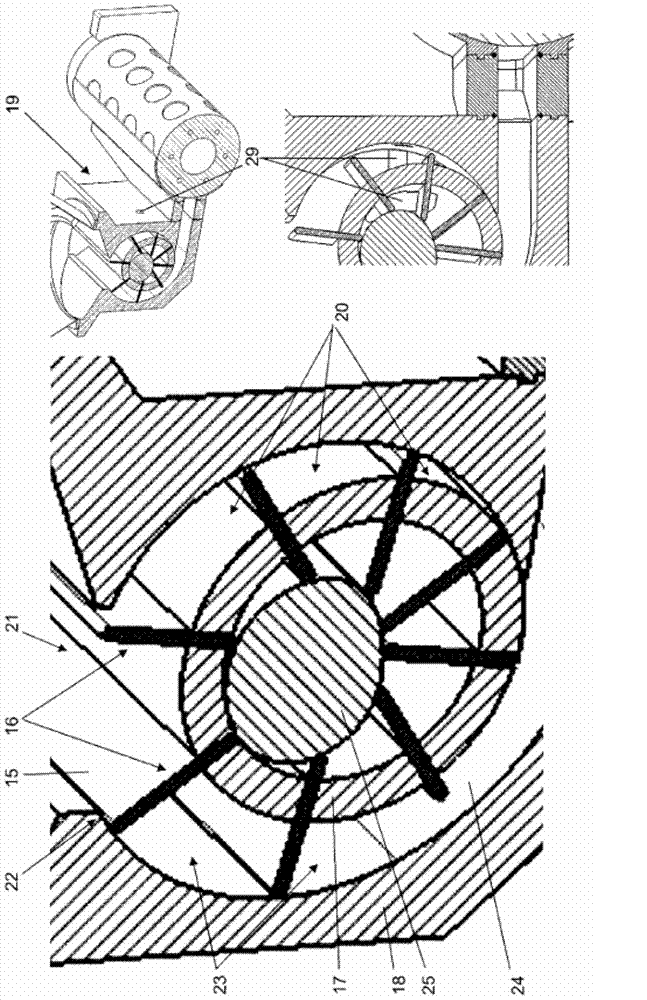

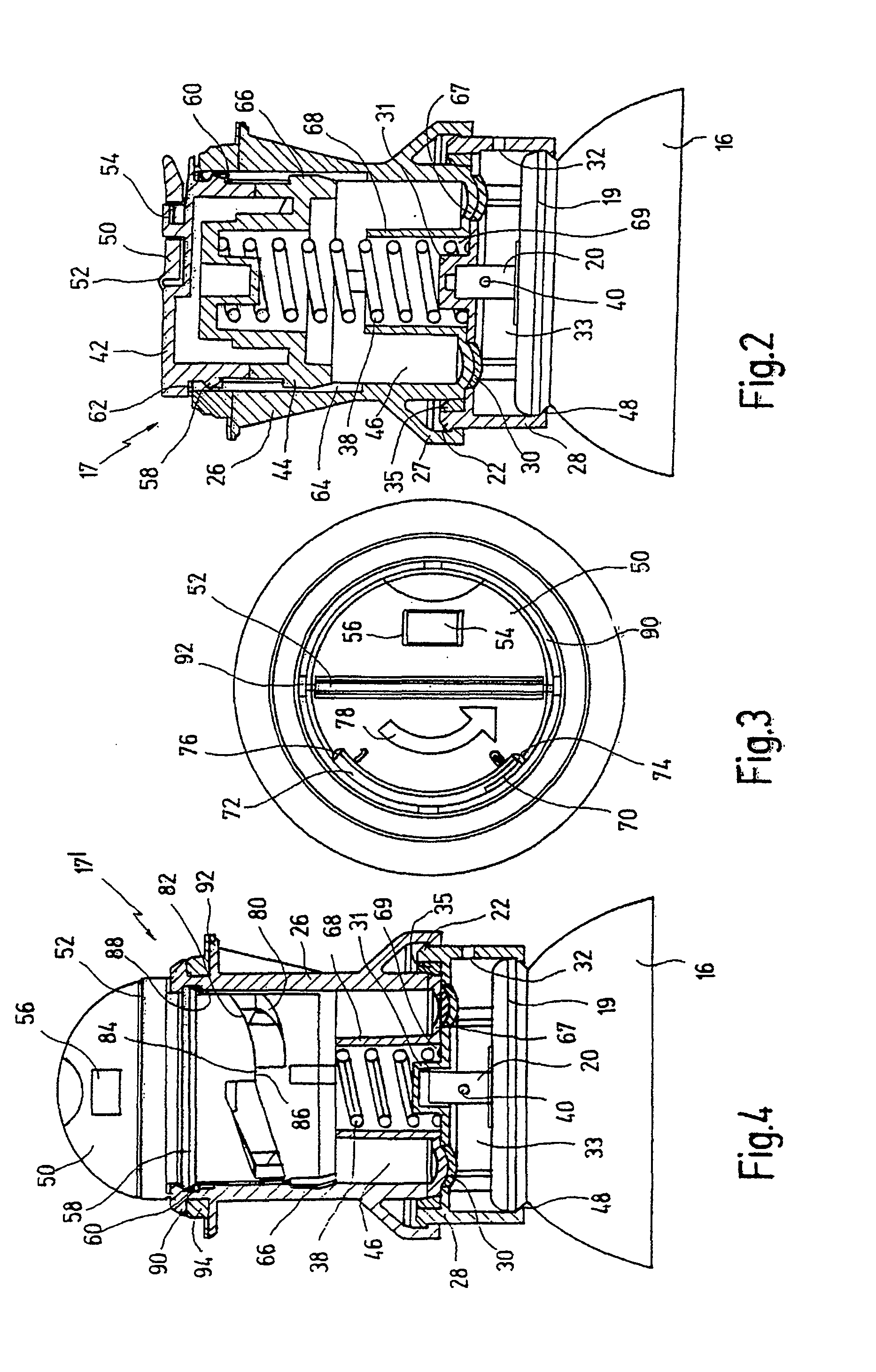

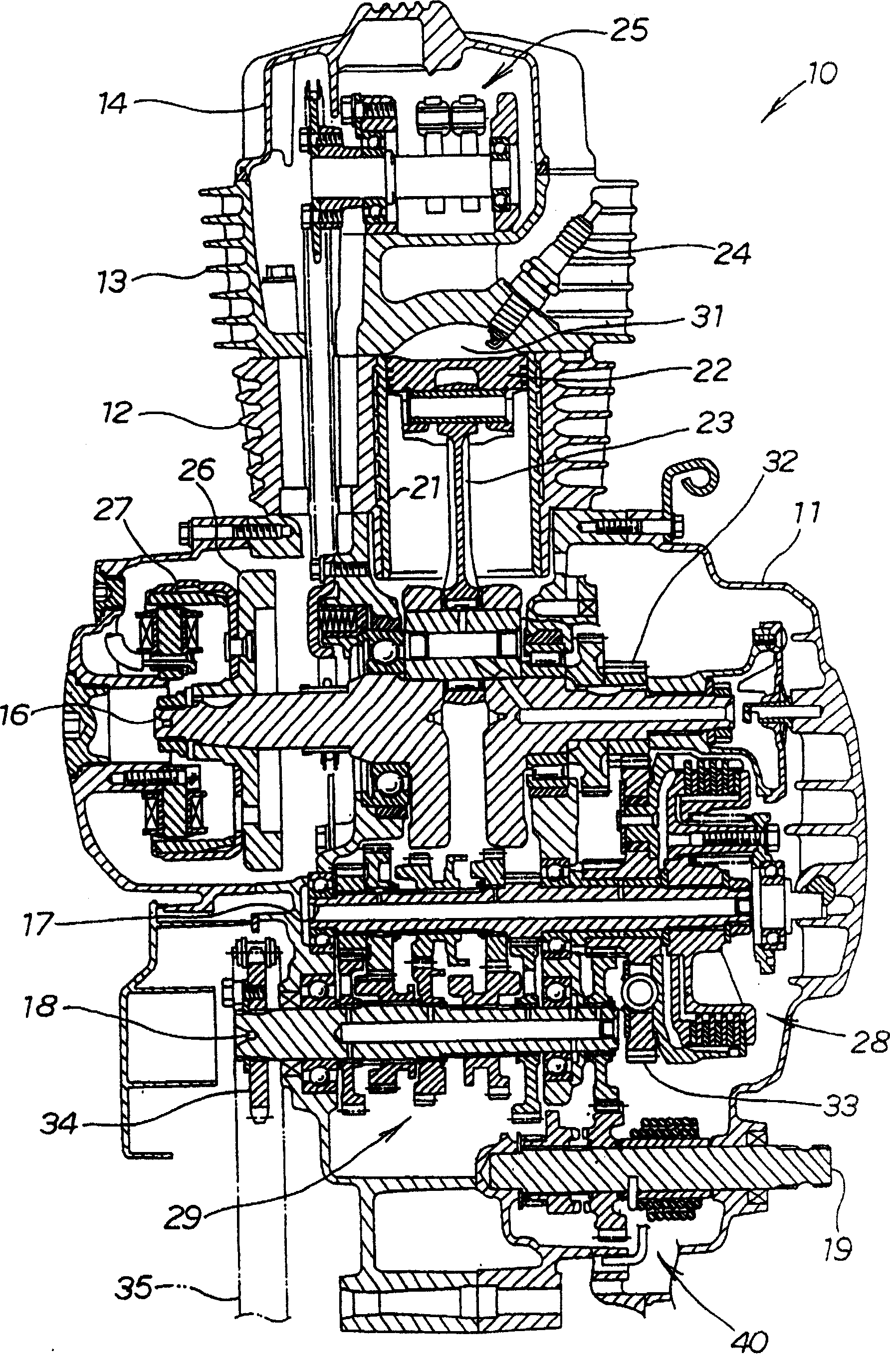

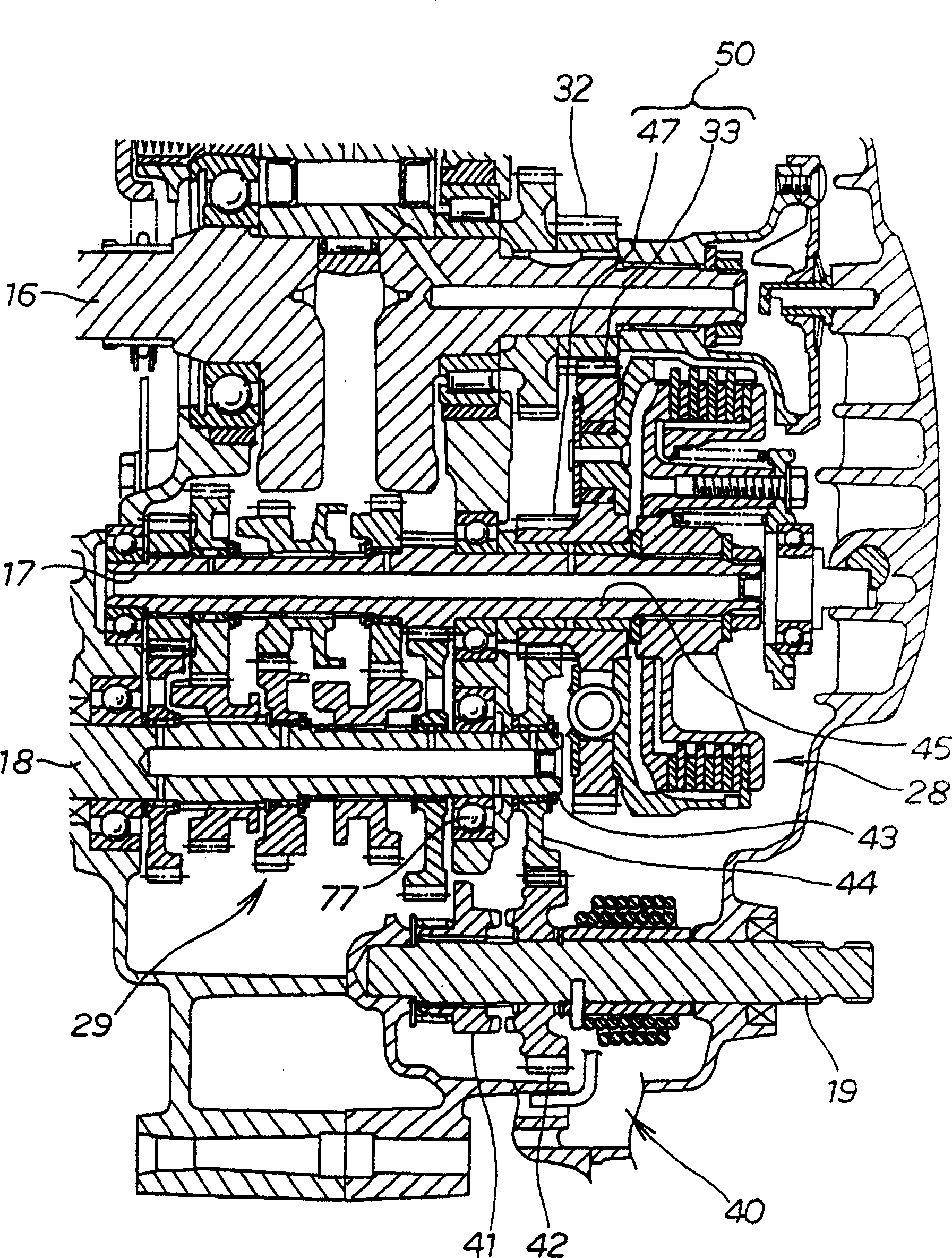

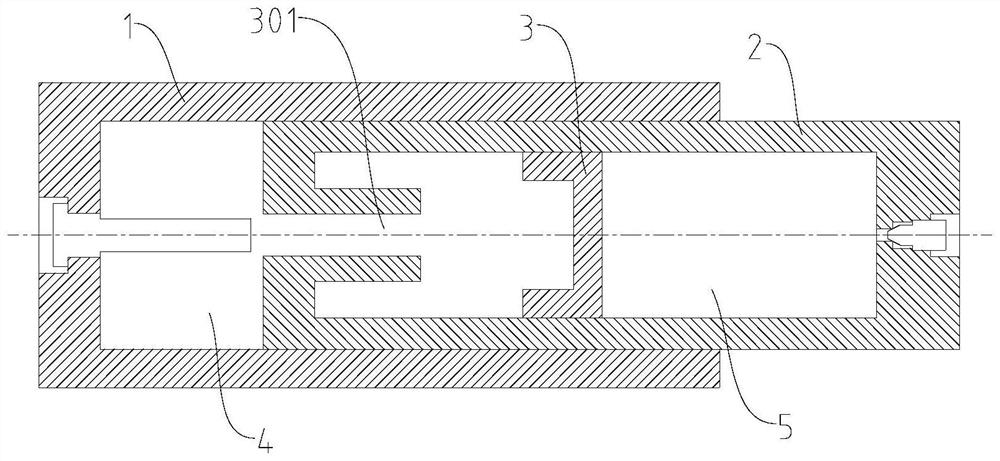

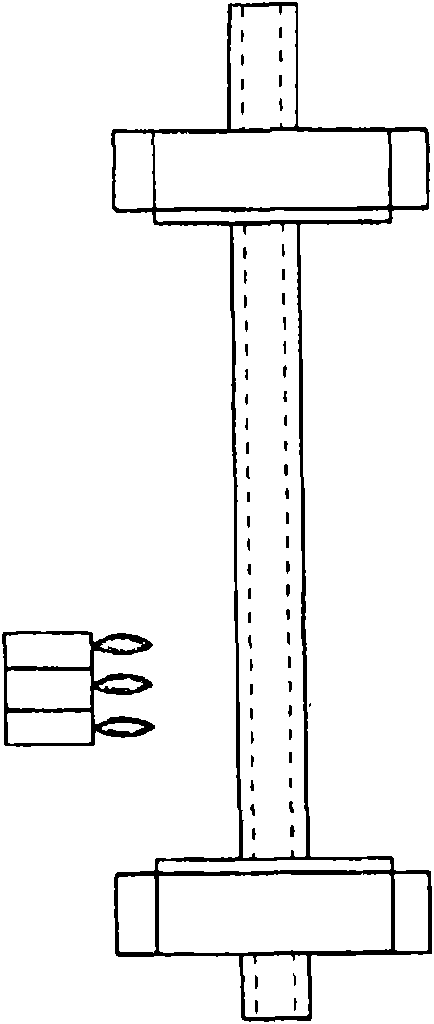

Hydrodynamic torque converter

InactiveUS6431335B1Positive effect on the efficiency of the converter operationReduce filling pressureRotary clutchesFluid actuated clutchesInterior spaceImpeller

A hydrodynamic torque converter having a converter housing defining interior space for receiving a converter work fluid, a turbine wheel arranged in interior space of the converter housing and rotatable with respect to the converter housing, a lockup clutch having a coupling element axially displaceably arranged on the turbine wheel for selectively coupling the turbine wheel with the converter housing. The converter housing and the coupling element define a pressure fluid space capable of being filled with a pressure fluid. The interior space is separated from the pressure fluid space for preventing fluid communication between the interior space and the pressure fluid space. The hydrodynamic torque converter also has a first channel connected to the interior space for guiding converter work fluid into the interior space, a second channel connected to the interior space for guiding converter work fluid out of the interior space and a third fluid channel connected to the pressure fluid space for selectively directing pressure fluid into and out of the pressure fluid space. The coupling element is displaced for at least partially canceling a rotational coupling of the converter housing and the turbine wheel when pressure fluid is directed into the pressure fluid space.

Owner:ZF FRIEDRICHSHAFEN AG

Liquid container and remanufacturing method of liquid container

ActiveUS8177342B2Increase resistanceIncrease capacityWriting implementsMetal-working apparatusEngineeringMechanical engineering

According to one aspect of the invention, a remanufacturing method of a liquid container forms an inlet in a downstream wall surface of a second chamber, which defines part of a bottom face of the liquid container. In the state of closing a liquid feeder and opening an air open structure, the remanufacturing method injects a liquid through the inlet to fill the second chamber with the liquid. In the state of opening the liquid feeder and closing the air open structure, the remanufacturing method injects the liquid through the inlet to fill a space from the second chamber to the liquid feeder with the liquid. The remanufacturing process seals the inlet after completion of the injection of the liquid. This arrangement enables the liquid to be efficiently refilled into the liquid container without damaging the functions of the liquid container.

