Patents

Literature

164results about How to "Keep the pressure constant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

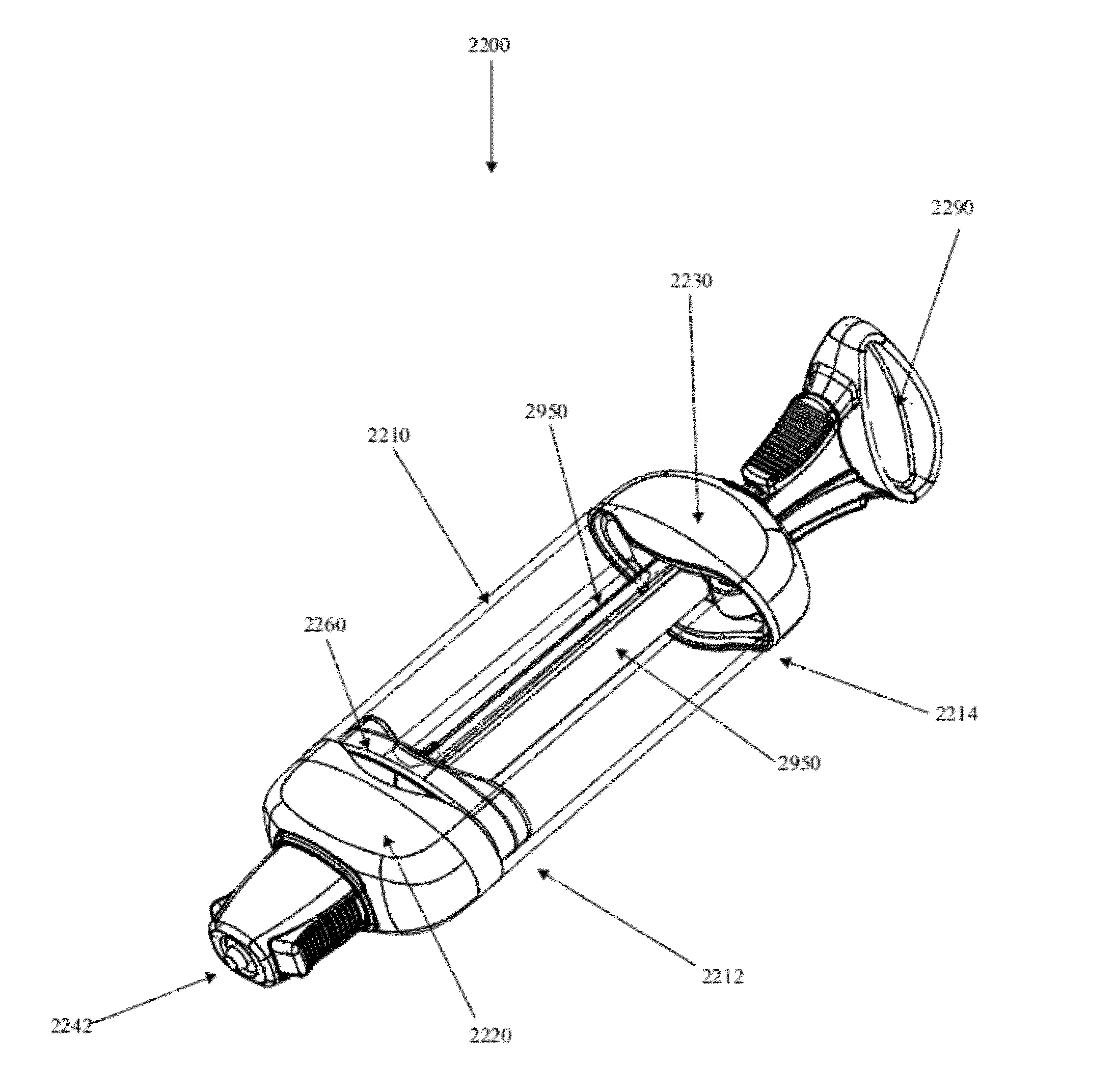

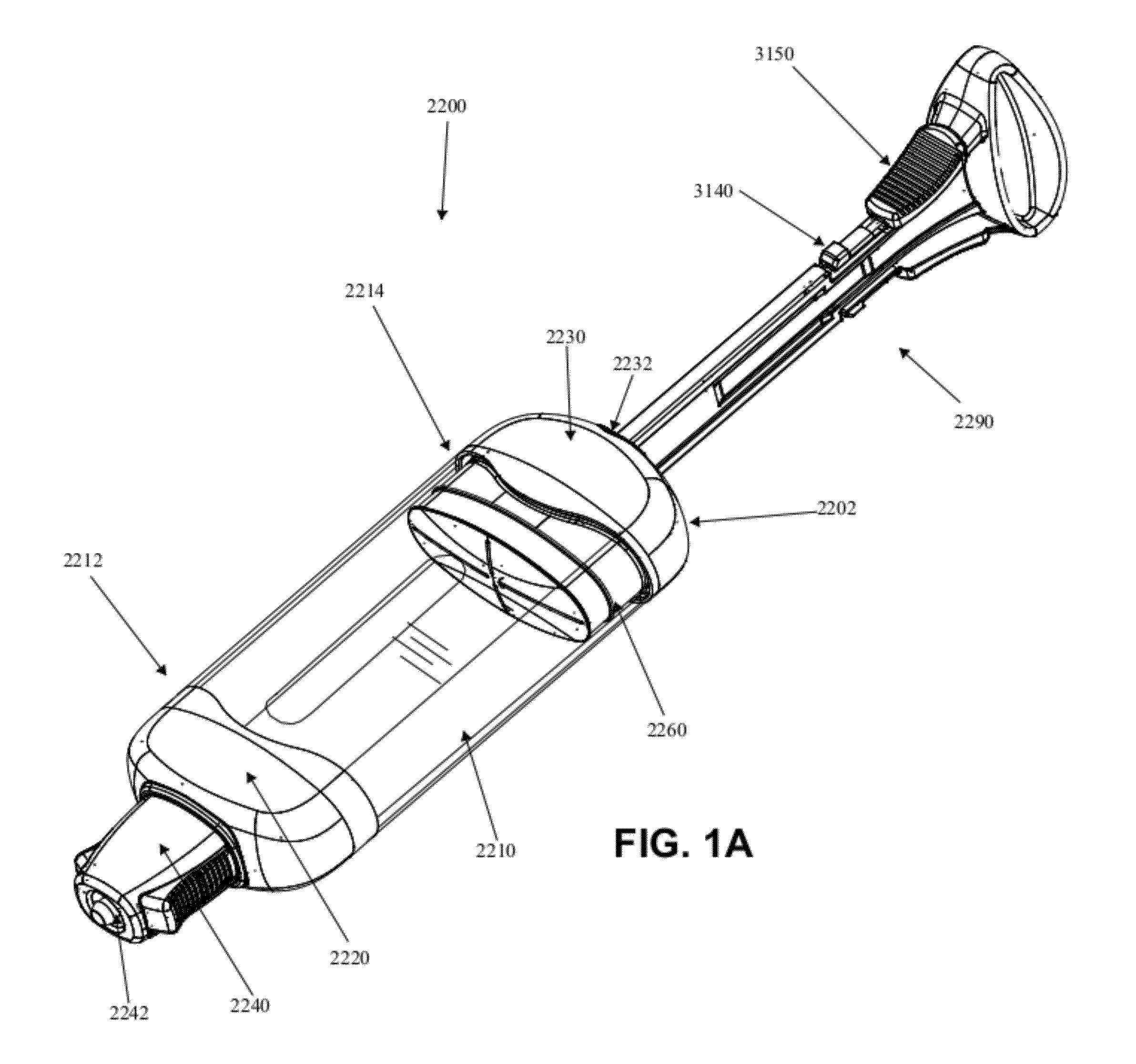

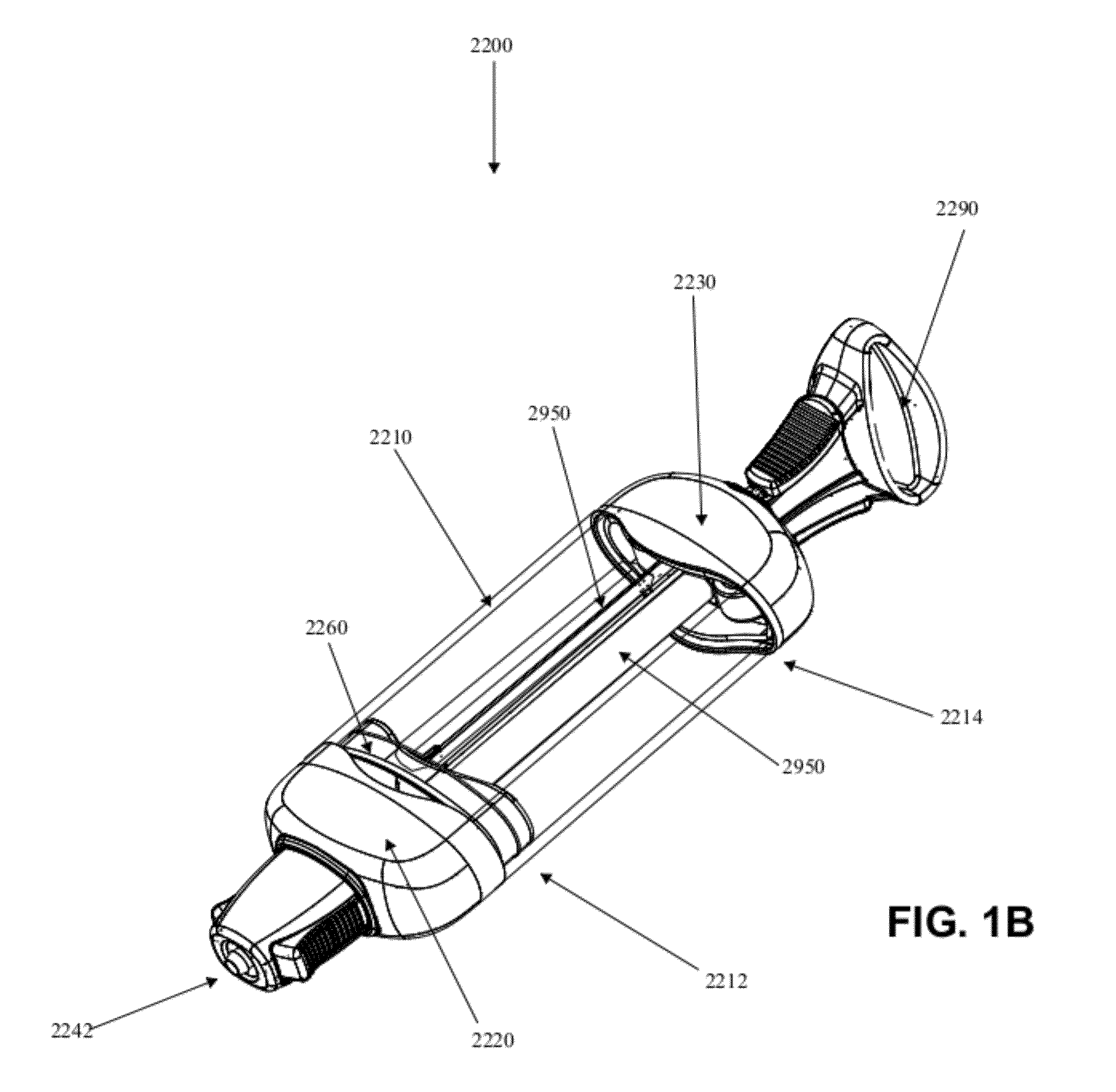

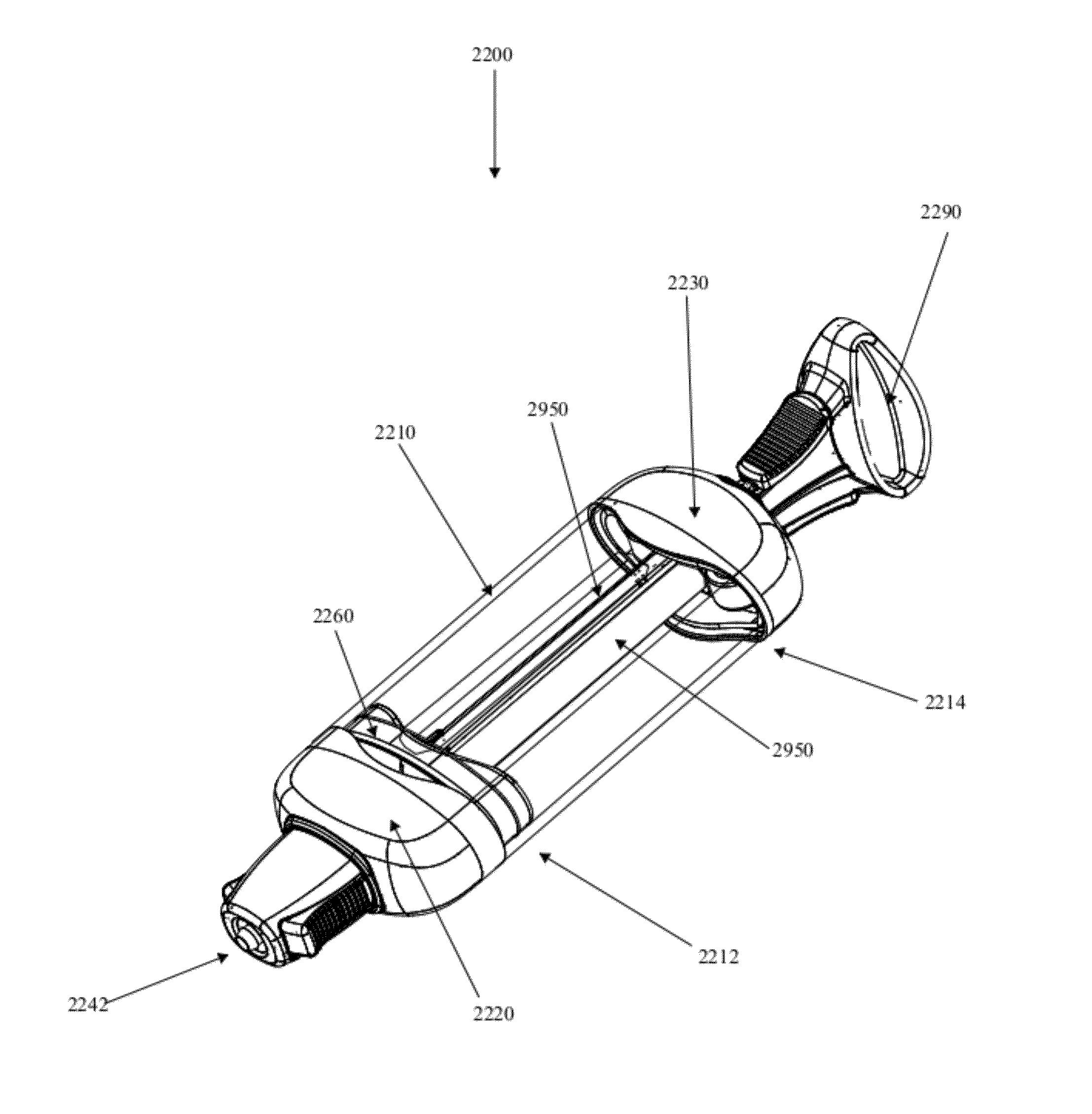

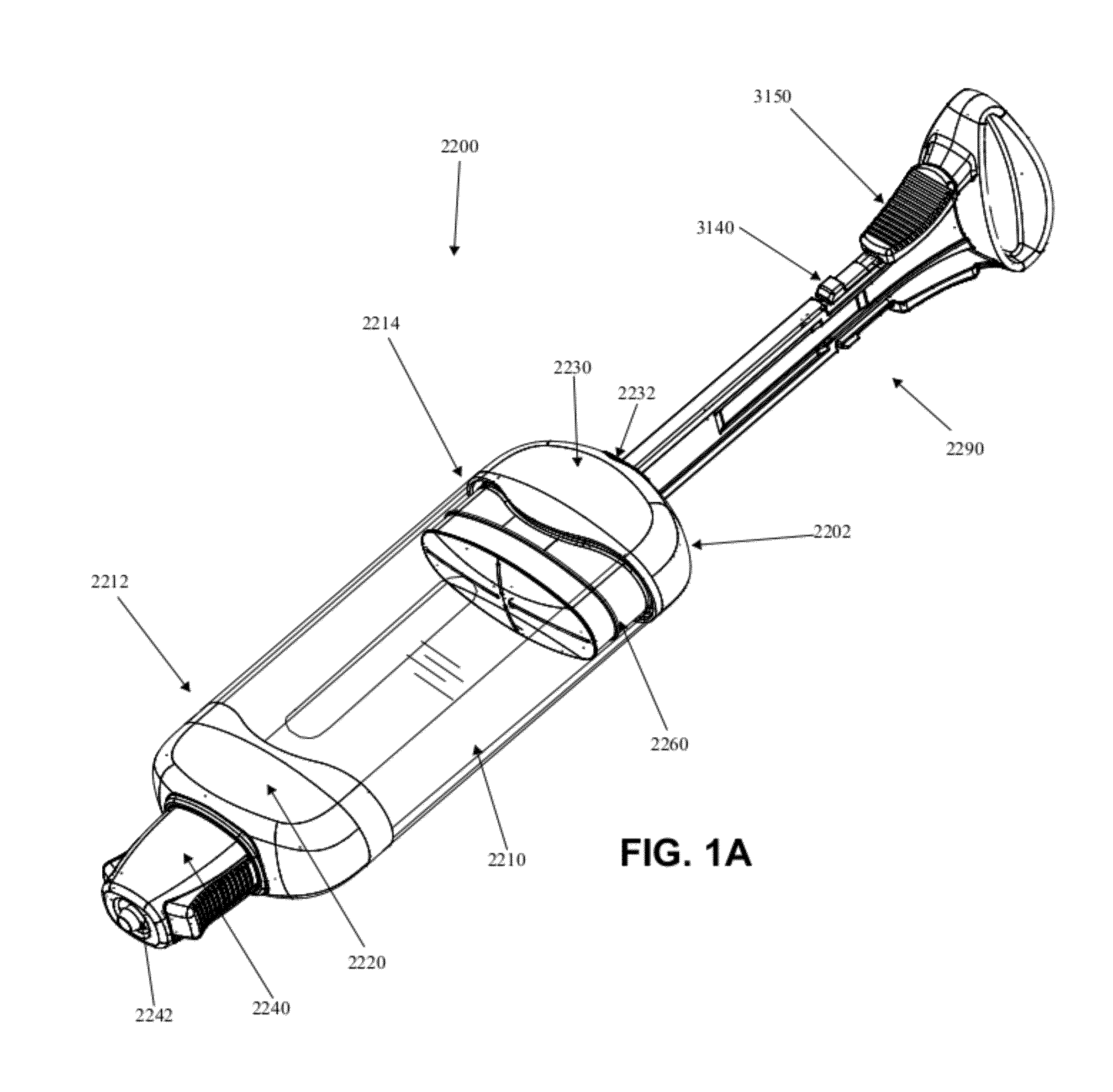

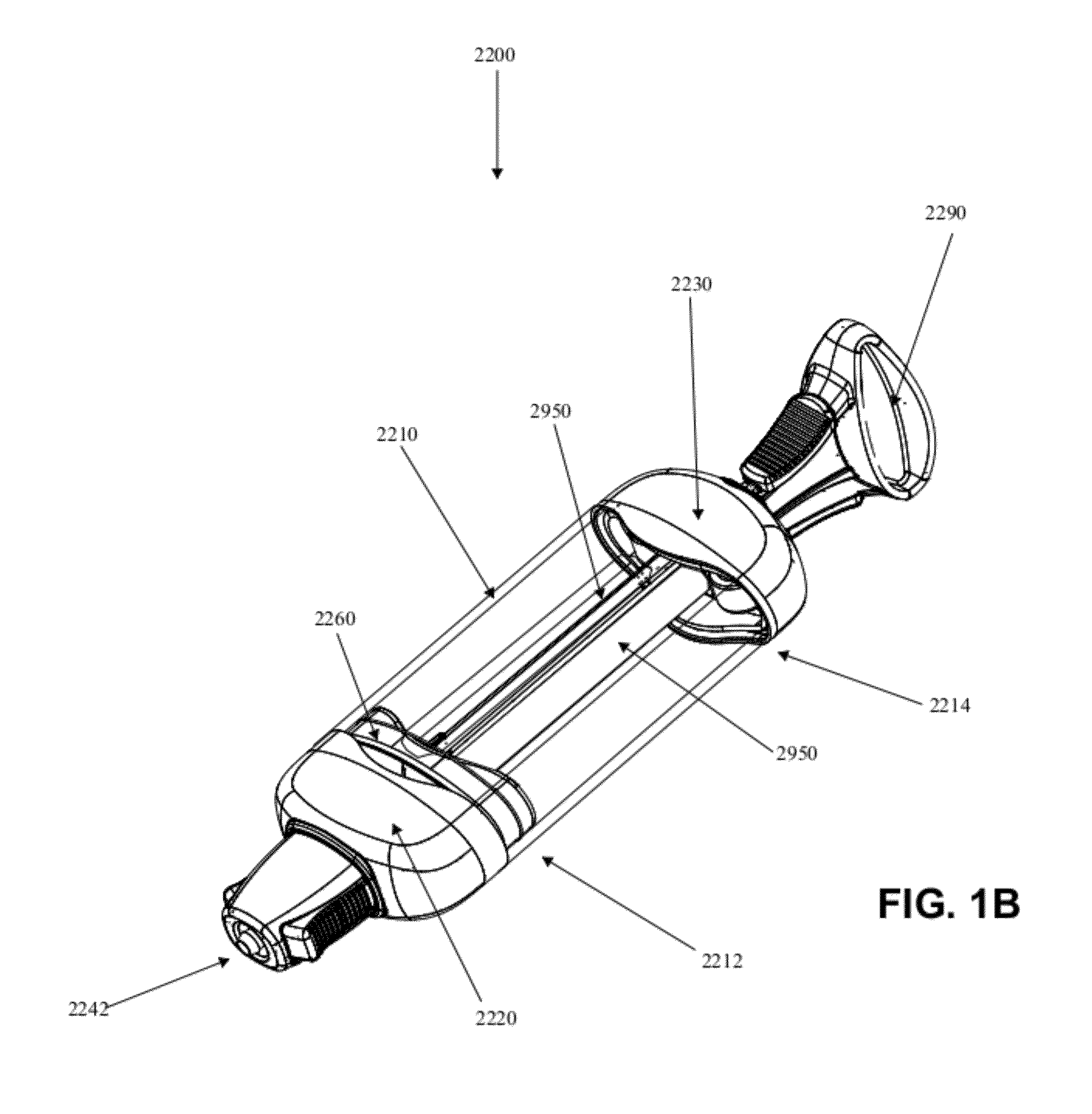

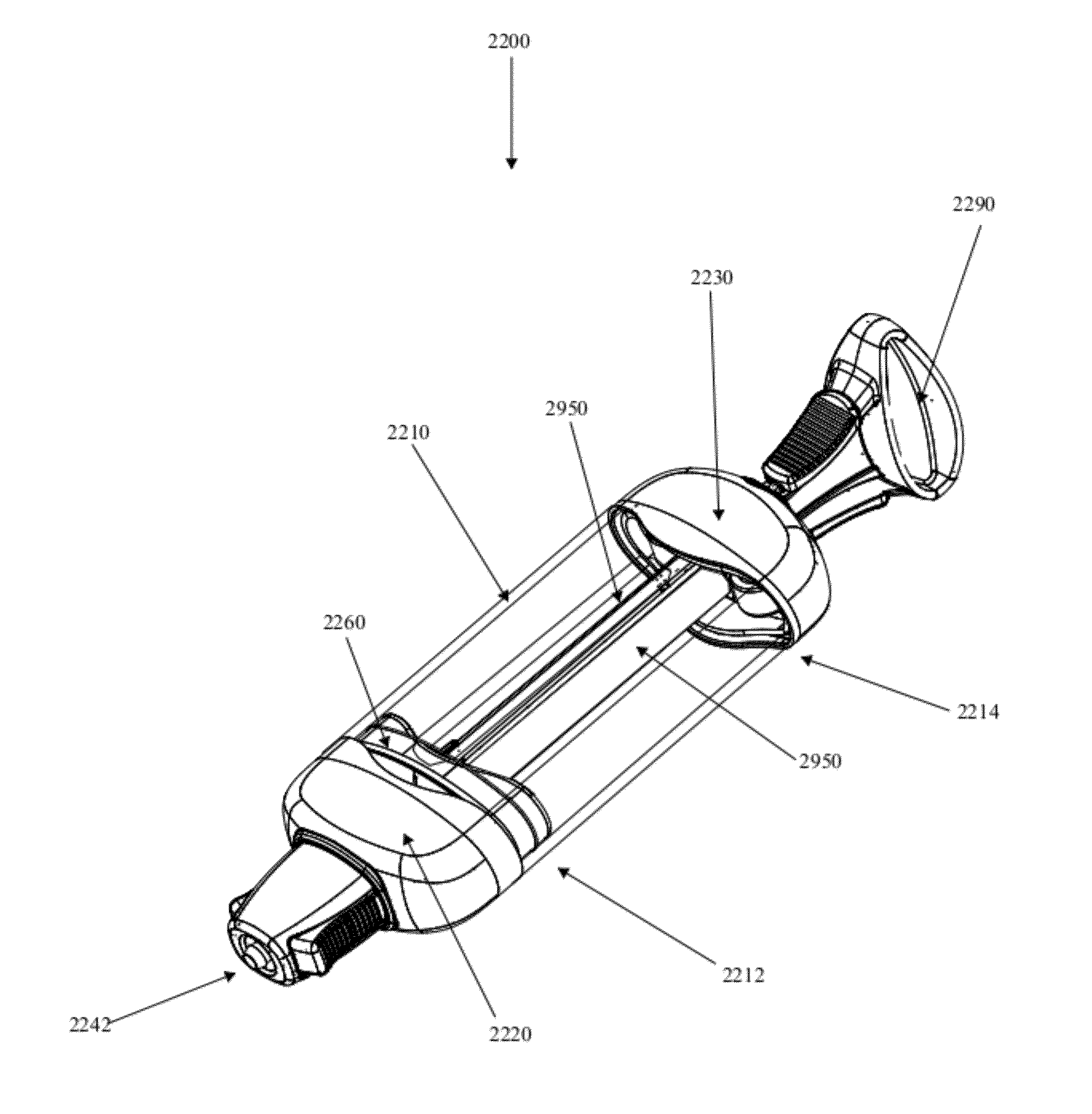

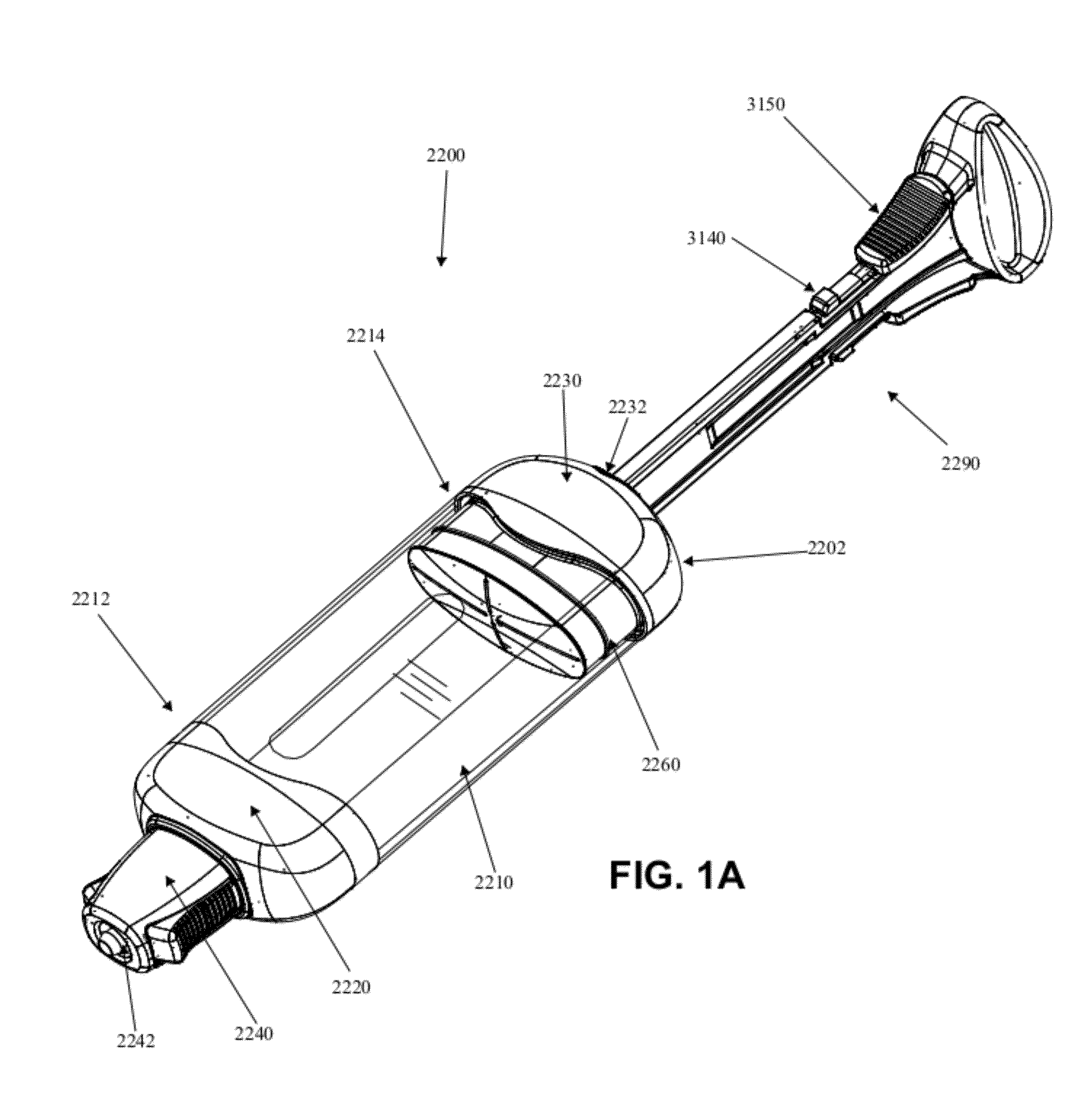

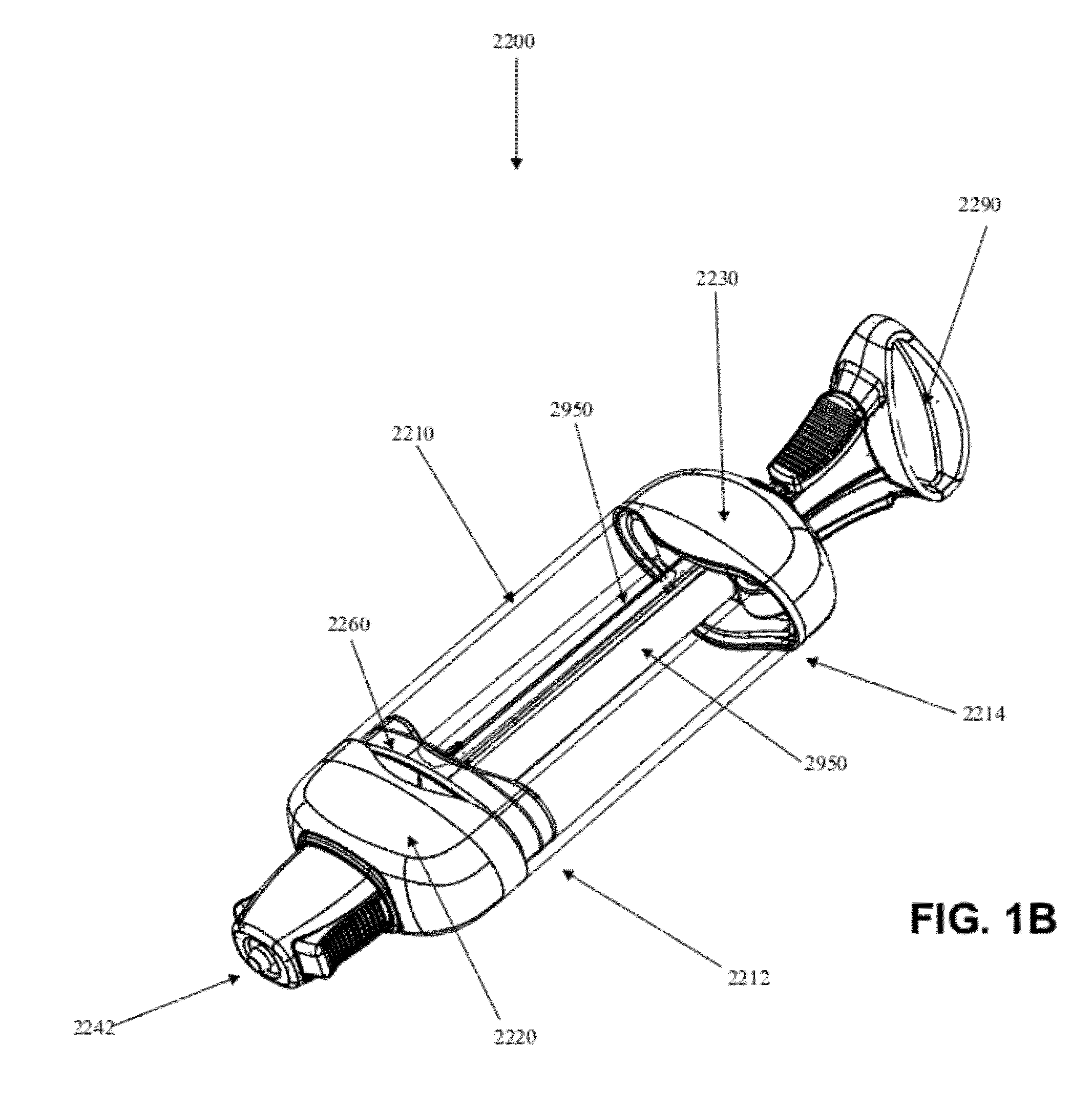

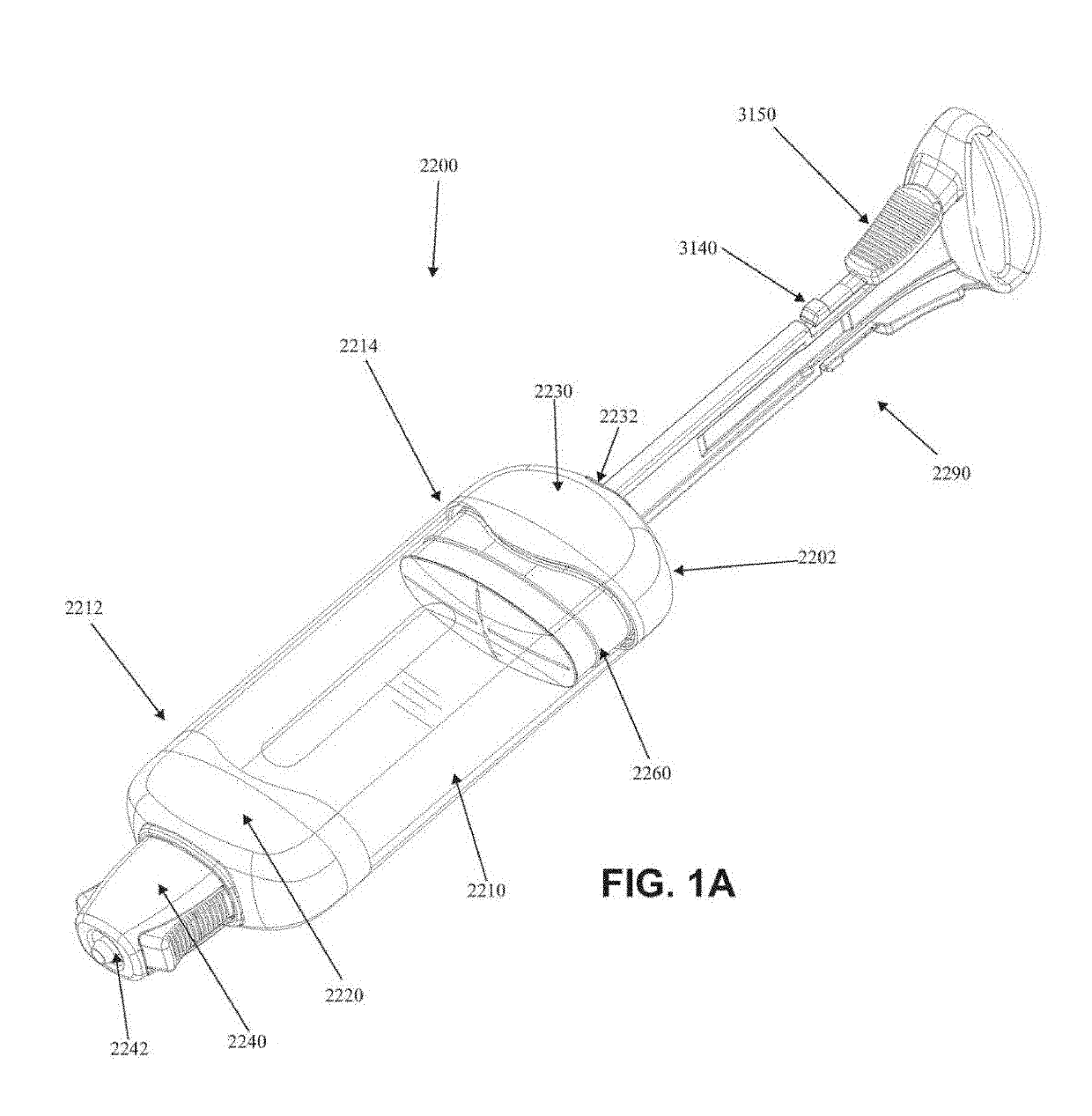

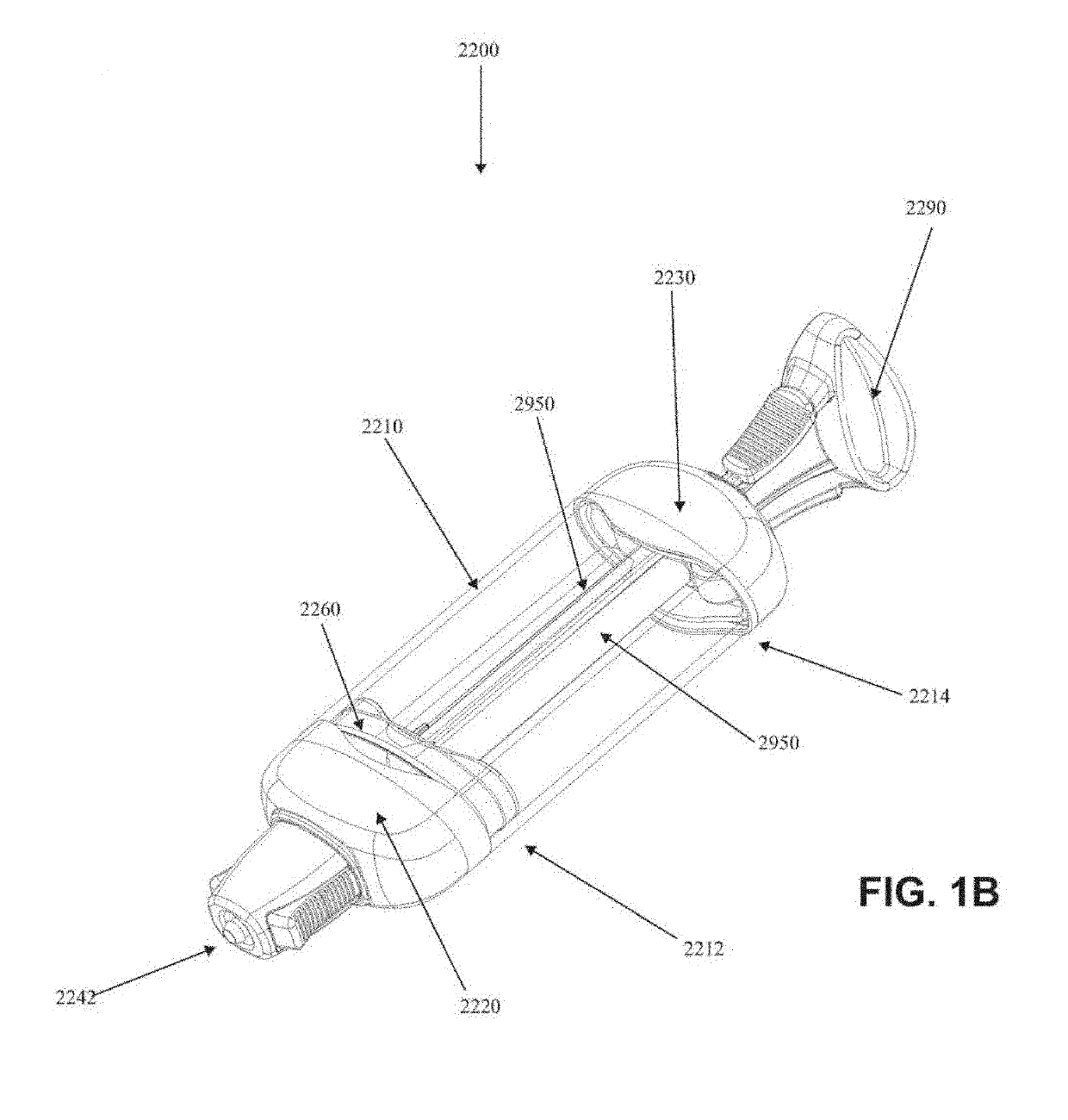

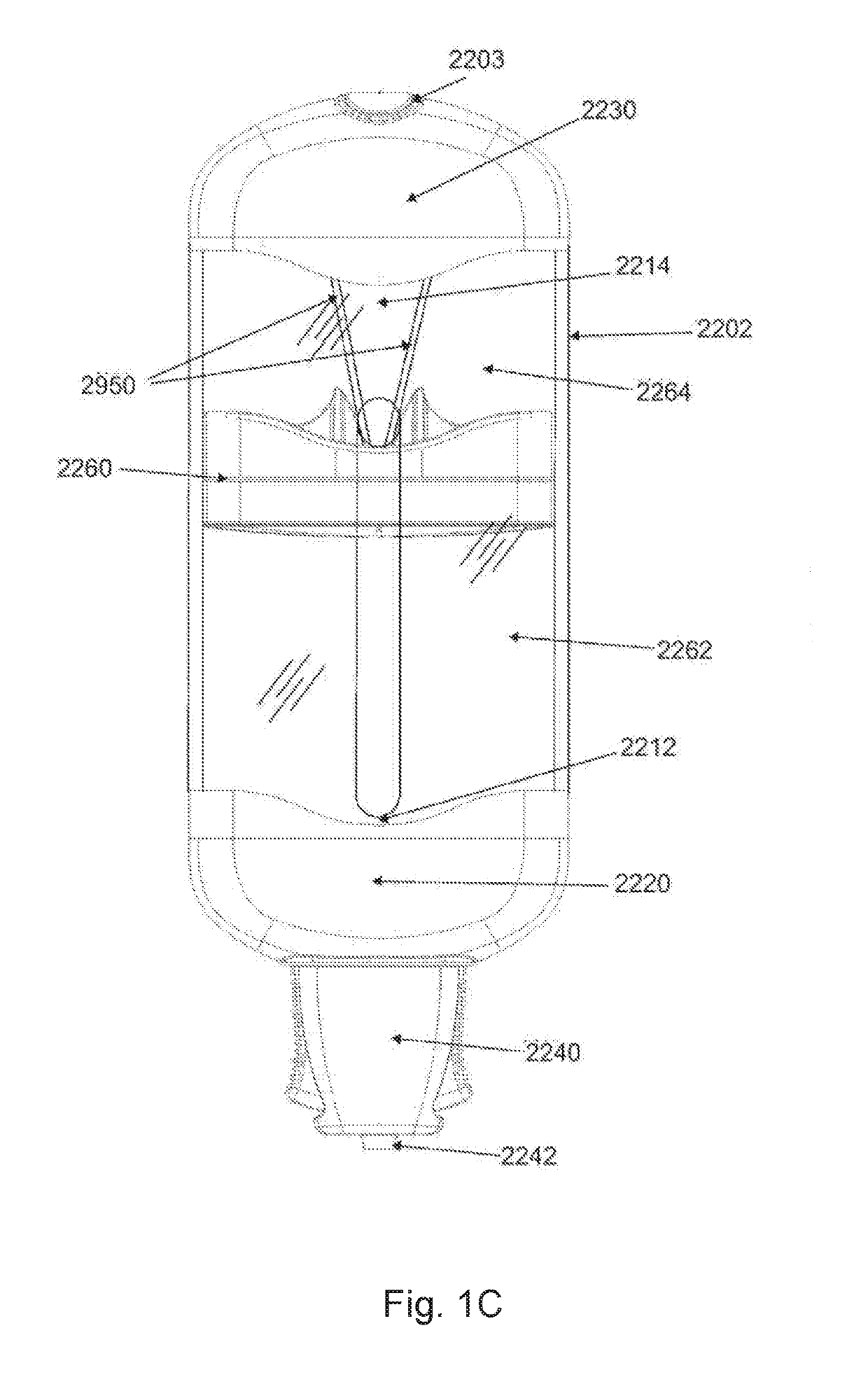

Controlled negative pressure apparatus and absorbency mechanism

ActiveUS20120071845A1Reduce pressureReduce frictionMedical devicesIntravenous devicesDamages tissuePhysical therapy

Methods and devices for treatment of damaged tissue are disclosed, including treatment of wounds by employing non-electrically powered, reduced pressure therapy devices. The devices are capable of generating a substantially constant reduced pressure with low tolerance for pressure fluctuations. Also disclosed herein are reduced pressure therapy systems that comprise an alarm system to detect the depleted state of the suction device and provide an alert to the patient and / or practitioner.

