device for pressure relief

A pressure and hydraulic technology, applied in buffers, transportation and packaging, railway car body parts, etc., can solve problems such as lack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In the following, identical or identically acting components are provided with the same reference symbols for the sake of clarity.

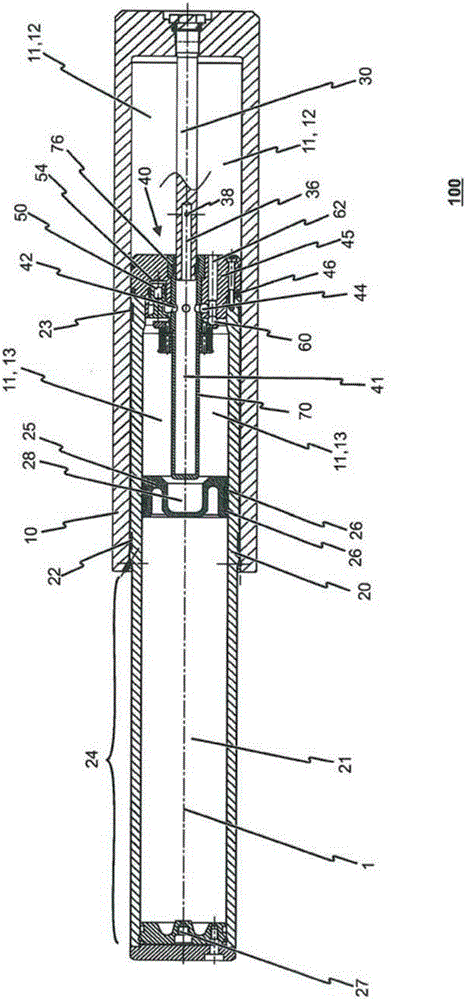

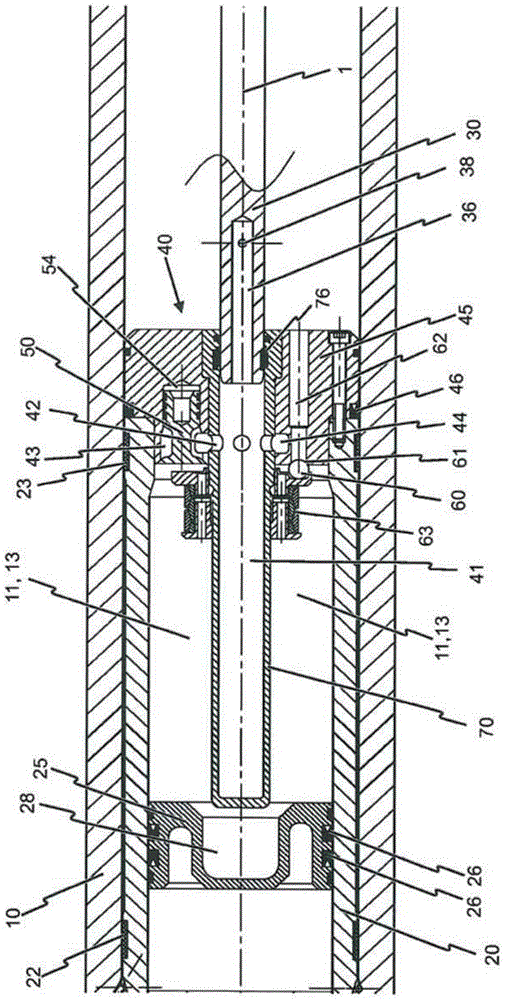

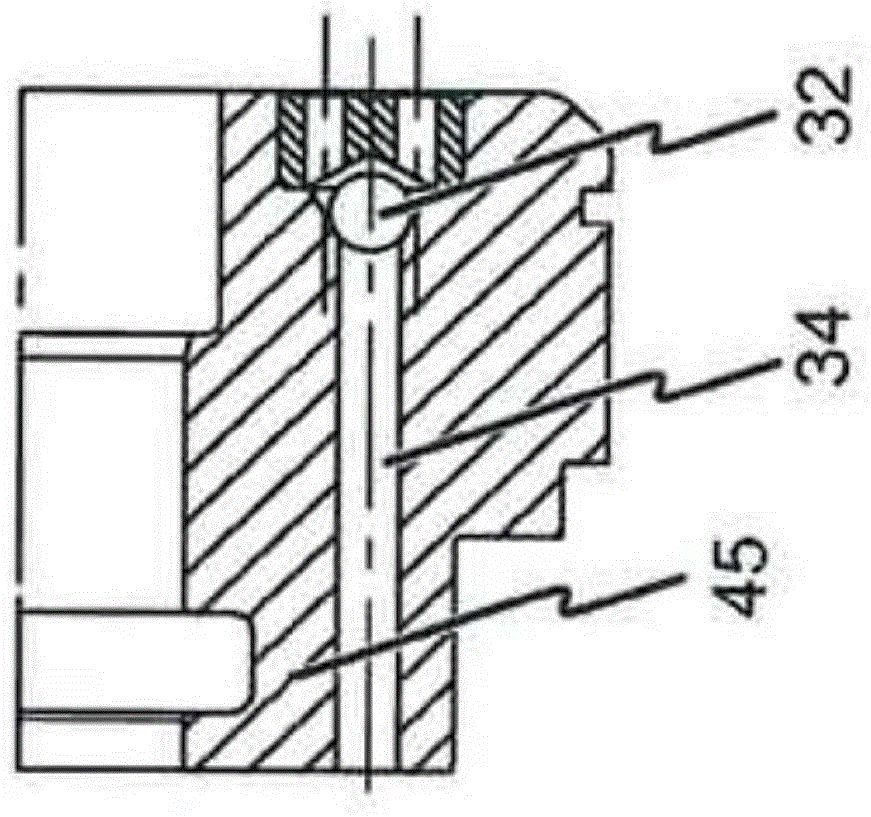

[0048] figure 1 A sectional view showing a first embodiment of a device for buffering pressure according to the present invention, said device mainly comprising a cylinder 10 and a hollow piston 20 telescopically movable along a central axis 1 in the cylinder, in which One end region of the hollow piston 20 is provided with a valve system 40 which divides the hydraulic chamber 11 formed inside the cylinder 10 into a rear hydraulic chamber region 12 and a front hydraulic chamber region 13 . The hydraulic chamber 11 thus extends at least partially into the hollow piston 20 . In other words, the front hydraulic chamber region 13 is formed inside the hollow piston 20 .

[0049] A separating piston 25 separates the front hydraulic chamber region 13 from an air chamber 21 formed inside the hollow piston 20 , wherein the air chamber 21 can be f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com