Integrated gear and pedal starting device for internal combustion engine

A gear and integrated technology, applied in the direction of starting device with manual crank, engine starting, hoisting device, etc., can solve the problems of easy deterioration of metal molds, low strength of small-diameter gears, low production capacity, etc., and achieve filling pressure Effects that increase, increase intensity, and reduce volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The best mode for carrying out the present invention will be described below based on the drawings.

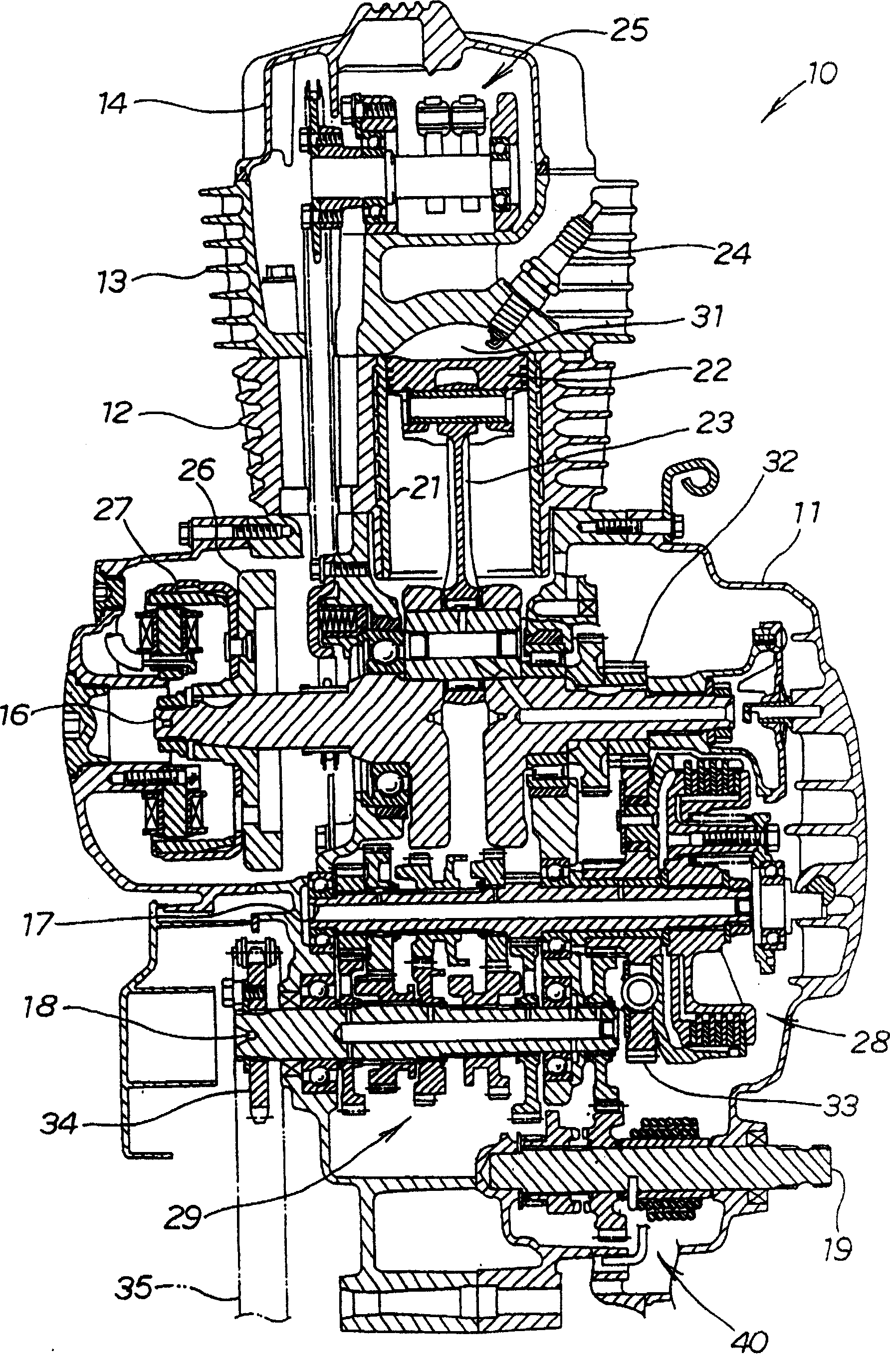

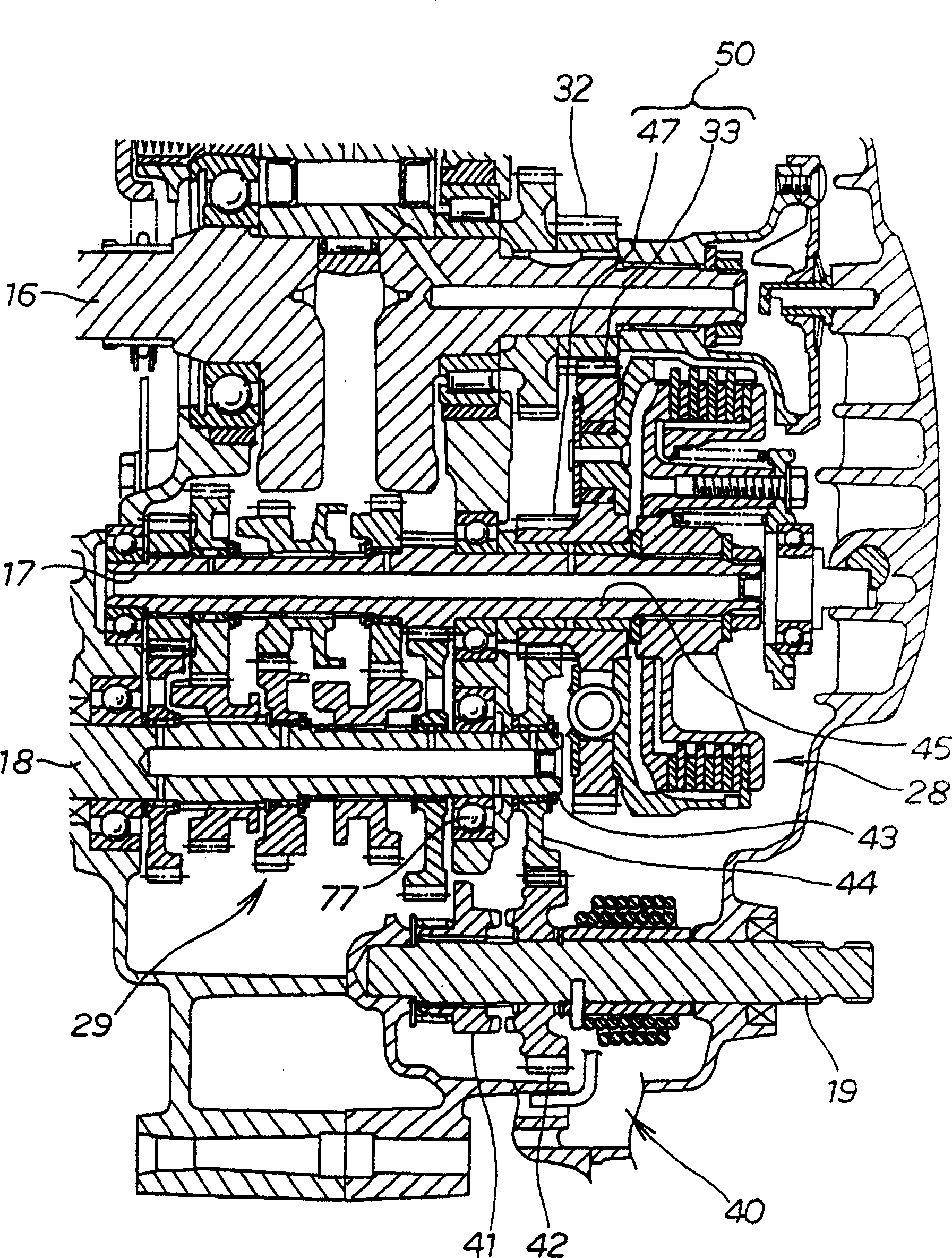

[0057] figure 1 It is a sectional view of the internal combustion engine of the present invention, and the structure of the internal combustion engine 10 is as follows: the appearance part is made of a crankcase 11, a cylinder block 12, a cylinder head 13 and a head cover 14, and a crankshaft 16 and a main shaft 17 are arranged parallel to each other on the crankcase 11. , countershaft 18 and kick start shaft 19, cylinder 21 is arranged on cylinder block 12, and piston 22 is accommodated in this cylinder 21 in the mode of free reciprocation, and this piston 22 is linked on the crankshaft 16 by connecting rod 23, in The cylinder head 13 is provided with an ignition spark plug 24 and a valve train 25 which is an air-cooled engine covered by the head cover 14 .