Owner:SEIKO EPSON CORP

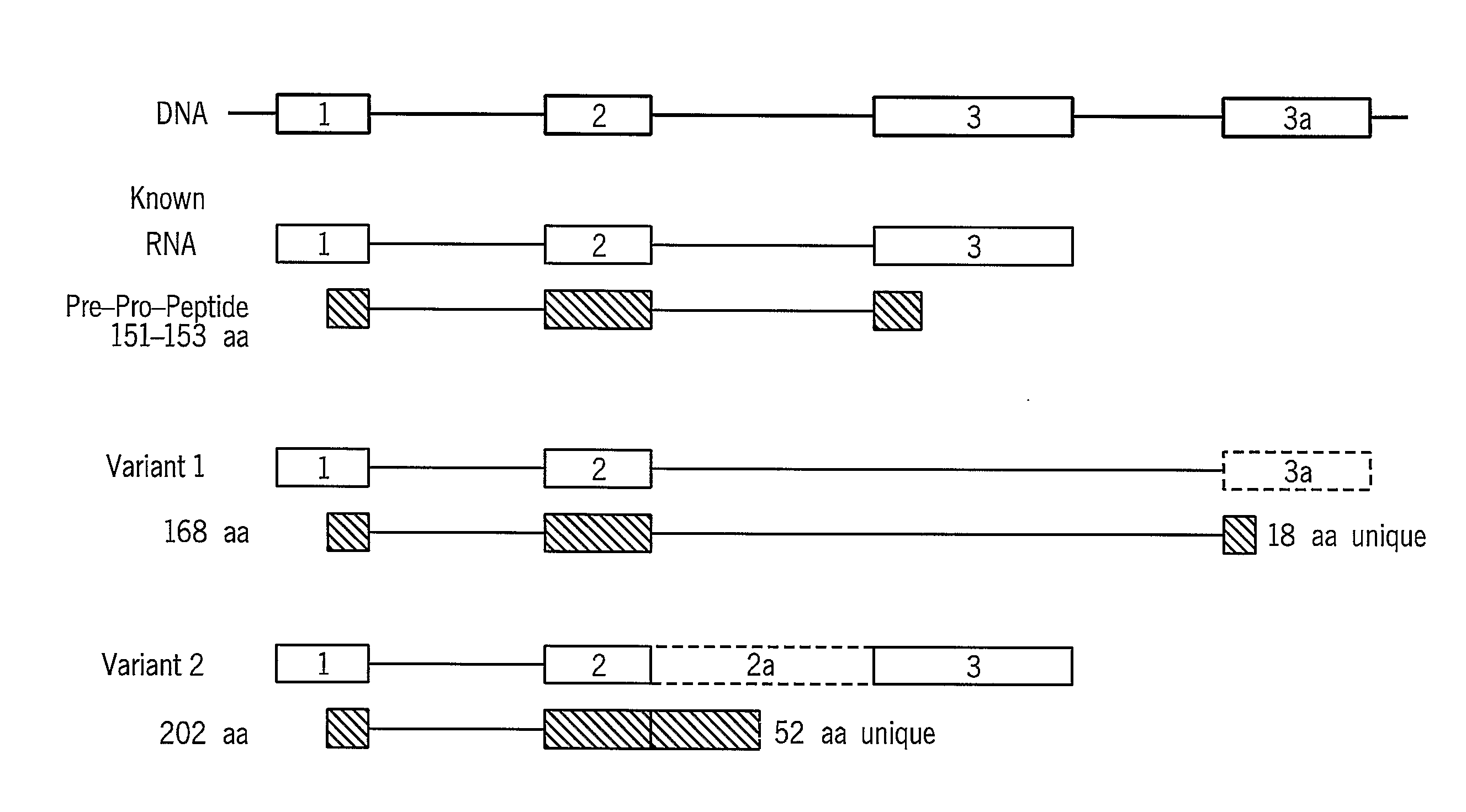

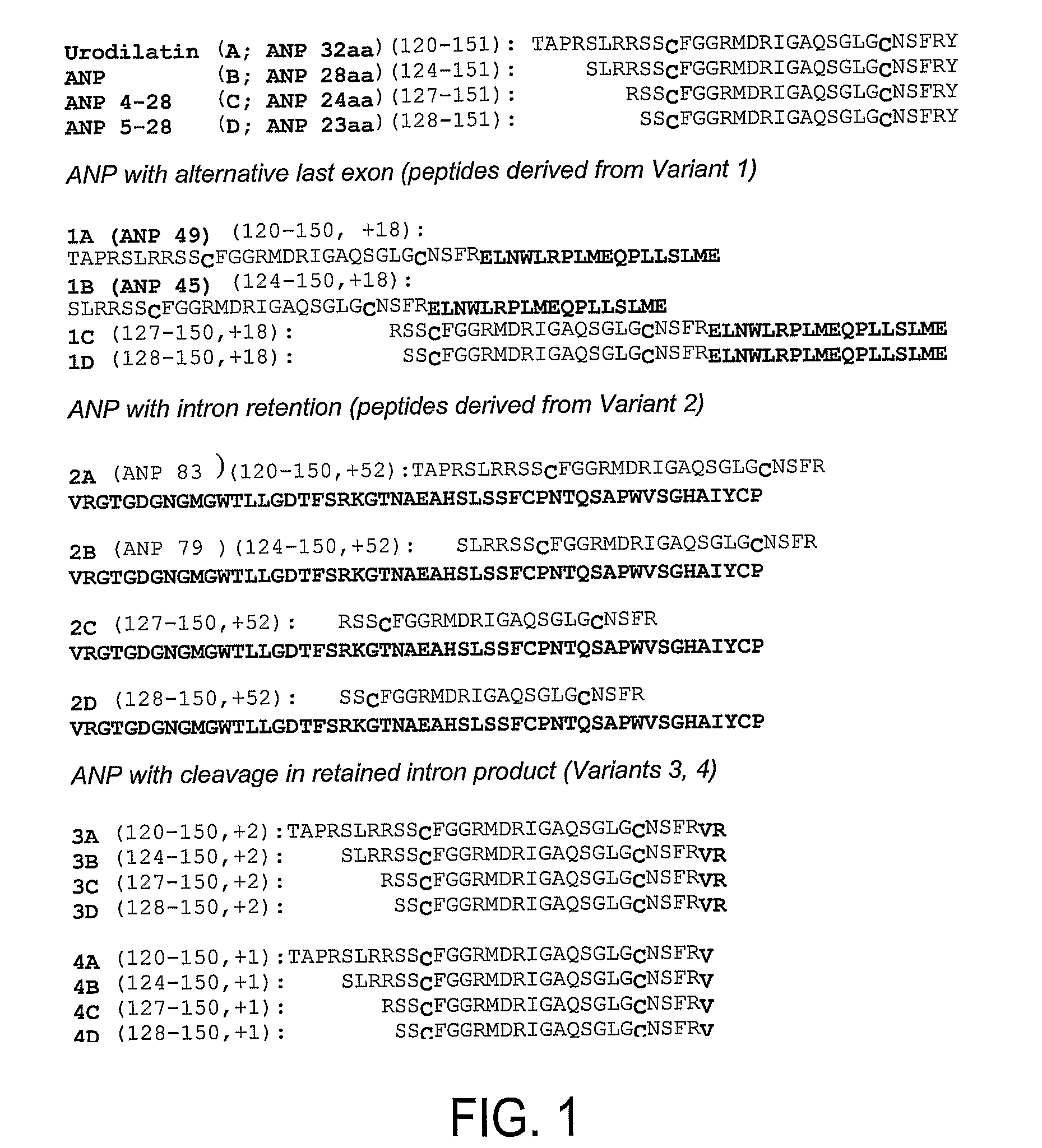

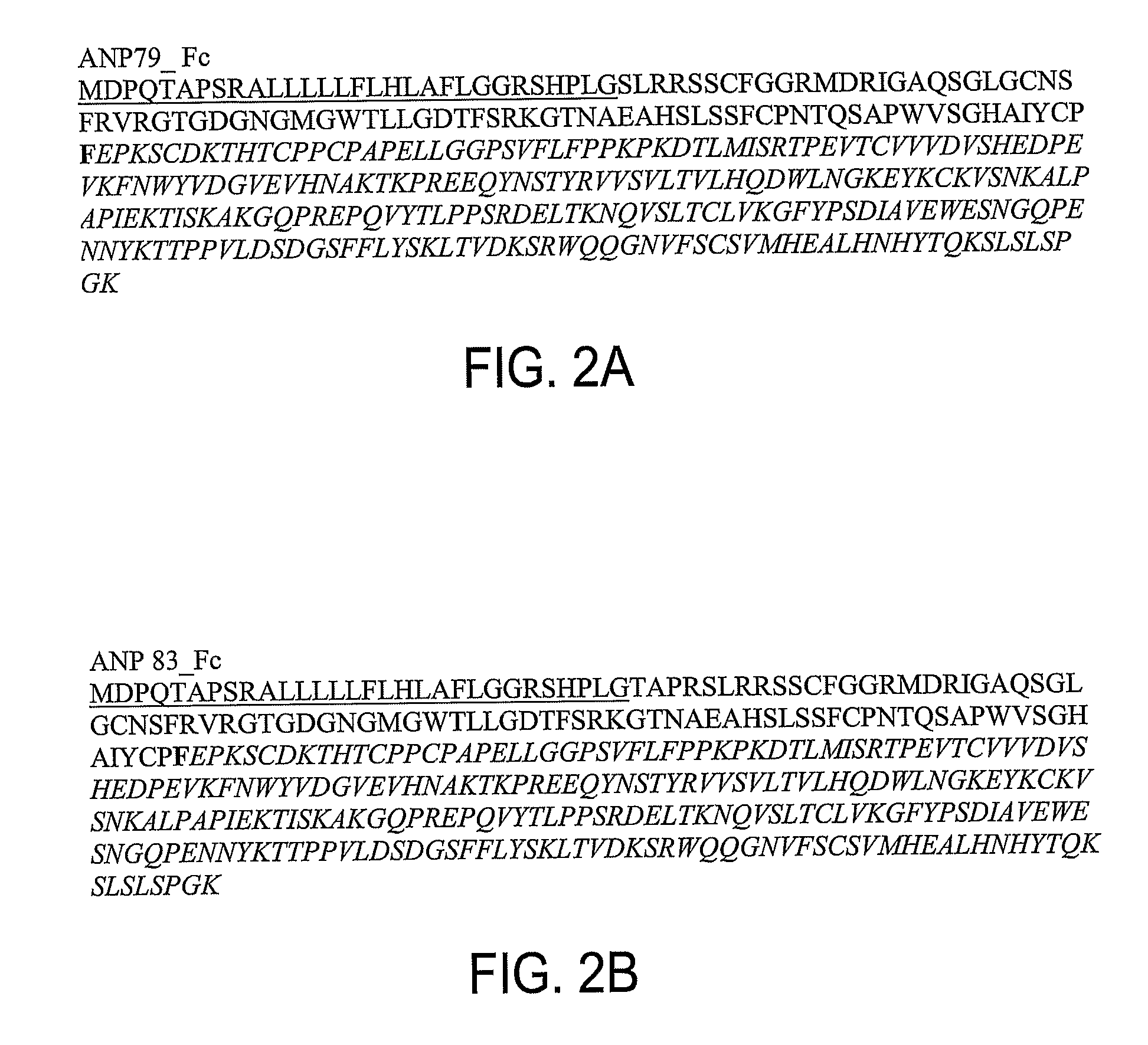

Atrial natriuretic peptide (ANP) splice variants and methods of using same

InactiveUS20090035287A1Useful in therapyReduce filling pressureOrganic active ingredientsBiocidePharmaceutical drugPolynucleotide

Owner:COMPUGEN

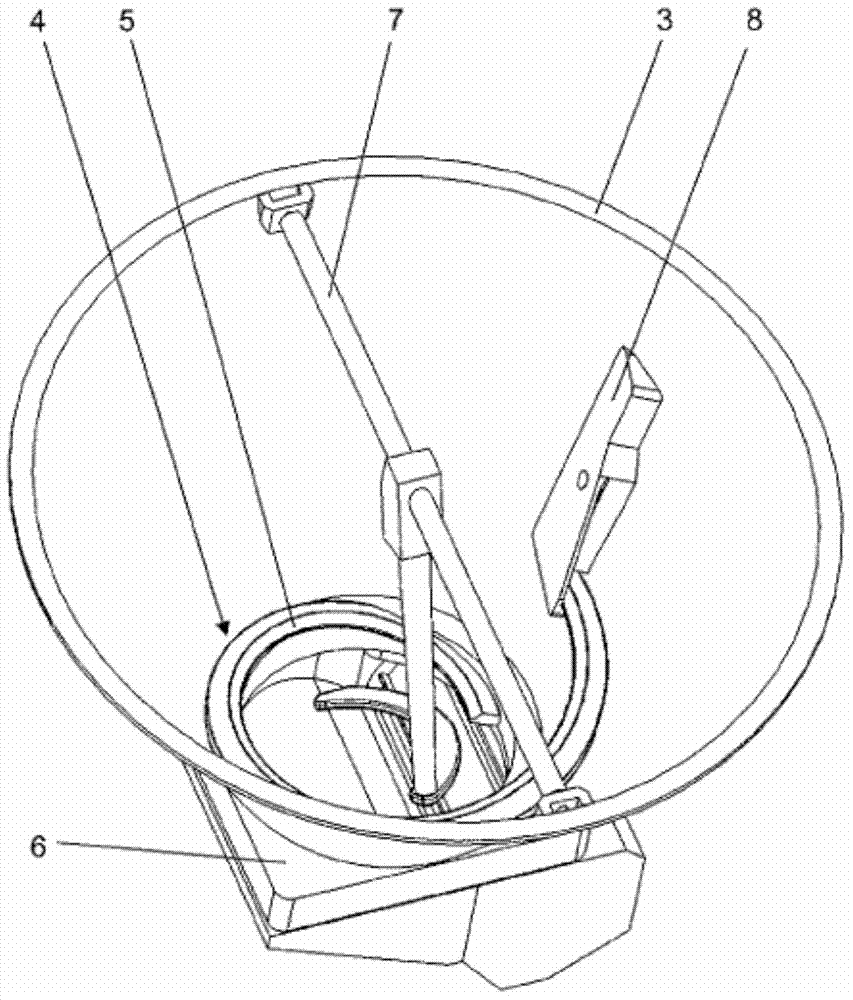

Mass supply system

ActiveCN104244722ASmall inertiaEasy to replaceMeat processingRotary piston pumpsEngineeringMechanical engineering

