Graphene micro-sheet/high-density polyethylene composite material and preparation method thereof

A technology of high-density polyethylene and graphene microchips, which is applied in the field of materials, can solve the problems of reducing the service life of PE pipes, poor wear resistance, waste of resources, etc., and achieve improved compatibility and dispersion, and good wear resistance , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

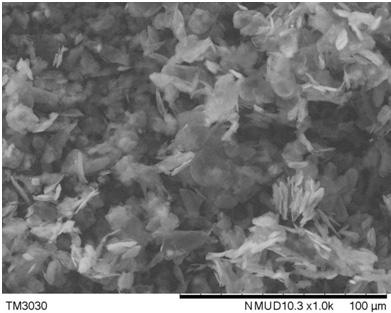

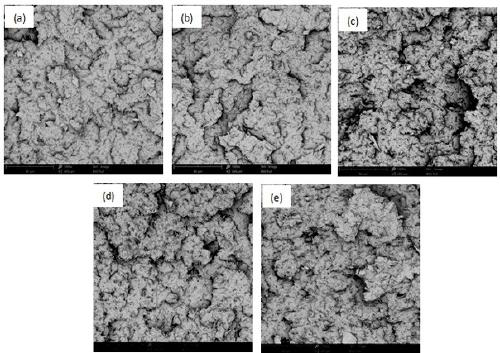

Image

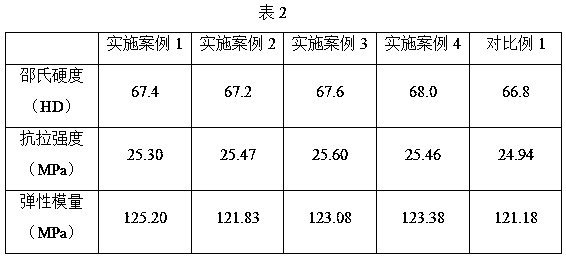

Examples

Embodiment 1

[0025] (1) The graphene microflakes, high-density polyethylene and silane coupling agent dried to constant weight were formulated into raw materials of each component according to the ratio, including 99.5 parts of high-density polyethylene, 0.5 parts of graphene microflakes, silane coupling agent 0.05 parts of the joint agent, and then mechanically mix evenly.

[0026] (2) Melt extrusion: put the uniformly mixed raw materials into a micro-twin-screw extruder, perform melt blending at a temperature of 140°C, and extrude at a temperature of 145°C.

[0027] (3) Injection molding: Injection molding the extruded material in step 2), wherein the injection molding process is as follows: the mold temperature is 50°C, the injection cylinder temperature is 220°C, the injection pressure is 0.25MPa, and the holding pressure is 0.25MPa. The time is 20s, and the closing time is 22s.

[0028] (4) MMS-2A microcomputer-controlled friction testing machine was used to test the friction propert...

Embodiment 2

[0031] Weigh 99 parts of high-density polyethylene, 1 part of graphene microflakes, and 0.1 part of silane coupling agent, prepare samples according to the steps and conditions of Example 1, and test their friction and mechanical properties.

Embodiment 3

[0033] Weigh 98.5 parts of high-density polyethylene, 1.5 parts of graphene microflakes, and 0.15 parts of silane coupling agent. Prepare samples and test friction and mechanical properties according to the steps and conditions of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com