Owner:KCI LICENSING INC

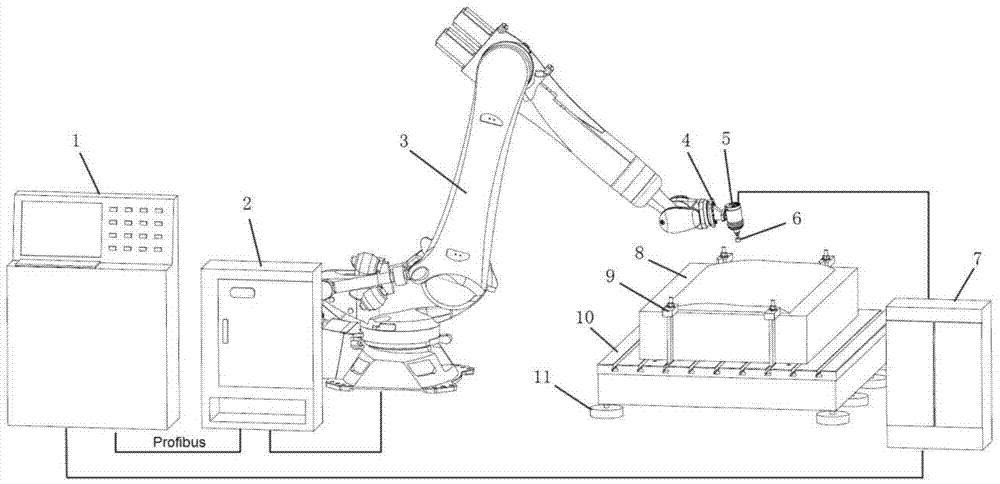

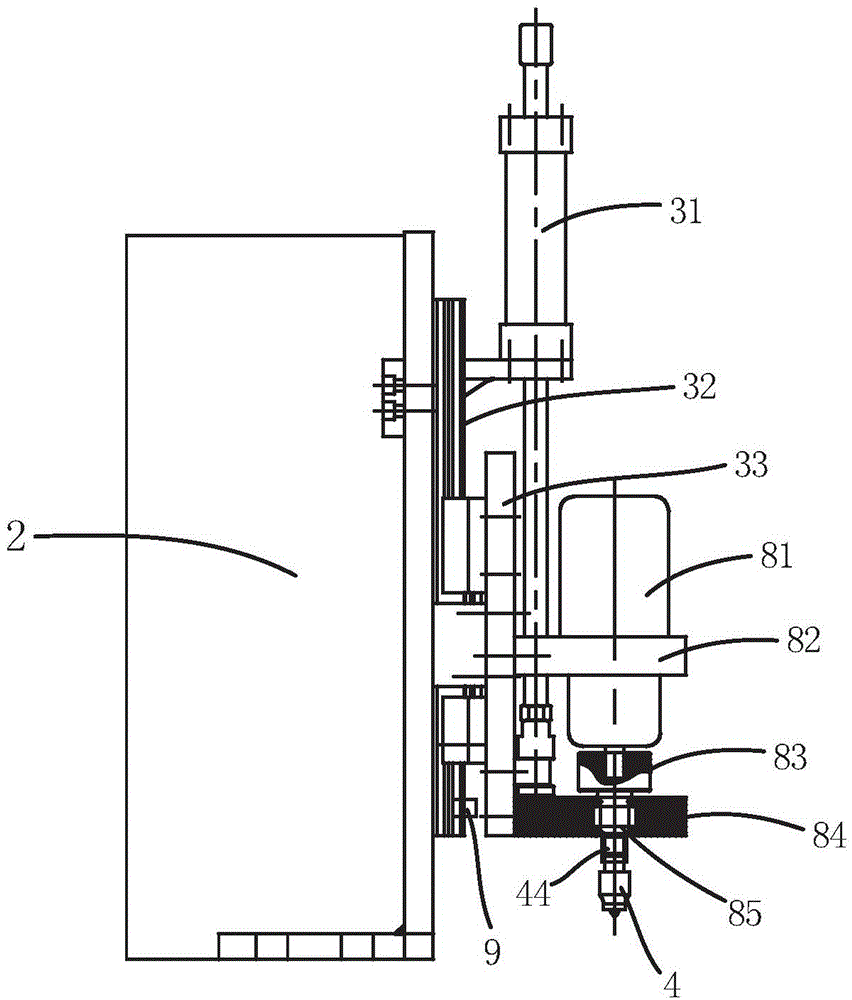

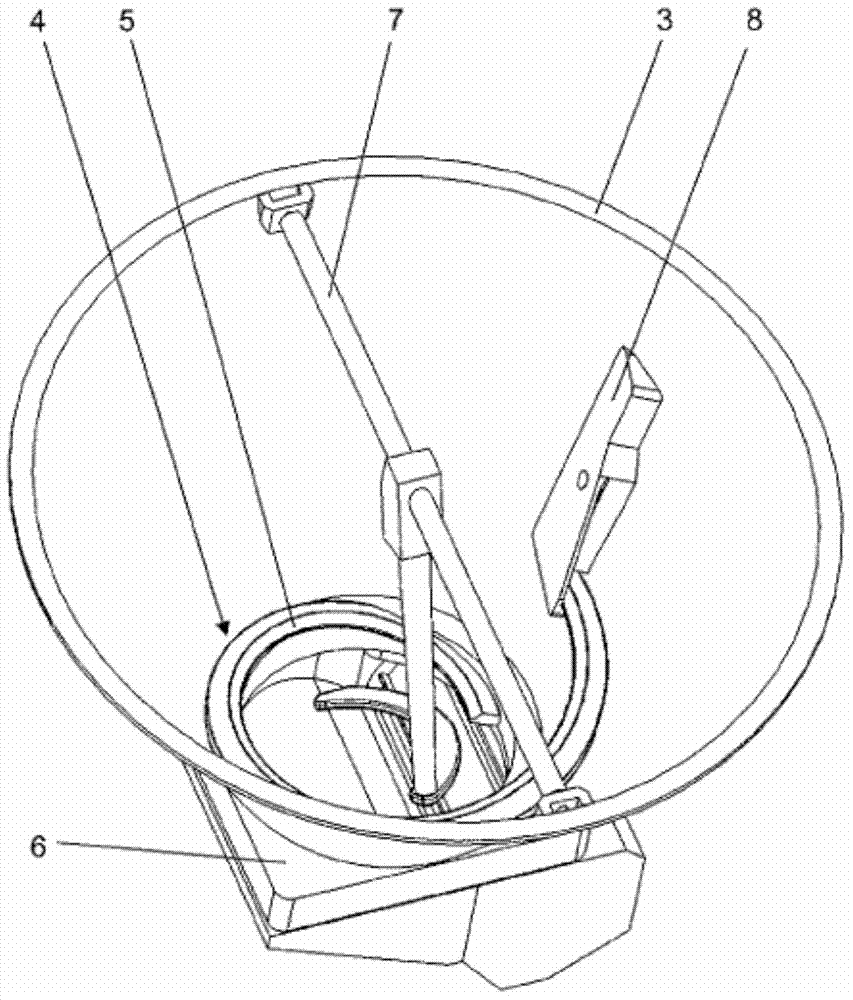

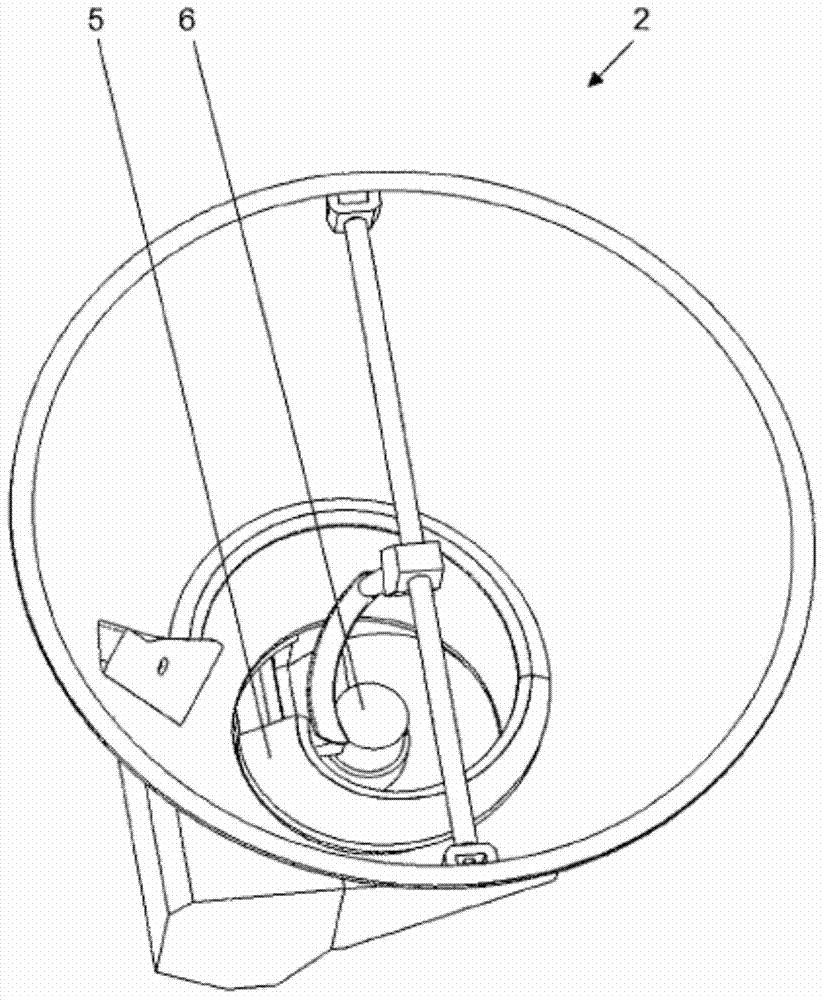

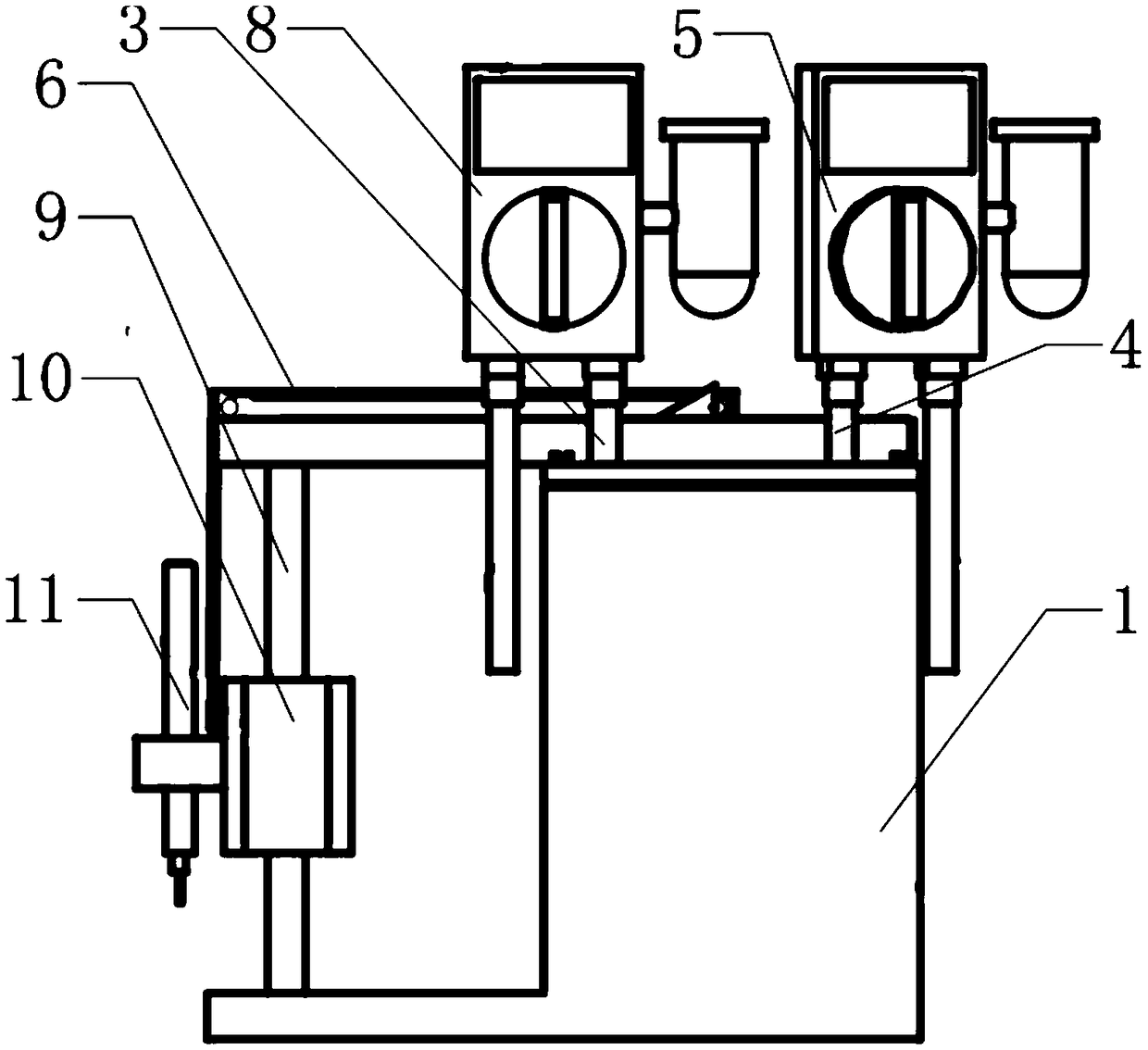

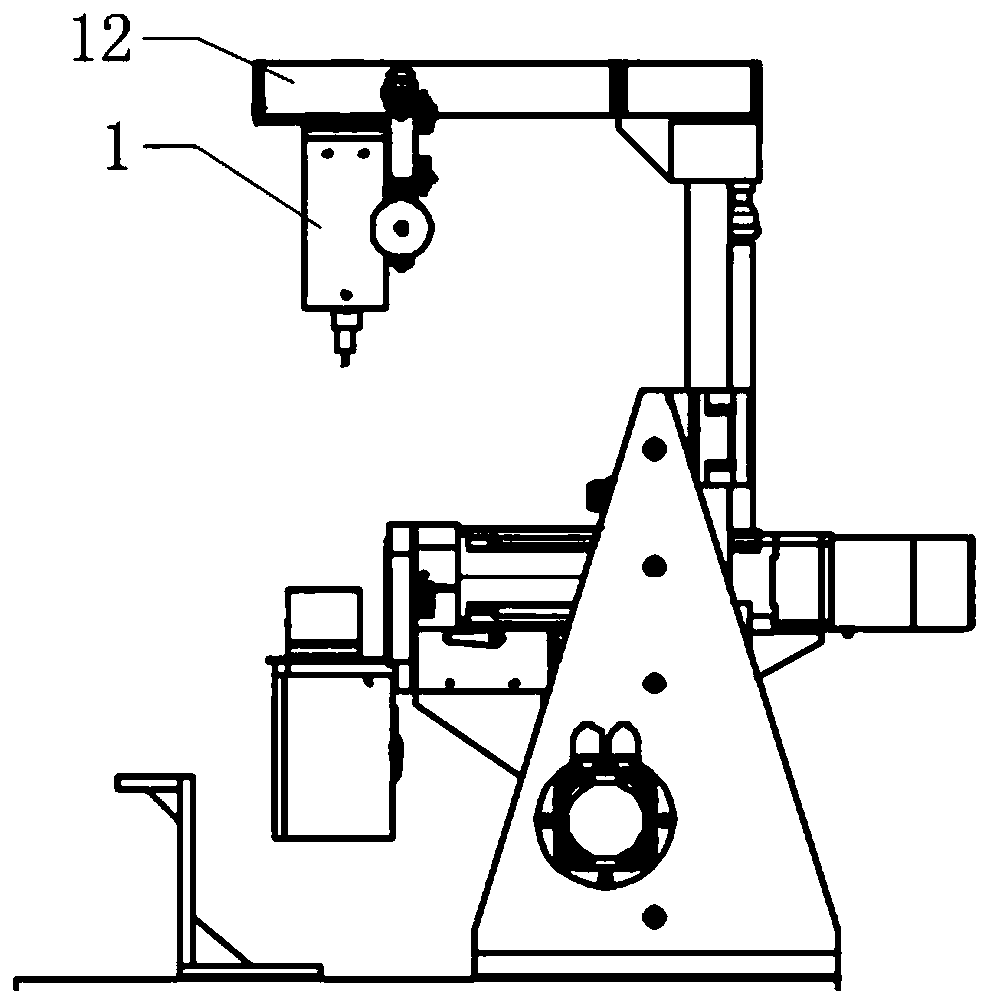

Free-form surface robot polishing system

ActiveCN103878666AWith soft force control functionKeep the pressure constantGrinding drivesGrinding machinesFree formMachined surface

The invention discloses a free-form surface robot polishing system. The system comprises a workbench, an industrial robot, a robot control cabinet, a polishing tool, a pneumatic main shaft, a connecting part, a pneumatic control cabinet and a system control cabinet. The system is high in automation degree, high in flexibility and particularly suitable for polishing a free-form surface. Specifically, the pneumatic main shaft fixed at the tail end of the industrial robot is used for clamping the polishing tool, the machined surface is tightly pressed by the polishing tool all the time by means of the pneumatic compliant force control function of the pneumatic main shaft, constant pressure is kept, the pose of the industrial robot is adjusted according to a planned route, the polishing pressure is in the normal direction of the machined surface, the polishing tool rotates at high speed through a pneumatic motor of the pneumatic main shaft, and then the industrial robot drives the polishing tool to polish a part according to the planned route.

Owner:中科君胜(深圳)智能数据科技发展有限公司

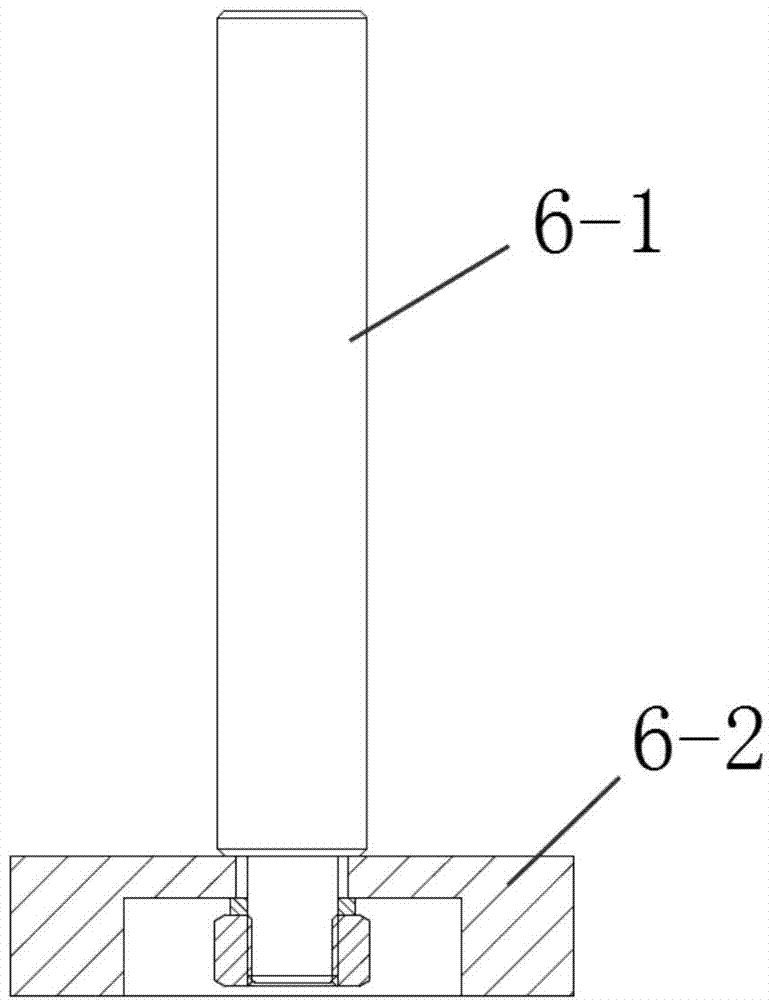

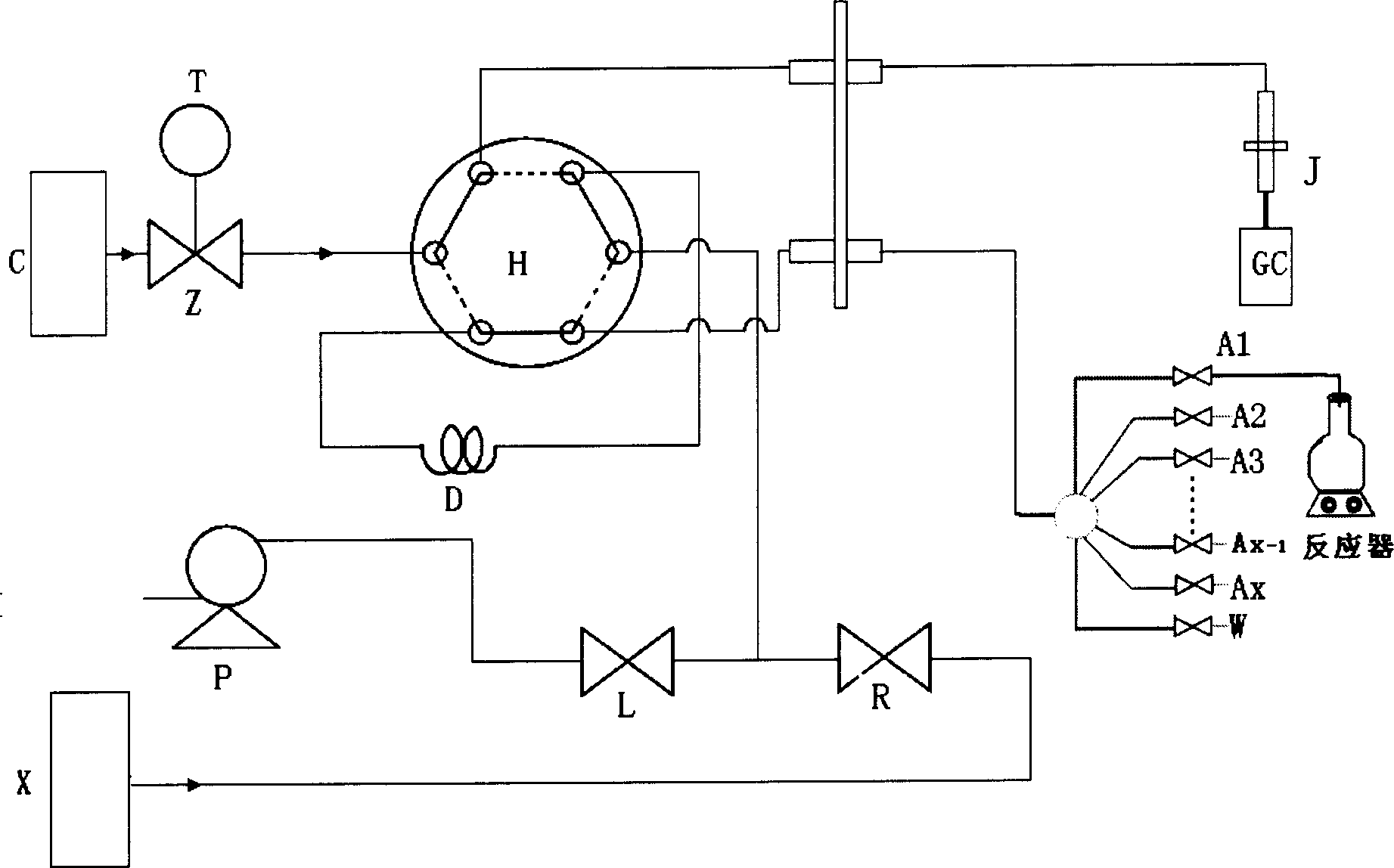

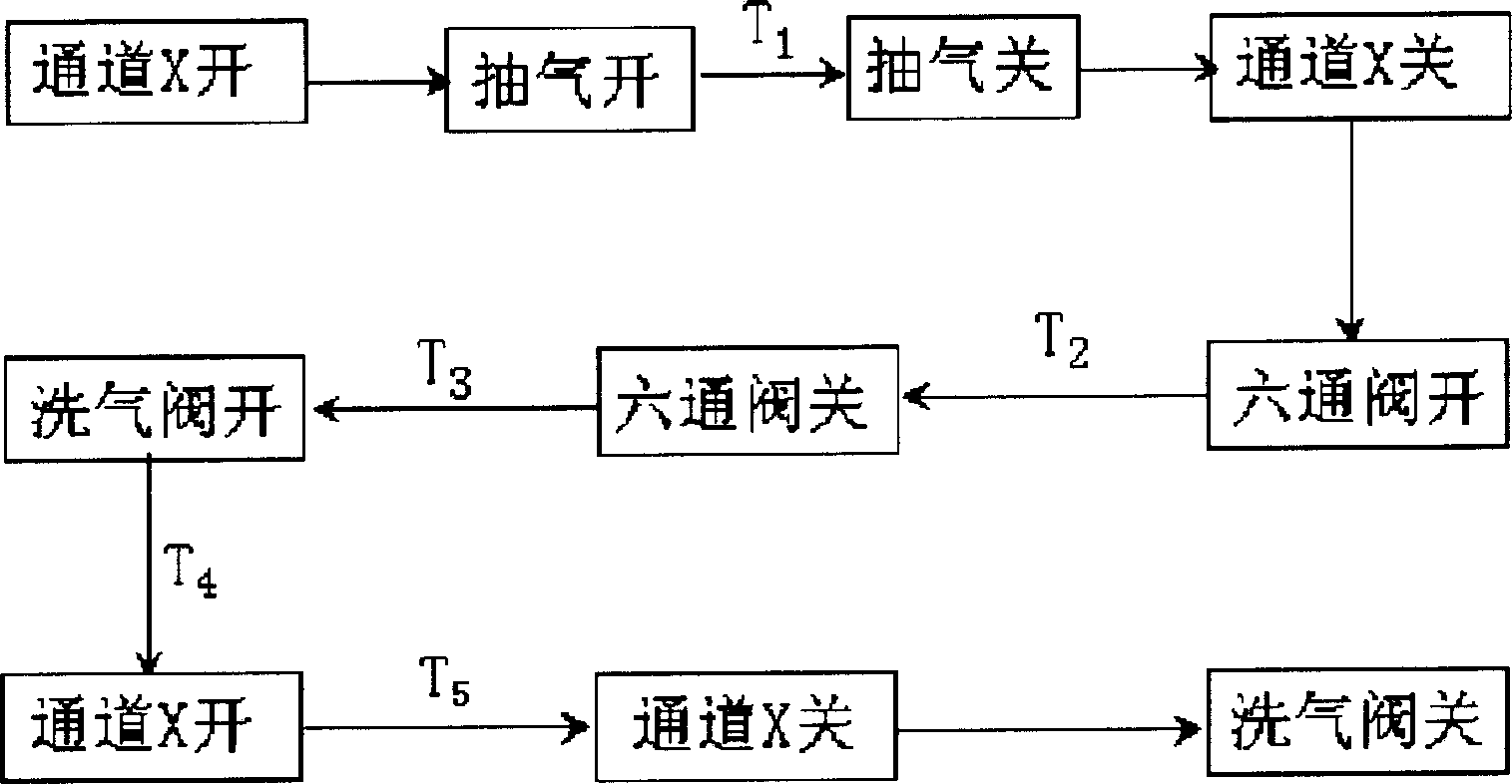

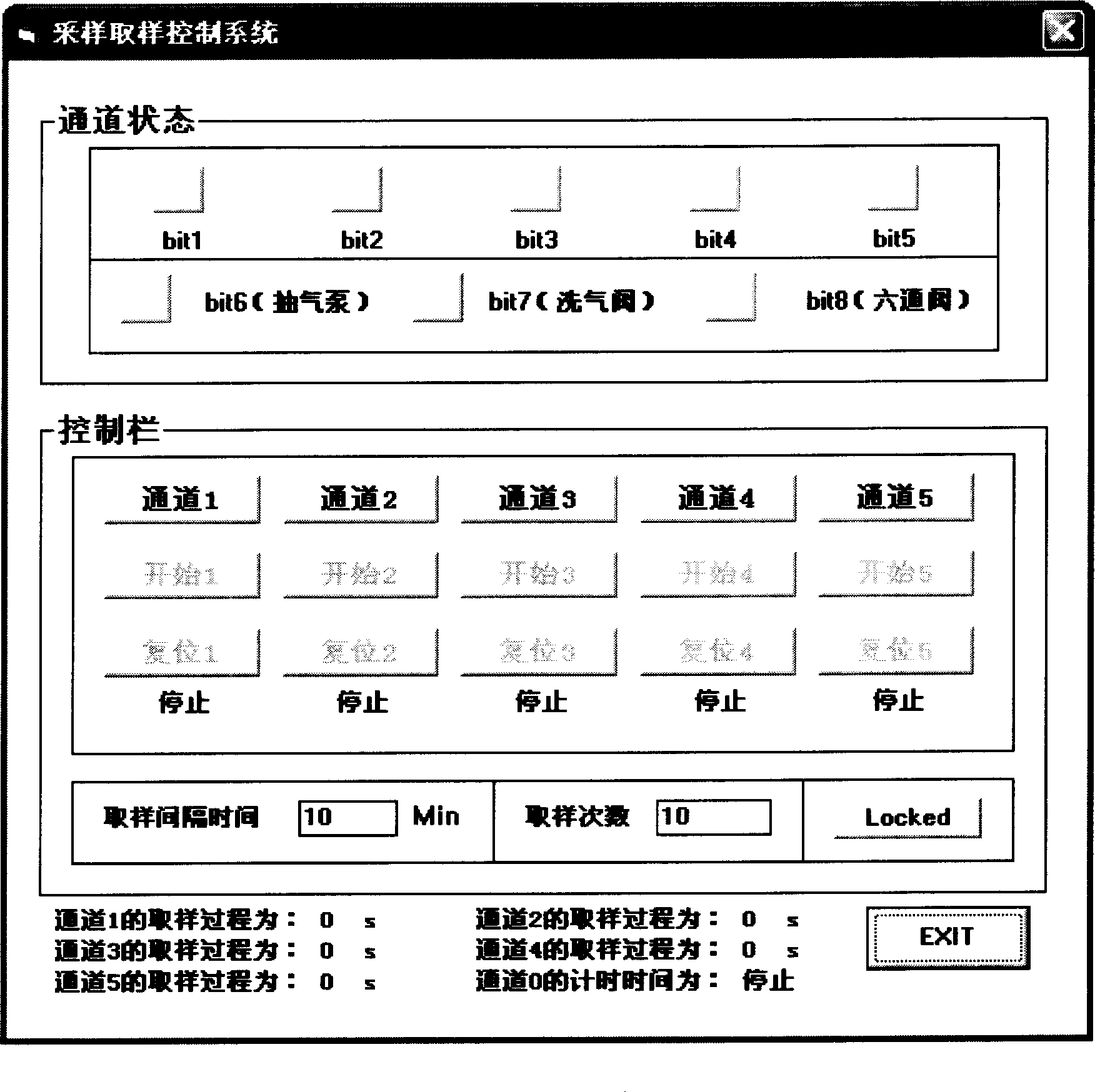

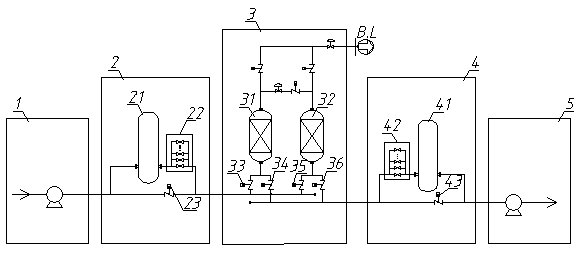

Fast On-line sampler with sample feeding for multi-channel gas and catalyst performance determining system

InactiveCN1818661AKeep the pressure constantTest accurateWithdrawing sample devicesGas handling apparatusAutomatic controlGas cylinder

An on-line quickly sampling and sample feeding device of multichannel gas consists of gas sampling unit formed by gas pipeline, multiple solenoid valves and a microdiaphragm vacuum pump; an fully-automatic six-way valve for feeding gas sample automatically; pipeline washing unit formed by a gas washing bottle and multiple solenoid valves; control unit formed by multiple switches being controlled manfully or being controlled automatically by computer .The property evaluating system of catalyst by utilizing said device is also disclosed .