Owner:GEA FOOD SOLUTIONS BAKEL

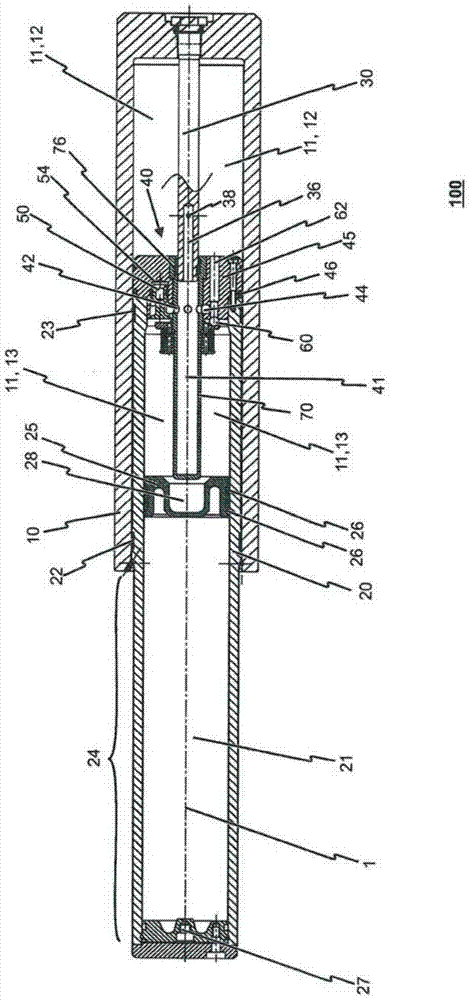

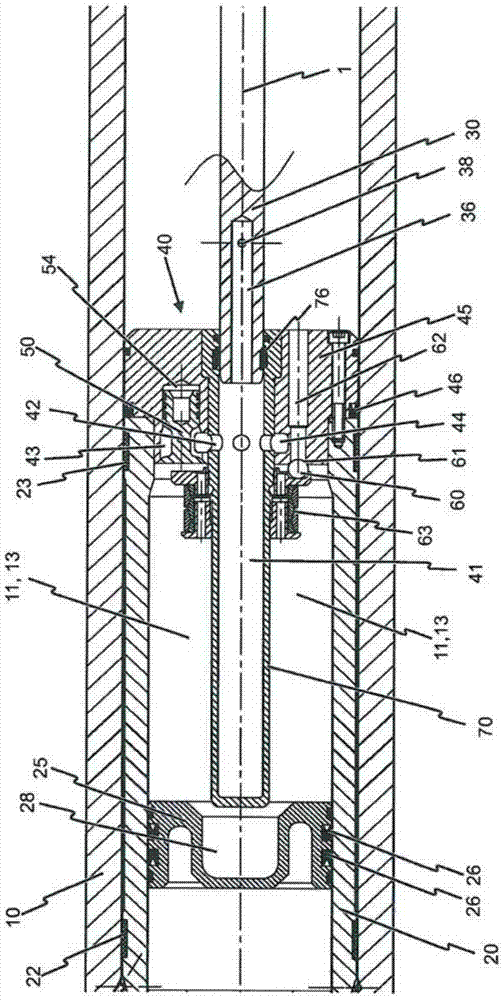

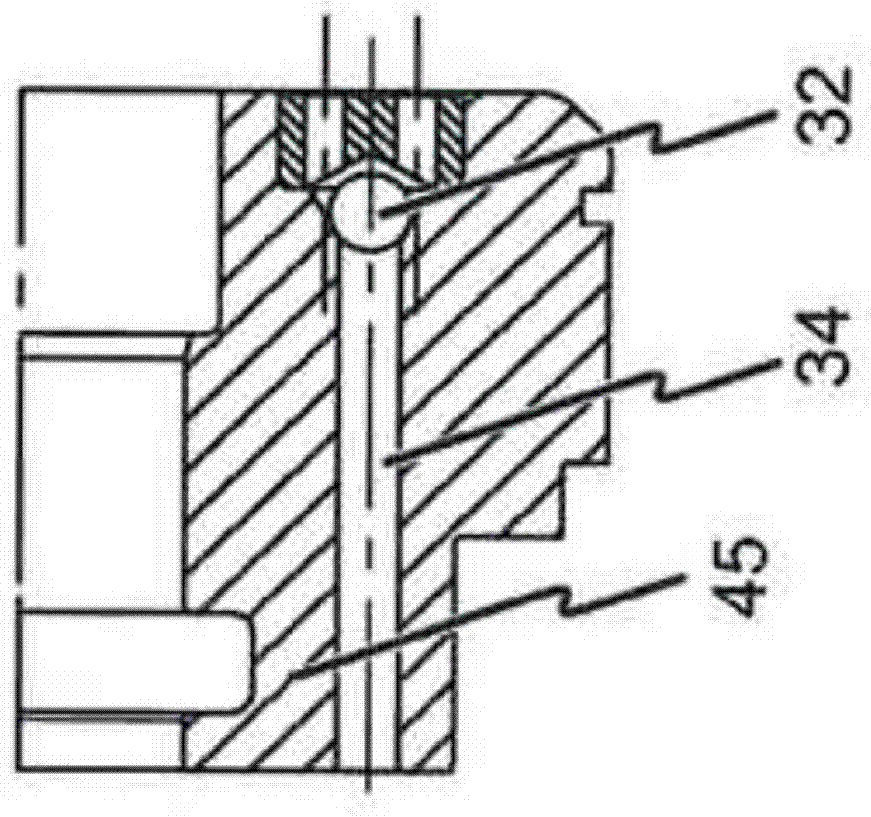

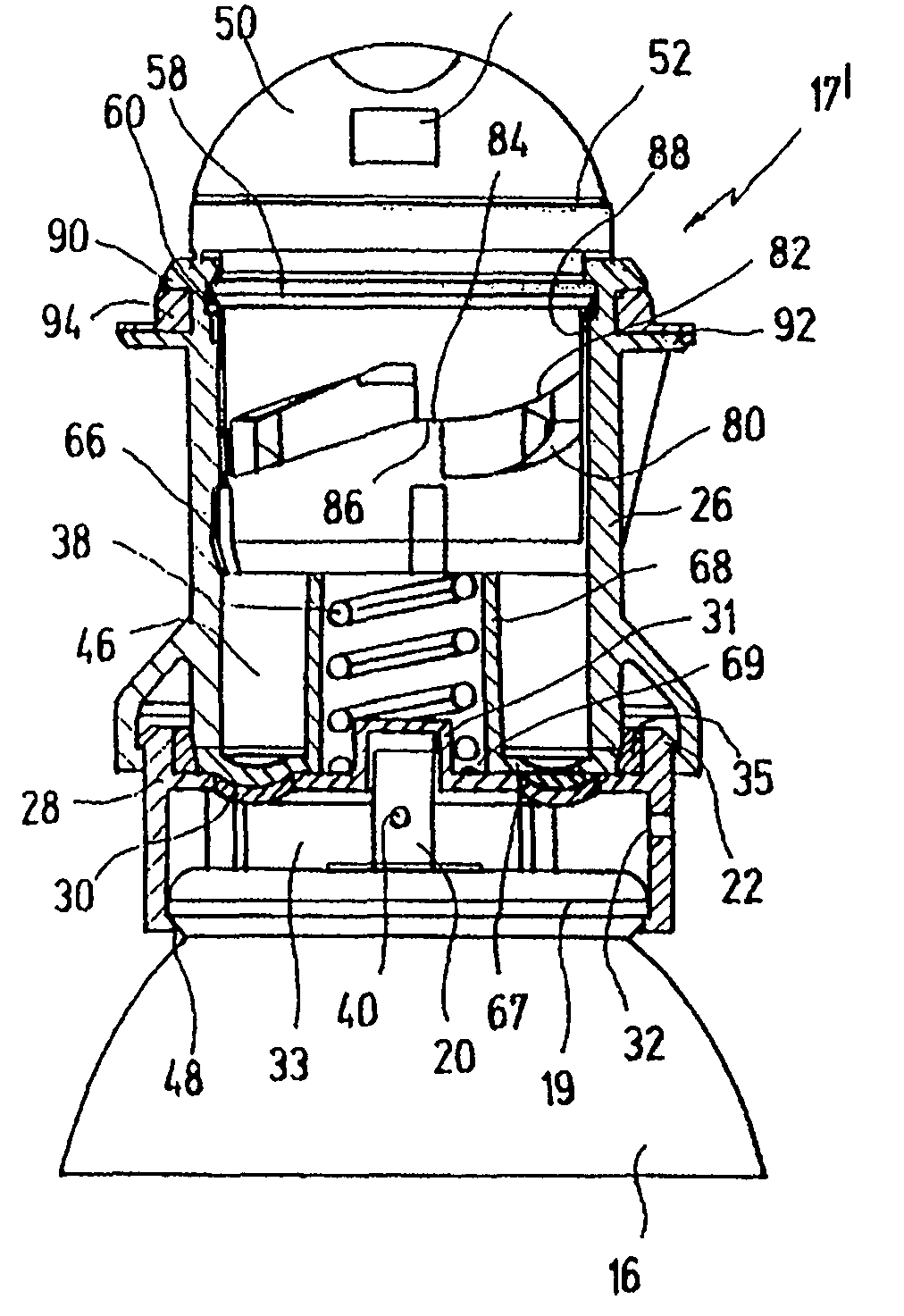

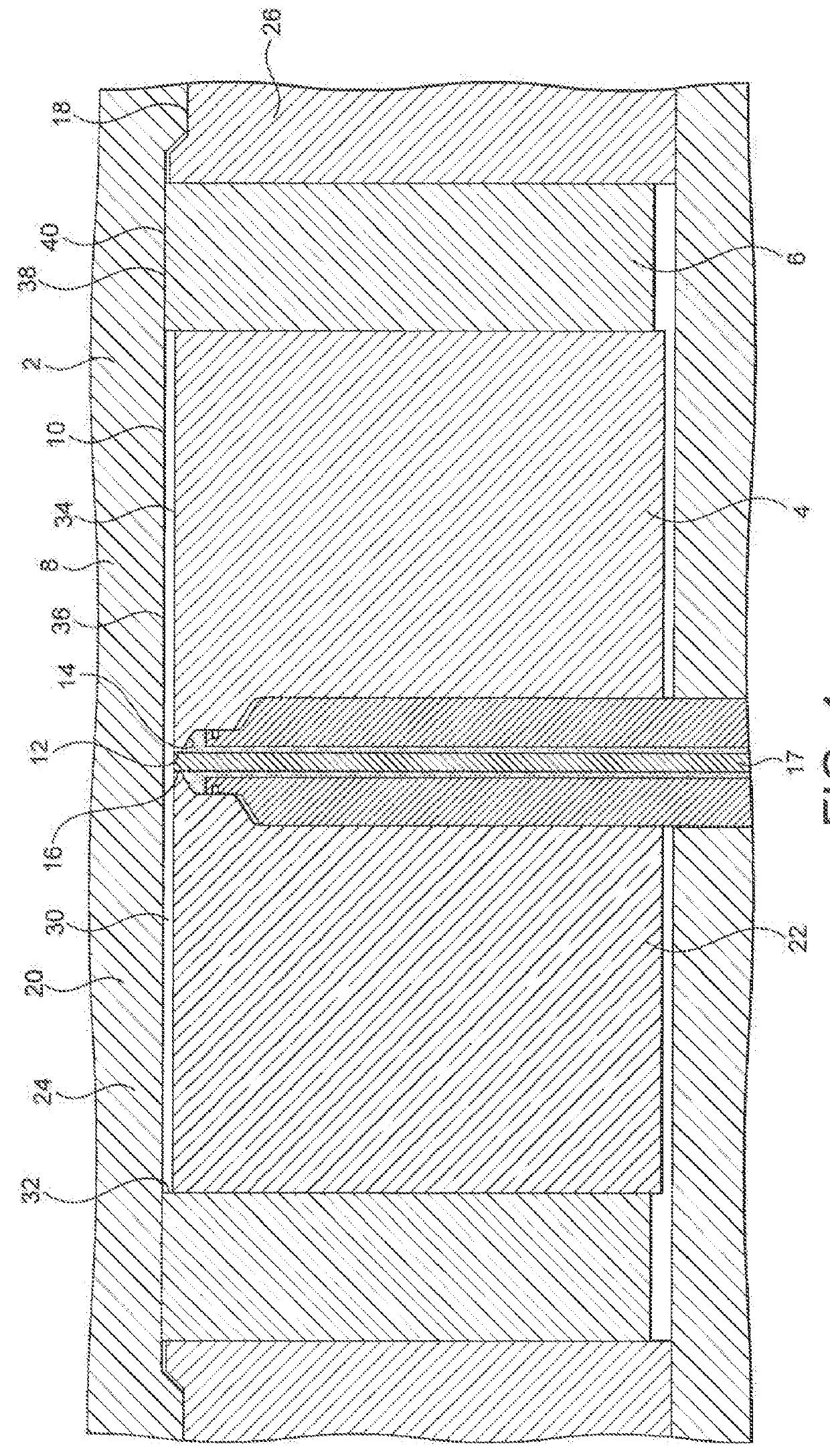

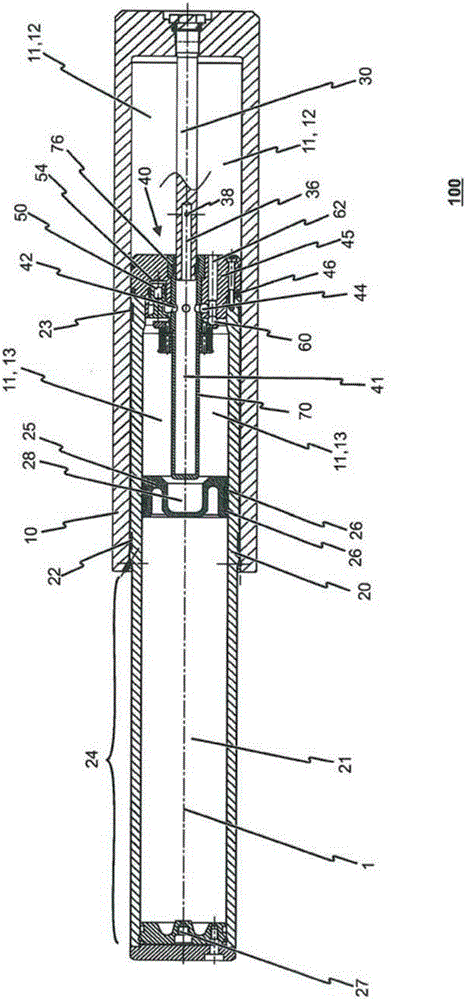

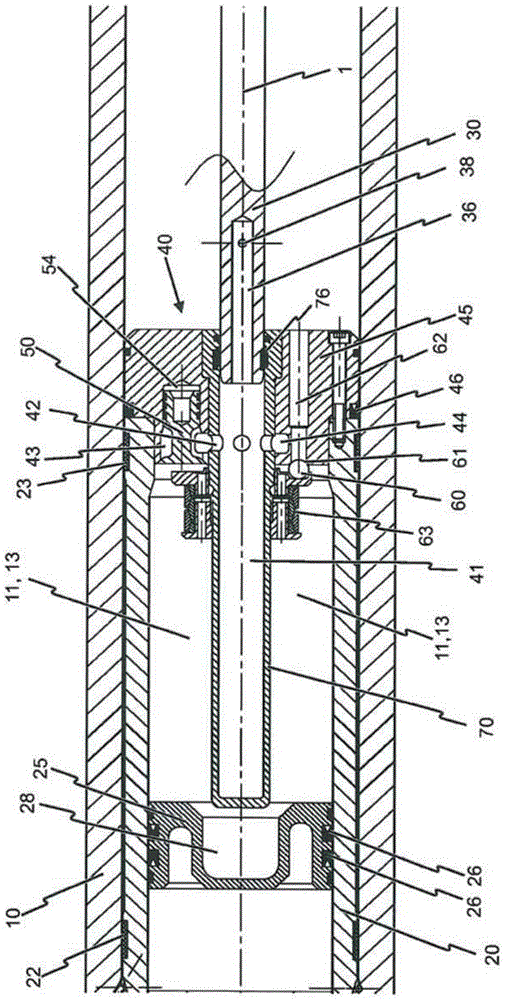

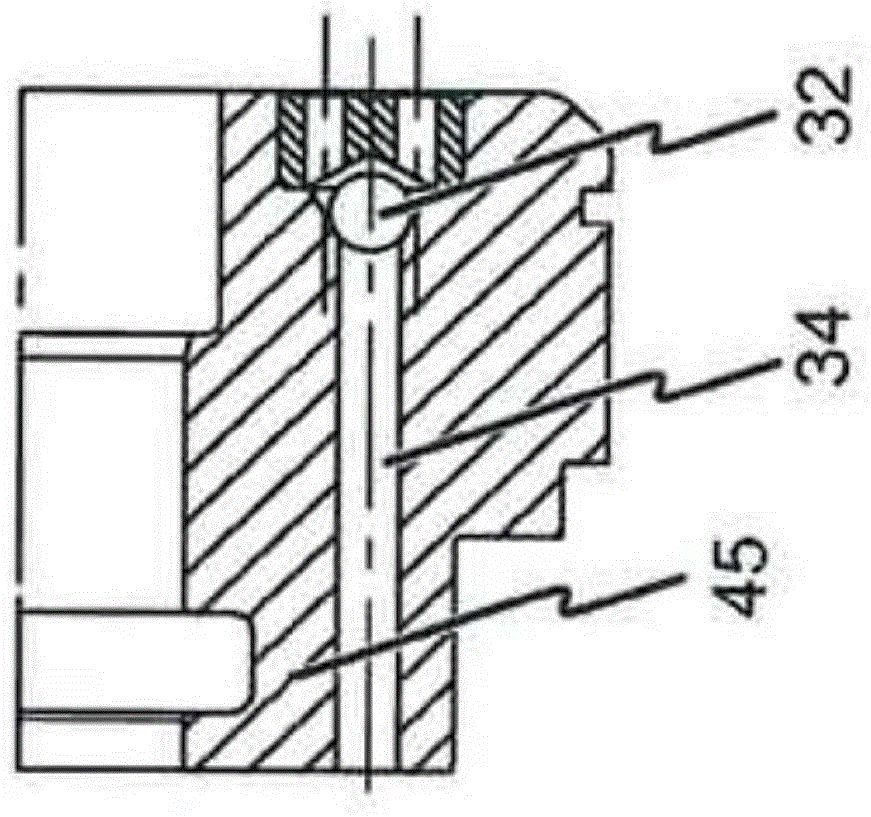

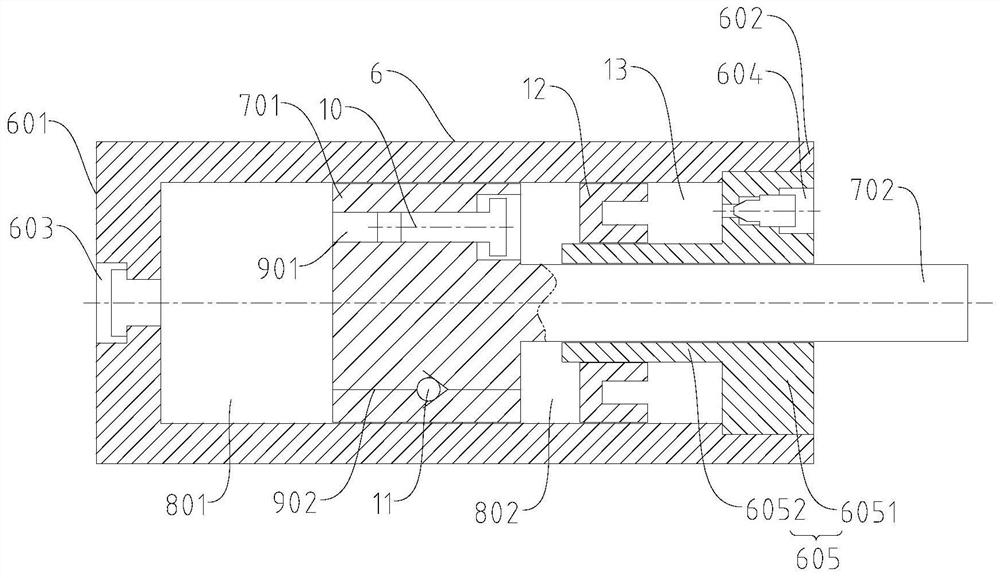

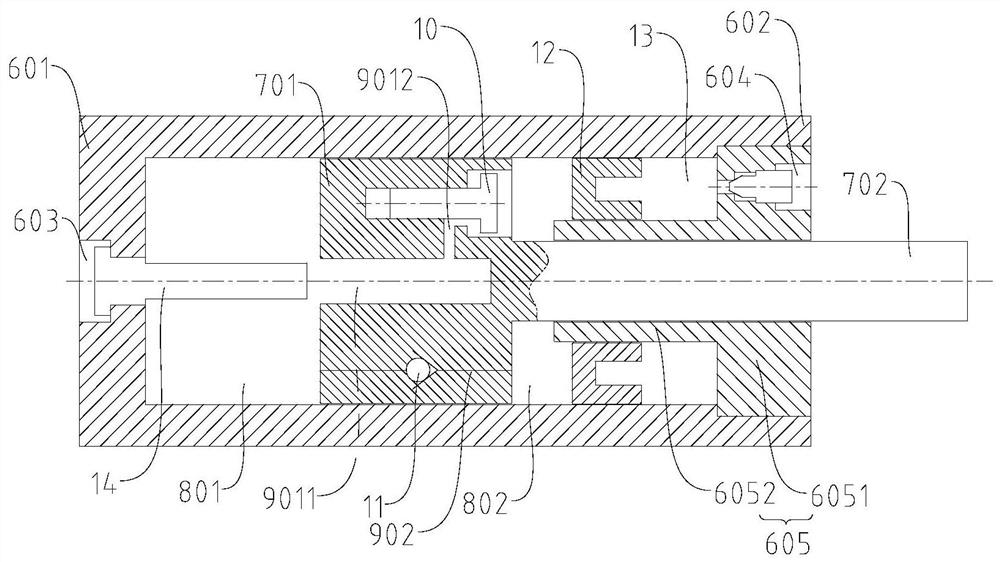

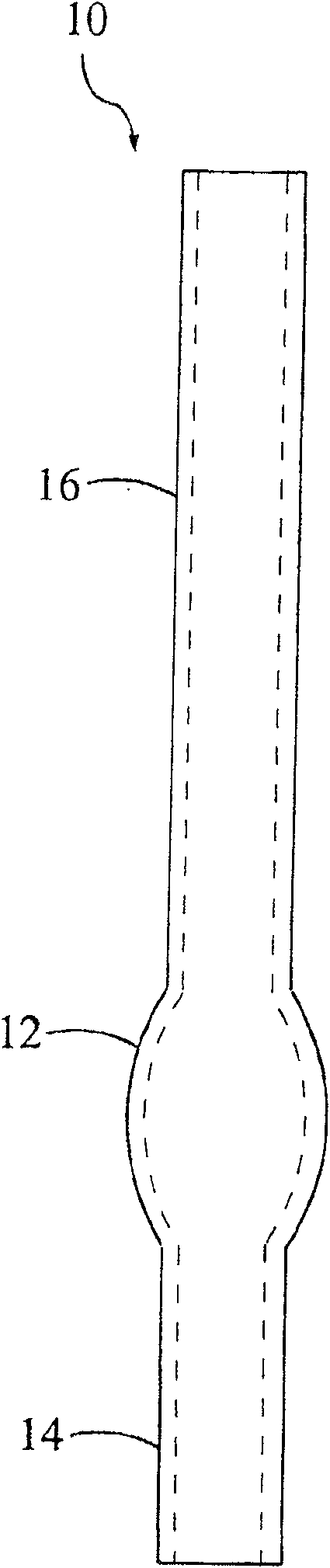

Device for damping pressure forces

ActiveCN104812653AQuick realization of the reset strokeExtended service lifeSpringsBufferPistonEngineering

The invention relates to a device (100) for damping pressure forces in the form of an impact absorber which is designed to be reversible even in the event of dynamic impact loads. The aim of the invention is to provide a device which is designed to absorb shocks in a reliable and reversible manner during normal operation and in the event of an overload. This is achieved by a device for damping pressure forces, said device having a valve arrangement (40) with an overflow region (41) which is connected to a rear hydraulic chamber region (12) and is designed such that hydraulic fluid can flow from the rear hydraulic chamber region (12) into a front hydraulic chamber region (13). A throttle pin (30) protrudes into a connecting region between the rear hydraulic chamber region (12) and the overflow region in order to control the flow speed of the hydraulic fluid from the rear hydraulic chamber region (12) in the direction of the overflow region (41). The throttle pin (30) can be converted from a first state in which hydraulic fluid can flow from the rear hydraulic chamber region (12) into the overflow region (41) into a second state in which the rear hydraulic chamber region (12) is separated from the overflow region (41) in a fluid-tight manner. Additionally, the valve arrangement (40), which is formed at an end region of the hollow piston, has an overload valve (60) which is connected to the rear hydraulic chamber region (12) via at least one overload channel (62).

Owner:VOITH PATENT GMBH

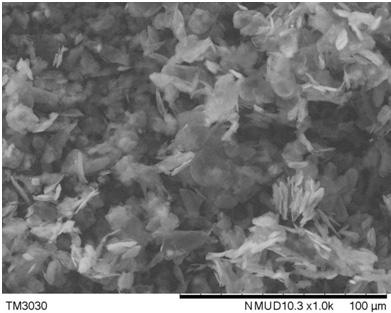

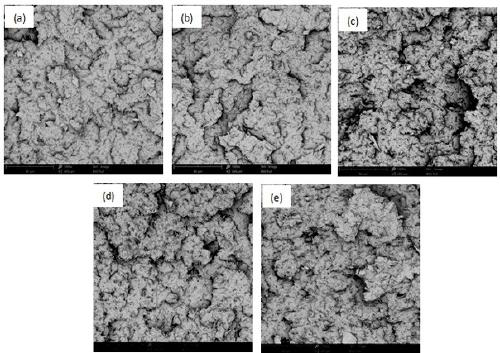

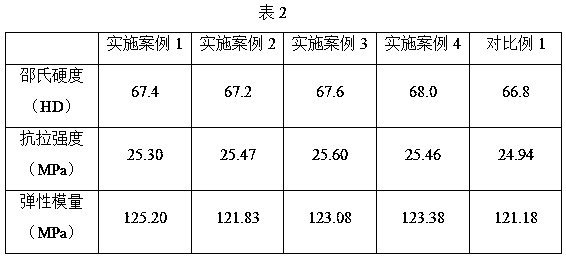

Graphene micro-sheet/high-density polyethylene composite material and preparation method thereof

The invention discloses a graphene micro-sheet / high-density polyethylene composite material and a preparation method thereof. Raw materials comprise a graphene micro-sheet, high-density polyethylene and a silane coupling agent. The performance of the high-density polyethylene is improved by using the graphene micro-sheet to prepare the high-density polyethylene composite material, and the frictionabrasion performance and mechanical properties of the composite material are greatly improved; the graphene micro-sheet / high-density polyethylene composite material has the advantages of low cost, high chemical stability and easiness for processing and molding and realizing large-scale production, and has a wider application prospect in the fields including gas transportation, water supply and pollution emission, agricultural irrigation, posts and telecommunications and communications and the like.

Owner:FUZHOU UNIV

Method for filling high-temperature liquid-phase chromatographic column of padding with fine particle size and dedicated device for method

InactiveCN104034830AReduce filling pressureGood repeatabilityComponent separationSlurryHigh pressure

The invention discloses a method for filling a high-temperature liquid-phase chromatographic column of padding with the fine particle size. The method is characterized by comprising the following steps: firstly stirring and mixing the padding with a homogenate solvent, performing ultrasonic dispersing treatment to obtain homogenate, then heating a pressurized solvent pipeline, a homogenate tank and the chromatographic column to enable the temperatures of the pressurized solvent pipeline, the homogenate tank and the chromatographic column to reach 50-90 DEG C, pouring the homogenate into the homogenate tank, connecting the pressurized solvent pipeline, a column filling pump, the homogenate tank and the chromatographic column through a pipeline, sealing the homogenate tank, pressurizing the homogenate tank to 50-200MPa after the temperature of the homogenate is uniform with that of the homogenate tank, and filling the column filling pump with the homogenate and a pressurized solvent. The filling method has relatively low requirements on the high pressure sealing property of filling equipment. Meanwhile, the invention further relates to a dedicated filling device necessary for the filling method.

Owner:DALIAN ELITE ANALYTICAL INSTR

Device for Dispensing a Fluid from the Hollow Space of a Container

InactiveUS20080099511A1Easy to assembleSimple structureLiquid dispensingInternal pressureAmbient pressure

Owner:SCHNEIDER PETER +3

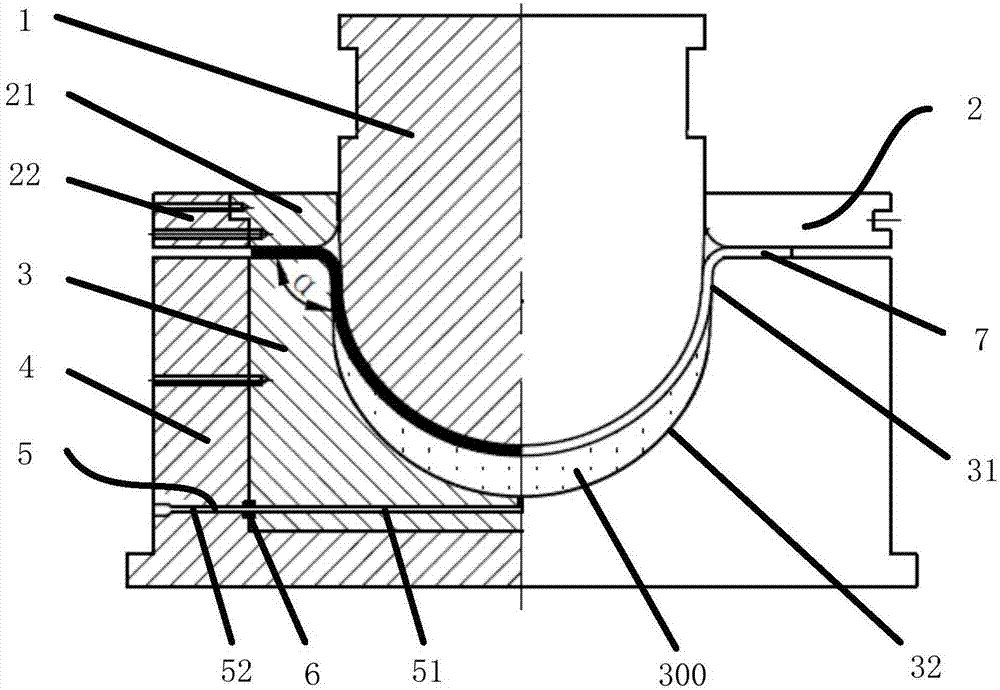

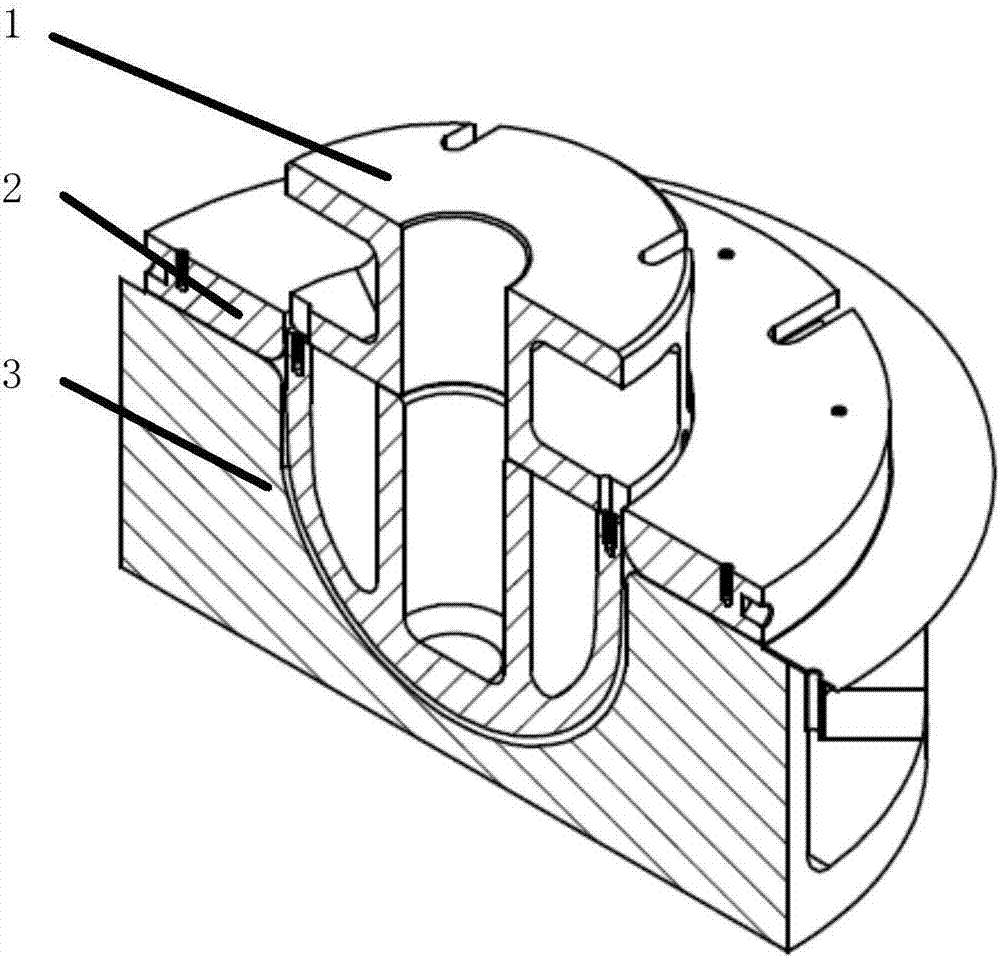

Revolving body part liquid-filling forming device and method

ActiveCN107570572AReduce filling pressureHigh precision of product sizeVehicle componentsEngineeringMechanical engineering

