Method for filling high-temperature liquid-phase chromatographic column of padding with fine particle size and dedicated device for method

A liquid chromatographic column and fine particle size technology, which is applied in the field of special equipment, can solve the problems of extremely high requirements for filling equipment and high filling pressure, and achieve the goals of reducing high-pressure sealing requirements, reducing filling pressure, and improving repeatability and stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

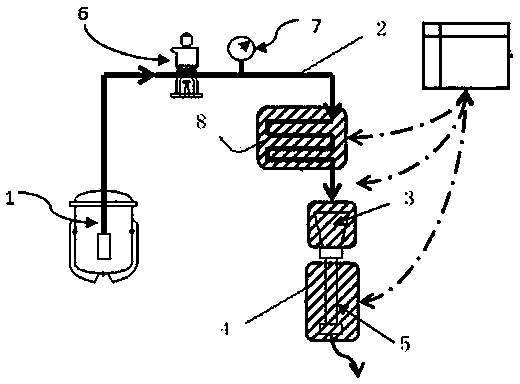

Embodiment 1

[0018] Place an elastic quartz capillary chromatographic column 5 with an inner diameter of 100 μm, an outer diameter of 360 μm, and a length of 15 cm in the chromatographic column sleeve 4, and fix it at the bottom of the homogenate tank 3; weigh 50 mg of C18 reverse-phase chromatography silica gel filler with a diameter of 3 μm, and add Prepare a homogenate solution with a concentration of 5mg / mL in 10mL acetone, oscillate and mix, and disperse by ultrasonic for more than 10min; control the heating wire to work through the temperature control system, and heat the pressurized solvent (methanol), homogenate tank 3 and chromatographic column 5 to 50°C, pour 200 μL of the homogenate solution into the homogenate tank 3; seal the homogenate tank 3, connect the pressurized solvent tank 1, the homogenate tank 3 and the chromatographic column 4 through pipelines, and turn on the column packing pump 6, Fill for 30min under 100MPa pressure; unload the capillary chromatographic column, h...

Embodiment 2

[0021] Place an elastic quartz capillary chromatographic column 5 with an inner diameter of 100 μm, an outer diameter of 360 μm, and a length of 15 cm in the chromatographic column sleeve 4, and fix it at the bottom of the homogenate tank 3; weigh 50 mg of C18 reverse-phase chromatography silica gel filler with a diameter of 3 μm, and add Prepare a homogenate solution with a concentration of 5mg / mL in 10mL acetone, oscillate and mix, and disperse by ultrasonic for more than 10min; control the heating wire to work through the temperature control system, and heat the pressurized solvent (methanol), homogenate tank 3 and chromatographic column 5 to 70°C, pour 200 μL of the homogenate solution into the homogenate tank 3; seal the homogenate tank 3, connect the pressurized solvent tank 1, the homogenate tank 3 and the chromatographic column 4 through pipelines, and start the column packing pump 6, Fill for 30min under 100MPa pressure; unload the capillary chromatographic column, han...

Embodiment 3

[0024] Place an elastic quartz capillary chromatographic column 5 with an inner diameter of 100 μm, an outer diameter of 360 μm, and a length of 15 cm in the chromatographic column sleeve 4, and fix it at the bottom of the homogenate tank 3; weigh 50 mg of C18 reverse-phase chromatography silica gel filler with a diameter of 3 μm, and add Prepare a homogenate solution with a concentration of 5mg / mL in 10mL acetone, oscillate and mix, and disperse by ultrasonic for more than 10min; control the heating wire to work through the temperature control system, and heat the pressurized solvent (methanol), homogenate tank 3 and chromatographic column 5 to 90°C, pour 200 μL of the homogenate solution into the homogenate tank 3; seal the homogenate tank 3, connect the pressurized solvent tank 1, the homogenate tank 3 and the chromatographic column 4 through pipelines, and turn on the column packing pump 6, Fill for 30min under 100MPa pressure; unload the capillary chromatographic column, h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com