Liquefied natural gas (LNG) filling station

A technology for liquefied natural gas and gas filling stations, which is applied in gas/liquid distribution and storage, pipeline systems, mechanical equipment, etc., and can solve the problems of long initial pre-cooling time, low gas filling accuracy and efficiency, and large footprint. Achieve the effect of improving reliability and safety, improving measurement accuracy, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

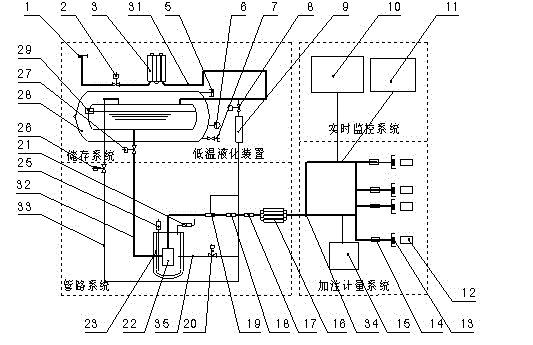

[0025] Such as figure 1As shown, the liquefied natural gas filling station of the present invention includes: an installation platform, a storage system, a pipeline delivery system, a filling and metering device, and a real-time monitoring system. The storage system, the pipeline delivery system, and filling and metering The device, the cryogenic liquefaction device 9 and the real-time monitoring system are fixed on the installation platform through the same skid body or different skid bodies; in this embodiment, the storage system includes: the first pipeline valve 2, the first pressure regulator 3 and LNG storage tank 28; the filling and metering device includes: gas filling controller 15, a plurality of gas filling guns 13 and the corresponding first pressure sensor 14 and flow meter 12 with gas filling gun 13, flow meter 12 is set On the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com