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

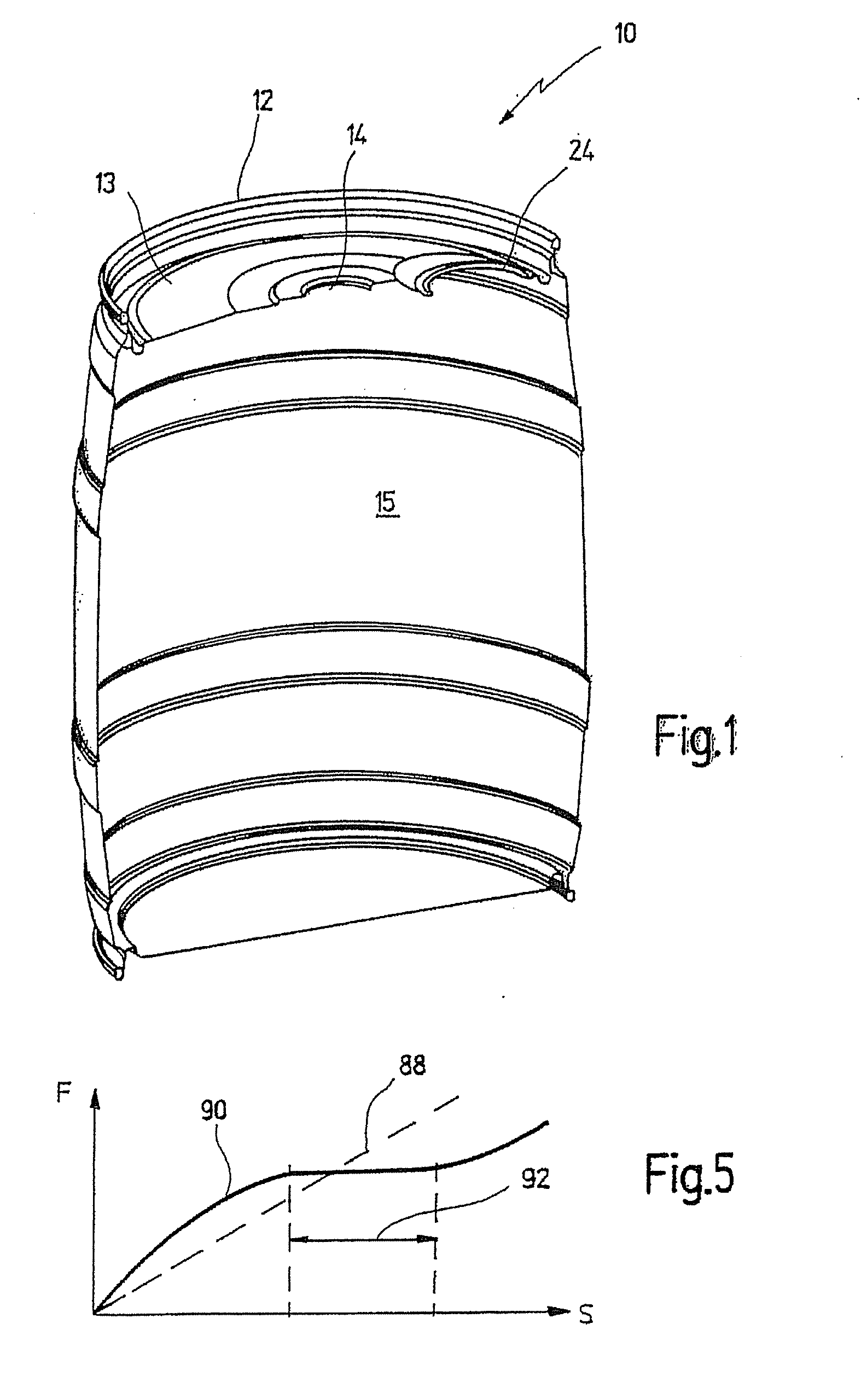

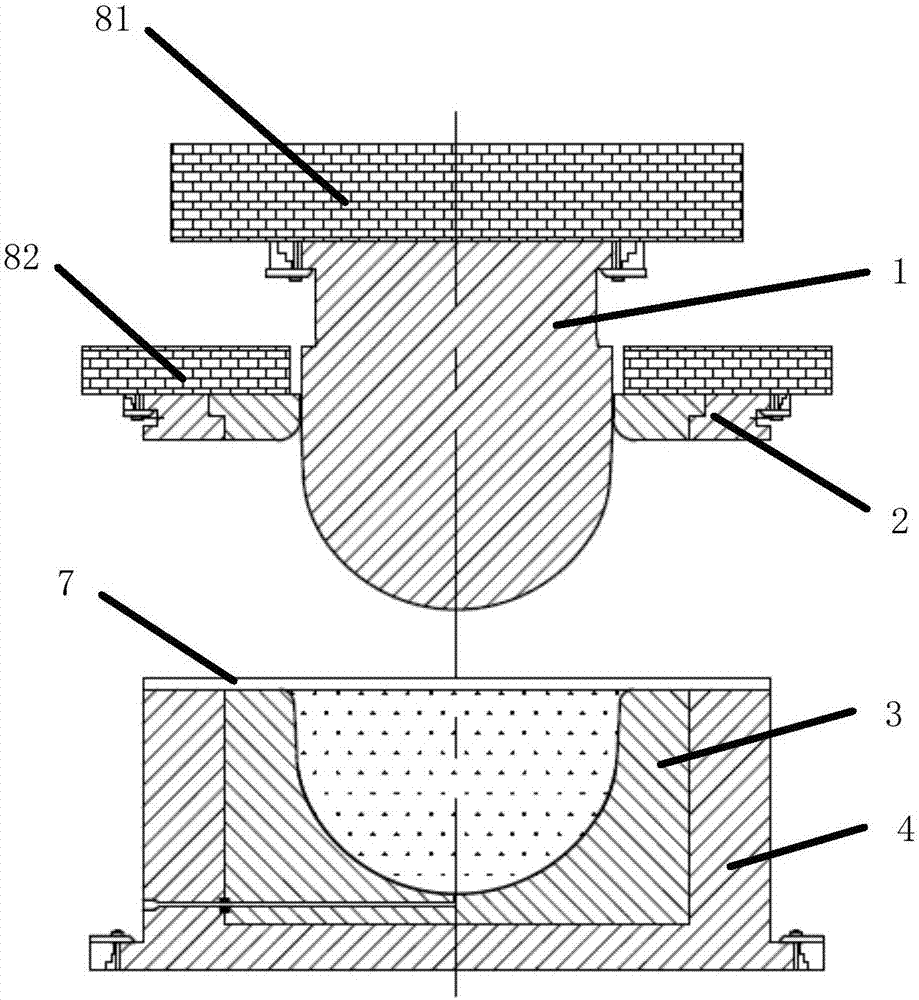

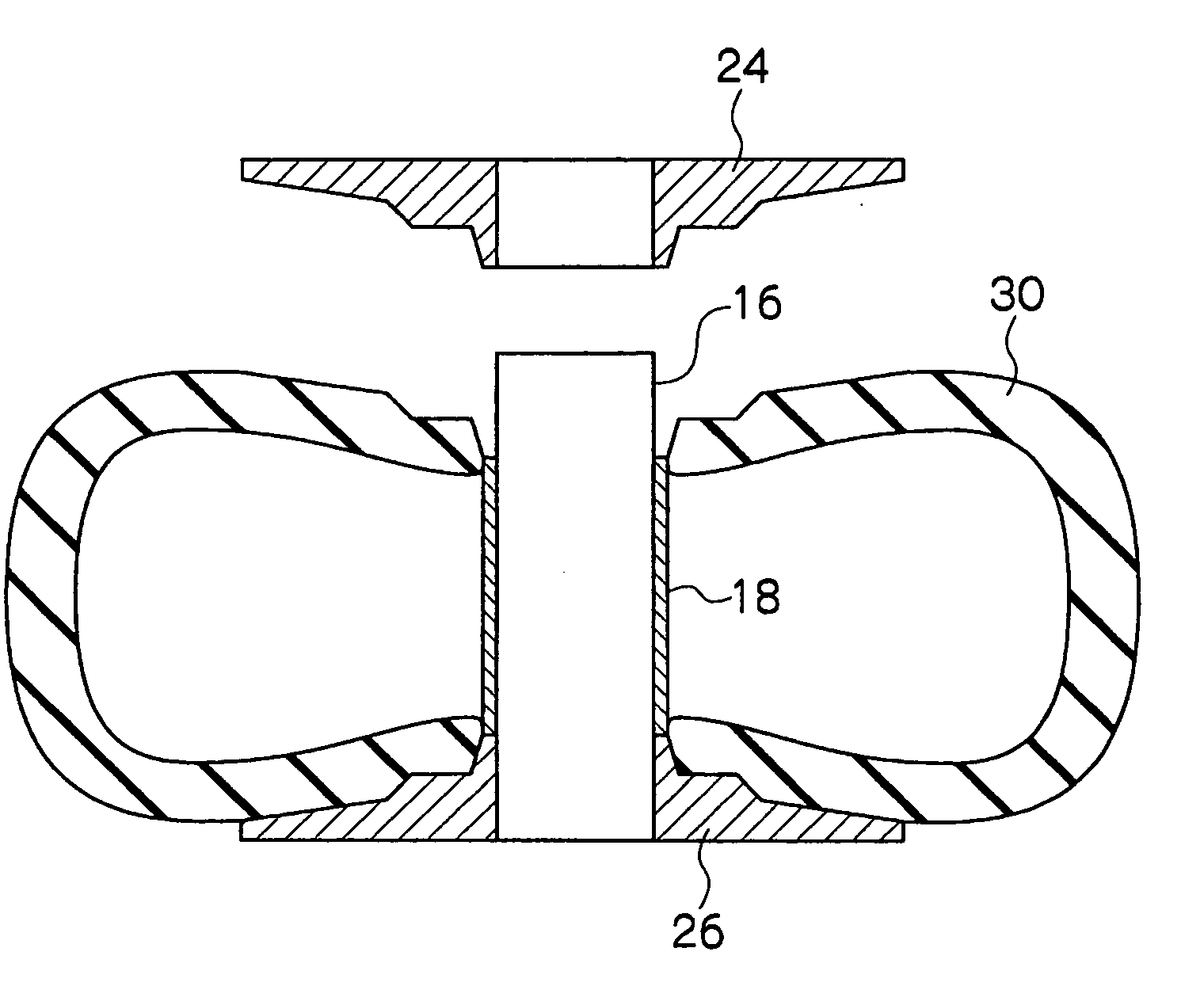

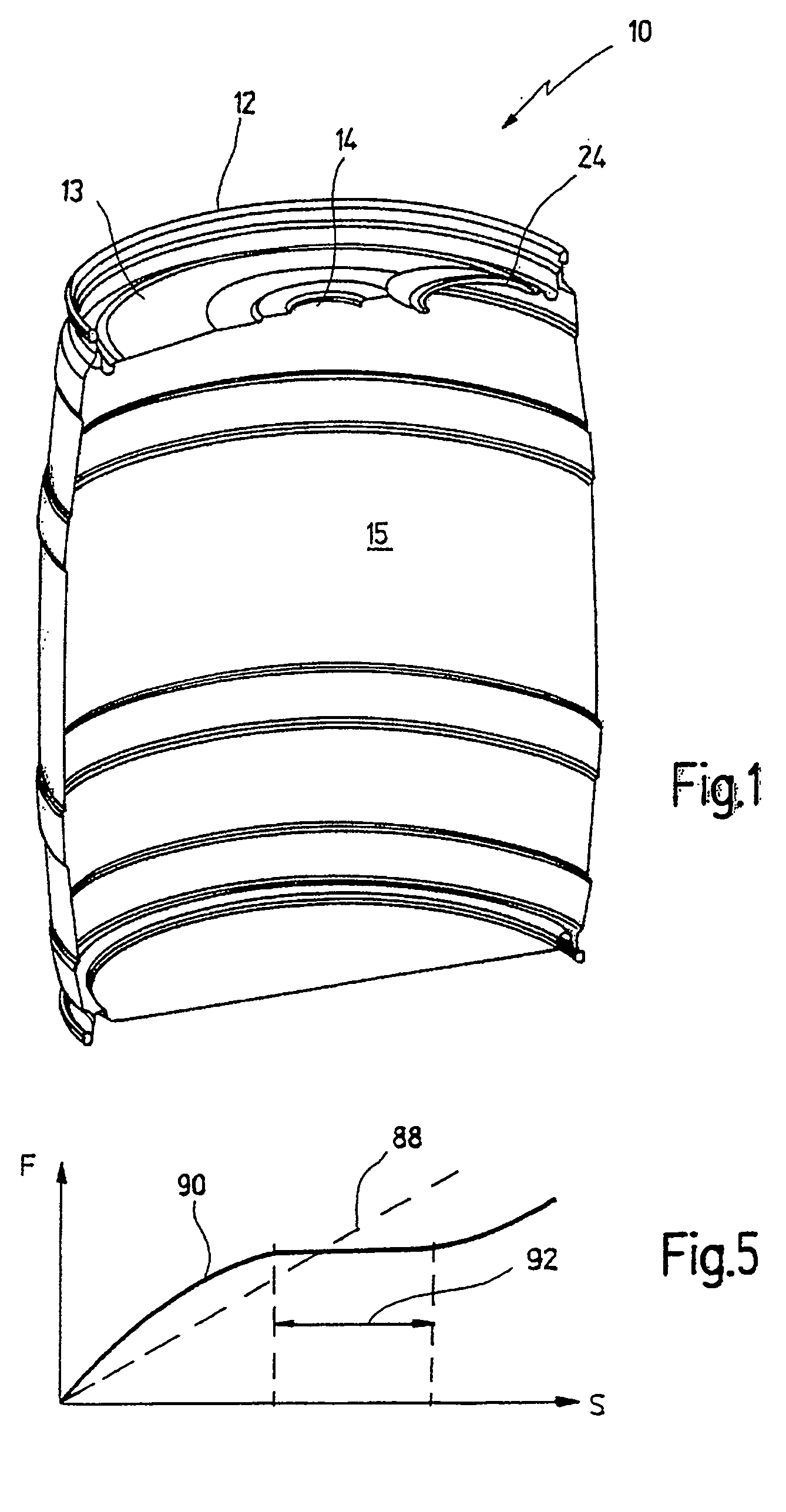

Tire Holding Unit, Molding Dies Having the Same, and Tire Vulcanization Method Using the Same

The purpose is to provide a convenient-to-use tire holding unit which allows vulcanization molding to be efficiently carried out, and prevents a green tire from being deformed, molding dies having the same, and a tire vulcanization method using the same. Molding dies 12 have a tire holding unit 14 for holding a green tire 30; a lower die main body 28; and an upper die main body 22. The tire holding unit 14 includes a center post 16 which is freely mountable to and dismountable from the molding dies 12; a bladder 18 mounted to the center post 16; and a central upper die part 24 and a central lower die part 26 mounted to the center post 16 at either end side of the bladder, respectively. The central upper die part 24 is freely mountable to and dismountable from the center post 16. In addition, the die-radial outside edge 26E of the central lower die part 26 is located at an outer side in a die radial direction of a location which corresponds to half the tire section height H of the molding dies 12. The upper die main body 22 and the central upper die part 24 constitute an upper die 21, and the lower die main body 28 and the central lower die part 26 constitute a lower die 29.

Owner:BRIDGESTONE CORP

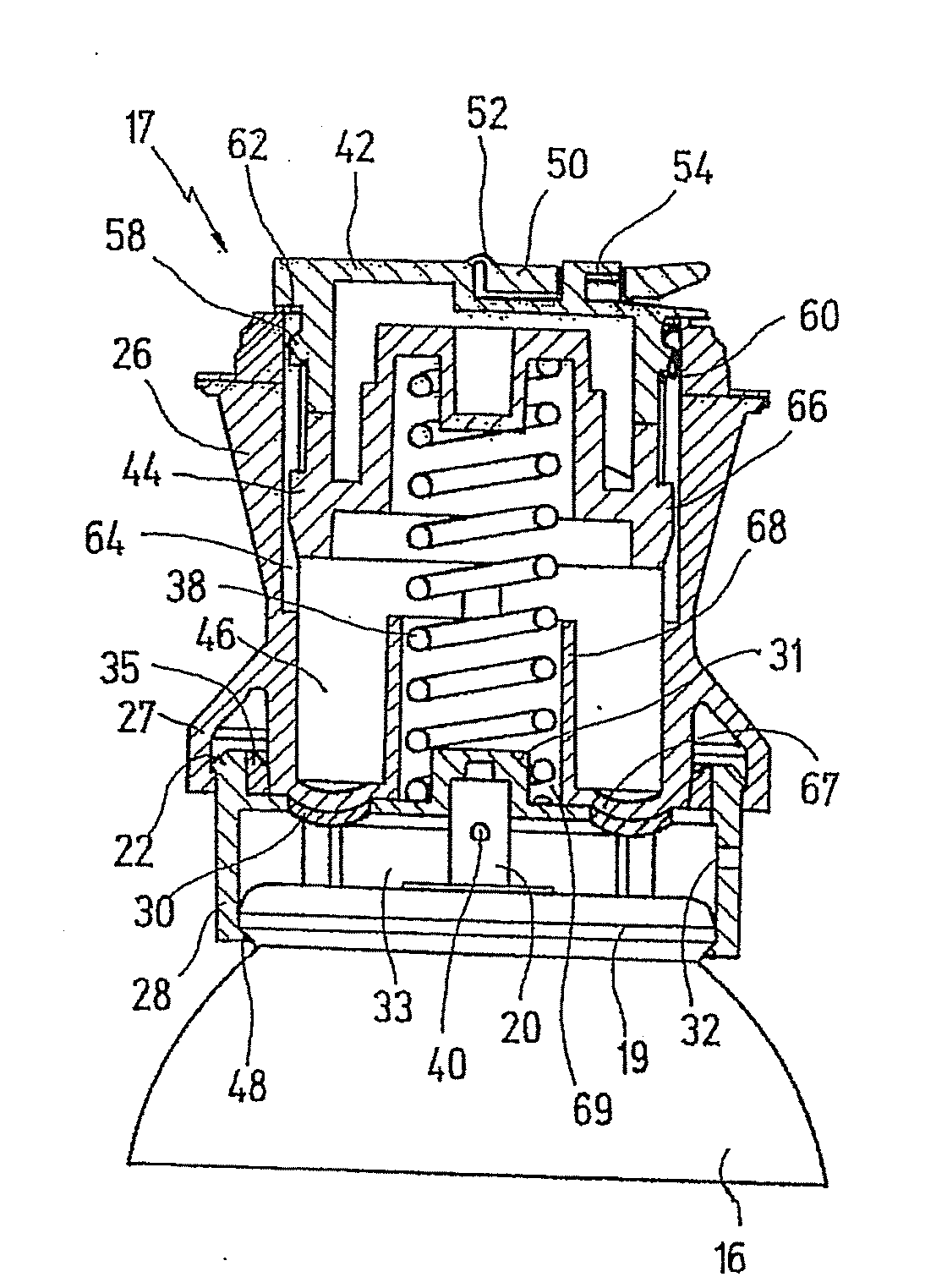

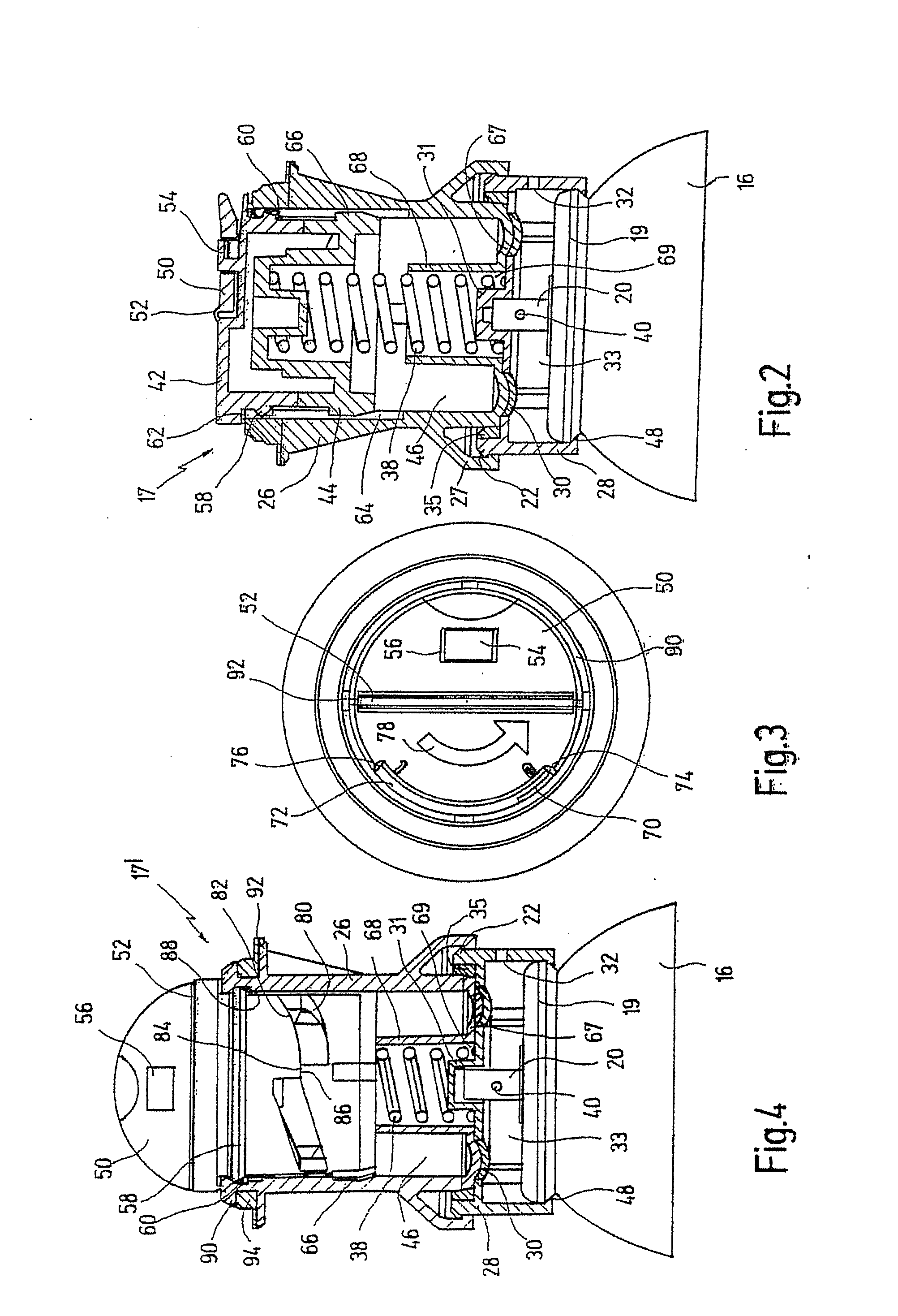

Device for dispensing a fluid from the hollow space of a container

InactiveUS7866510B2Easy to assembleSimple structureClosure using stoppersLiquid dispensingInternal pressureAmbient pressure

Disclosed is a device for dispensing a fluid, in particular a carbonated beverage, from a storage chamber of a container towards the outside via at least one closeable discharge port, comprising a pressure reservoir which is separated from the storage chamber and in which a pressurized propellant is accommodated, and which can be connected to the storage chamber via a pressure regulation mechanism. The pressure regulation mechanism includes an axially moveable regulating element that is impinged upon by means of a spring in the direction of an open position in which propellant is discharged from the pressure reservoir into the storage chamber. The ambient pressure to which the container is exposed acts upon the regulating element in the direction of the open position, and the internal pressure inside the storage chamber of the container acts upon the regulating element in the direction of the closed position.