Owner:XI AN JIAOTONG UNIV

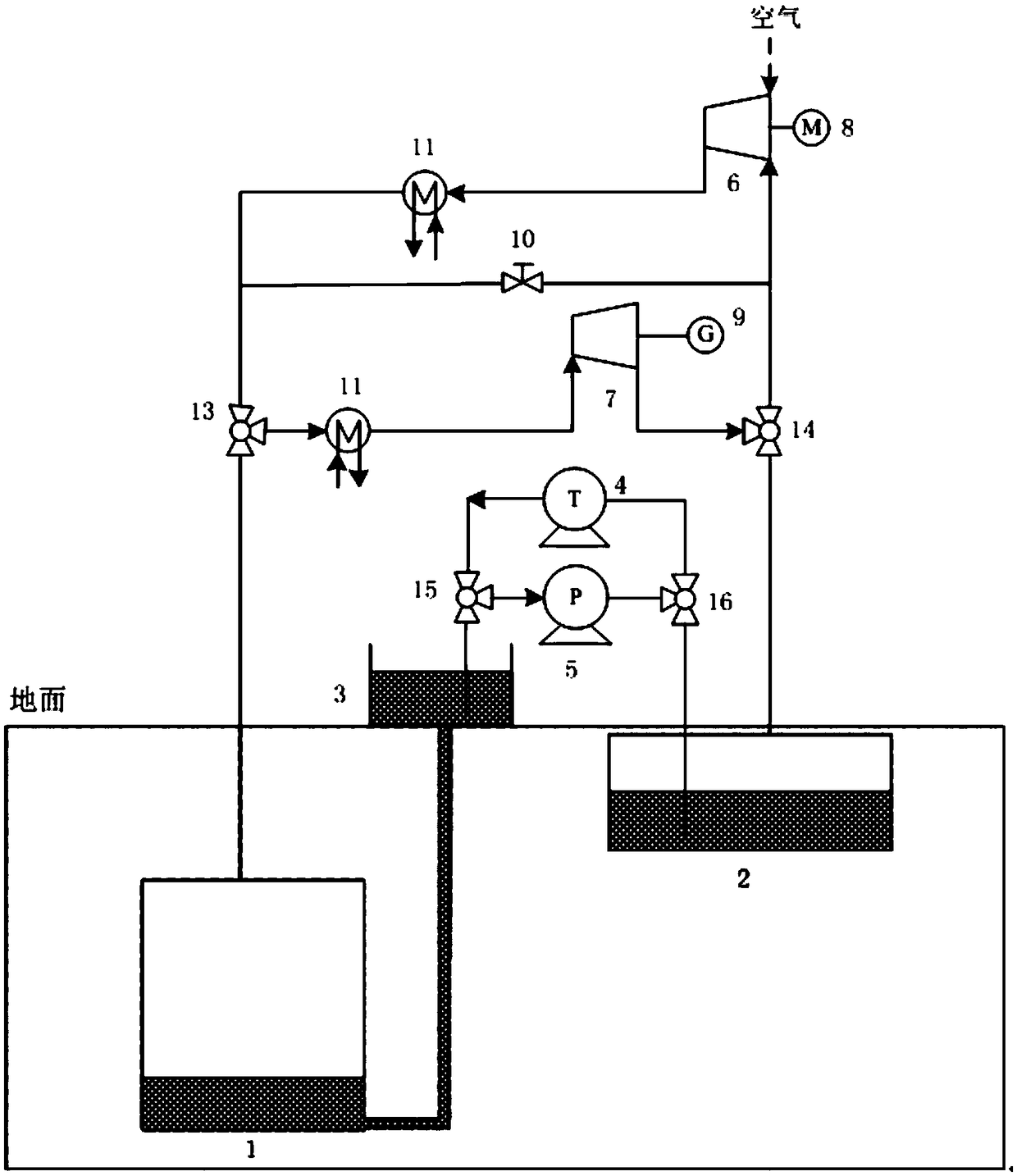

Constant-pressure water pumping compressed gas energy storage system and energy storage method

ActiveCN108930627AAvoid lostReduce lossesHydro energy generationEngine componentsAutomotive engineeringBattery energy storage

The invention discloses a constant-pressure gas storage water pumping compressed gas energy storage system and an energy storage method. A high-pressure constant-pressure gas storage cabin, a water-gas jointly containing cabin and a water storage pool are arranged, stable sealing pressure is provided through the water-level difference of the high-position water storage pool and the low-position high-pressure constant-pressure gas storage cabin, the investment cost of the system is greatly reduced, the recovering age limit of the energy storage system is shortened, the operating economy of thesystem is improved, the energy loss in the throttling pressure stabilizing process is avoided, it is guaranteed that a compressor and an expansion machine run under the constant working condition, thesystem efficiency is improved, the water-gas jointly containing cabin and the water storage pool form a water pumping energy storage system, the high-pressure constant-pressure gas storage cabin anda water storage pool close to the ground form a water pumping energy storage system, that is the double water pumping energy storage systems are formed, in the energy storage process and the energy releasing process, flowing changing speeds of water in the water storage pool and water in the low-position high-pressure gas storage cabin are slow, the loss of the water in the flowing process is relatively small, and the efficiency of the water pumping energy storage system formed by the high-pressure constant-pressure gas storage cabin and the water storage pool close to the ground is improved.

Owner:XI AN JIAOTONG UNIV

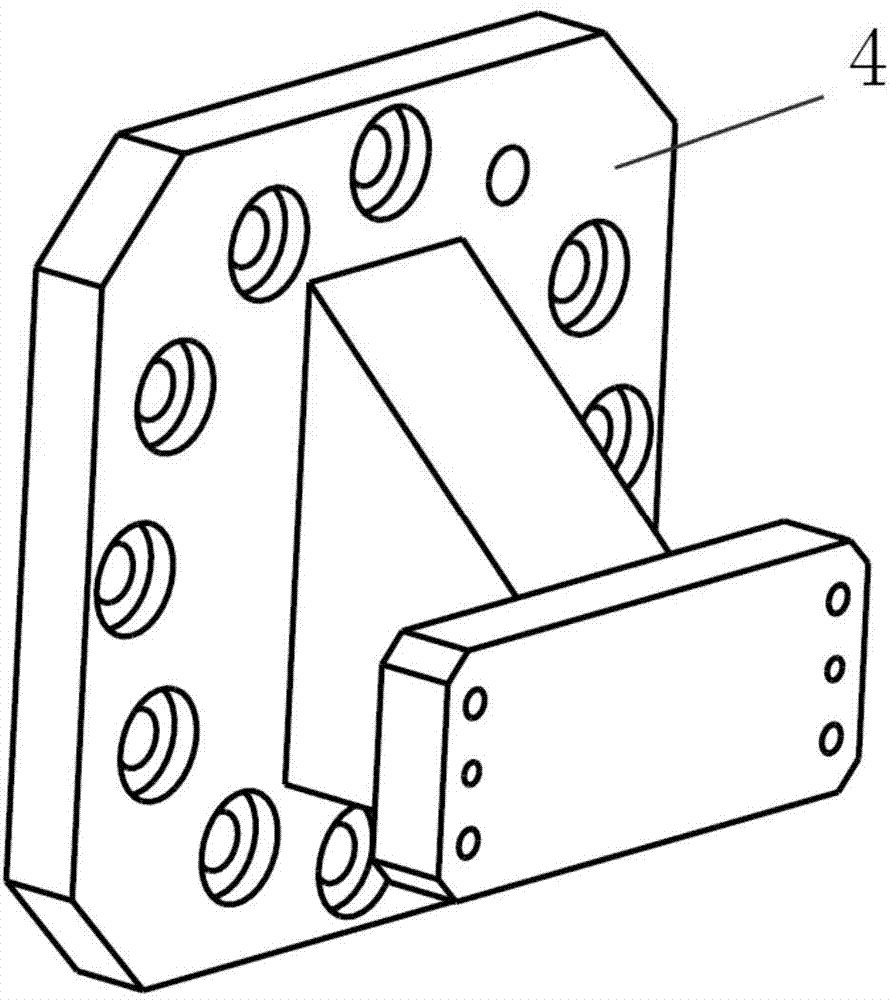

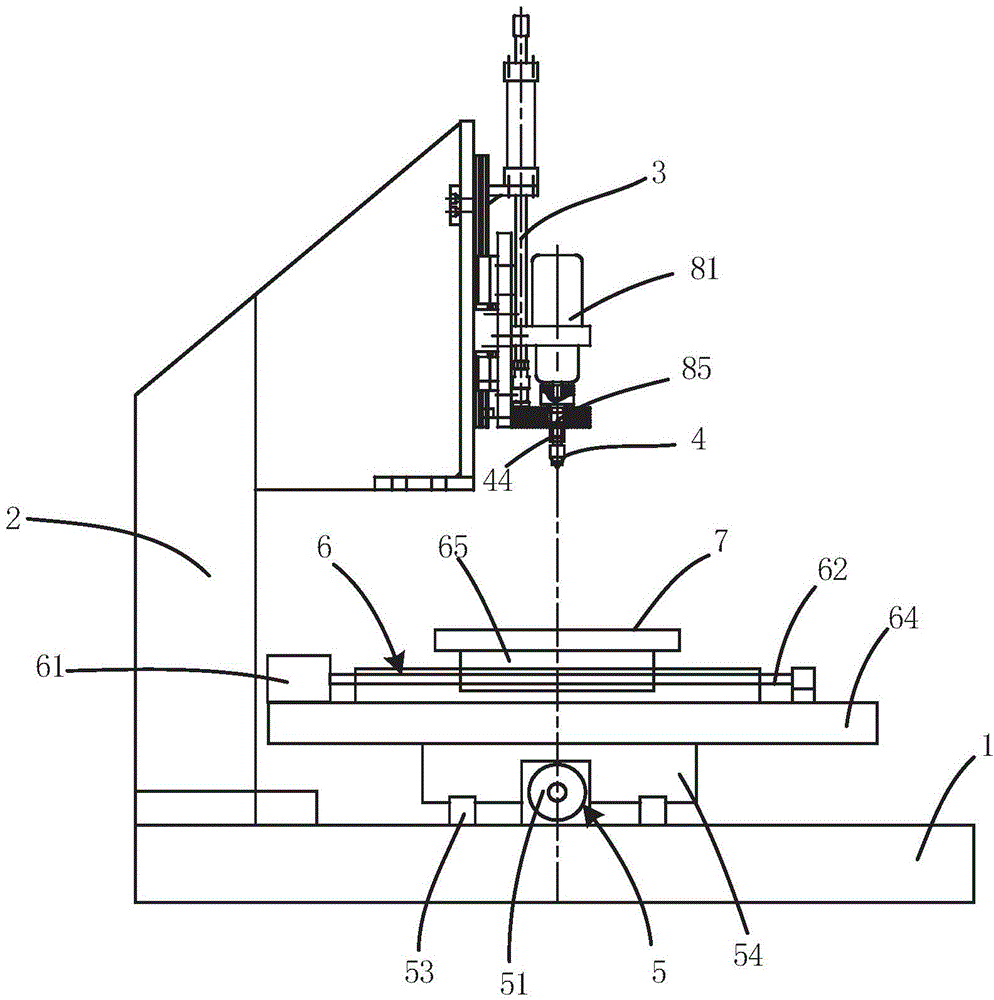

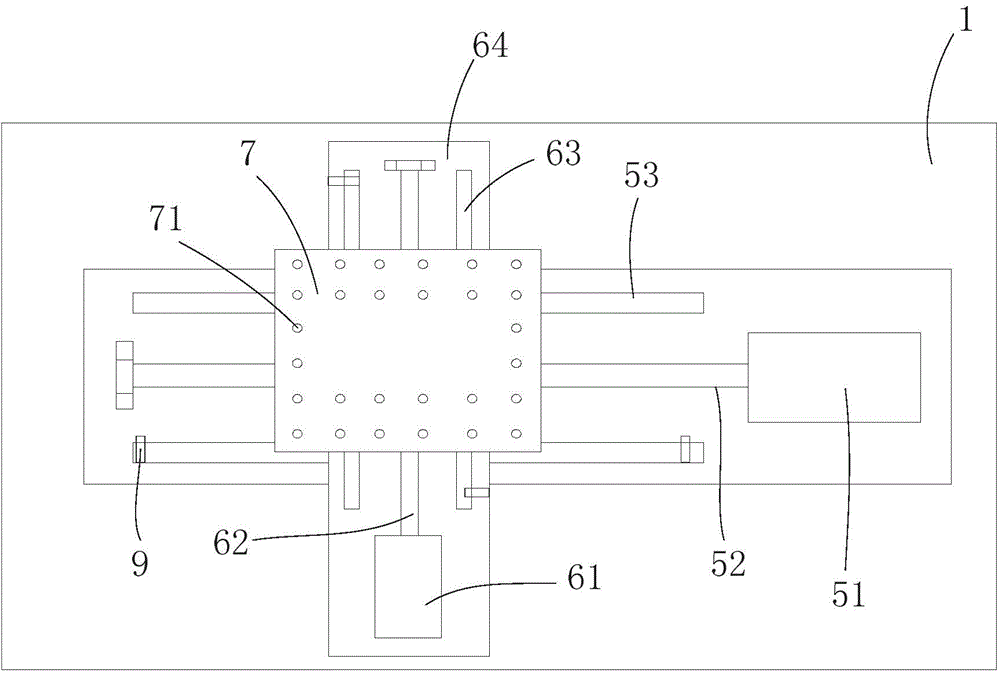

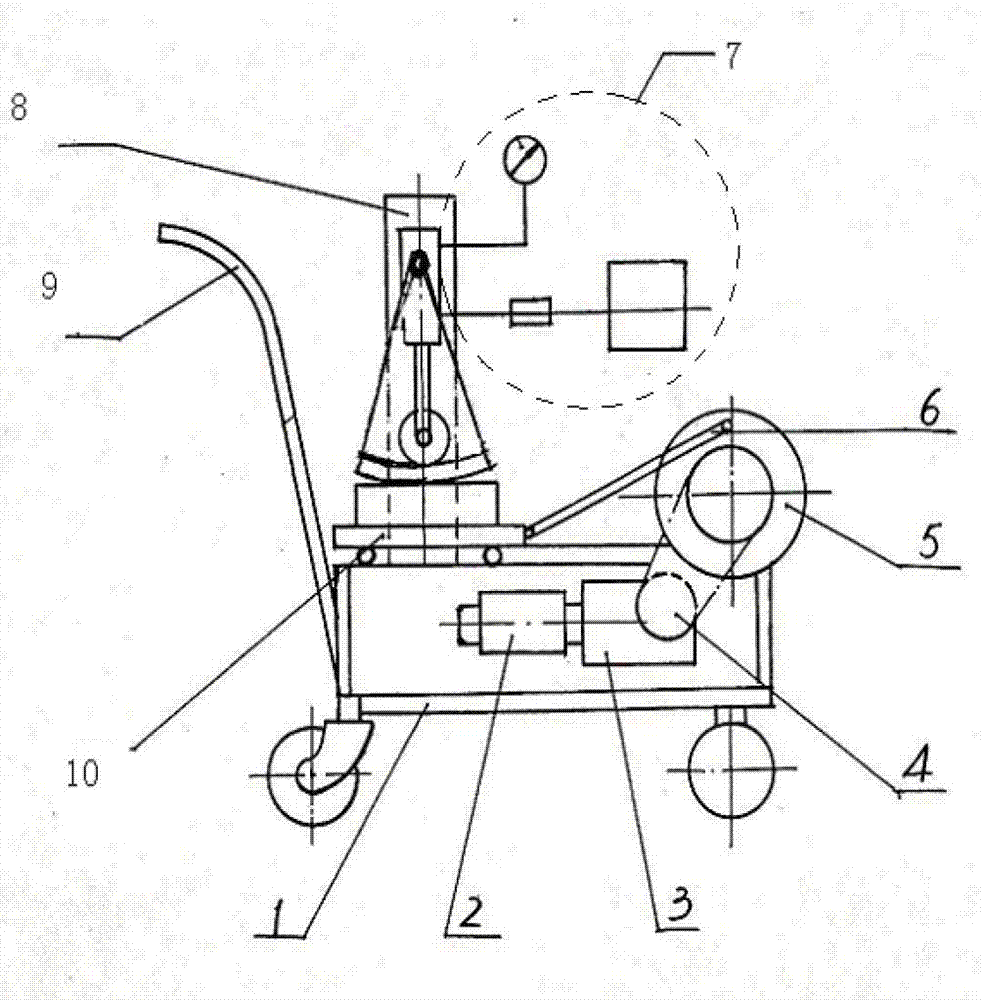

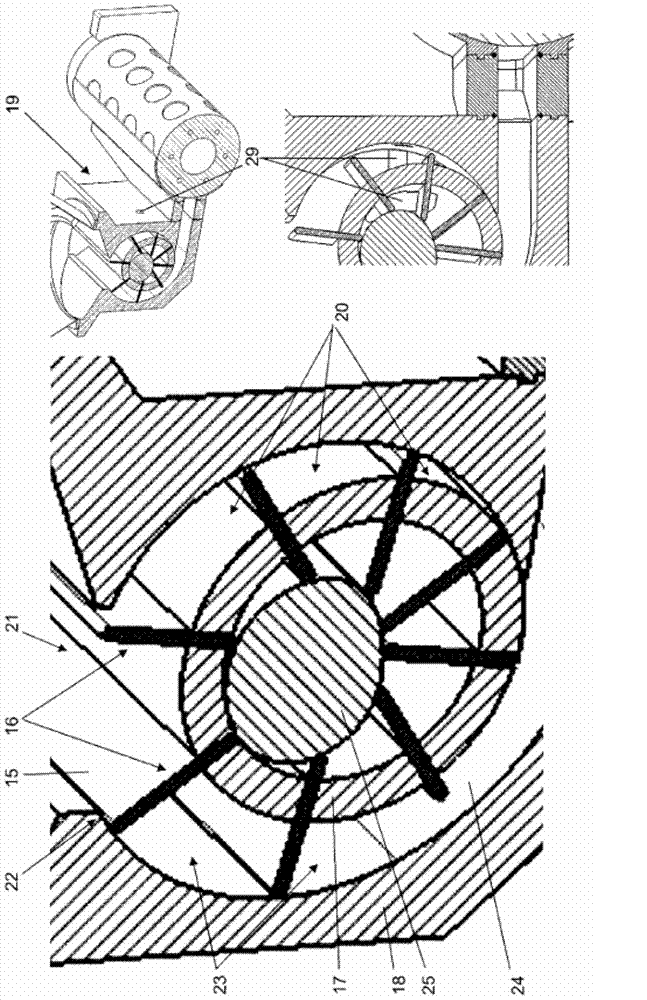

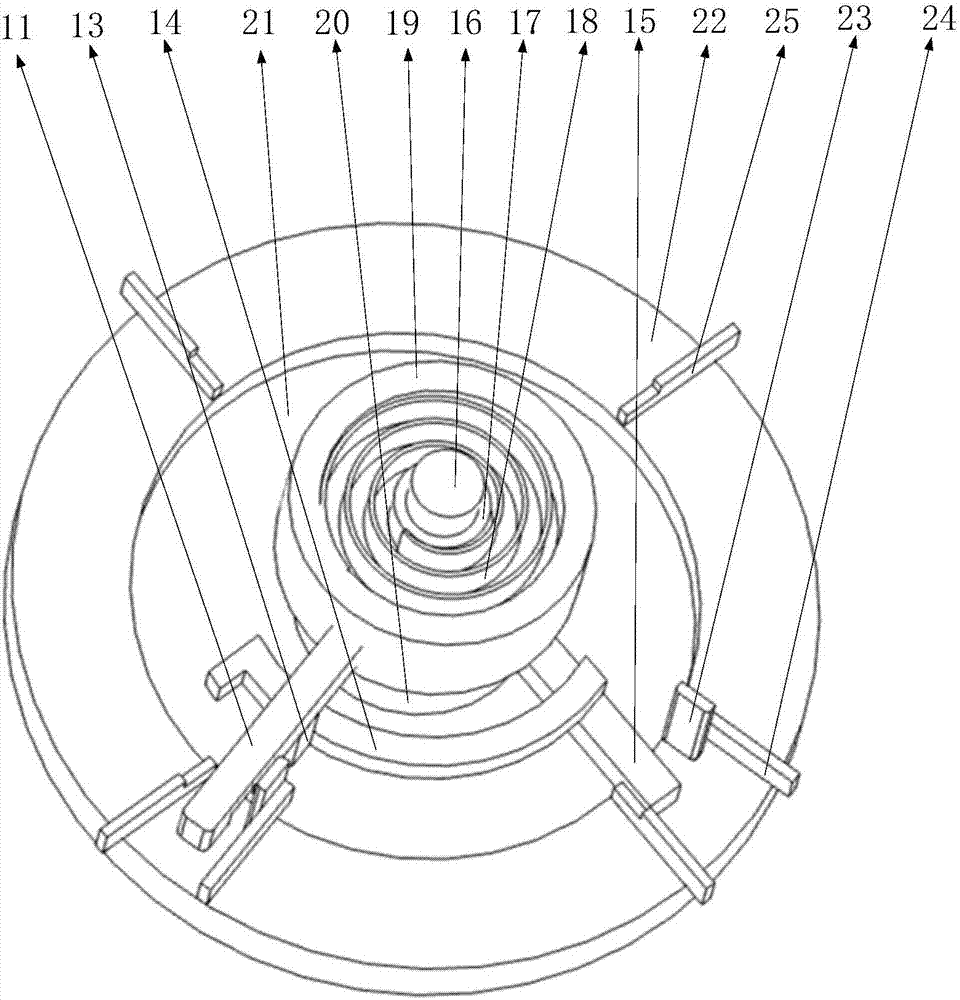

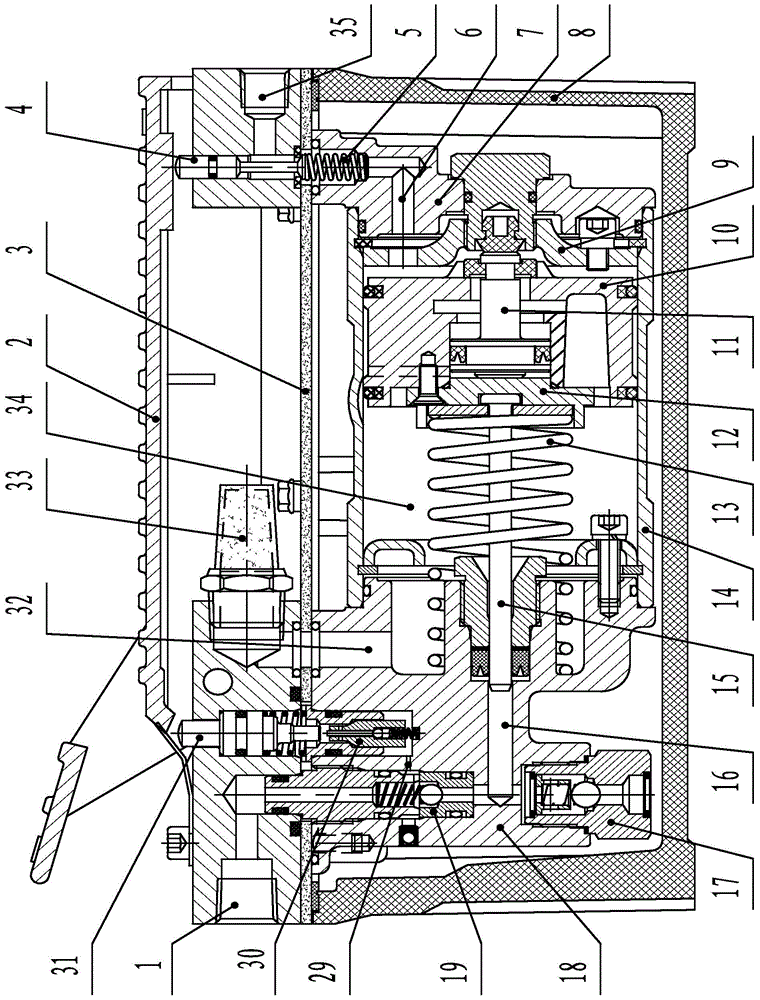

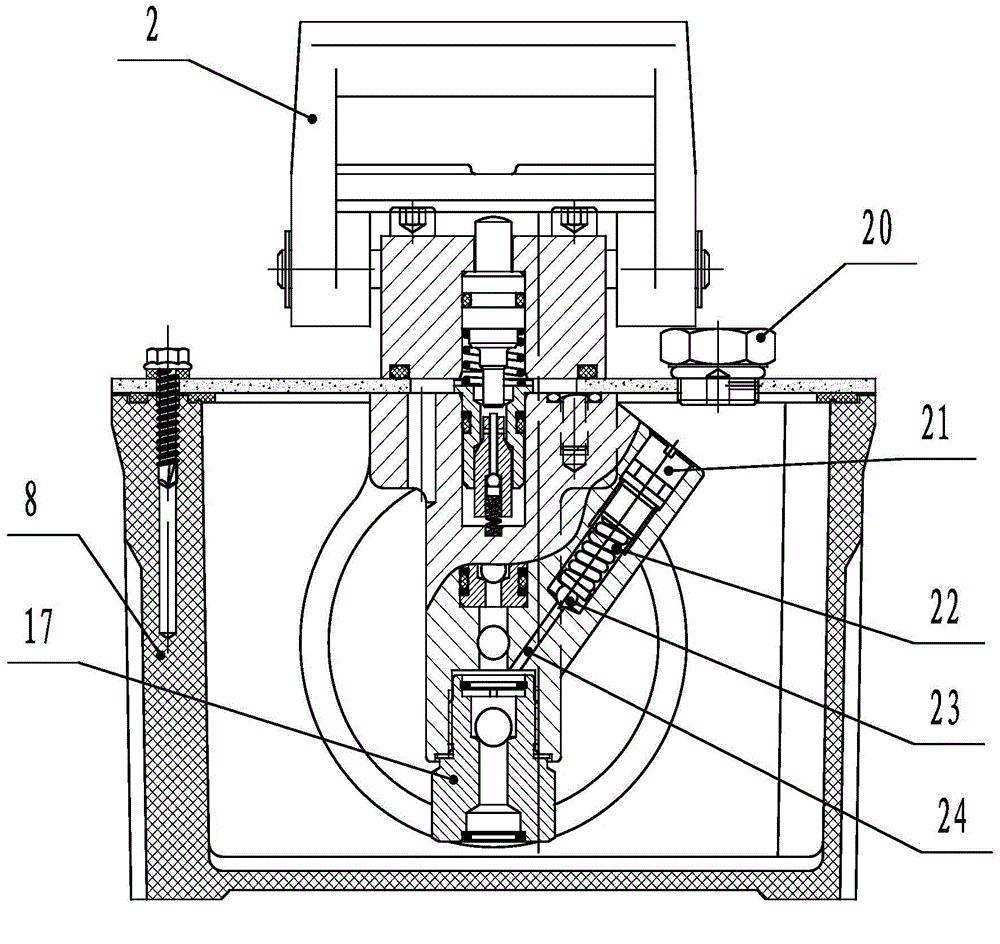

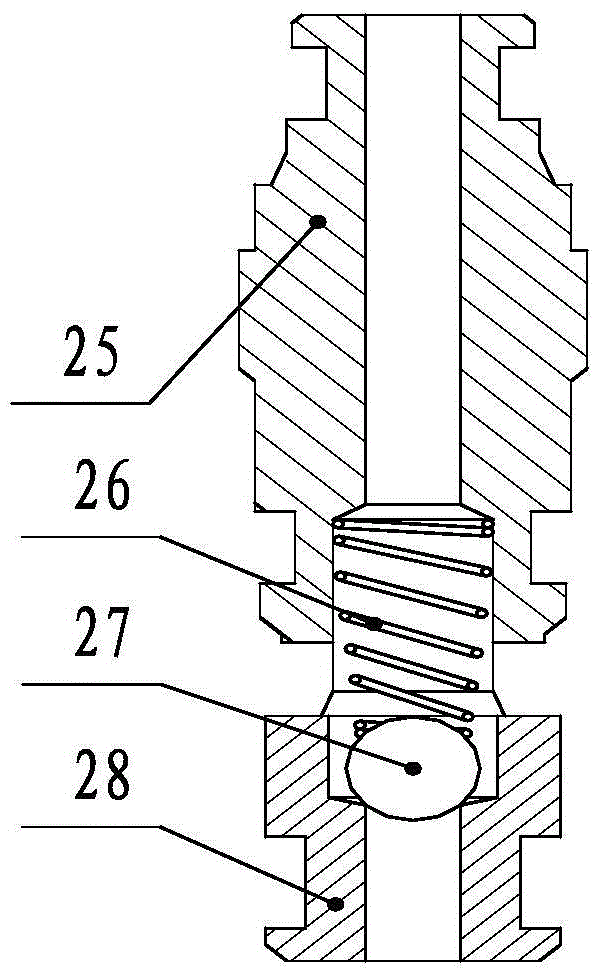

Friction-stir welding equipment

ActiveCN104985320AQuality improvementReduce torsional or impact forcesNon-electric welding apparatusEngineeringFriction stir welding

