Low-temperature liquid storage tank vacuum interlayer pearlife filling technology

A technology of vacuum interlayer and cryogenic liquid, which is applied in gas/liquid distribution and storage, fixed-capacity gas storage tanks, pressure vessels, etc. It can solve the problems of deterioration of thermal insulation performance, filling of interlayer space, and decline of thermal insulation performance of storage tanks, etc., to achieve thermal insulation Improved performance and non-destructive storage time, improved quality and efficiency, and reduced filling times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

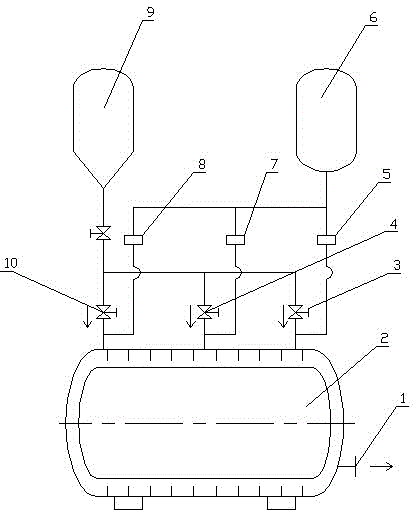

[0046] Several filling ports are installed on the shell of the low-temperature liquid storage tank 2, and the filling ports are connected to the pearlite storage tank 9 through a filling valve, such as figure 1 As shown, several filling ports are connected in parallel, one end of the several filling ports is connected to the dry compressed nitrogen port of the dry nitrogen storage tank 6 through a compaction valve, and one end of the shell of the cryogenic liquid storage tank 2 is connected to the vacuum port through the valve 1. unit. First fill the head and tail of the interlayer of the low-temperature liquid storage tank, and then fill the middle of the low-temperature liquid storage tank; first fill the place without the compressed air device, and then fill the place with the compressed air device; when there are multiple filling ports, fill and compact the separated filling ports one by one , the process steps are as follows:

[0047] ⑴ Initialization: Connect all joint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com