Owner:HUBER PACKAGING GROUP

Low-temperature liquid storage tank vacuum interlayer pearlife filling technology

InactiveCN104913187AQuality improvementImprove efficiencyPressure vesselsLiquid storage tankEngineering

The invention discloses a low-temperature liquid storage tank vacuum interlayer pearlife filling technology. By virtue of the negative pressure, a low-temperature container vacuum interlayer is filled with pearlife; then the flow resistance of the pearlife in the vacuum interlayer is overcome by use of positive pressure, so that the purpose of compaction is achieved. The filling technology has the characteristics of being simple and convenient in technical operation and high in filling efficiency, and filling is performed under a seal state isolated from air and water; by virtue of a filling, compaction and repetitive filling and compaction process, the vacuum interlayer is seamlessly filled with the pearlife, so that the insulation performance and service life of a storage tank are ensured.

Owner:江西制氧机有限公司

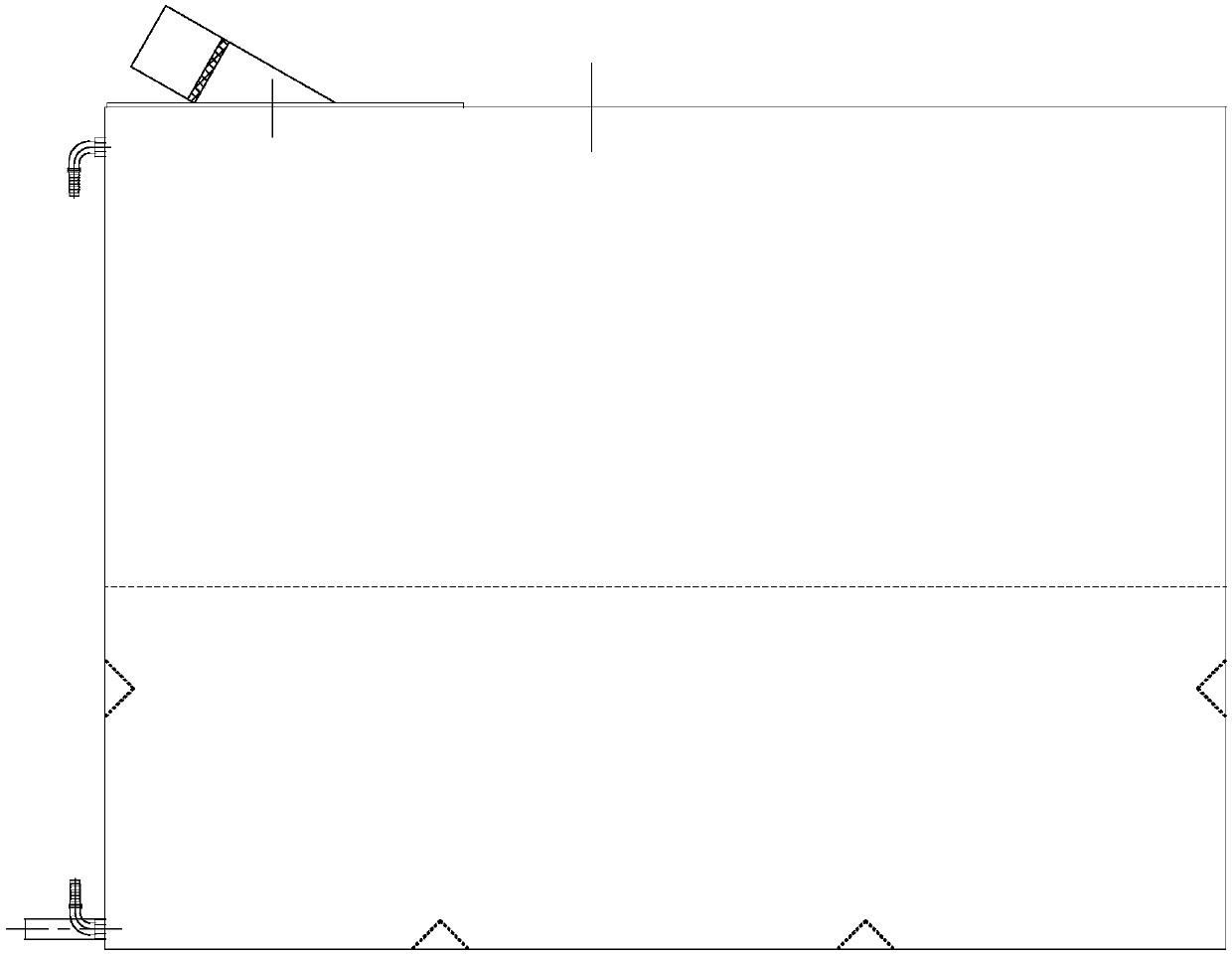

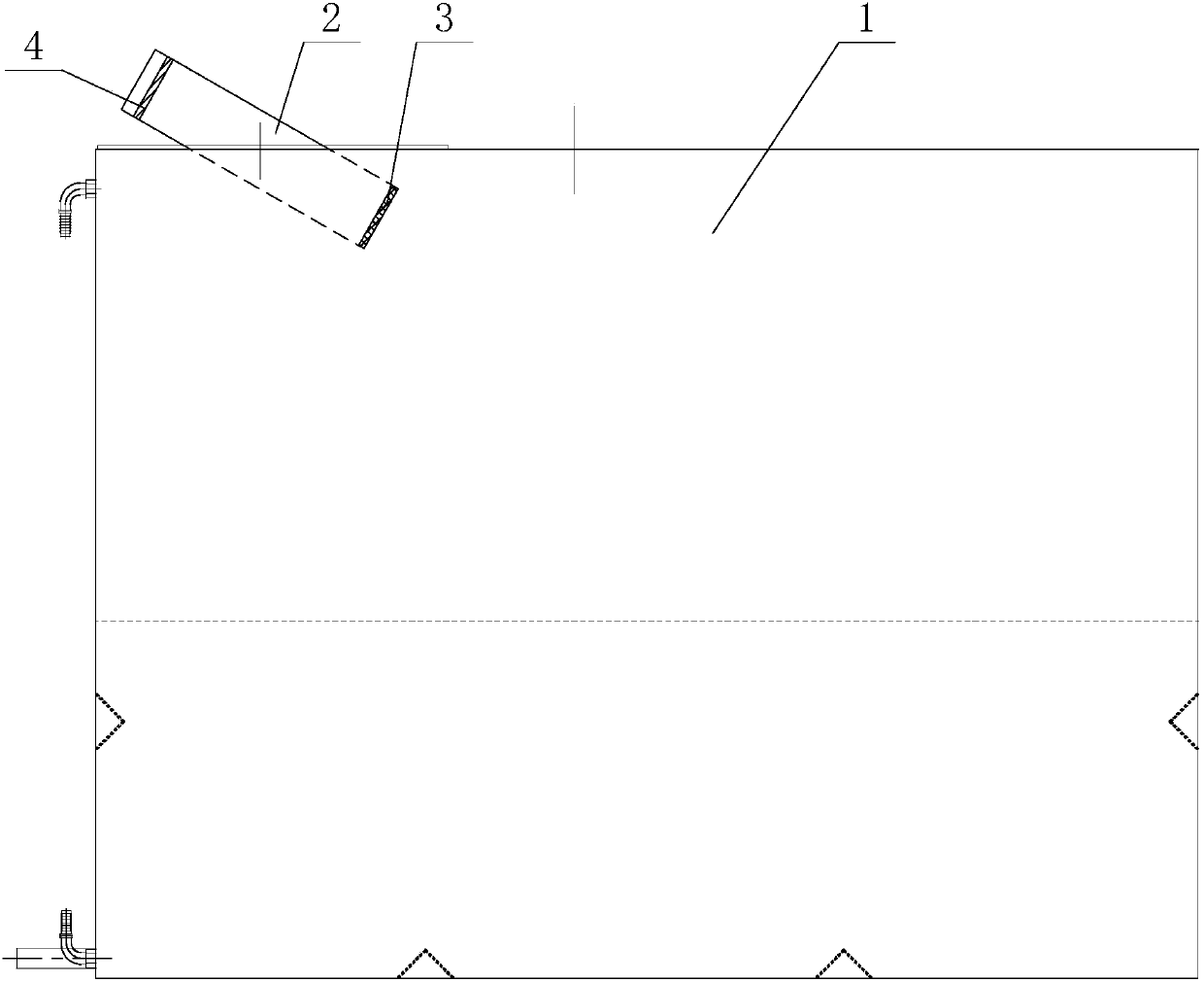

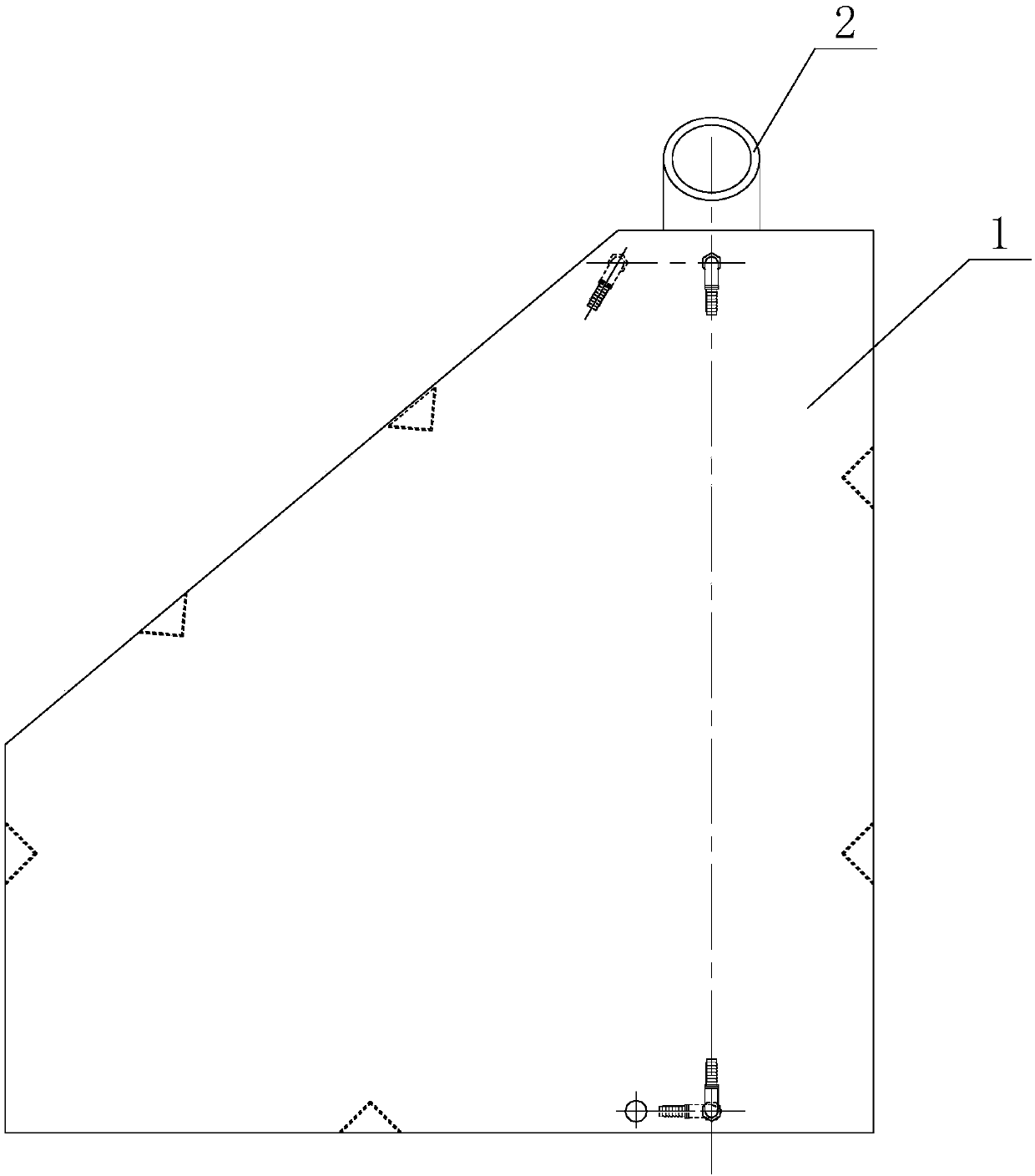

Oil tank for diesel generator set

PendingCN107687384ASimple structureEasy to implementMachines/enginesLiquid fuel feedersDiesel generatorOil tank

The invention discloses an oil tank for a diesel generator set. The oil tank comprises an oil tank body, an opening is formed in the upper portion of the oil tank body, an oil filling pipe matched with the opening is obliquely arranged on the opening, the upper end of the oil filling pipe is located on the outer portion of the oil tank body, the lower end of the oil filling pipe extends into the oil tank body, and a filtering net is arranged at the lower end. The oil tank for the diesel generator set is simple in structure and easy to achieve, the oil filling pipe of the oil tank is obliquelyarranged and extends into the oil tank body, and the filtering net is arranged at the lower end of the oil filling pipe, so that the distance between a spearhead of an oil filling gun and the filtering net is guaranteed; the oil filling pressure is lowered, so that splashing is avoided.

Owner:江苏瑞昌哥尔德发电设备股份有限公司

Injection Moulding Method

A method of injection moulding an article, the method comprising the steps of: (a) providing an injection mould comprising a plurality of mould parts defining a mould cavity of the injection mould, the plurality of mould parts including first and second movable mould parts, the injection mould further comprising an injection inlet for injecting molten thermoplastic resin material into the mould cavity, wherein the injection inlet is located in the vicinity of the first movable mould part and the second movable mould part is remote from the injection inlet; (b) disposing the first and second movable mould parts in a first configuration so as to define a first intermediate moulding cavity, in which first configuration the first movable mould part is in a first rearward position and the second movable mould part is in a first forward position; (c) injecting molten thermoplastic resin material into the first intermediate moulding cavity through the injection inlet to fill the first intermediate moulding cavity with the molten material; (d) closing the injection inlet; (e) after commencement of the injecting step and at least partly after the closing step, moving the second movable mould part from the first forward position to a second rearward position; (f) moving the first movable mould part from the first rearward position to a second forward position; and (g) moving the second movable mould part from the second rearward position to a third forward position thereby to dispose the first and second movable mould parts in a final configuration so as to define a final moulding cavity of the injection mould filled with the molten material, the final moulding cavity defining a cavity outer surface which defines the outer shape of the article to be moulded.