The invention provides friction-stir welding equipment. The friction-stir welding equipment comprises a machine tool body for friction-stir welding. A stir head is installed on a spindle of the machine tool body. A floating supporting structure is arranged between the stir head and the spindle and comprises a connecting component and an elastic supporting piece. The connecting component is fixed to the spindle, the lower portion of the connecting component and the upper portion of the stir head are matched through a plurality of concave parts and convex parts, and the connecting component and the stir head can rotate synchronously. The elastic supporting piece is arranged between the lower end of the connecting component and the upper end of the stir head in an abutting mode. A limiting structure is arranged on the connecting component and used for preventing the stir head from disengaging from the lower end of the connecting component. The friction-stir welding equipment can keep pressure constant in welding and improve the quality of welded joints. When disturbance or other accidents occur, torsion or impact force on the stir head can be reduced, so that the stir head is easy to protect and not prone to fracture, and the service life of the stir head is prolonged. The structure of the spindle is simplified, so that the whole equipment has a light weight and a small size, materials are saved, and cost is lowered.

Owner:重庆派馨特机电有限公司

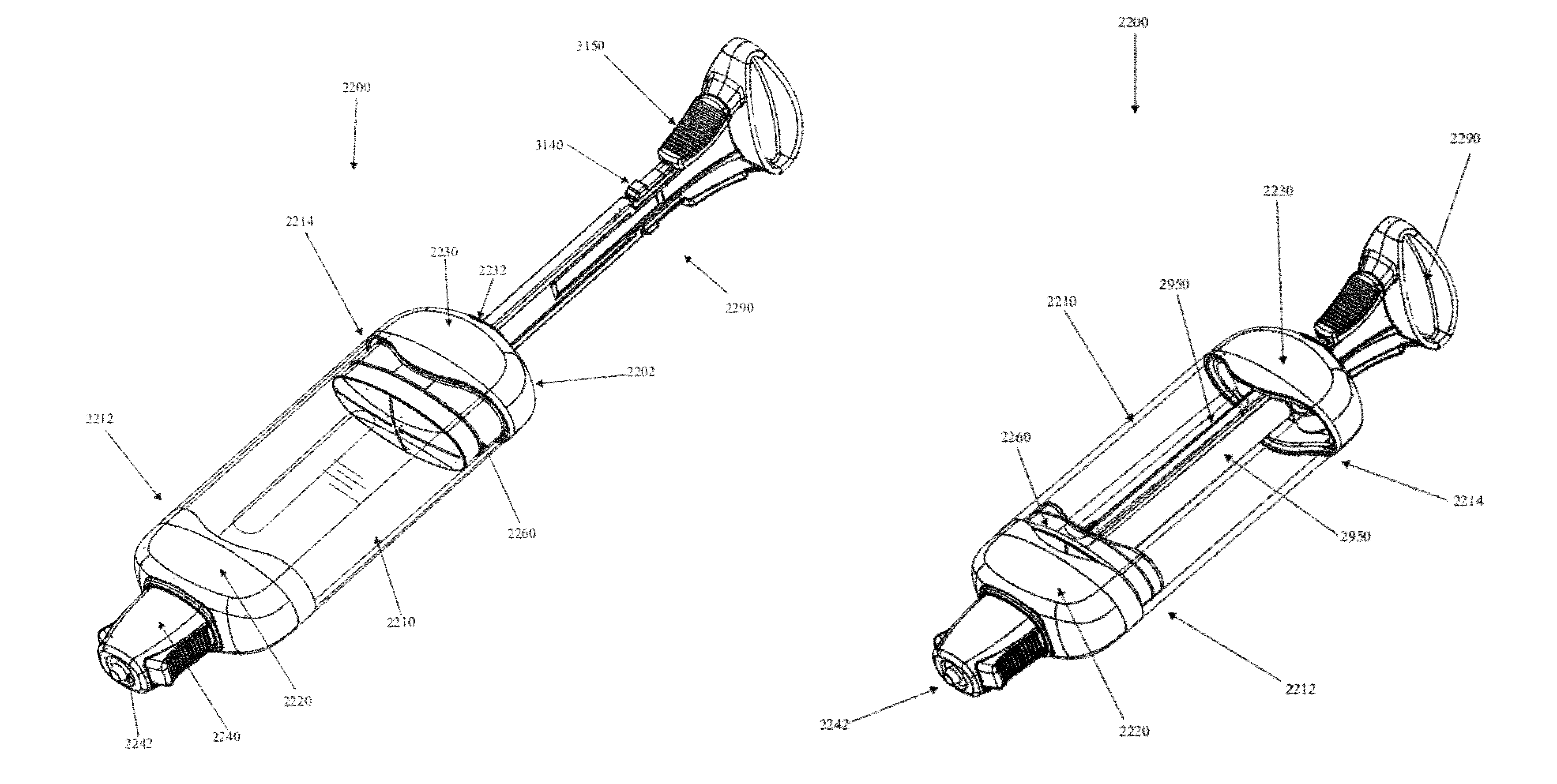

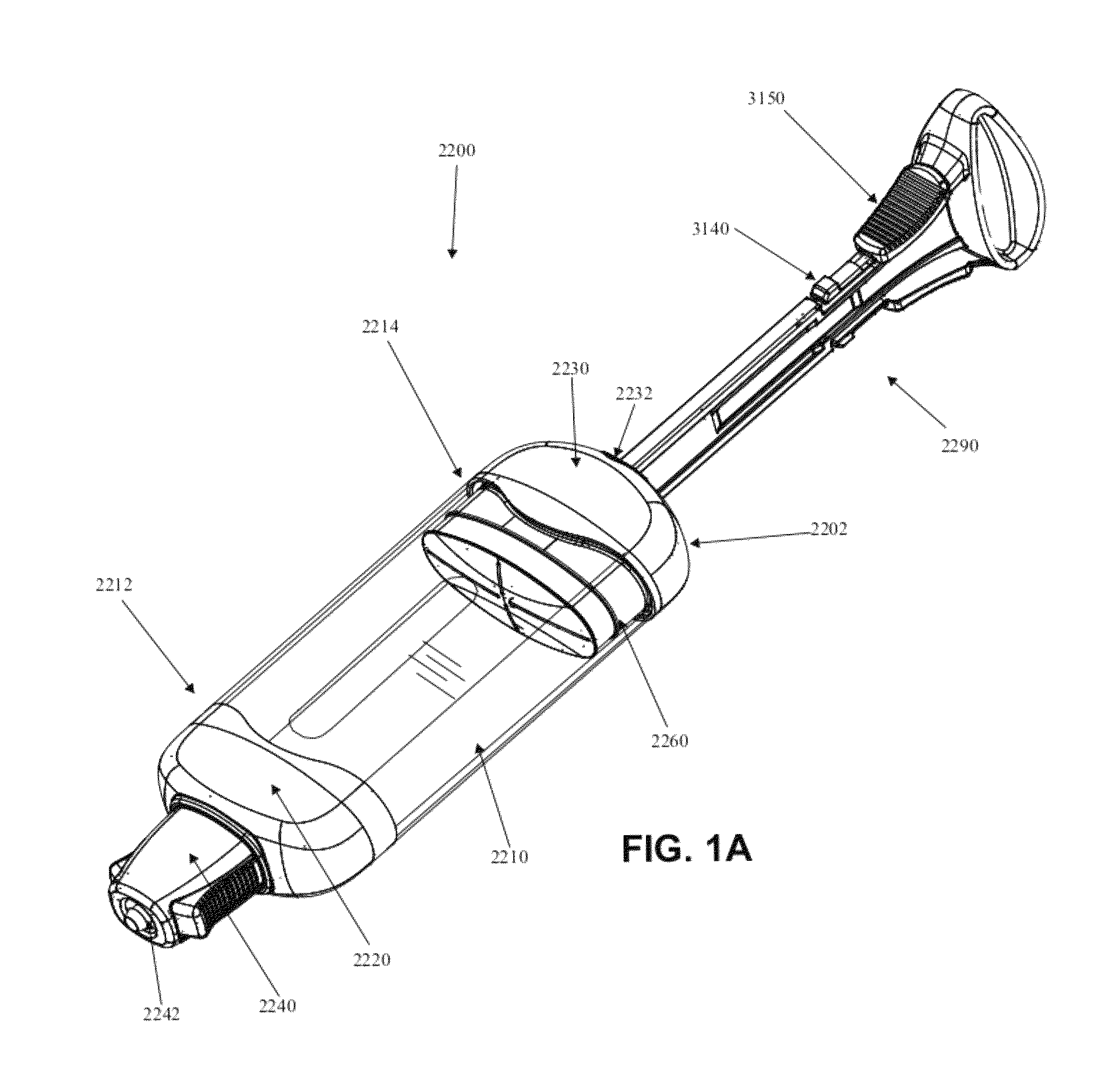

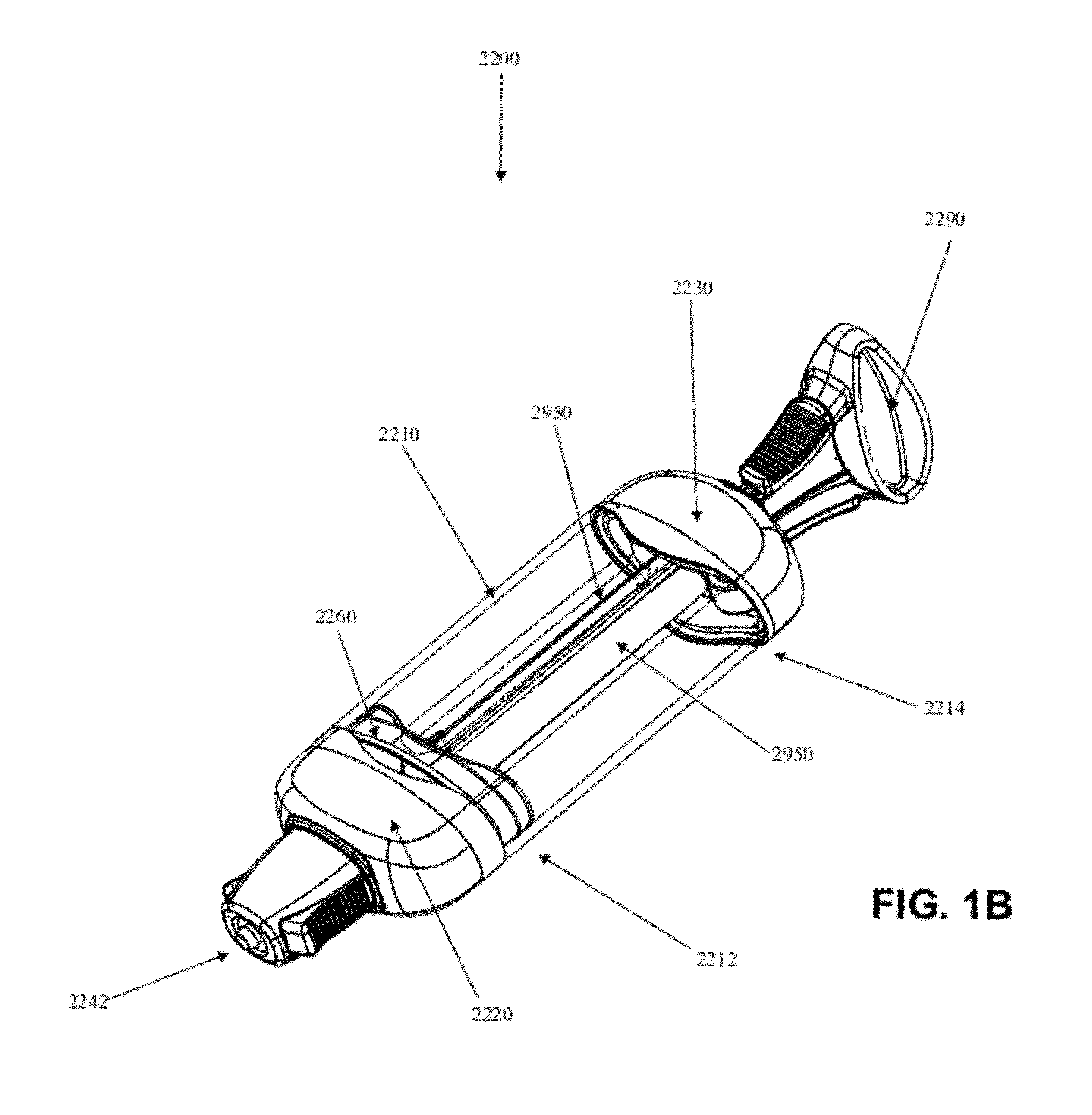

Controlled negative pressure apparatus and alarm mechanism

ActiveUS8753322B2Reduce frictionConstant pressureMedical devicesIntravenous devicesDamages tissuePhysical therapy

Owner:3M INNOVATIVE PROPERTIES CO

Controlled negative pressure apparatus and alarm mechanism

ActiveUS20120209225A1Reduce pressureReduce frictionMedical devicesIntravenous devicesDamages tissuePhysical therapy

Methods and devices for treatment of damaged tissue are disclosed, including treatment of wounds by employing non-electrically powered, reduced pressure therapy devices. The devices are capable of generating a substantially constant reduced pressure with low tolerance for pressure fluctuations. Also disclosed herein are reduced pressure therapy systems that comprise an alarm system to detect the depleted state of the suction device and provide an alert to the patient and / or practitioner.

Owner:KCI LICENSING INC

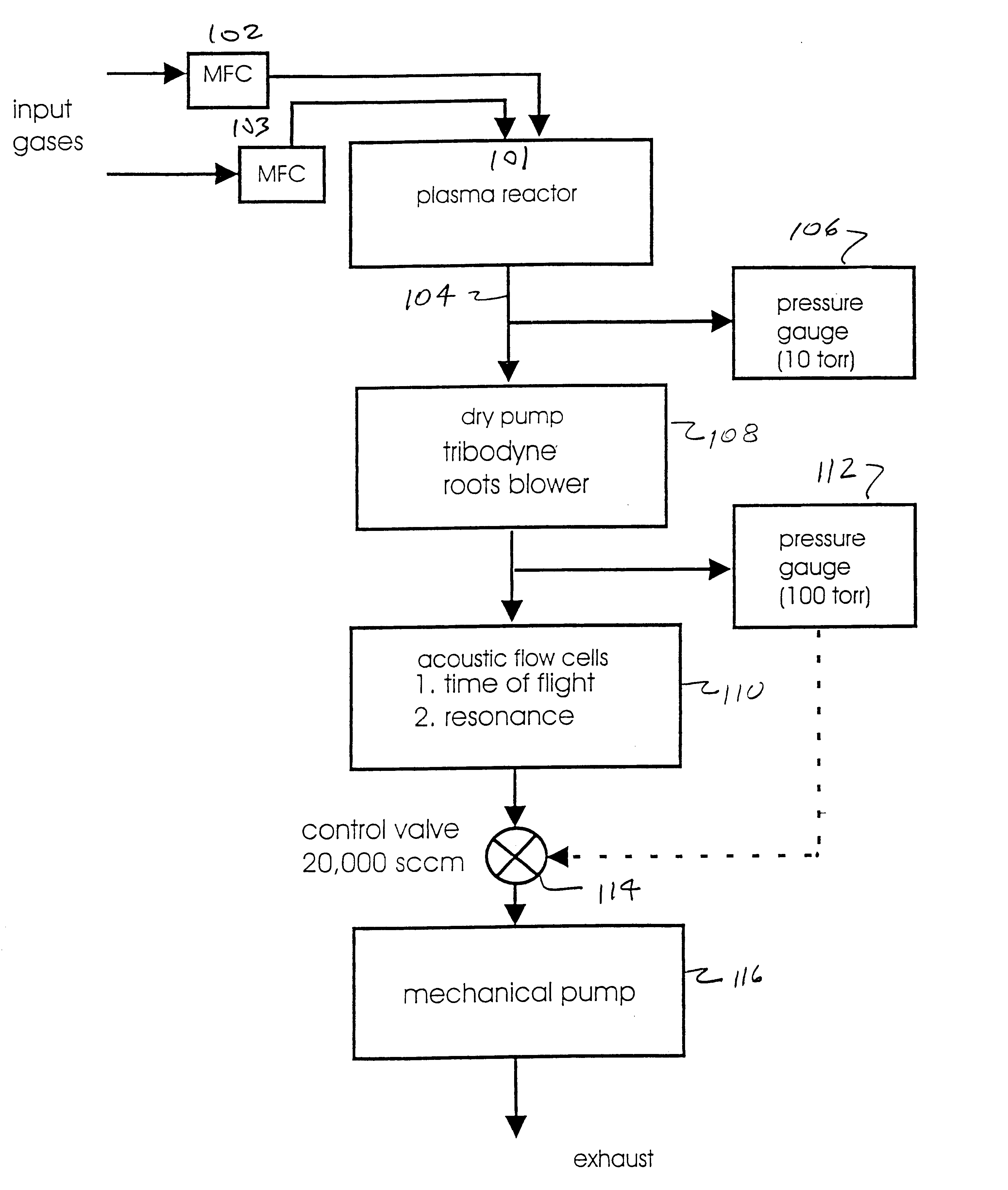

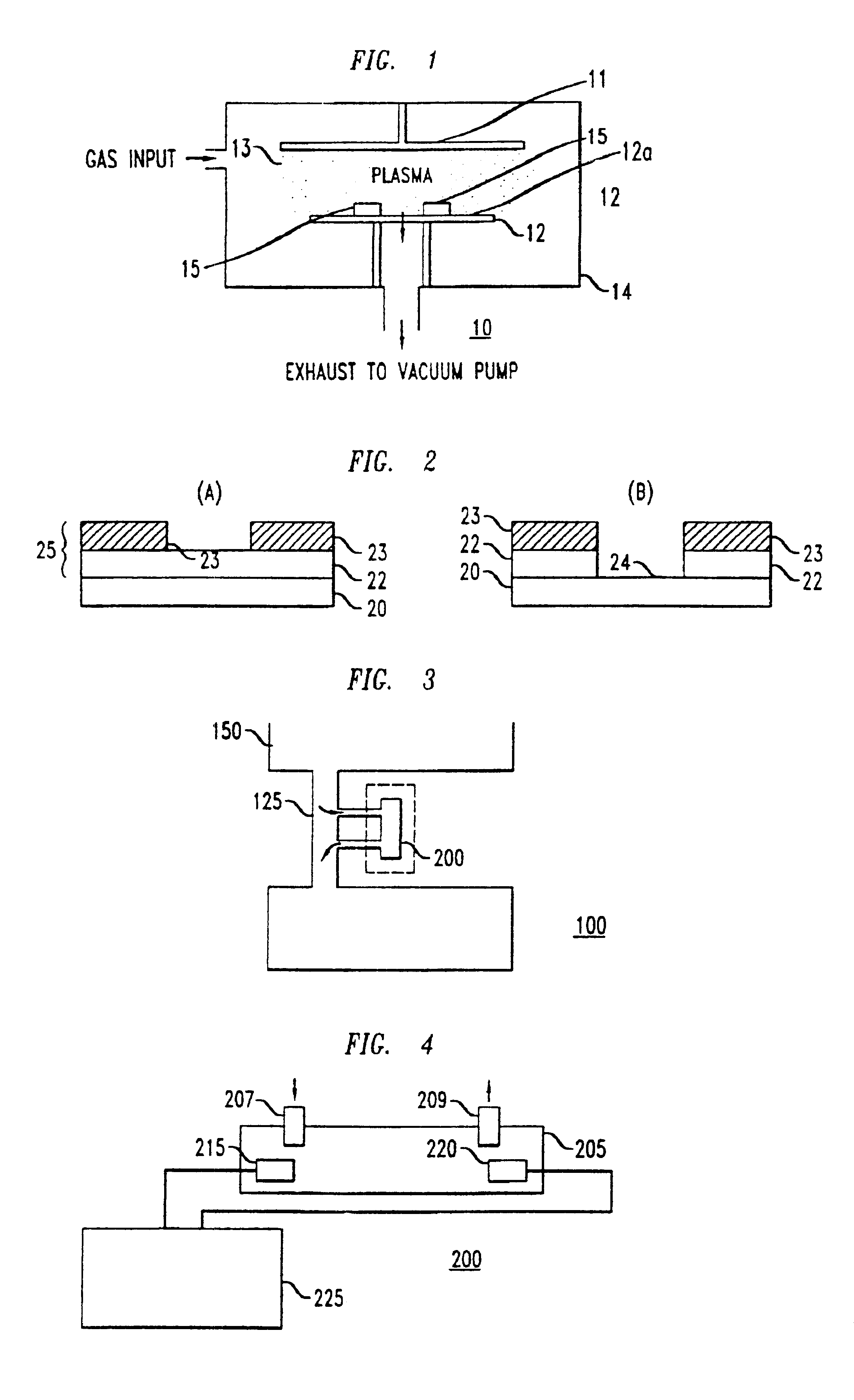

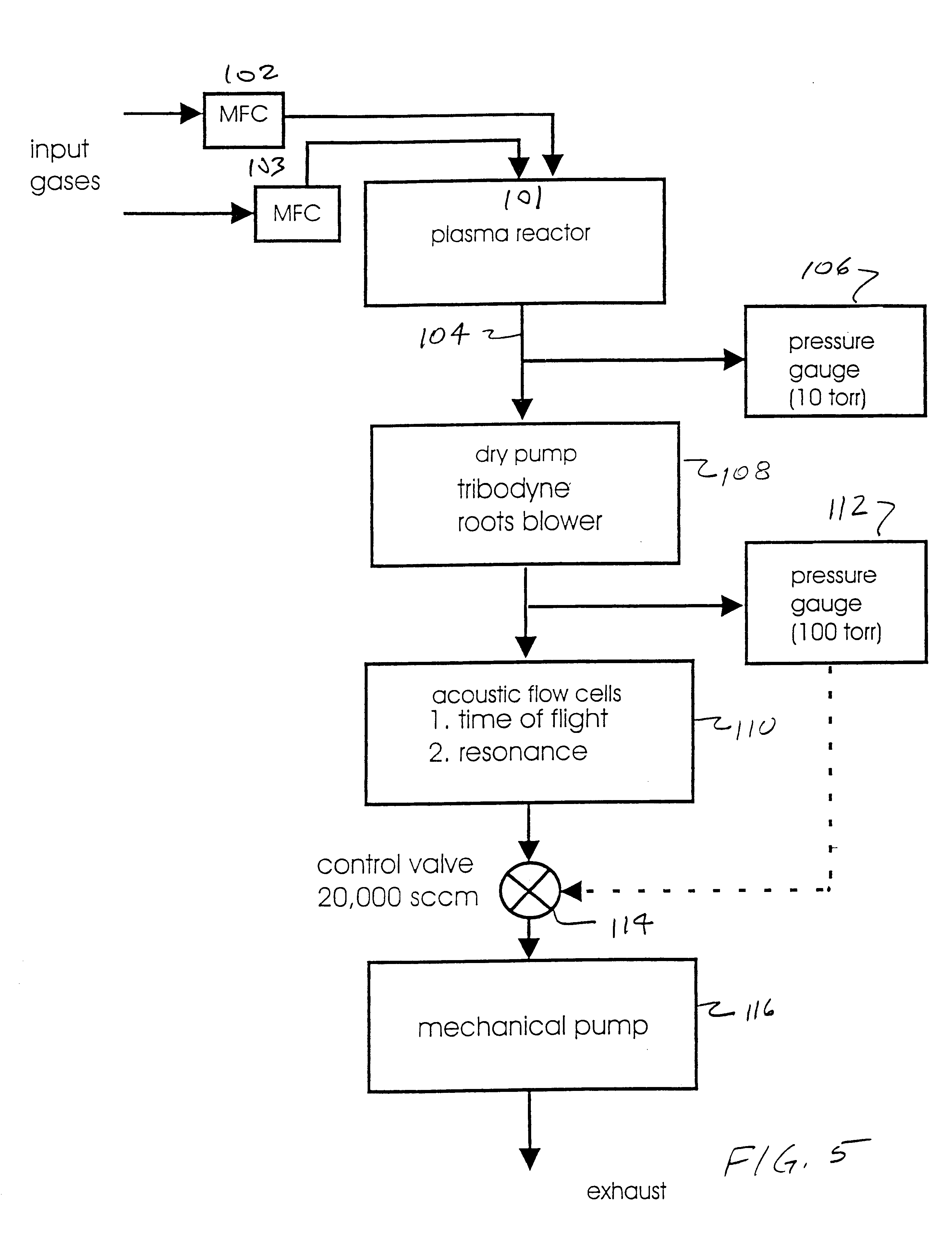

Acoustic time of flight and acoustic resonance methods for detecting endpoint in plasma processes

InactiveUS6367329B1Increasing mean free pathReduces density of gasAnalysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesAcousticsPlasma reactor

A method for determining the endpoint of a plasma etch process is disclosed. The endpoint of the plasma etch process is determined using an acoustic cell attached to an exhaust port on a reaction chamber of a plasma reactor. The gas from the reaction chamber flows into the acoustic cell during the plasma etch process. Acoustic signals are periodically transmitted through the gas flowing in the acoustic cell and a first velocity for the acoustic signals associated with etching a first material layer formed on a substrate is determined. Thereafter, the endpoint of the plasma etch step is determined when the first velocity changes to a second velocity associated with etching the first material layer through its thickness to its interface with an underlying material layer. The gas from the reaction chamber flows through a compressor prior to flowing into the acoustic cell to increase the gas pressure in the acoustic cell.

