Pneumatic surge suppressor

A surge suppressor, suppressor technology, applied in pump control, machine/engine, liquid fuel engine, etc., to solve problems such as leakage, cross-contamination, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

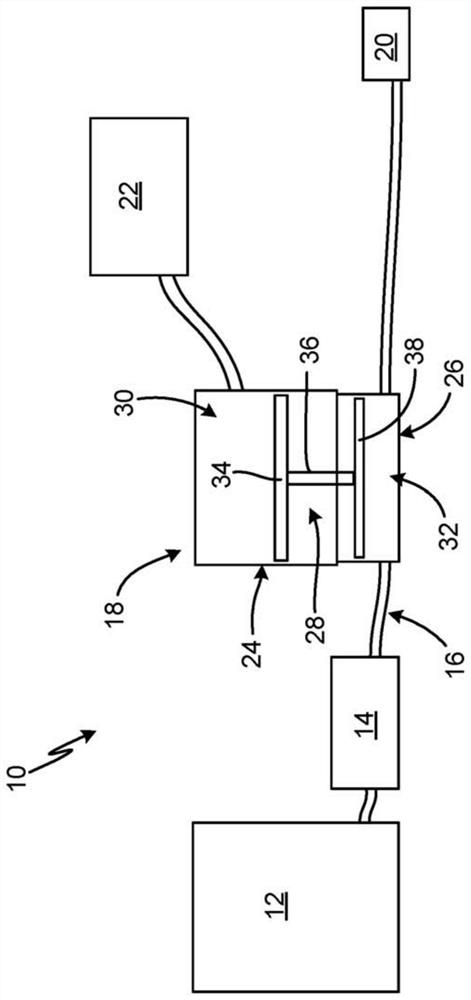

[0015]figure 1 It is a schematic block diagram of the fluid processing system 10. The fluid treatment system 10 includes a reservoir 12, a pump 14, a fluid line 16, a surge suppressor 18, an outlet 20, and a working fluid source 22. The surge suppressor 18 includes an air housing 24, a process housing 26, a suppressor mechanism 28, a working fluid chamber 30, and a process fluid chamber 32. The suppressor mechanism 28 includes a pressurizing member 34, a shaft 36, and a pressure control member 38.

[0016]The fluid treatment system 10 is configured to provide a process fluid at a certain pressure at the outlet 20. In some examples, the process fluid is paint, such that the fluid treatment system 10 is a paint treatment system. In some examples, the process fluid is a lubricant, such that the fluid treatment system 10 is a lubricant treatment system. In some examples, among other options, the process fluid is an automotive fluid, such as oil, coolant, cleaning fluid, and transmission fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com