Owner:GR8 ENG

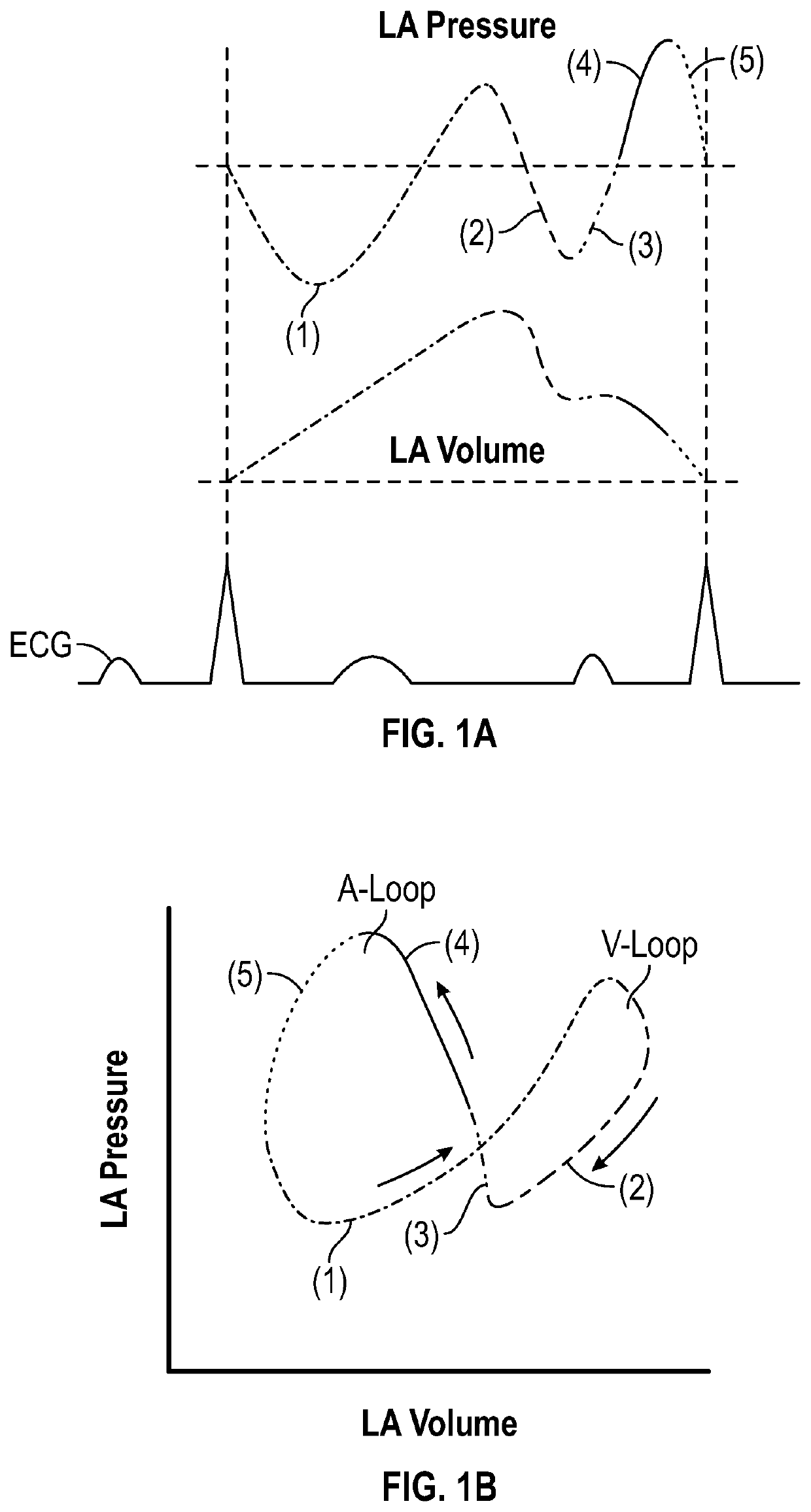

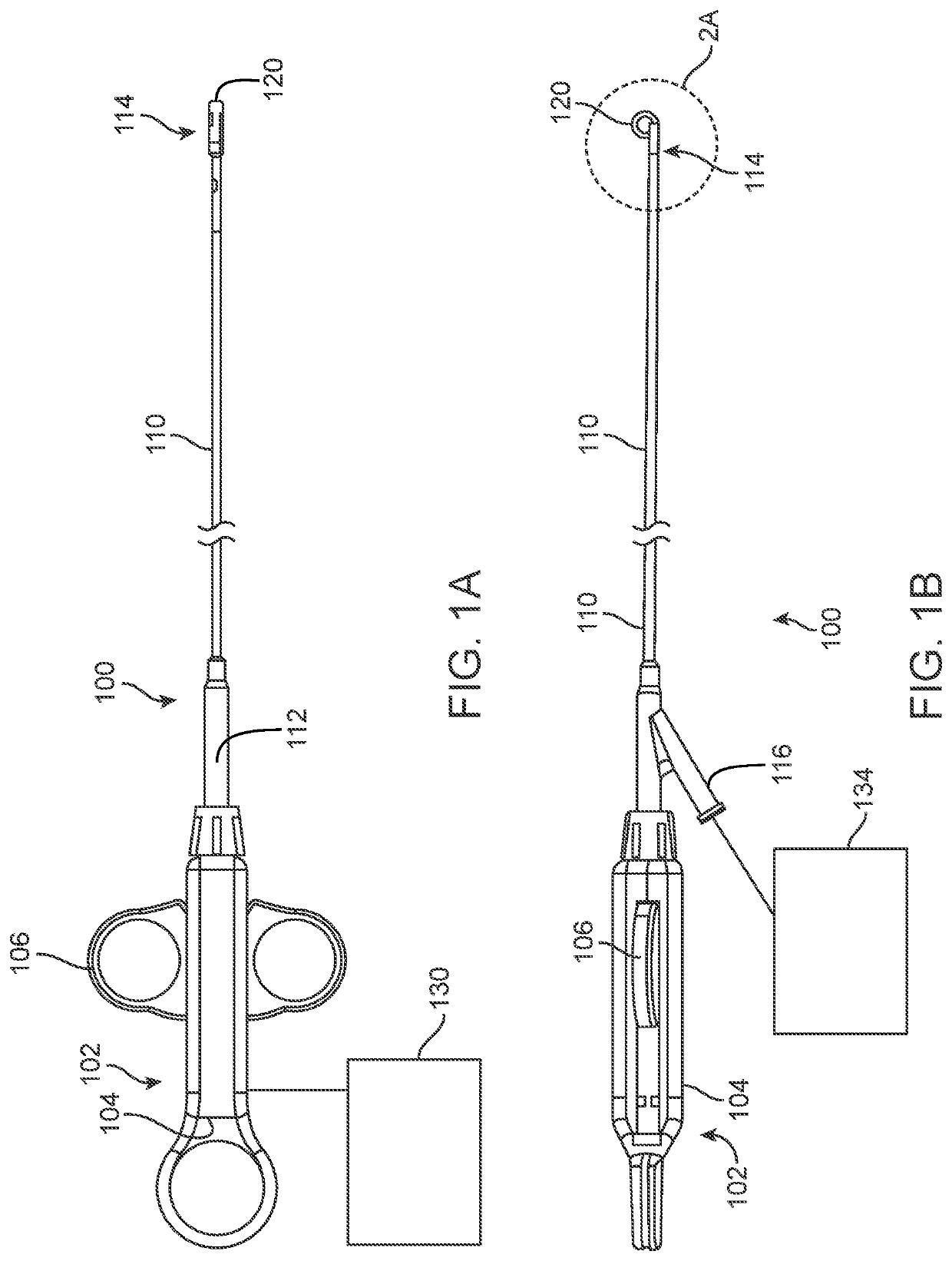

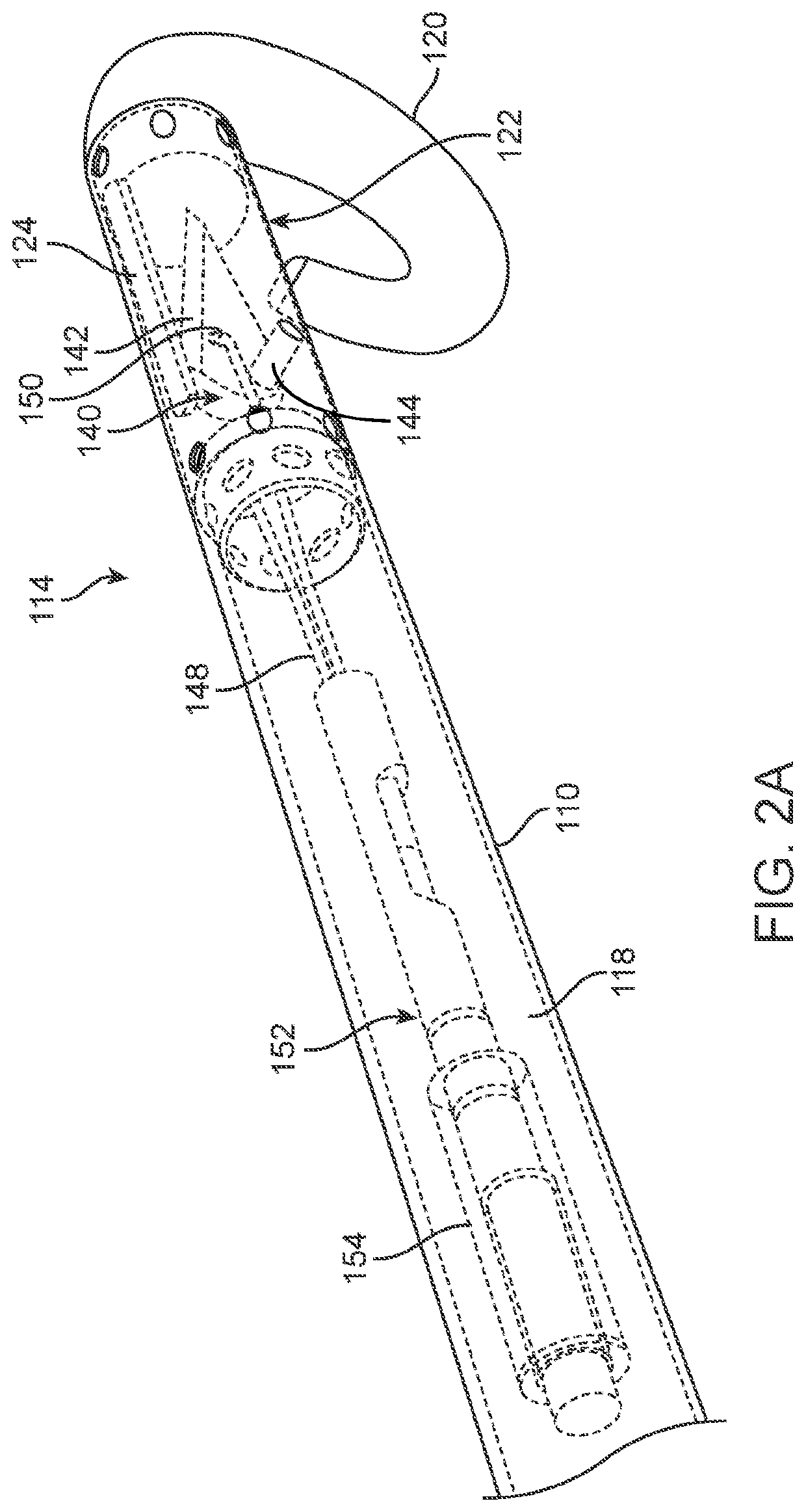

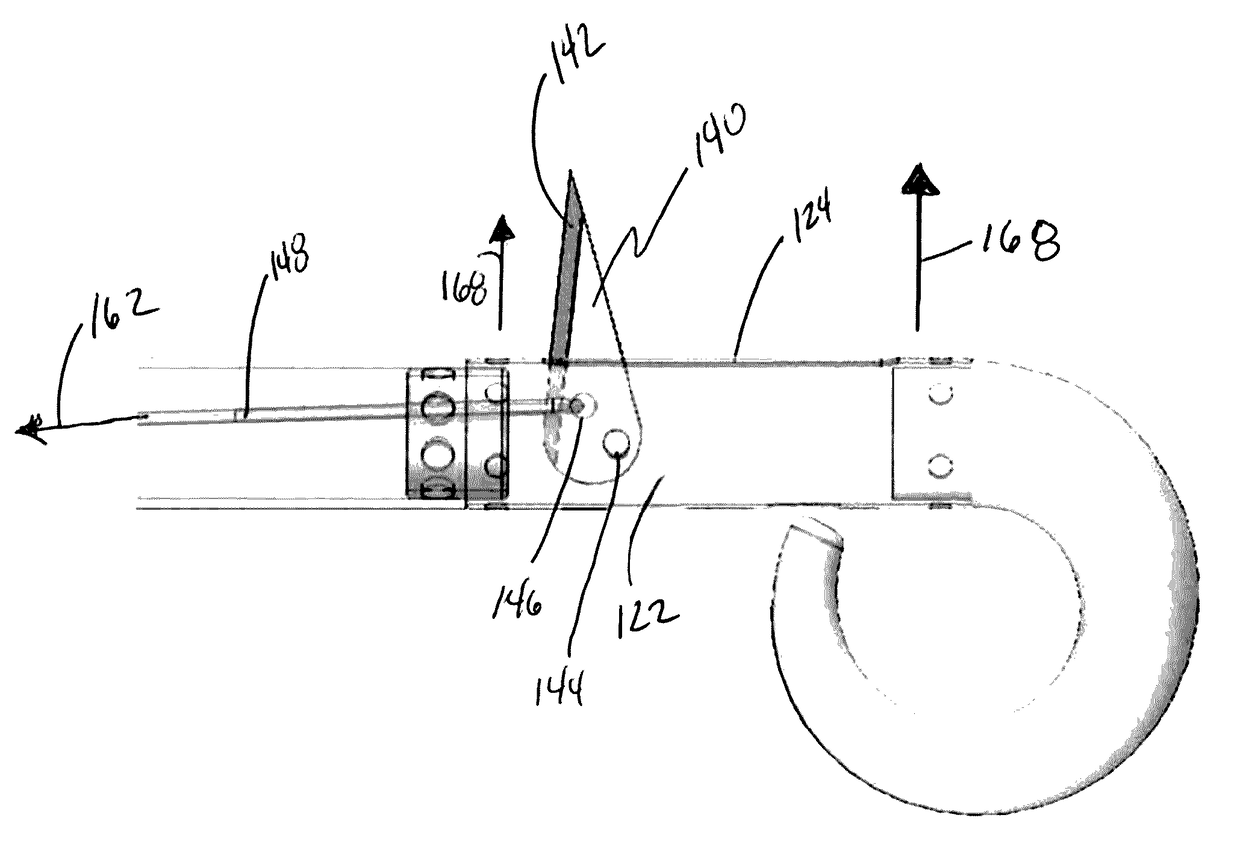

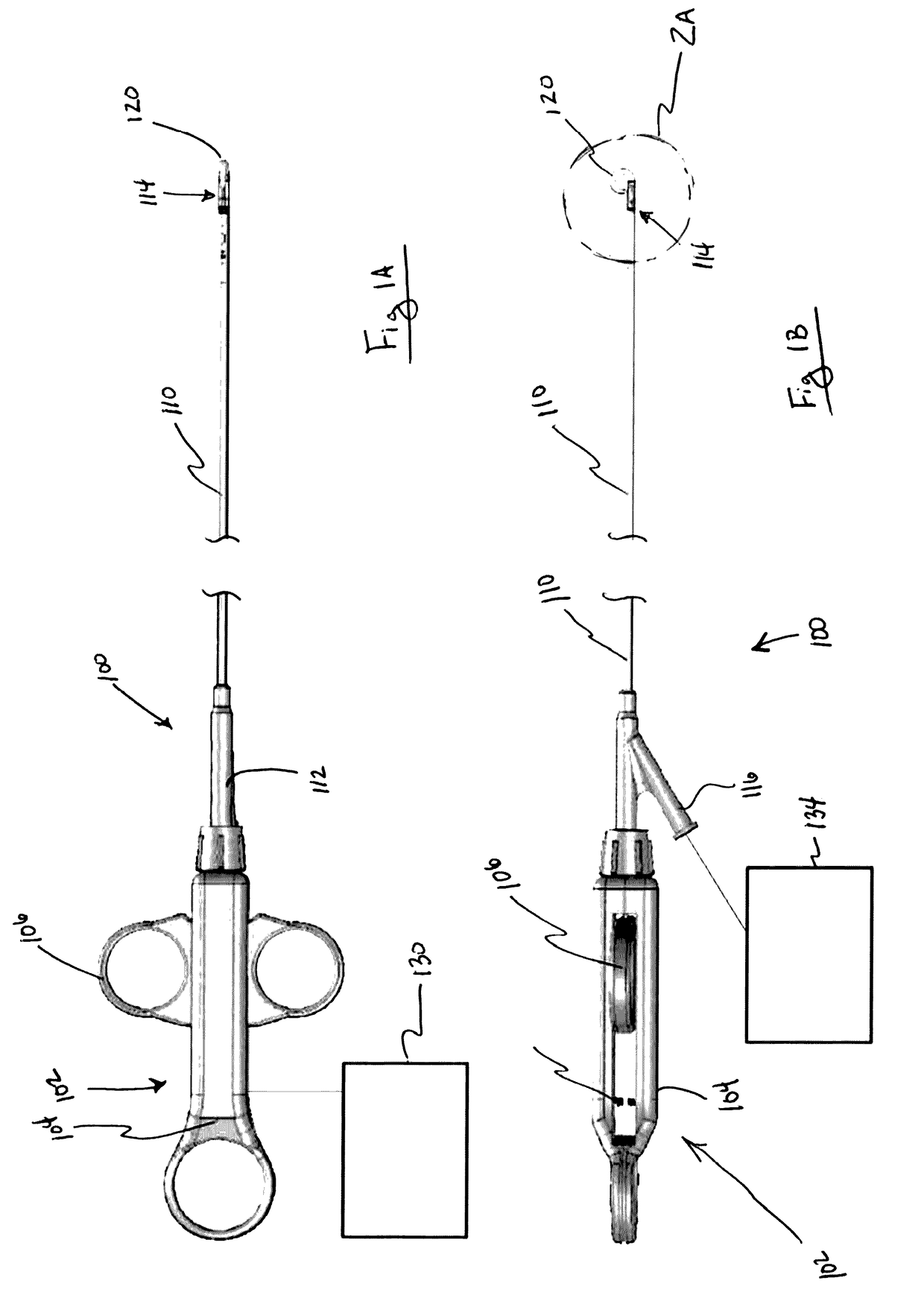

Methods and devices for diastolic assist

ActiveUS10864014B2Increase volumeImprove heart functionElectrocardiographyIncision instrumentsVentricular fillingRat heart

The devices and method described herein allow for therapeutic damage to increase volume in these hyperdynamic hearts to allow improved physiology and ventricular filling and to reduce diastolic filling pressure by making the ventricle less stiff.