Owner:BELL SEMICON LLC +1

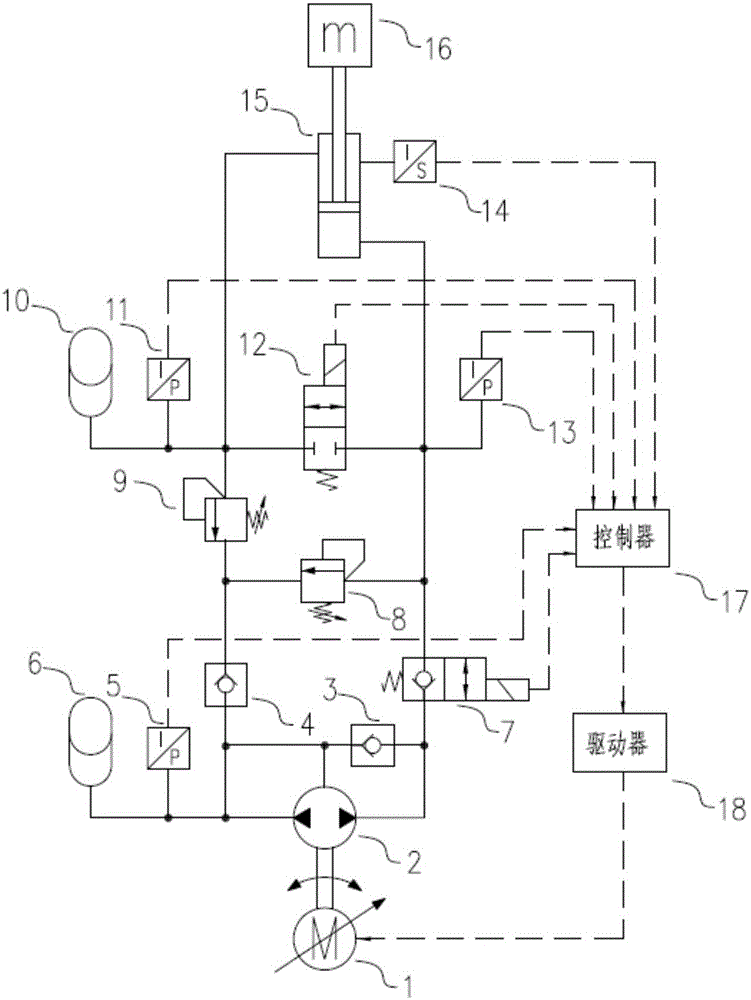

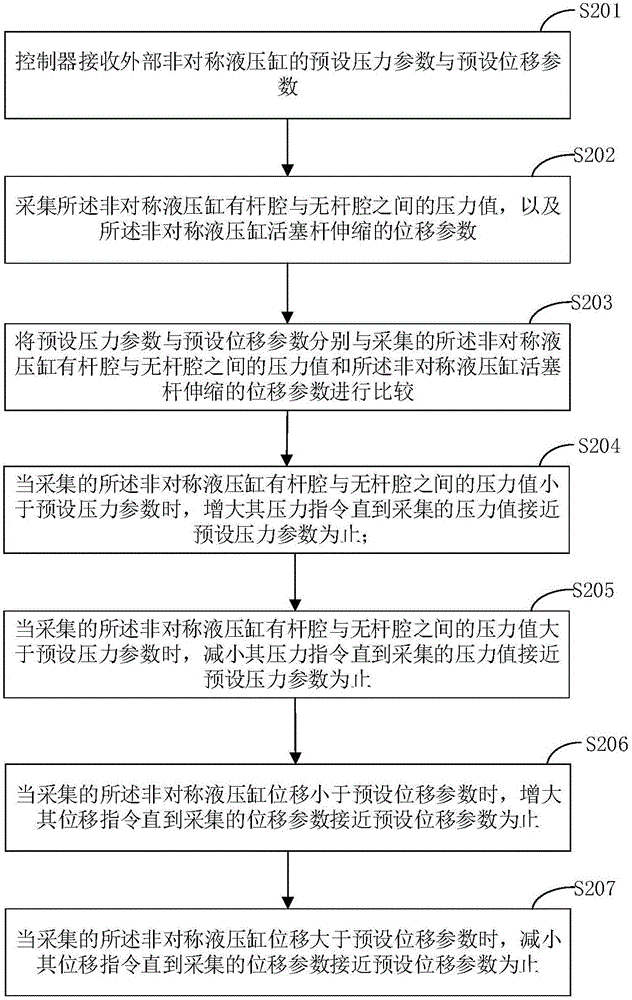

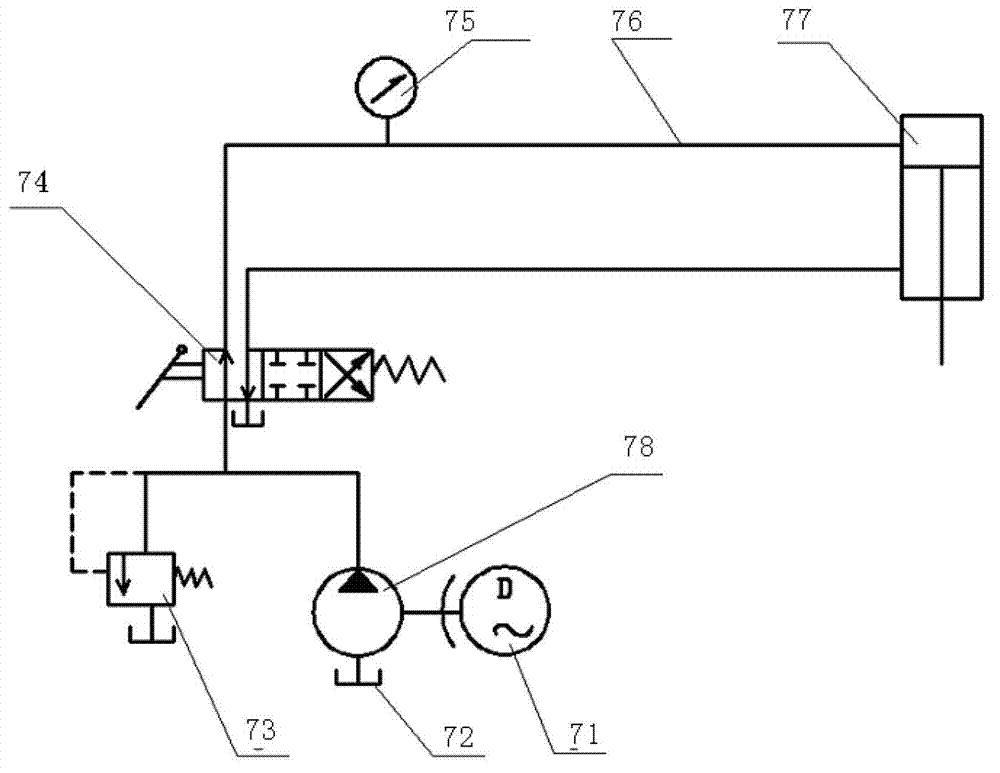

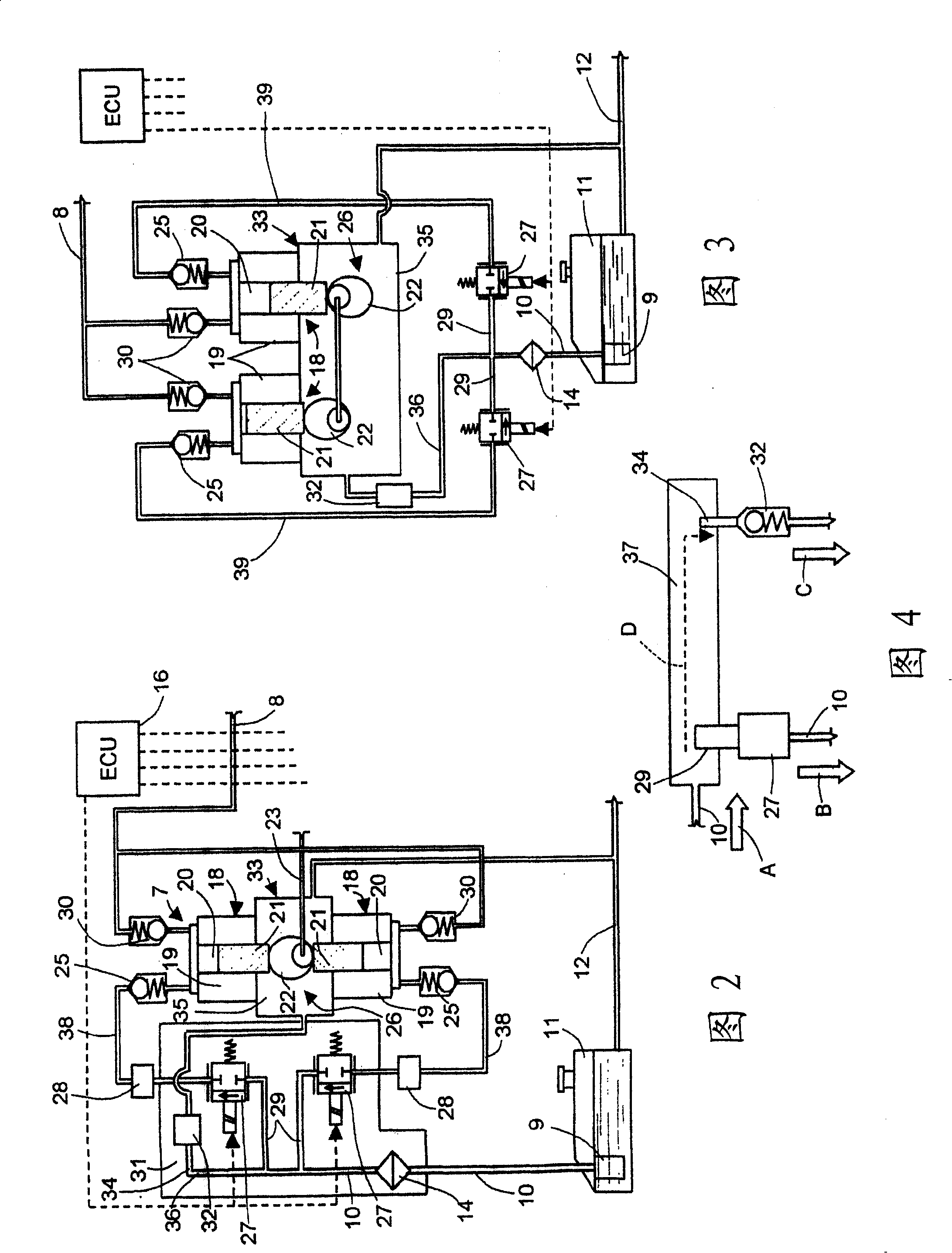

Constant-backpressure direct drive type electro hydraulic servo system and control method thereof

ActiveCN105715597ASolve the problem of traffic imbalanceReduce loop costsServomotorsFluid-pressure actuator componentsMovement controlElectro hydraulic

The invention provides a constant-backpressure direct drive type electro hydraulic servo system and a control method thereof. The constant-backpressure direct drive type direct electro hydraulic servo system comprises a controller, a driver, a servo motor, a bidirectional constant delivery pump and an asymmetric hydraulic cylinder, wherein the controller, the driver and the servo motor are sequentially connected, the controller controls the servo motor to operate through the driver, the servo motor, the bidirectional constant delivery pump and the asymmetric hydraulic cylinder are sequentially connected, and the servo motor controls the output flow and direction of the bidirectional constant delivery pump for realizing motion control over the asymmetric hydraulic cylinder. The invention further provides the control method of the constant-backpressure direct drive type electro hydraulic servo system. The control method is suitable for controlling the asymmetric hydraulic cylinder of a vertical or non-horizontal installation structural style, the problem of unbalanced flow of the asymmetric hydraulic cylinder and the problem of pressure jump generated in reversing are completely solved, the loop cost can be greatly lowered on the premise of meeting the requirements of the system control accuracy and the response characteristic, and the control scheme can be simplified.

Owner:CISDI ENG CO LTD

Laser impact warm forming method with uniform heat and constant pressure functions and device

ActiveCN102513698AEvenly heatedMeet the temperature range requirements of different warm formingLaser beam welding apparatusTemperature controlSystem pressure

The invention discloses a laser impact warm forming method with uniform heat and constant pressure functions and a device. According to the invention, a heating coil is adopted for increasing the temperature of a system, an oil pump is used for sucking cold liquid to lower the temperature of the system, so as to ensure that the temperature of the system is controlled within a pre-set temperature range; an overflow value is used for setting system pressure, the oil pump is used for sucking liquid into the cavity of a die so as to reach an appointed pressure; and laser induced impact wave is used as a power source for warm forming and enhancing to panel veneer. According to the invention, the advantages of both warm forming technique and laser impacting technique are combined, liquid is adopted for heating the panel veneer, the heating temperature is uniform and easy to control; the pressure control device is guaranteed to produce continuous back pressure so as to enable the stress to the panel veneer to be balanced. The method provided by the invention improves the forming performance of the panel veneer during laser impact forming process, and provides a novel concept to the formation of the panel veneer; and while the panel veneer is formed, the service life and stress and corrosion resisting performance of the panel veneer are improved.

Owner:JIANGSU UNIV

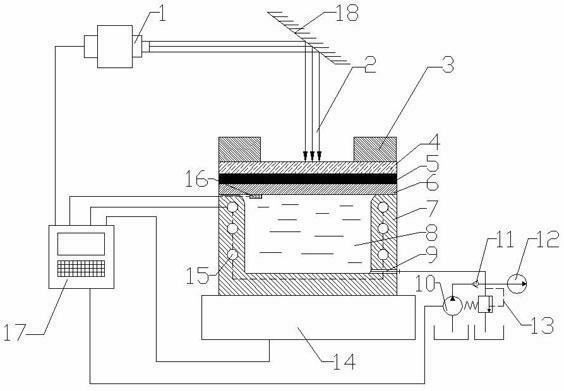

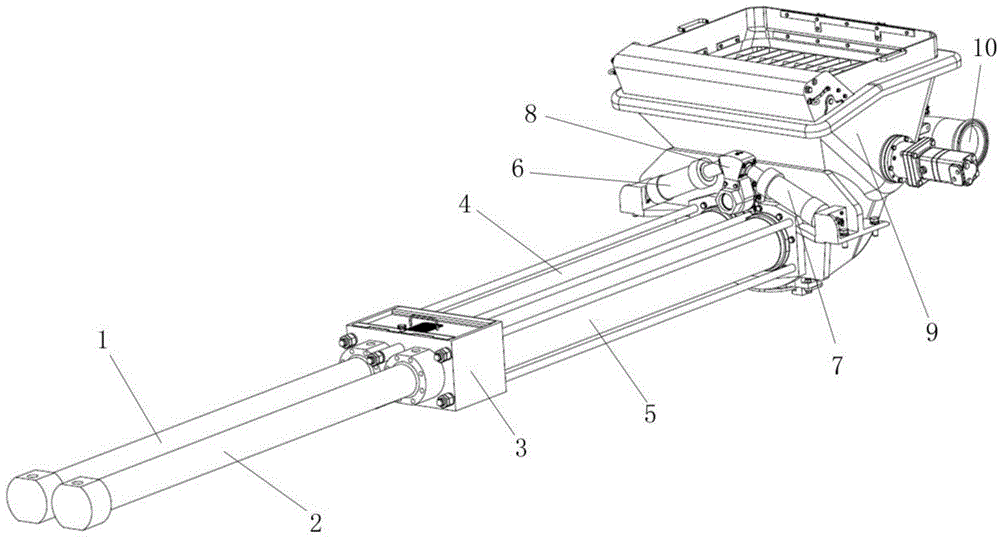

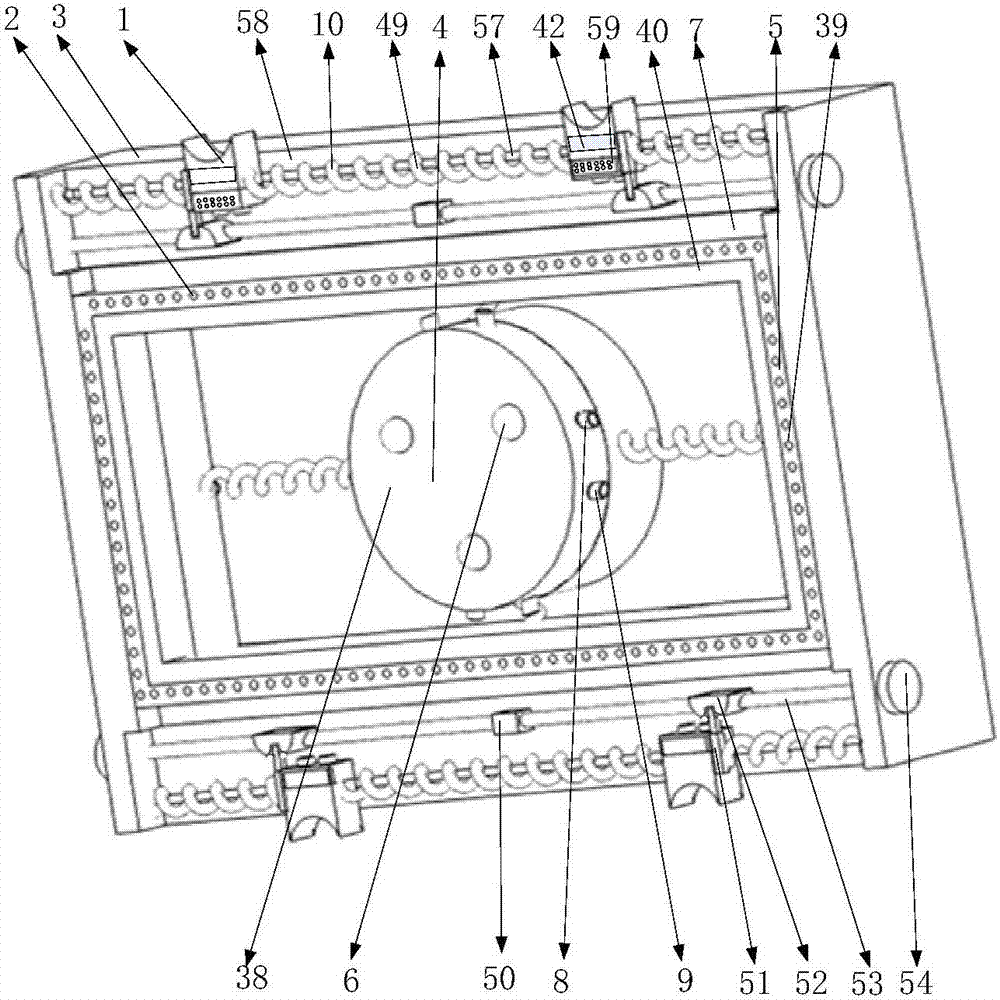

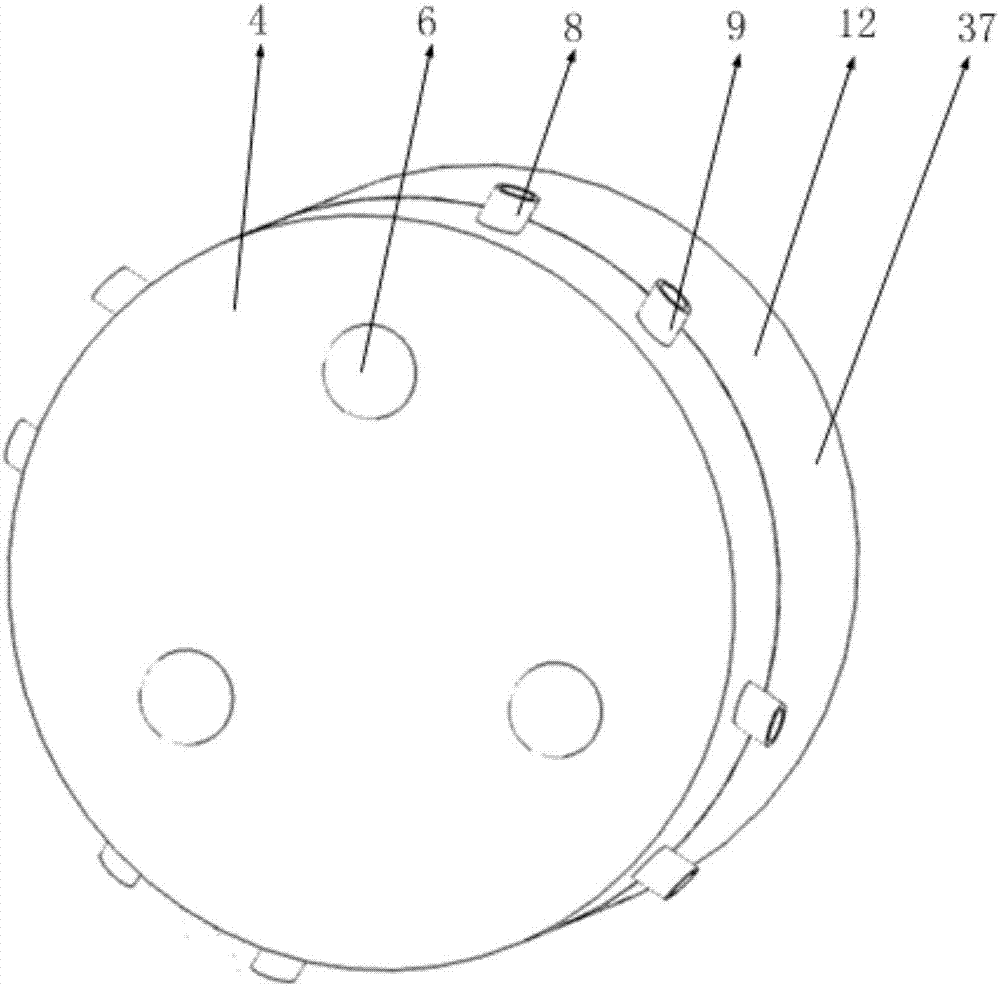

Movable asphalt mixture forming machine

InactiveCN102735513ASimple structureSimple processPreparing sample for investigationAsphaltSpeed reduction

The invention provides a movable asphalt mixture forming machine which comprises a vehicle body, a speed reduction mechanism, a test die frame for arranging a test die, a hydraulic loading system and a wheel milling bracket assembly. The movable asphalt mixture forming machine is characterized in that the vehicle body is provided with wheels; the speed reduction mechanism is arranged in the vehicle body; the test die frame is movably arranged on the upper surface of the vehicle body; and the hydraulic loading system is used for driving a milling wheel in the wheel milling bracket assembly to apply a load to the test die in the test die frame.