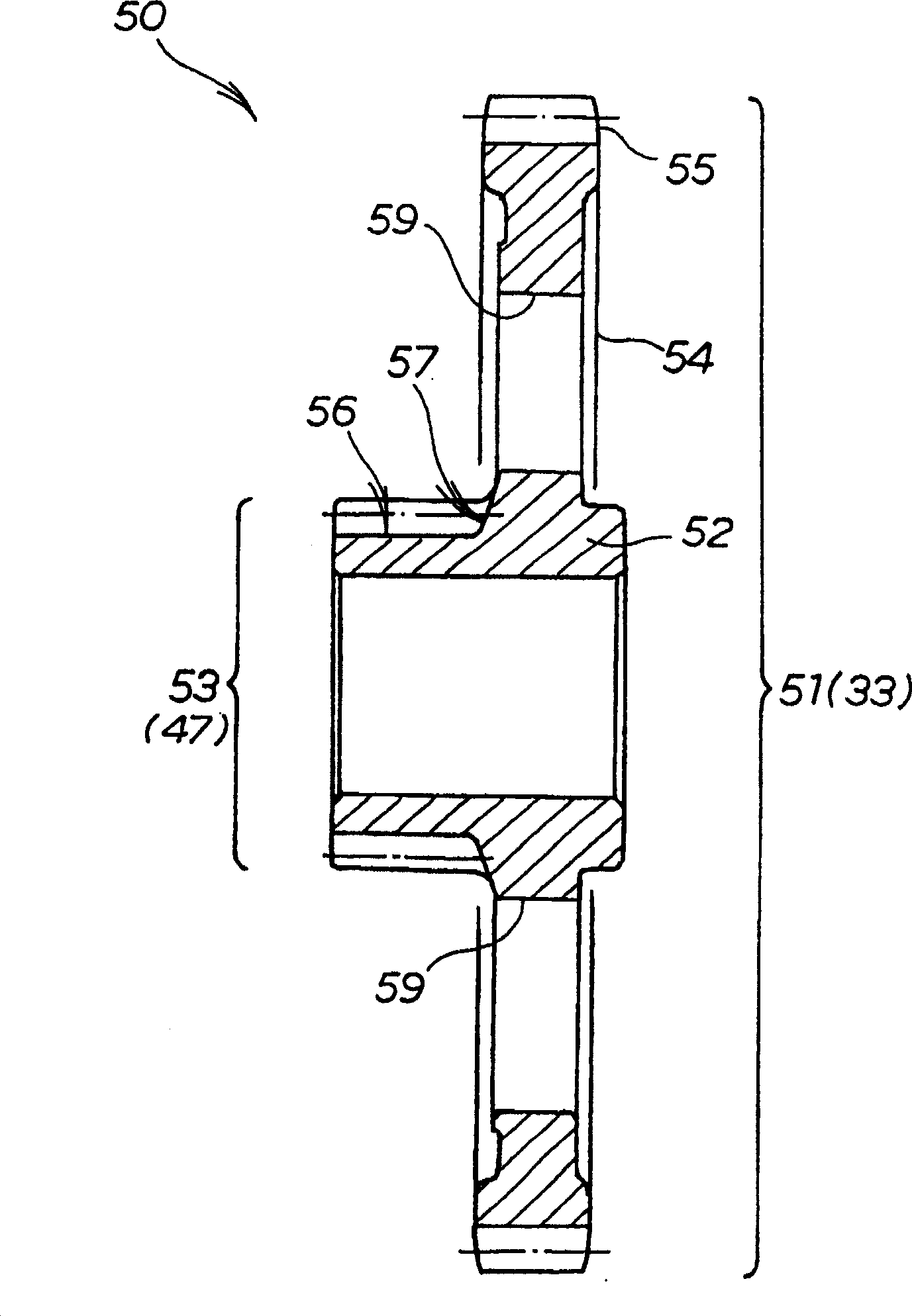

[0058] 26 is an inertia wheel (flywheel), 27 is the rotor of an alternator, 28 is a clutch mechanism, 29 is a tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com