Owner:CORDYNAMIX

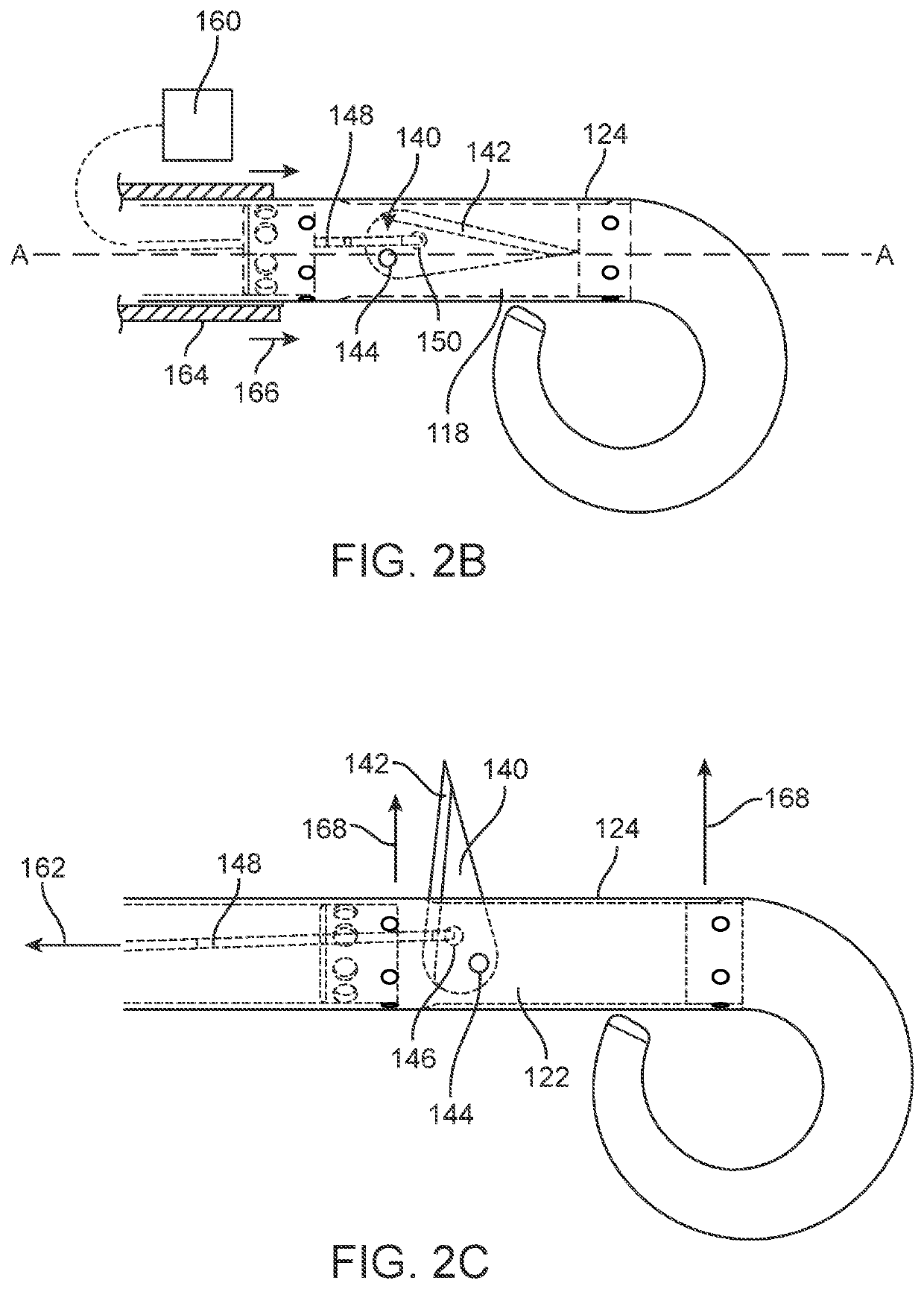

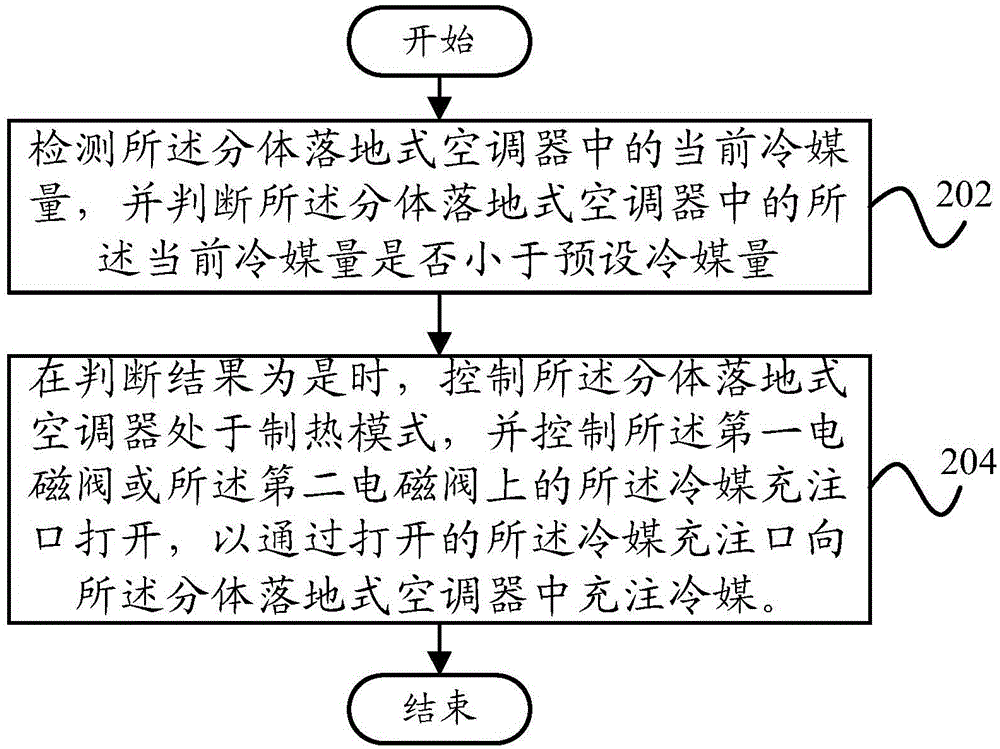

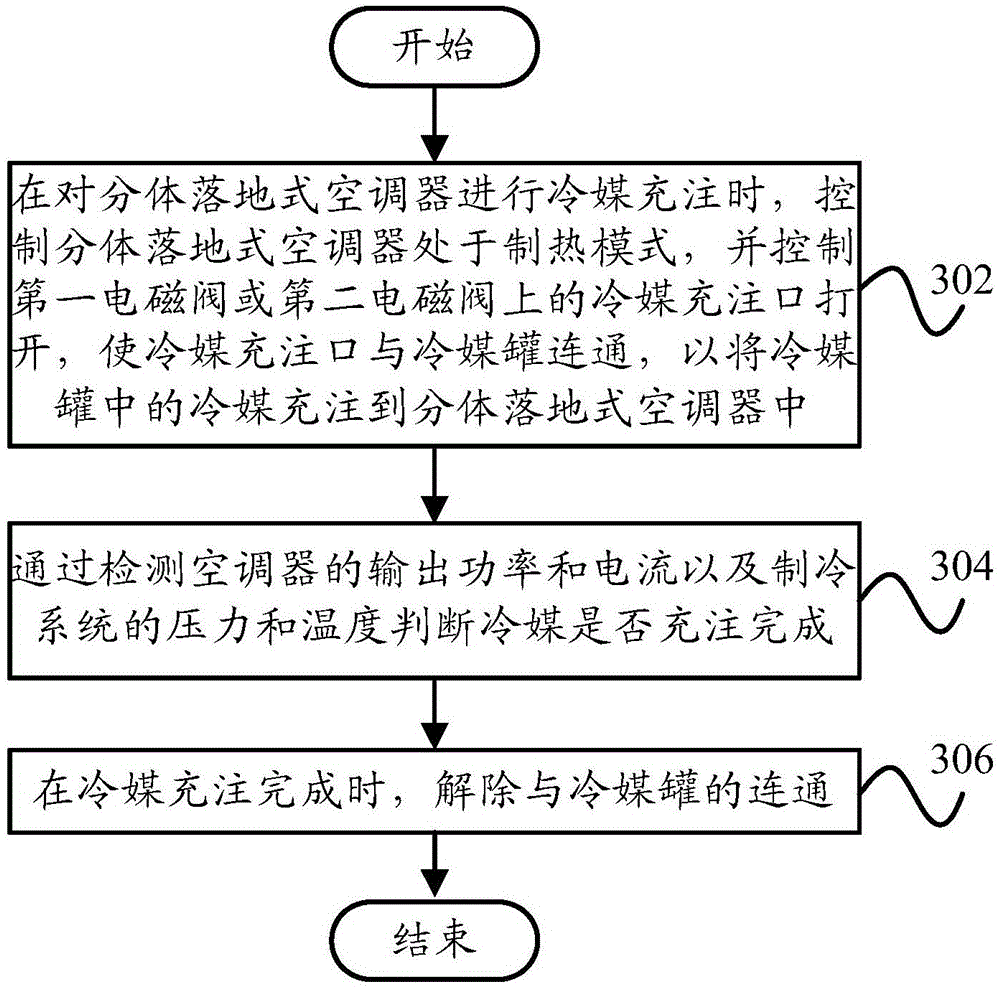

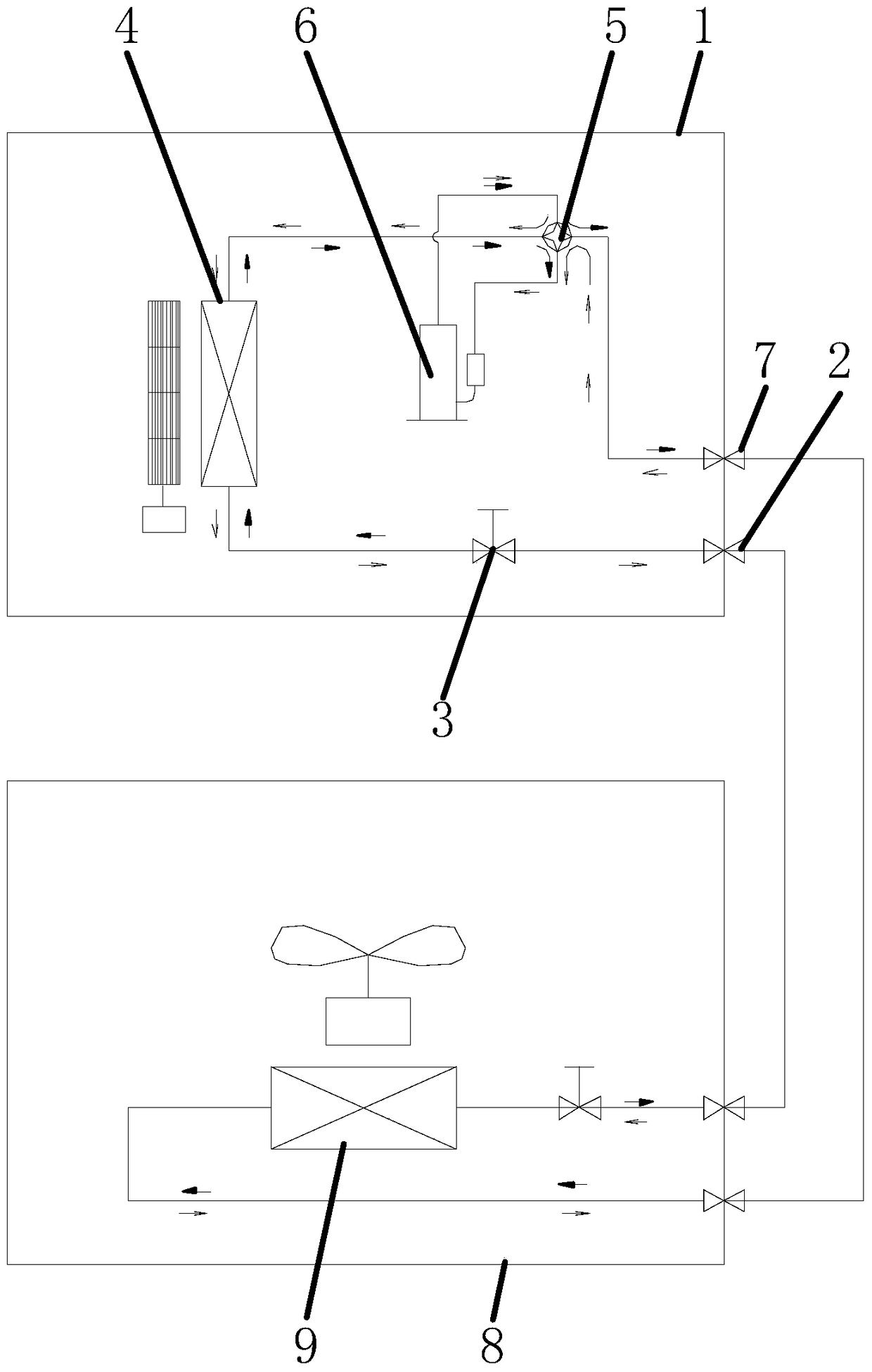

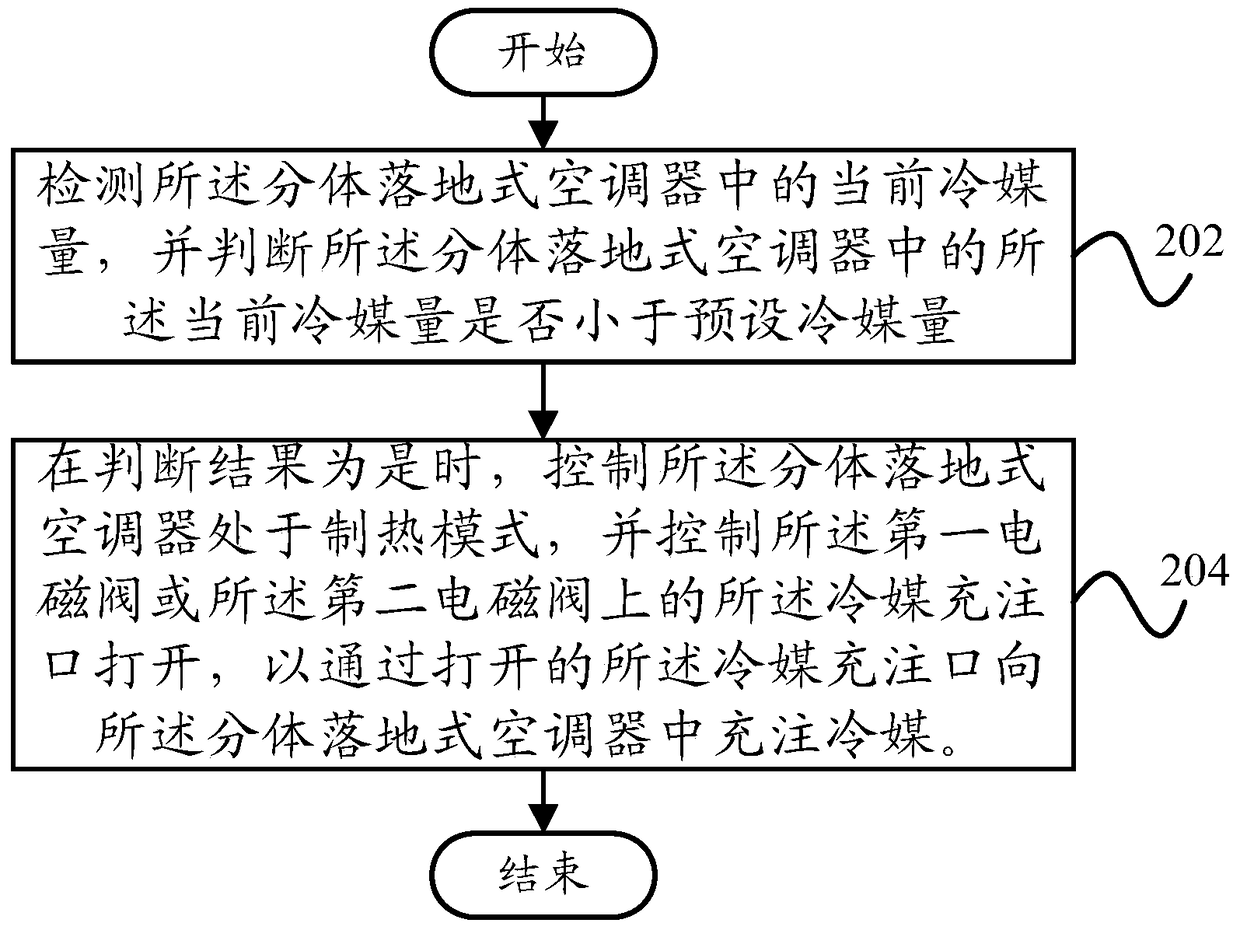

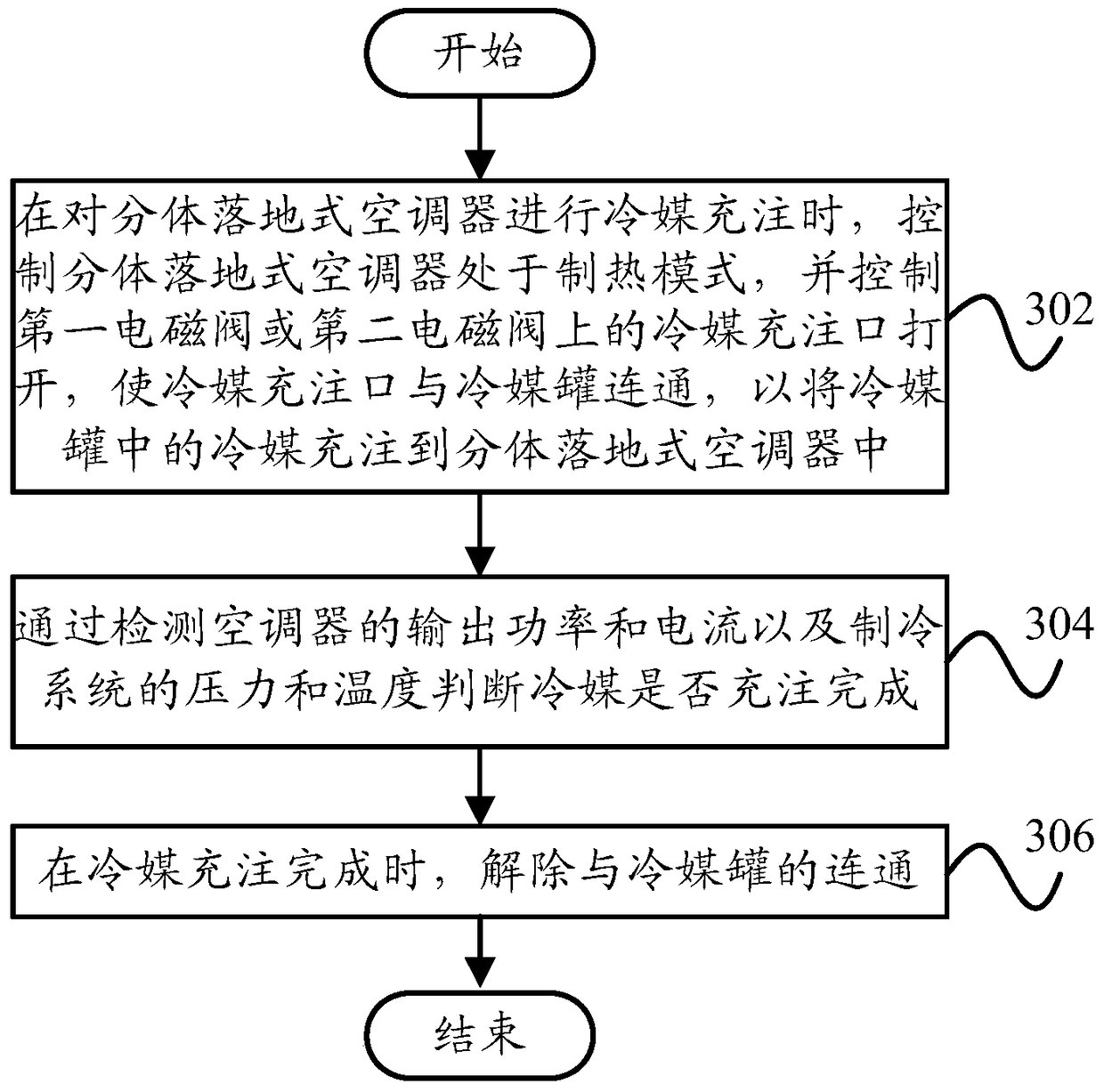

Split floor type air conditioner and control method and control device thereof

ActiveCN105042700AReduce filling pressureImprove safety and reliabilityMechanical apparatusSpace heating and ventilation safety systemsFour-way valveEngineering

The invention provides a split floor type air conditioner, and a control method and a control device of the split floor type air conditioner, wherein the split floor type air conditioner comprises an indoor unit and an outdoor unit; the indoor unit comprises a first electromagnetic valve, a throttling device, an indoor heat exchanger, a four-way valve, a compressor and a second electromagnetic valve communicated in sequence; a refrigerant filling port is formed in the first electromagnetic valve or the second electromagnetic valve; the outdoor unit comprises an outdoor heat exchanger; one end of the outdoor heat exchanger is connected with the first electromagnetic valve; and the other end of the outdoor heat exchanger is connected with a second electronic expansion valve. The split floor type air conditioner can reduce the refrigerant filling pressure to guarantee the refrigerant filling safety and reliability.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

device for pressure relief

ActiveCN104812653BQuick realization of the reset strokeExtended service lifeSpringsBufferEngineeringHydraulic fluid

The invention relates to a device (100) for damping pressure forces in the form of an impact absorber which is designed to be reversible even in the event of dynamic impact loads. The aim of the invention is to provide a device which is designed to absorb shocks in a reliable and reversible manner during normal operation and in the event of an overload. This is achieved by a device for damping pressure forces, said device having a valve arrangement (40) with an overflow region (41) which is connected to a rear hydraulic chamber region (12) and is designed such that hydraulic fluid can flow from the rear hydraulic chamber region (12) into a front hydraulic chamber region (13). A throttle pin (30) protrudes into a connecting region between the rear hydraulic chamber region (12) and the overflow region in order to control the flow speed of the hydraulic fluid from the rear hydraulic chamber region (12) in the direction of the overflow region (41). The throttle pin (30) can be converted from a first state in which hydraulic fluid can flow from the rear hydraulic chamber region (12) into the overflow region (41) into a second state in which the rear hydraulic chamber region (12) is separated from the overflow region (41) in a fluid-tight manner. Additionally, the valve arrangement (40), which is formed at an end region of the hollow piston, has an overload valve (60) which is connected to the rear hydraulic chamber region (12) via at least one overload channel (62).

Owner:VOITH PATENT GMBH

Split floor-standing air conditioner and its control method and control device

ActiveCN105042700BRealize constant speed regulationReduce energy consumptionMechanical apparatusSpace heating and ventilation safety systemsFour-way valveEngineering

The invention provides a split floor type air conditioner, and a control method and a control device of the split floor type air conditioner, wherein the split floor type air conditioner comprises an indoor unit and an outdoor unit; the indoor unit comprises a first electromagnetic valve, a throttling device, an indoor heat exchanger, a four-way valve, a compressor and a second electromagnetic valve communicated in sequence; a refrigerant filling port is formed in the first electromagnetic valve or the second electromagnetic valve; the outdoor unit comprises an outdoor heat exchanger; one end of the outdoor heat exchanger is connected with the first electromagnetic valve; and the other end of the outdoor heat exchanger is connected with a second electronic expansion valve. The split floor type air conditioner can reduce the refrigerant filling pressure to guarantee the refrigerant filling safety and reliability.

Owner:GD MIDEA AIR CONDITIONING EQUIP CO LTD +1

Pneumatic surge suppressor

ActiveCN112135970AReduce filling pressureReduce vibrationFluid parameterPositive displacement pump componentsWorking fluidEngineering

A surge suppressor includes a boost mechanism configured to balance pressures between a working fluid and a process fluid. The boost mechanism includes a boost member that is acted on by a charge pressure of the working fluid. A shaft extends from the boost member to a pressure control member bounding the process fluid and acting on the process fluid. The boost member can have a larger effective area than the pressure control member to provide a pressure multiplication between the charge pressure and the process fluid pressure. In addition, pressure control valves are mounted to an air housingand actuated open by the boost mechanism. Actuating one of the pressure control valves open increases the charge pressure. Actuating the other pressure control valve open decreases the charge pressure.

Owner:GRACO INC

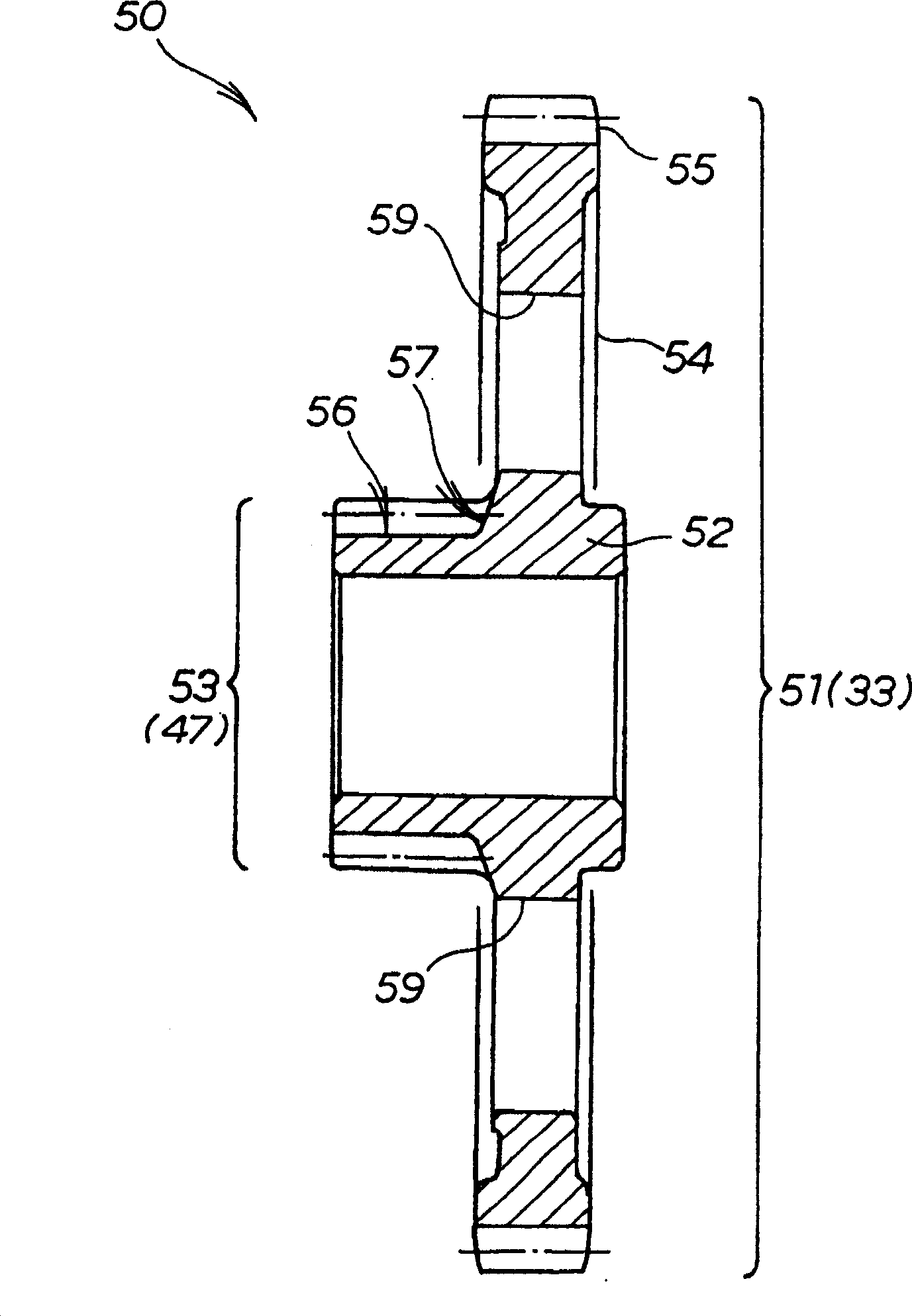

Integrated gear and pedal starting device for internal combustion engine

ActiveCN100462593CIncrease packing densityReduce filling pressureMuscle operated startersPortable liftingInduction hardeningInternal combustion engine

The invention provides an integrally molded gear capable of inhibiting drop of strength of a pinion. A comparison example is indicated in figure 7(a). A hardened part (105) indicated by hatching can be provided by applying induction hardening on a pinion (104). Hardening depth at a perpendicular corner part (102), however, is very small. A vicinity of the perpendicular corner parts (102) becomes a fragile part when load acts on the pinion (104). Figure (b) indicates an embodiment. A hardened part (75) indicated by hatching can be provided by applying induction hardening on a pinion (53). Sufficient hardening depth can be secured although hardening depth at an inclined surface (57) is a little bit small. Consequently, strength of the pinion (53) is increased. Since a conventional perpendicular corner part is changed to the inclined surface, strength after hardening is averaged and strength of the pinion can be increased.