Owner:HEBEI PROVINCIAL COMM PLANNING & DESIGN INST

Controlled negative pressure apparatus and alarm mechanism

ActiveUS20120083754A1Reduce frictionConstant pressureMedical devicesIntravenous devicesDamages tissuePhysical therapy

Methods and devices for treatment of damaged tissue are disclosed, including treatment of wounds by employing non-electrically powered, reduced pressure therapy devices. The devices are capable of generating a substantially constant reduced pressure with low tolerance for pressure fluctuations. Also disclosed herein are reduced pressure therapy systems that comprise an alarm system to detect the depleted state of the suction device and provide an alert to the patient and / or practitioner.

Owner:3M INNOVATIVE PROPERTIES CO

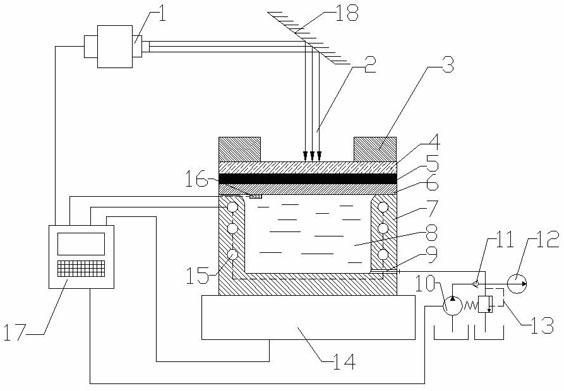

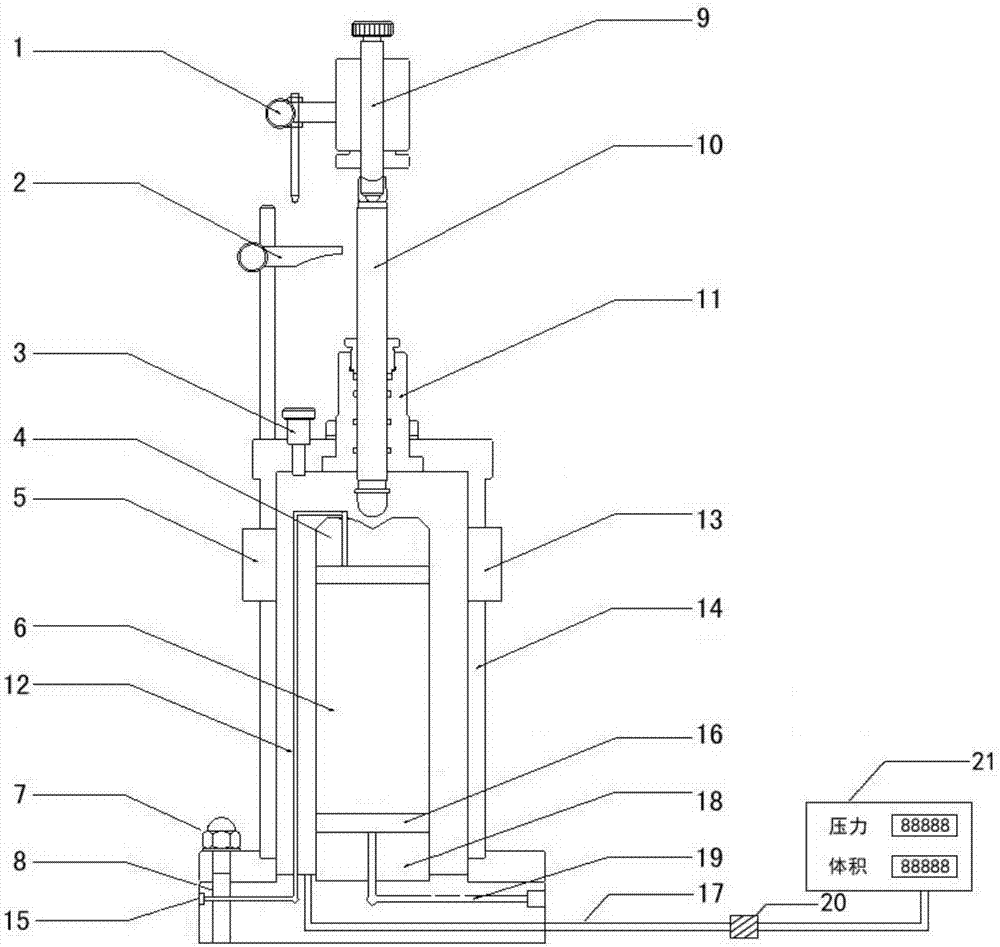

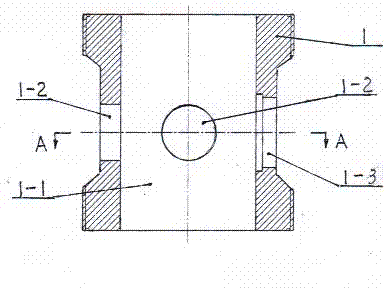

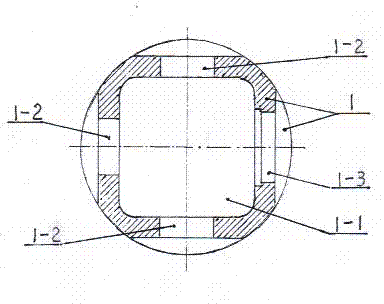

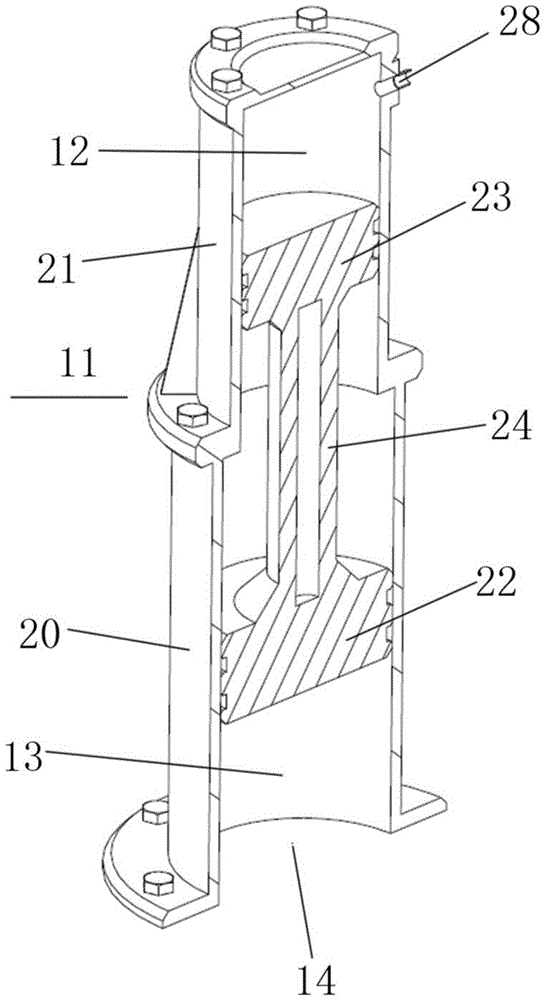

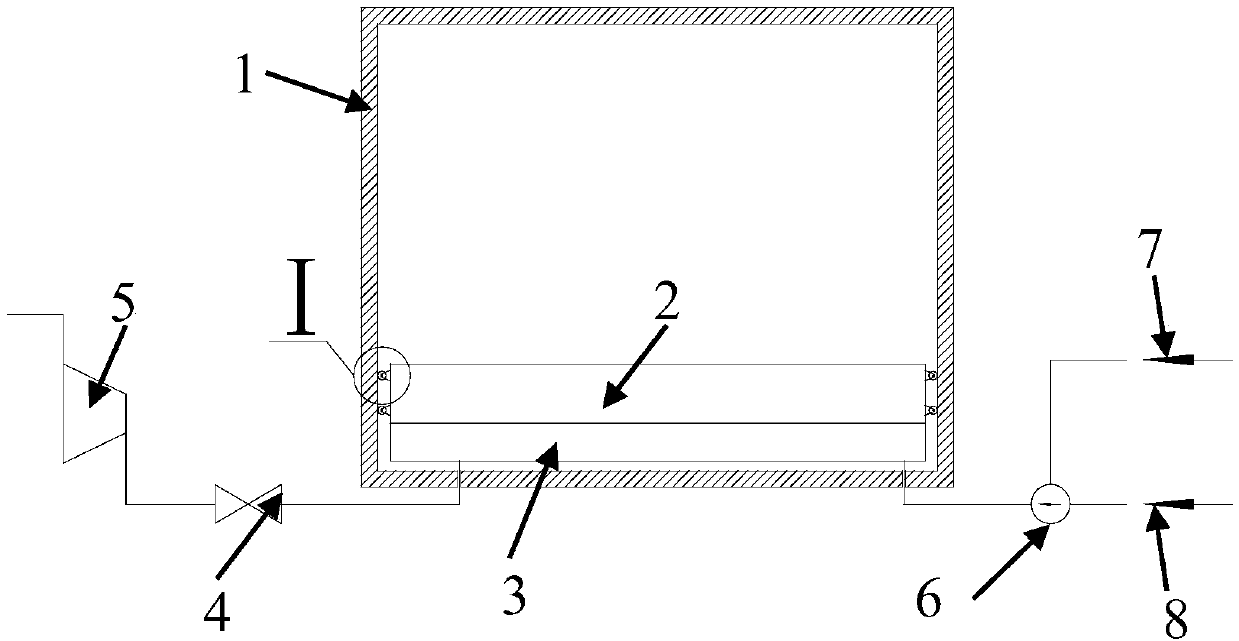

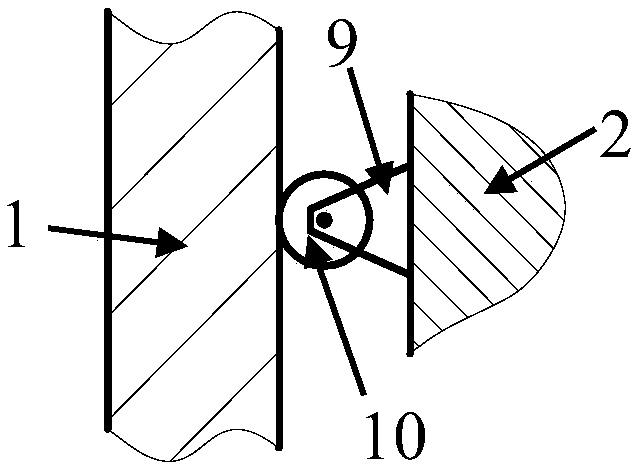

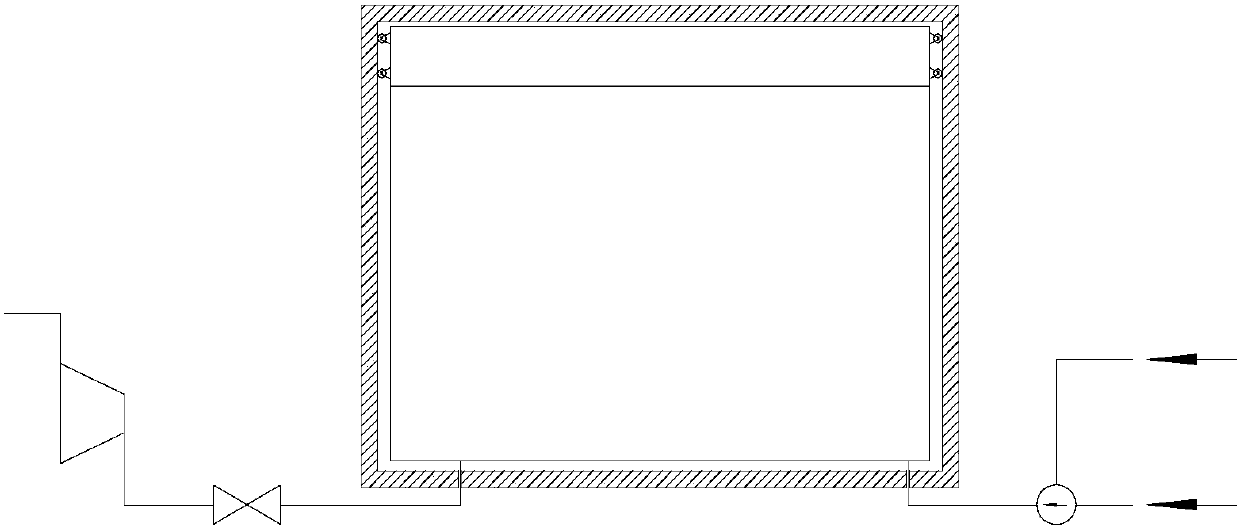

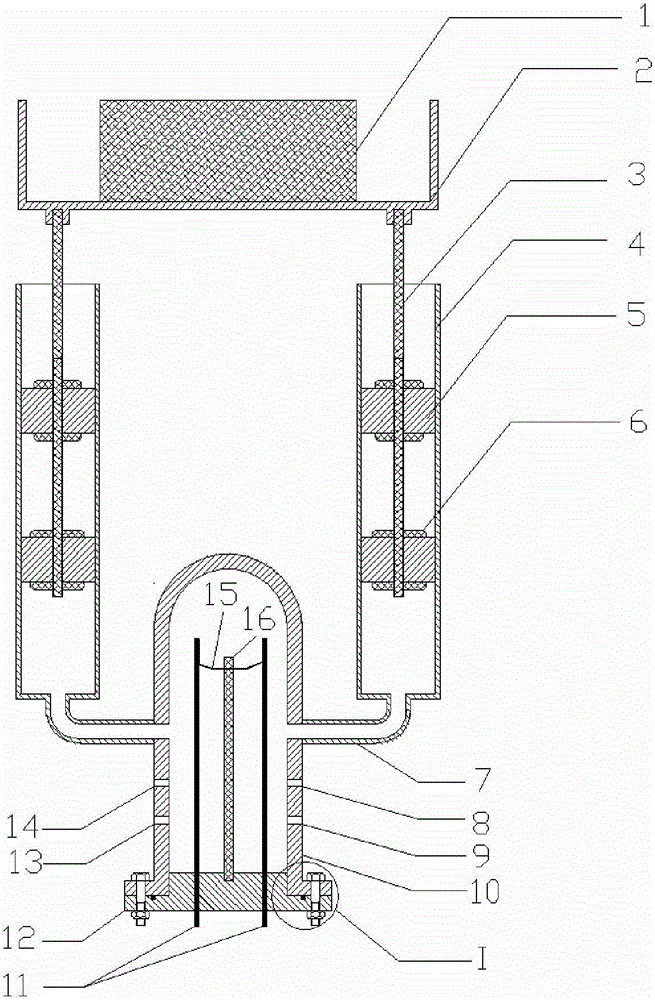

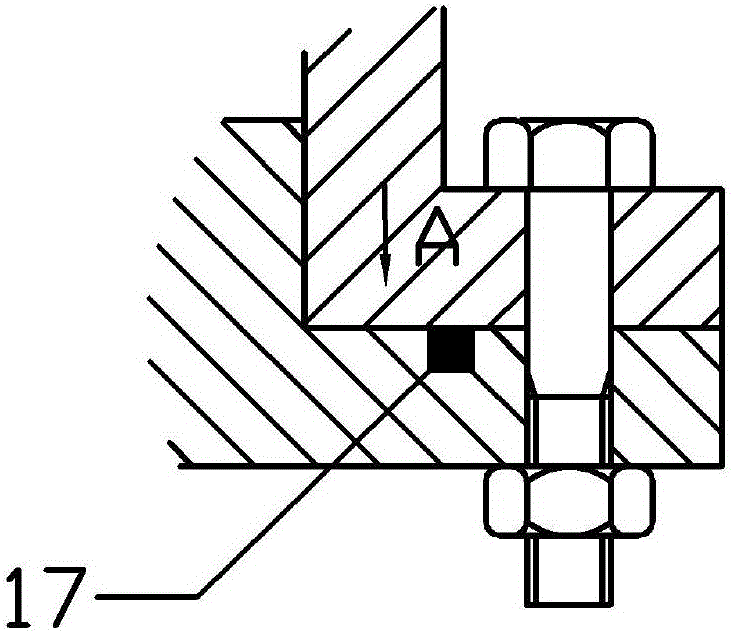

Triaxial experiment instrument pressure chamber for measuring rock specimen volume strain and operation method thereof

PendingCN107991170AConstant pressureAvoid subjective influenceStrength propertiesWater sourceEngineering

The invention discloses a triaxial experiment instrument pressure chamber for measuring rock specimen volume strain and an operation method thereof. The triaxial experiment instrument pressure chambercomprises a base and a pressure cabin arranged on the base, wherein the pressure cabin is a confining pressure sealed accommodating cavity; a precise volume pressure controller and a pressure sensorconnected in the pressure cabin jointly act; the pressure in the cabin is enabled to be strictly invariant by regulating the water inlet and outlet quantity, so that the water outlet quantity is the volume strain of a rock specimen; finally, the conversion is performed with vertical strain to obtain Poisson's ratio. The condition that errors caused by subjective influence of operators during the position selection in a traditional strain gage pasting method is avoided; the phenomenon of liquid leakage caused by strain gauge conducting wires is also avoided; meanwhile, all parameters can be obtained through once experiment; the data non-unified errors caused by many time of experiments are avoided; the experiment operation process is greatly simplified; the experiment efficiency is improved; the confining pressure is provided through water injection from water inlet holes. Compared with traditional method using oil pressure, the method has the advantages that the water sources are wide;high economic performance is realized; the control is easy.

Owner:CHANGAN UNIV

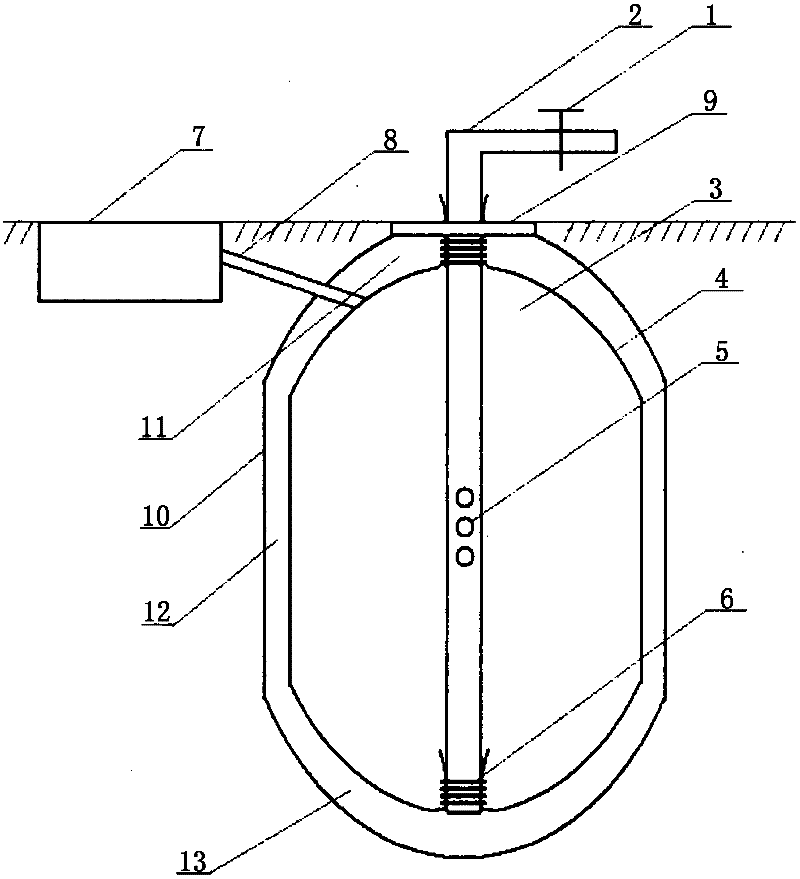

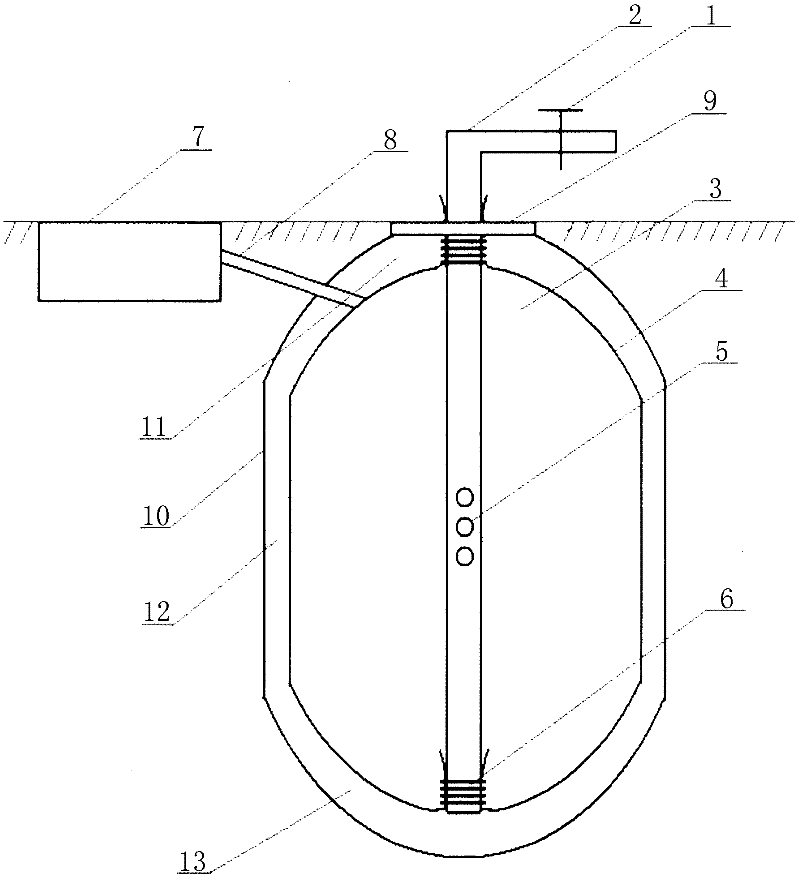

Device and method for quickly constructing small water cellar

The invention discloses a device and a method for quickly constructing a small water cellar. The device disclosed by the invention comprises an inflatable air bag corresponding to the inner wall of the water cellar and a steel pipe for inflating the air bag, wherein the steel pipe is inserted into the air bag and is fixedly connected with an upper port and a lower port of the air bag in a sealing manner. The method for quickly constructing the small water cellar by use of the device comprises the steps of excavating a foundation pit, pouring to form a cellar bottom, putting a constructing device, charging air at 5-6kpa to the device, pouring to form cellar walls and a cellar top, sucking air in the device and taking out the device; using cement mortar, waterproof mortar and cement to treat fine aggregate concrete inner walls; and finally, mounting a cellar cover. The device and the method for quickly constructing the small water cellar have the characteristics of the structure is simple, the use is convenient, the labor can be saved, the cost is reduced, and the construction period is shortened. In addition, the constructed water cellar is firm and durable.

