Mass supply system

A mold and food technology, applied in the field of object supply system and method, can solve the problems of complexity, inappropriate handling of the whole muscle, etc., and achieve the effect of small inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

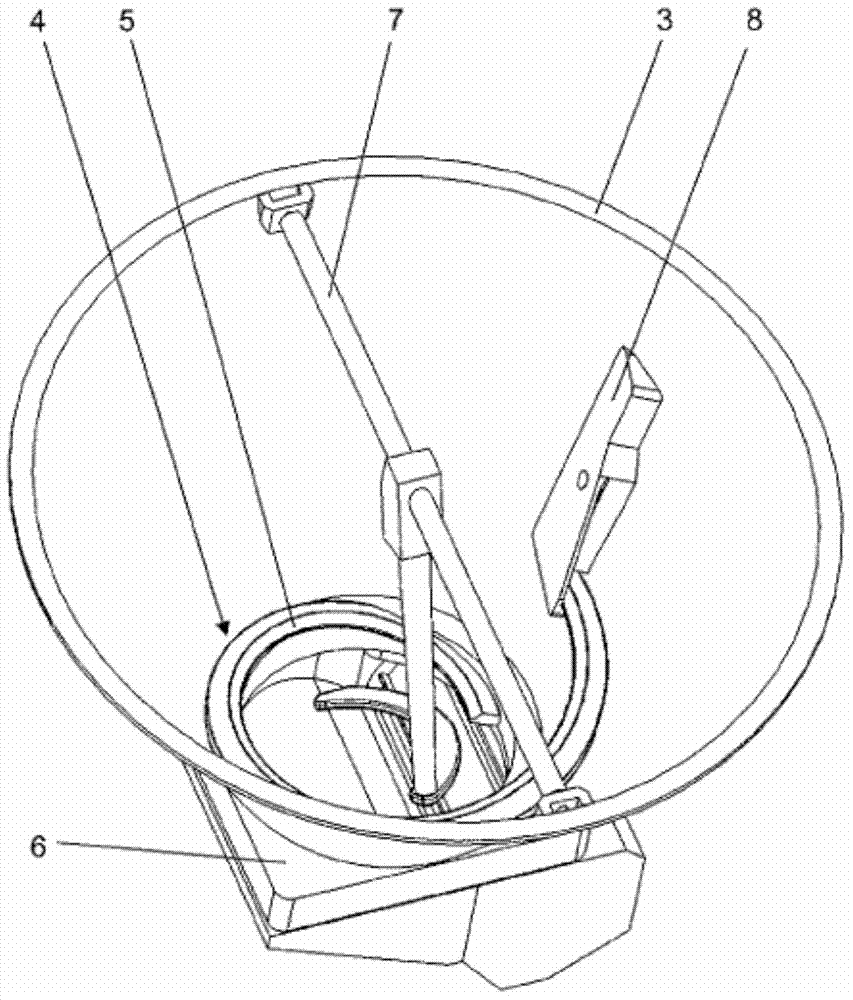

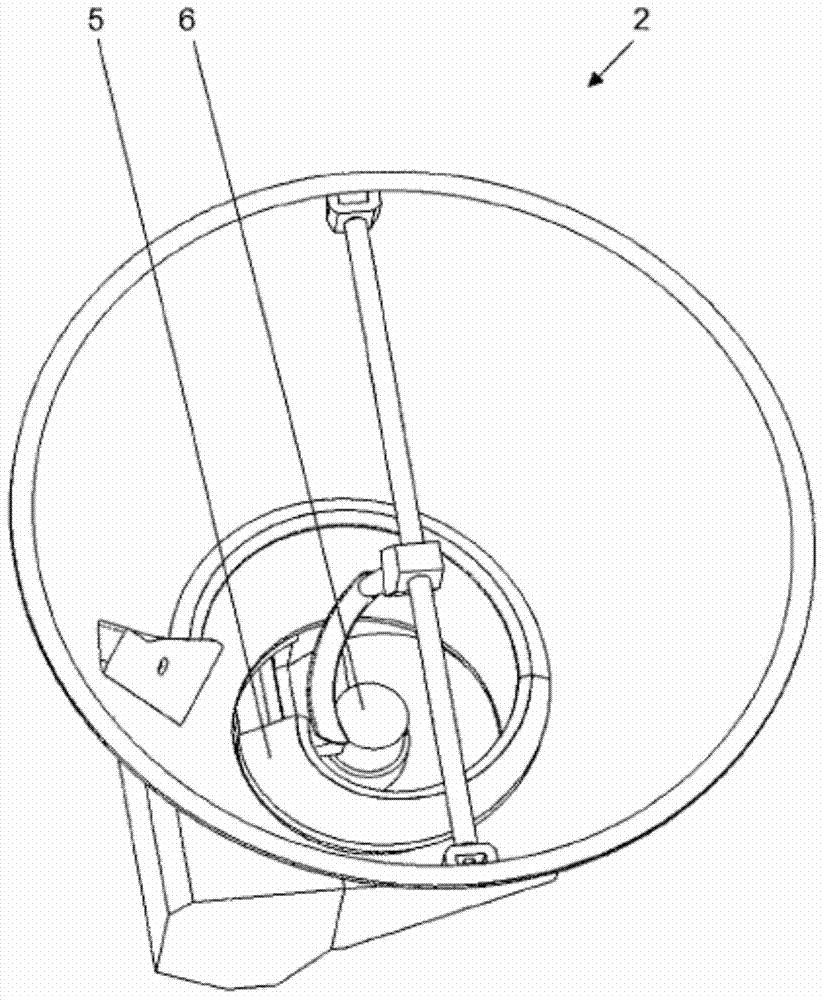

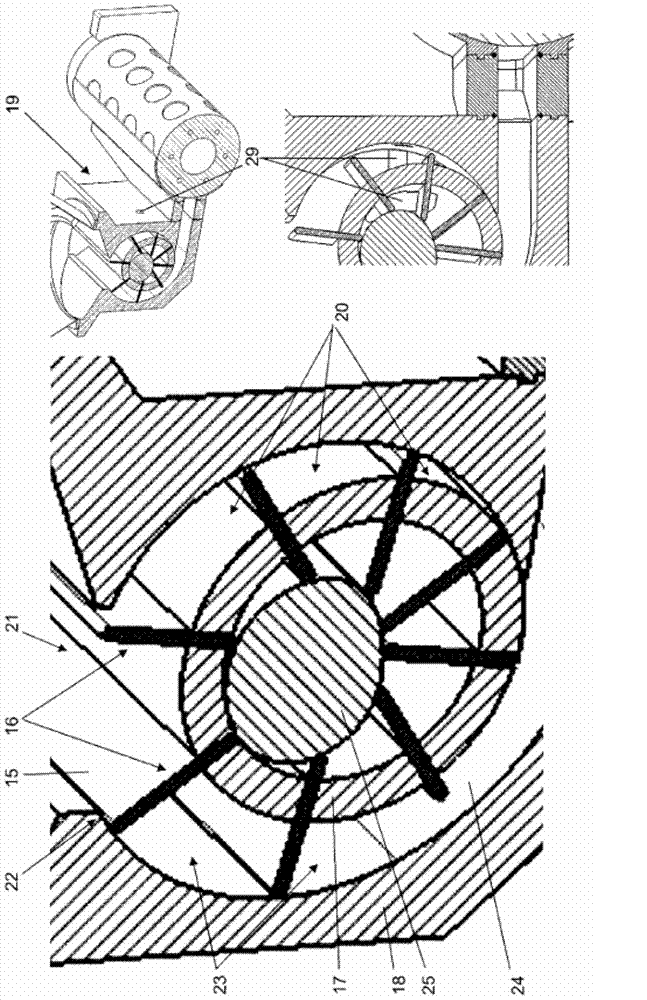

[0092] Figure 1a and 1b The hopper is shown preferably connected to the inventive system. Meat conveyors can be used to insert pieces of food product into the hopper 3, for example by a separate lifting unit placed along the inventive system. It is also possible to integrate the lifting unit into the inventive system. In this design, the hopper is tapered. To avoid meat sticking to the hopper side walls and to prevent bridge formation, the hopper walls are preferably at an angle of about 30° with respect to their central axis. The outlet of the hopper is fluidly connected to the inlet of the feed pump. Even though some food pieces can be fed to the inlet of the pump by gravity, most of the food pieces need to be conveyed to the inlet of the feed pump with a feeder 4, such as a rotary feeder 4, which in this embodiment includes feeder blades 5 , In this embodiment, the feeder blade 5 is helical. By reducing the gap between the outer circumference of the feeder blade 5 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com