Owner:HONDA MOTOR CO LTD

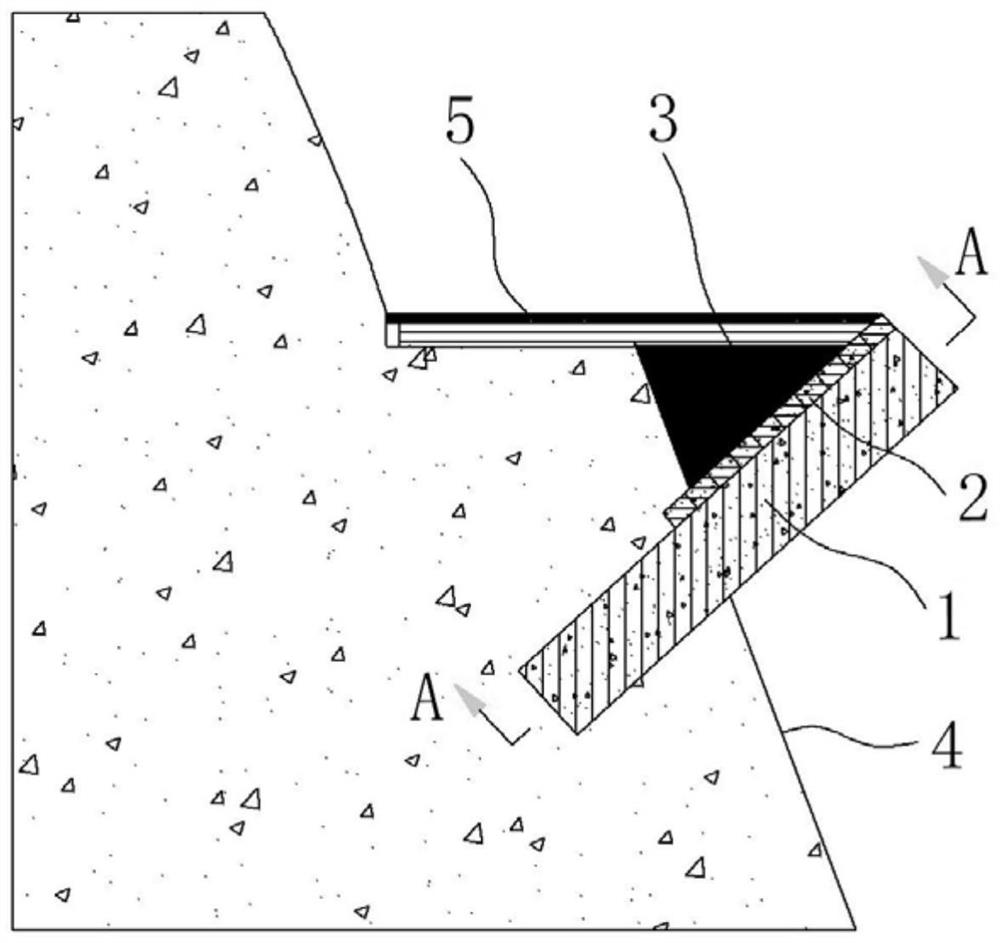

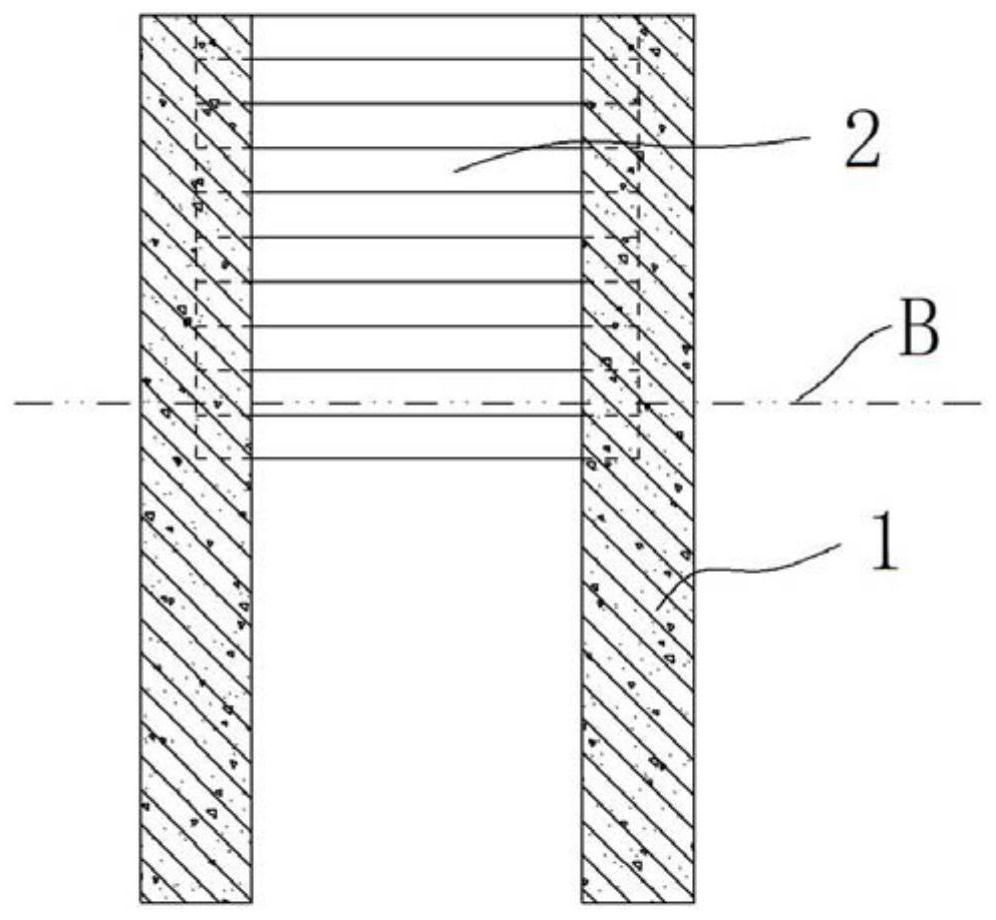

Inclined overhanging type supporting and retaining structure

The invention provides an inclined overhanging type supporting and retaining structure which comprises at least two overhanging piles which are partially buried in a canyon slope surface and are arranged at intervals in the length direction of the canyon slope surface, the overhanging piles are arranged upwards in an inclined mode relative to the horizontal plane, a soil retaining plate (bearing plate) is arranged on every two adjacent overhanging piles, and the area between each soil retaining plate and the canyon slope surface is a fill area. The fill area is of a solid structure or a spacedsupporting column structure. According to the supporting structure, the terrain characteristics of a steep canyon are fully utilized, the overhanging piles are obliquely and upwards arranged on the slope surface of the canyon relative to the horizontal plane to form an overhanging structure, the section size and the length of the overhanging piles can be effectively reduced, and the constructioncost is reduced; the problems that under the steep canyon terrain condition, filling is difficult, the size of a retaining structure is large, the retaining height is limited, and the occupied area islarge can be effectively solved. Meanwhile, the riverway can be effectively prevented from being invaded along the riverway section, and the risk of underwater construction is avoided.

Owner:中铁二院重庆勘察设计研究院有限责任公司

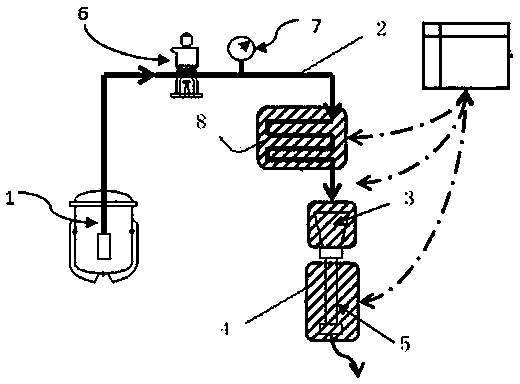

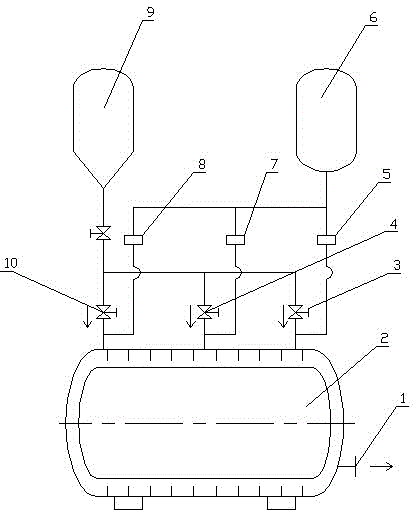

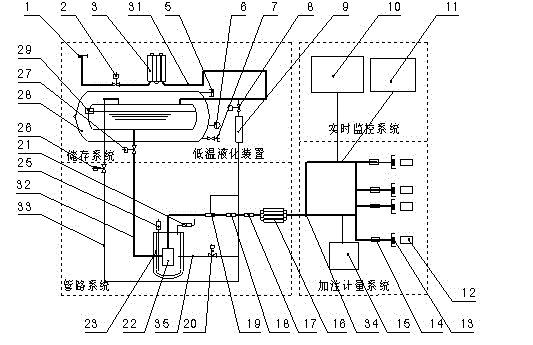

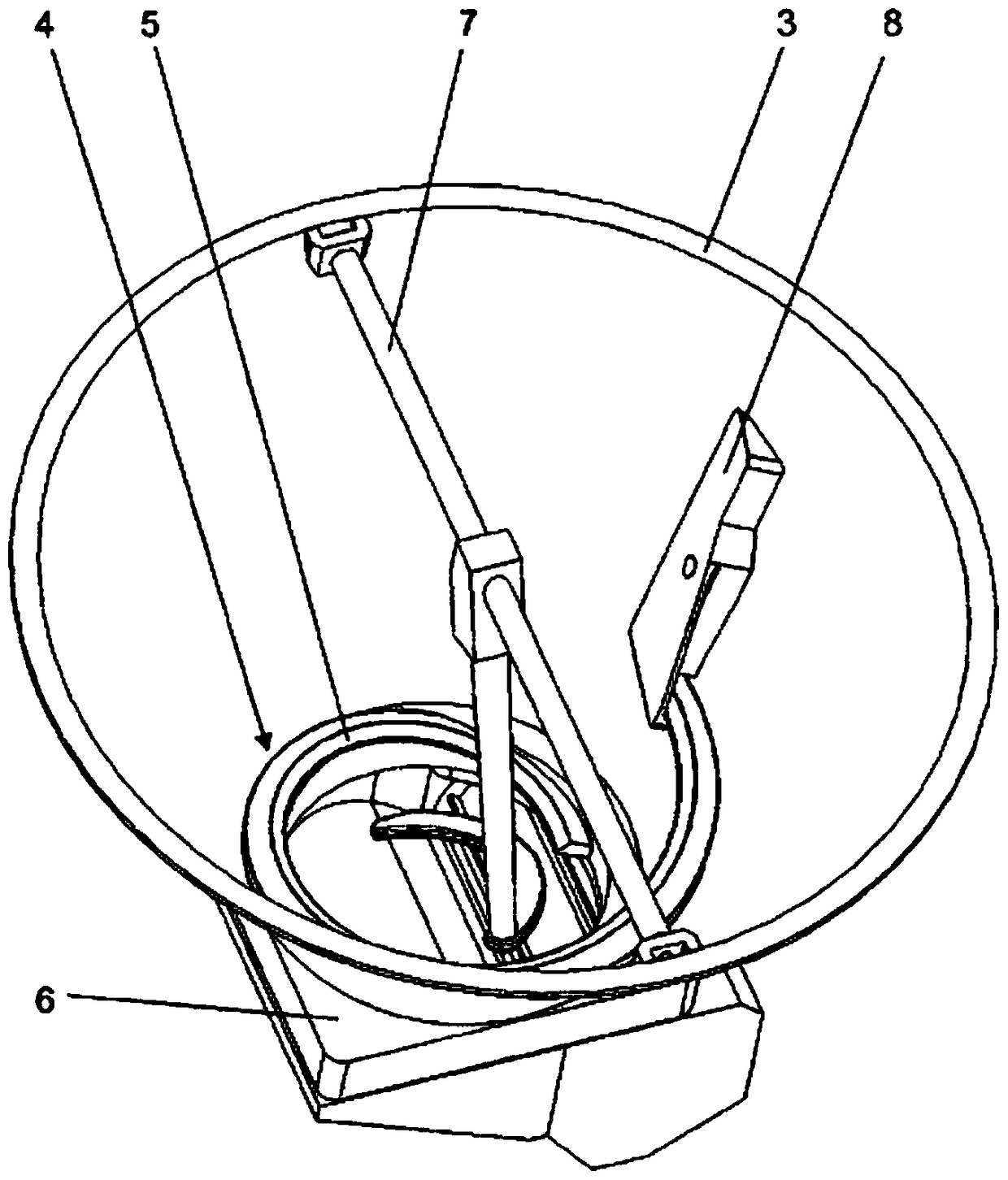

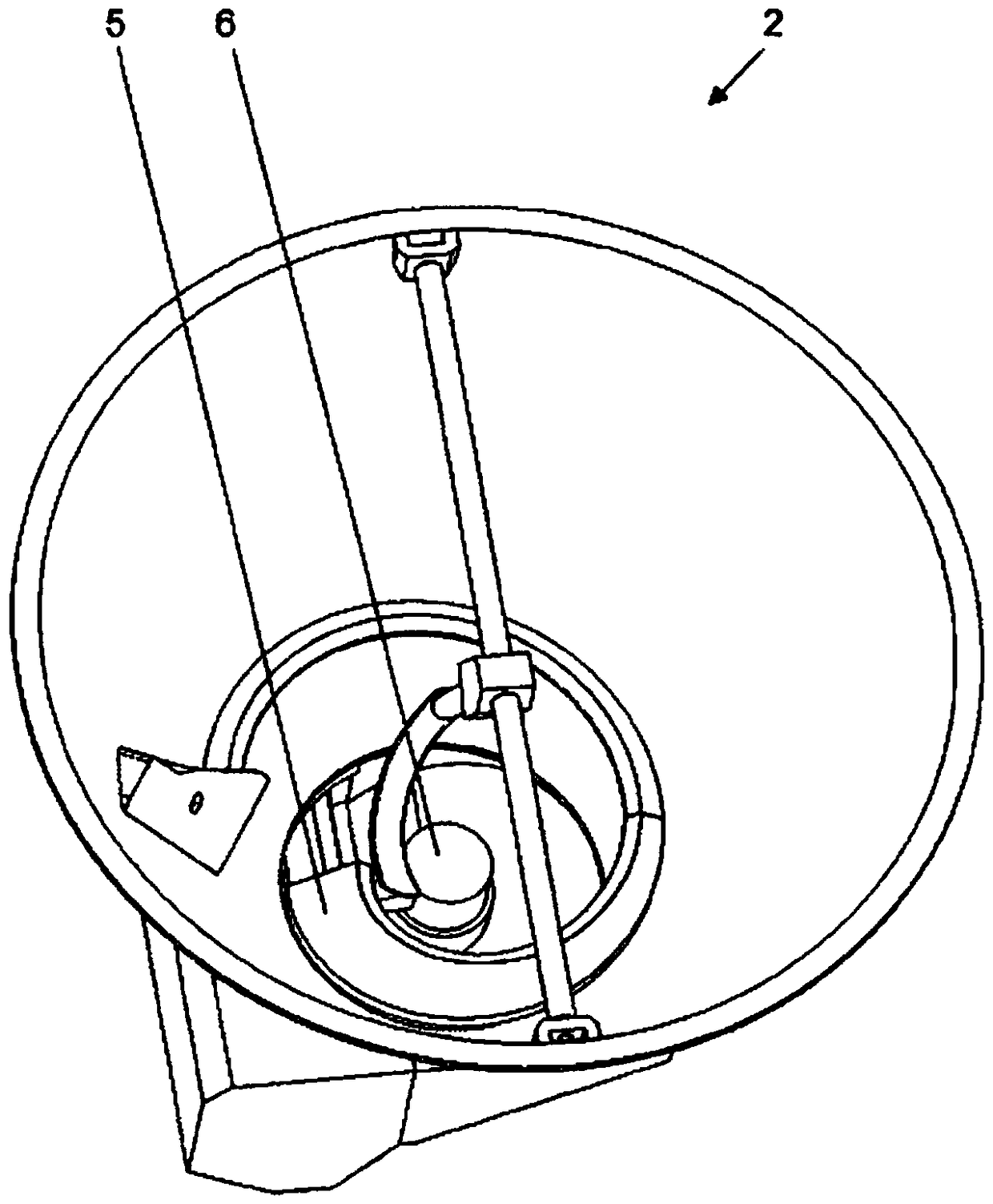

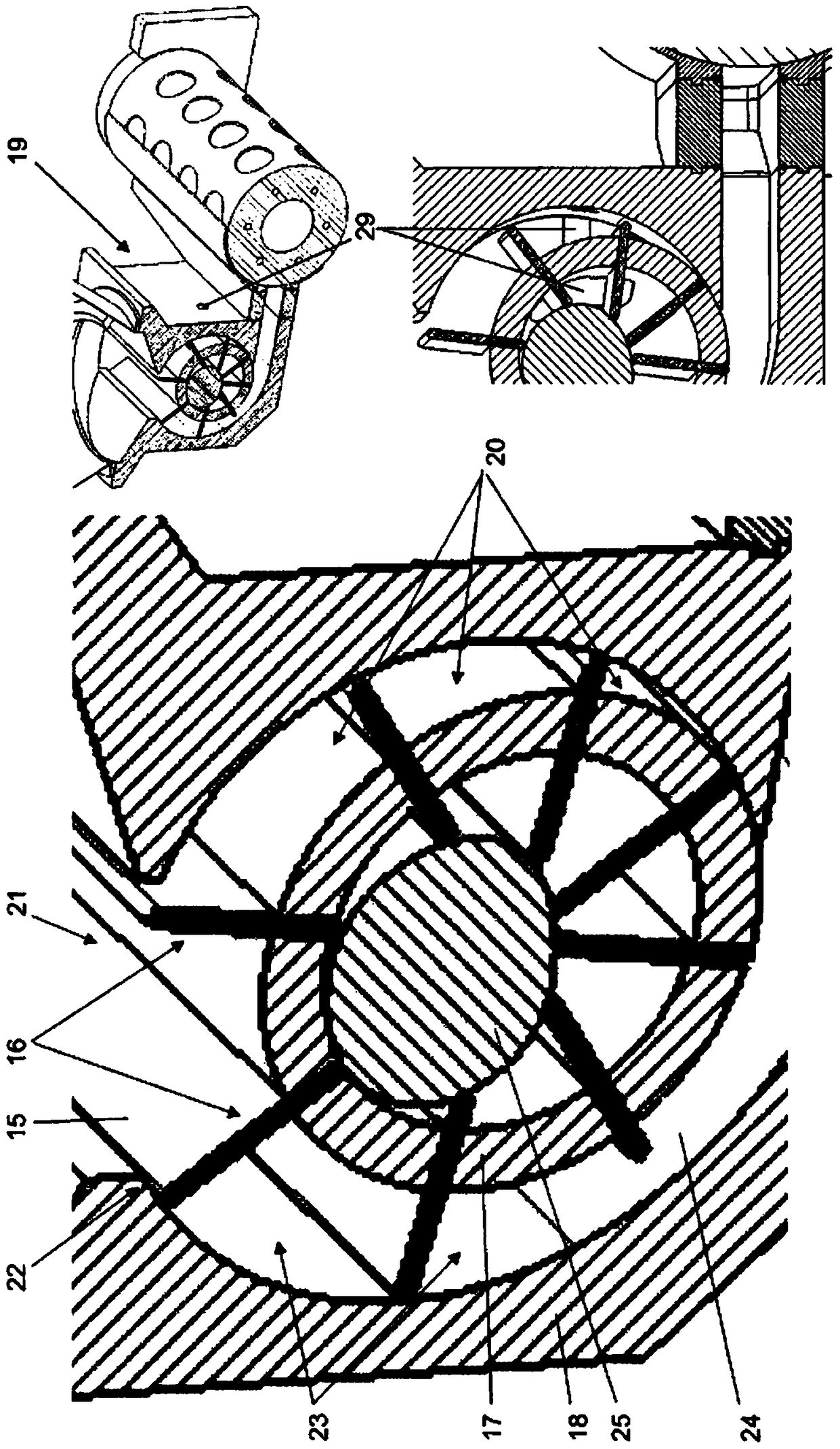

Liquefied natural gas (LNG) filling station

The invention discloses a gas filling method of a liquefied natural gas (LNG). The method can be used for filling for various vehicles at normal pressure or lower pressure, reducing environment pollution and saving resources. In the method, gas-liquid separation is performed on a gas-state natural gas mixed in the LNG during delivery of the LNG in a storage system to a filling metering device; the purified LNG is delivered to the filling metering device; the separated gas-state natural gas is transformed to a liquid-state natural gas through liquefaction; and the liquid-state natural gas is returned to the storage system. The invention also discloses an LNG filling station built based on the filling method. The LNG filling station has the advantages of low emission loss, short pre-coolingtime of initial starting, high gas filling precision and efficiency, long lossless storage time and the like, thereby promoting the promotion and the application of an LNG automobile.

Owner:ZHANGJIAGANG FURUI SPECIAL EQUIP CO LTD

Block supply system and method

ActiveCN104244722BSmall inertiaEasy to replaceMeat processingRotary piston pumpsEngineeringMechanical engineering

Owner:GEA FOOD SOLUTIONS BAKEL

liquid gas buffer

ActiveCN110953280BSmall volume changeSmall amount of activitySpringsGas and liquid based dampersEngineeringCylinder block

The invention provides a liquid-gas buffer, comprising: a cylinder body; a first piston assembly: including a piston head and a force transmission rod, the piston head is arranged in the cylinder body, and the cylinder body is divided into a first liquid cavity and a second A liquid chamber, the force transmission rod extends out of the cylinder; the piston head is provided with a first fluid channel and a second fluid channel communicating with the first liquid chamber and the second liquid chamber; the first fluid channel is provided with The first switching element is configured to open when the pressure in the first liquid chamber is greater than the pressure in the second liquid chamber; the second fluid channel is provided with a second switching element configured to open when the pressure in the second liquid chamber is greater than the pressure in the first liquid chamber. When the liquid chamber is under pressure, it is opened; the second piston assembly is arranged around the force transmission rod, and the second liquid chamber is formed between the piston head and the cylinder port to form an air chamber. The piston assembly of the liquid-gas buffer adopts a partly built-in and partly externally designed structure, which is used as a liquid cavity separation component and a force transmission component to make the buffer structure more compact.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST

High intensity discharge lamps, arc tubes and methods of manufacture

InactiveCN100550258CReduce filling pressureTube/lamp vessel fillingGas discharge lamp detailsEngineeringHigh intensity

Owner:ADVANCED LIGHTING TECH

Methods and devices for diastolic assist

ActiveUS20170164968A1Increase volumeImprove heart functionElectrocardiographyIncision instrumentsBiomedical engineeringVentricular filling

The devices and method described herein allow for therapeutic damage to increase volume in these hyperdynamic hearts to allow improved physiology and ventricular filling and to reduce diastolic filling pressure by making the ventricle less stiff.

Owner:CORDYNAMIX

Aluminum-chromium alloy casting technology

The invention relates to the technical field of metal casting, and discloses an aluminum-chromium alloy casting technology. According to the aluminum-chromium alloy casting technology, a prepared aluminum-chromium alloy has the advantages of being excellent in casting property and mechanical property, high in strength, high in temperature creep limit, good in stability, good in machinability, small in casting crack sensitivity, good in liquidity, airtightness and crack resistance, high in corrosion resistance, high in surface corrosion resistance and stress corrosion resistance, high in impacttoughness, high in elongation rate, good in casting performance and wide in application range.

Owner:安徽省含山县兴建铸造厂

High-intensity discharge lamp, arc lamp tube and method for manufacturing same

InactiveCN101552169AReduce filling pressureTube/lamp vessel fillingTube/lamp vessels closingHigh intensityEngineering

The invention provides a non-nib arc lamp tube (12) for a high-intensity discharge lamp and a method for manufacturing same, wherein seal gas is isolated based on different density of gas, the arc lamp tube (12) can remains communication with non-control gas during a lifting and filling step and a followed step for hermetic sealing of lamp tube by clipping in position of lead wire assembly (32). In addition, final pressure of the filling gas sealed in the arc lamp tube (12) can be controlled by controlling temperature of filling gas durning seal period, therefore the method avoids need of pump controlling filling gas pressure.

Owner:ADVANCED LIGHTING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com