Owner:庄文贤

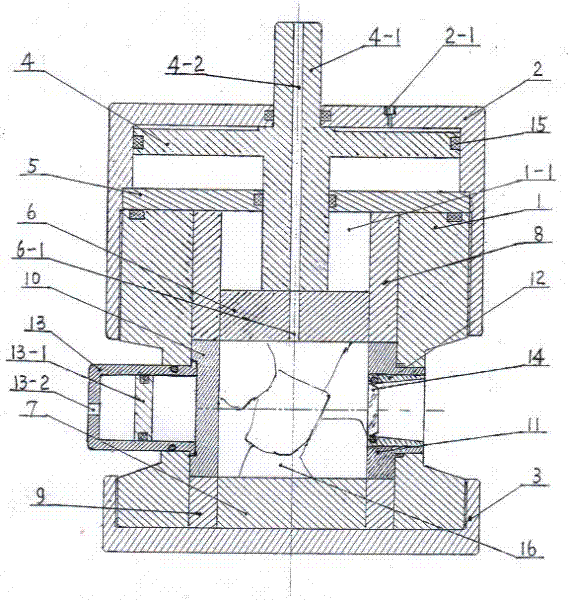

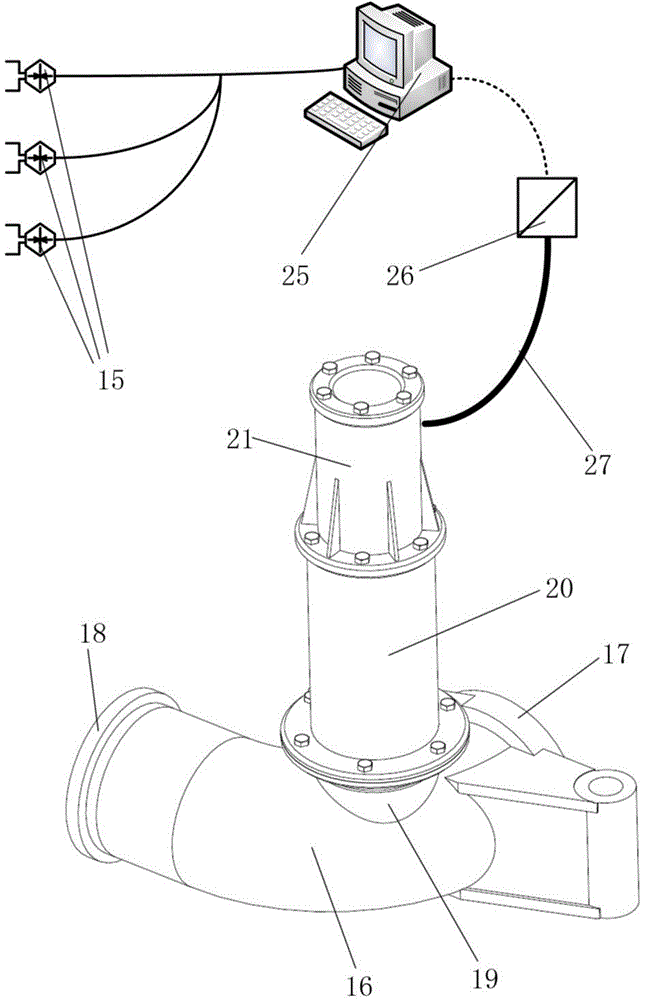

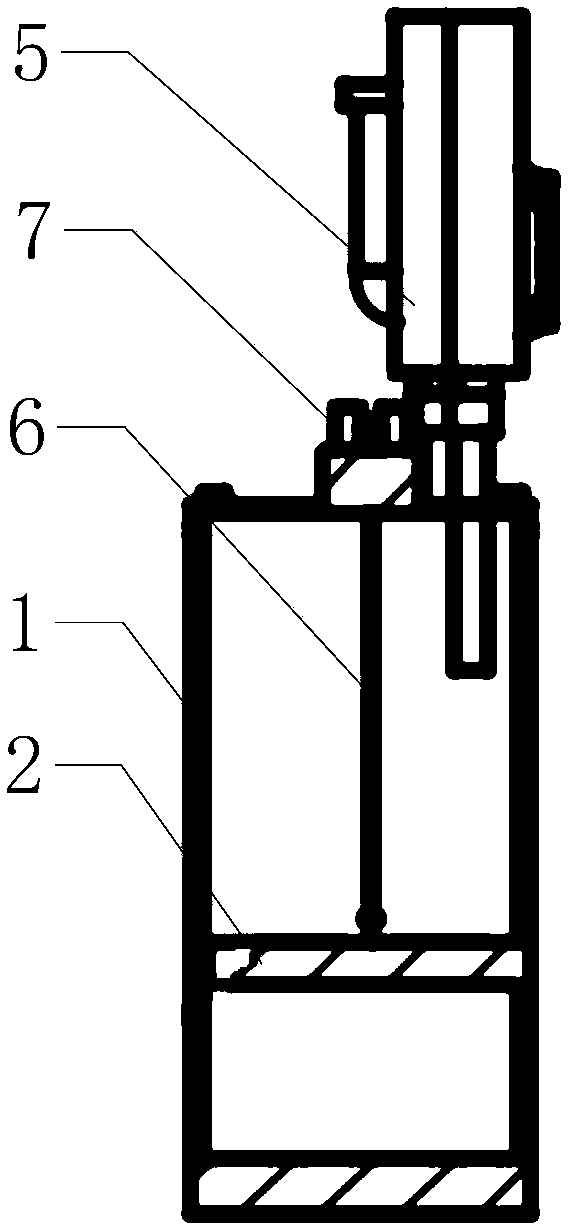

Coal and gas outburst jet characteristic simulation experiment device

InactiveCN102645518AReproduce the salient situationGuaranteed tightnessMaterial analysisMechanical engineeringSlow speed

The invention belongs to an experiment device for gas monitoring in a coal mine and particularly relates to a coal and gas outburst jet characteristic simulation experiment device. The upper end of a sleeve (1) is in threaded connection with an upper end cover (2), and the lower end of the sleeve (1) is in threaded connection with a lower end cover (3); a lower pressing plate (7) is installed between the inside of the sleeve (1) and the lower end cover (3); a lower positioning plate (9) is installed between the lower pressing plate (7) and the sleeve (1); a solid pressure measuring plate (10) is arranged on the lower positioning plate (9); an oil cylinder (13) is embedded on the solid pressure measuring plate (10); a hollow side pressing plate (11) is arranged on the lower positioning plate (9) at the right side; upper positioning plates (8) are arranged on the hollow side pressing plate (11) and the solid pressure measuring plate (10); an upper pressing plate (6) is arranged above a coal sample (16); a baffle (5) is arranged above the sleeve (1); a piston rod (4-1) is arranged in a central hole of the baffle (5); and a piston (4) is arranged between the inside of the upper end cover (2) and the baffle (5). The coal and gas outburst jet characteristic simulation experiment device has the beneficial effects that the influence of passively opening an outburst port on outburst energy due to slow speed is avoided, the pressure is kept constant, and the required pressure can be accurately adjusted.

Owner:LIAONING TECHNICAL UNIVERSITY

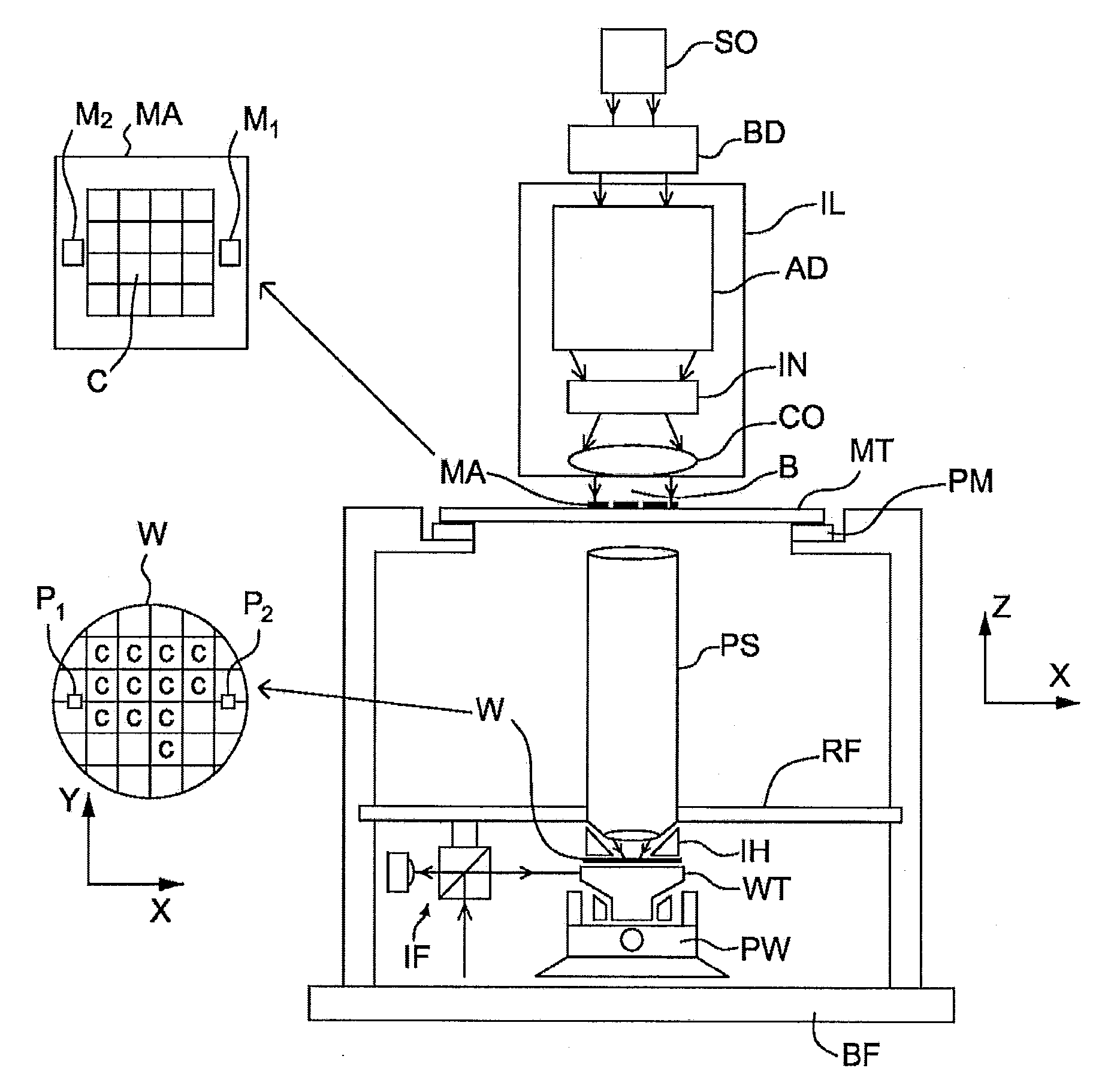

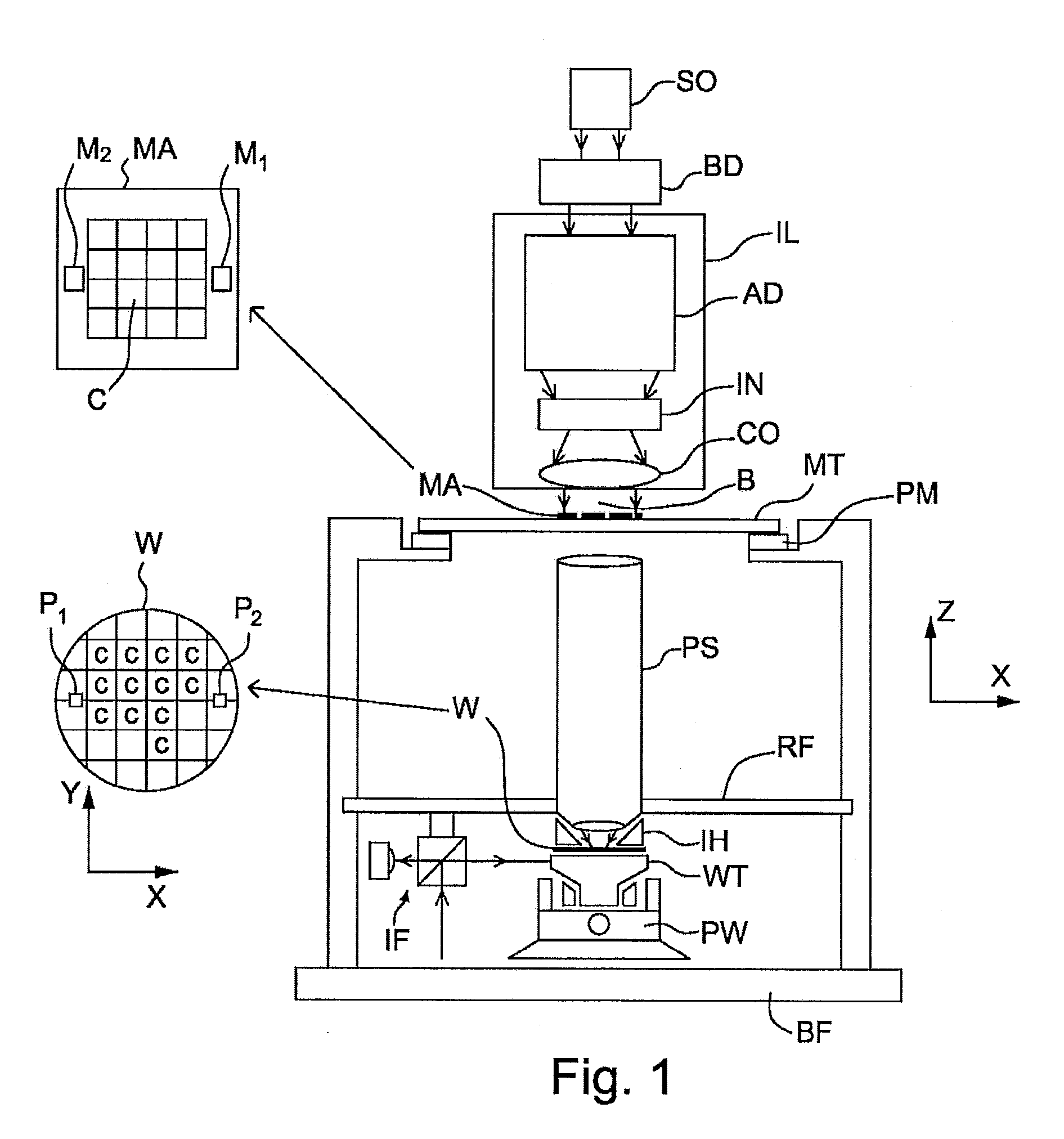

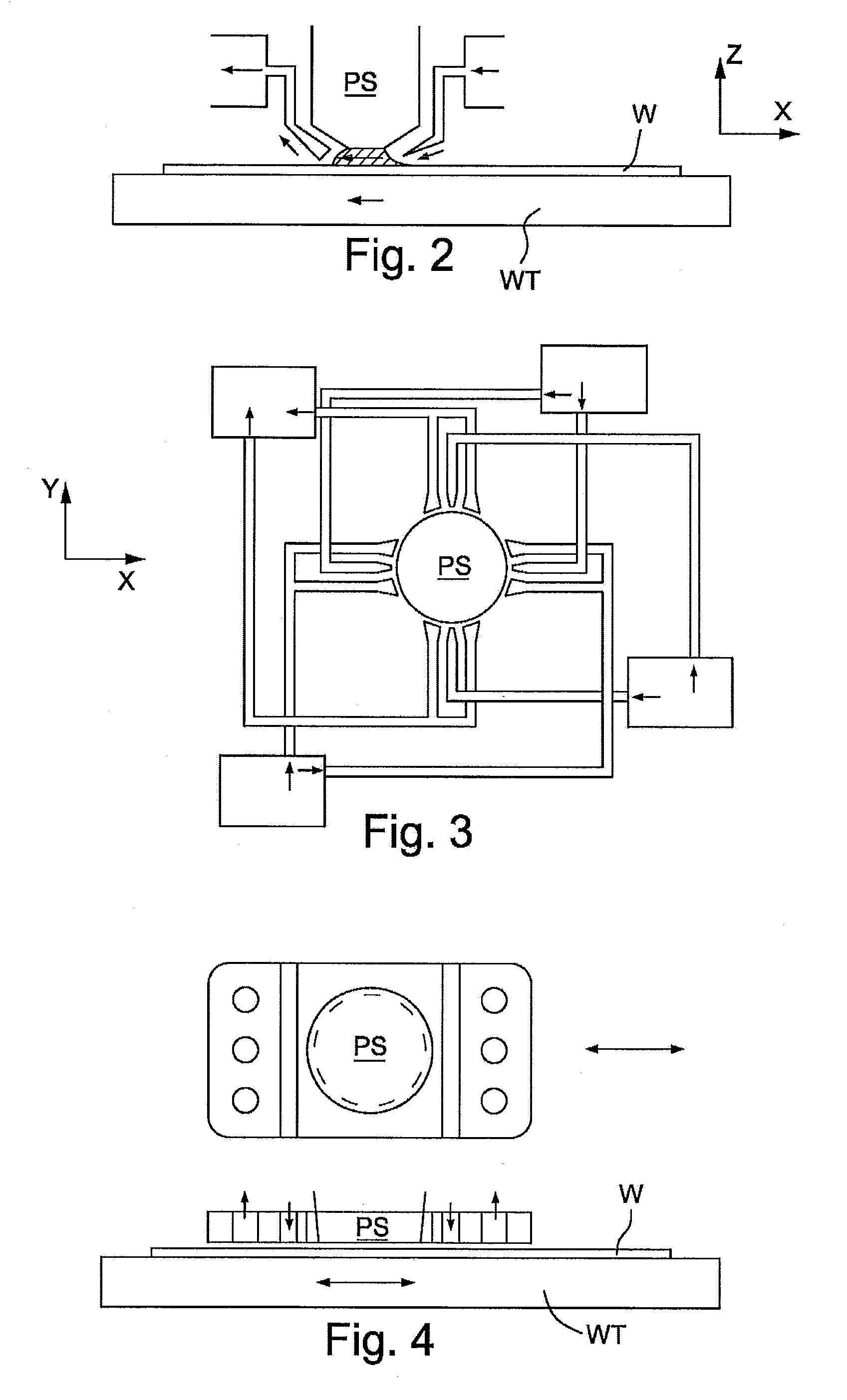

Fluid supply system, a lithographic apparatus, a method of varying fluid flow rate and a device manufacturing method

InactiveUS20100208221A1Constant pressureReduce and eliminate temperature variationPhotomechanical apparatusPhotographic printingEngineeringFluid supply

A fluid supply system for a lithographic apparatus, includes a controller configured to vary fluid flow rate to a first component from a fluid source while maintaining total flow resistance to fluid downstream of the fluid source substantially constant.

Owner:ASML NETHERLANDS BV

Controlled Negative Pressure Apparatus And Alarm Mechanism

ActiveUS20190298899A1Reduce pressureReduce frictionMedical devicesIntravenous devicesDamages tissuePhysical therapy

Methods and devices for treatment of damaged tissue are disclosed, including treatment of wounds by employing non-electrically powered, reduced pressure therapy devices. The devices are capable of generating a substantially constant reduced pressure with low tolerance for pressure fluctuations. Also disclosed herein are reduced pressure therapy systems that comprise an alarm system to detect the depleted state of the suction device and provide an alert to the patient and / or practitioner.

Owner:3M INNOVATIVE PROPERTIES CO

Pressure compensation device for concrete pumping and concrete pumping device

The invention discloses a pressure compensation device for concrete pumping. The pressure compensation device comprises a cylinder body (11) and a hydraulic control part; a piston is arranged inside the cylinder body and divides an inner cavity of the cylinder body (11) into a hydraulic cavity (12) and a concrete cavity (13); an opening (14) of the concrete cavity (13) can be communicated with fluid in a concrete pumping pipeline; the hydraulic control part controls hydraulic pressure in the hydraulic cavity (12) according to pumping pressure in the concrete pumping pipeline so as to control the movement of the piston. The pressure compensation device can keep pressure in the concrete conveying pipeline constant during concrete pumping. The invention further discloses a concrete pumping device with the pressure compensation device.

Owner:ZOOMLION HEAVY IND CO LTD

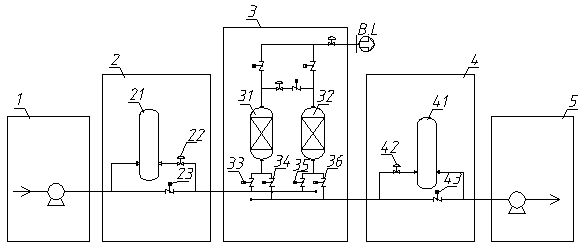

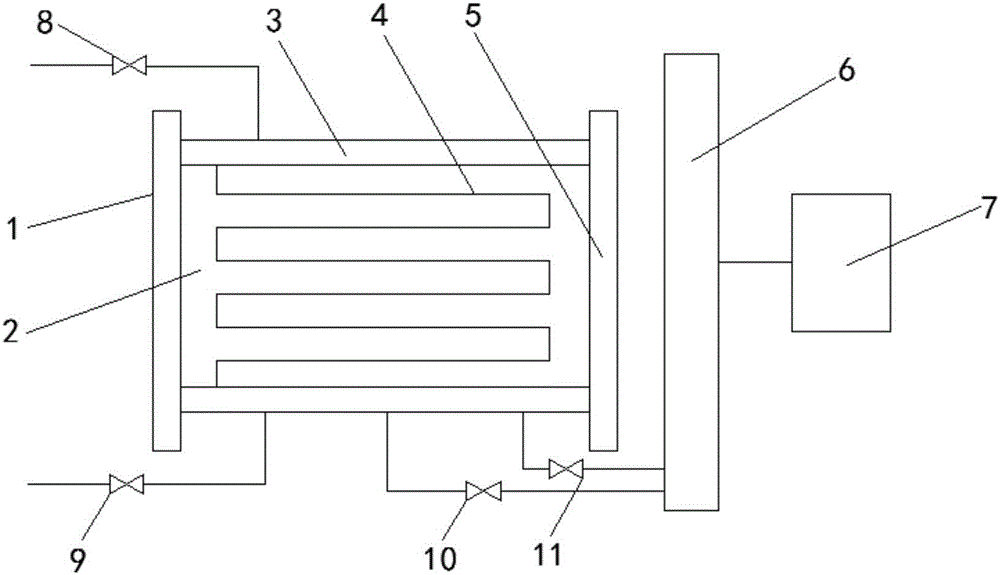

System and method for preparing oxygen by vacuum pressure swing adsorption

PendingCN108939820AIncrease pressureKeep the pressure constantProductsReagentsVacuum pressureTime delays

The invention relates to a system and method for preparing oxygen by vacuum pressure swing adsorption. The system comprises a velocity type fan, an adsorptive separation unit and a velocity type vacuum pump, wherein a fan work condition control unit is connected between the air inlet of the adsorptive separation unit and the velocity type fan; a vacuum pump work condition control unit is connectedbetween the exhaust of the adsorptive unit and the velocity type vacuum pump; prediction and adjustment can be carried out in advance by regulating the openness of a control valve A when pressure fluctuates, so that the influence caused by time delay of valve action can be eliminated; the inlet flow rate of the fan work condition control unit is equal to the outlet flow rate of the velocity typefan, the pressure of a buffer tank B is kept constant by controlling the flow rate of a valve B to be equal to the inlet flow rate of the vacuum pump, and the inlet flow rate and pressure of the velocity vacuum pump can be kept constant, so that the inlet pressure and outlet pressure are ensured to be smooth.

Owner:CHENGDU HUAXITANG ENVIRONMENTAL PROTECTION TECH CO LTD

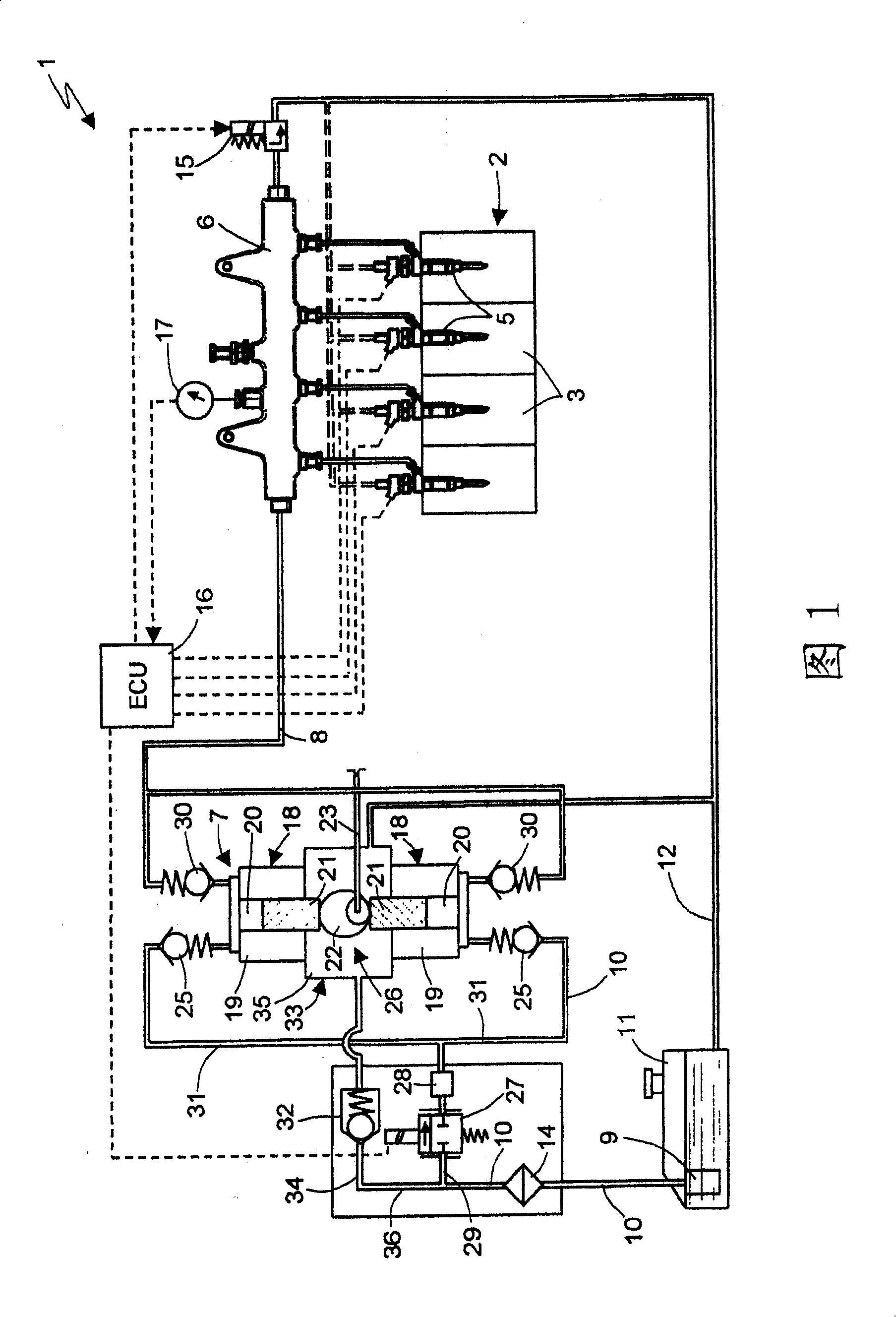

Improvement to a fuel-injection system for an internal-combustion engine

InactiveCN101182826AImprove reliabilityKeep the pressure constantLow pressure fuel injectionMachines/enginesSolenoid valveCrankcase

The invention provides an injection system. The injection system includes a high-pressure pump (7) with variable flow rate. The high-pressure pump has at least one pumping element (18). The pumping element is provided with a fuel inlet pipe (10). The oil inlet valve (25) and the oil outlet valve (30) connected with the oil outlet pipe (8). A pressure regulator (32) is provided on the inlet pipe (10) downstream of the metering solenoid valve (27), which is designed to meter the flow of the pump (7) according to the operating conditions of the internal combustion engine. The pressure regulator (32) is designed to discharge excess fuel into the chamber (35) of the crankcase (33) to lubricate the common actuation structure (26) of the pumping element. Between the inlet (29) of the solenoid valve (27) and the inlet (34) of the pressure regulator (32) there is a control volume (37) designed to accommodate a quantity of fuel that The amount ensures sufficient fuel flow in the area corresponding to the inlet (29) of the solenoid valve (27).

Owner:CENT RICERCHE FIAT SCPA

Sterilizing method for low temperature steam sterilized traditional Chinese medicine

The invention provides a sterilizing method for low temperature steam sterilized traditional Chinese medicine, and relates to the technical field of traditional Chinese medicine sterilizing methods. The sterilizing method comprises the following steps: placing traditional Chinese medicine into a sterilizing room; vacuuming the sterilizing room; introducing high-temperature and high-pressure steam into the sterilizing room; when the pressure in the sterilizing room reaches a sterilizing pressure, preheating for stabilizing; continually introducing high-temperature and high-pressure steam, so that the temperature in the sterilizing room rises to a sterilizing temperature; starting sterilization; entering a drying process after finishing the sterilization; drying and standing for 24 hours to wait for the growth of spores; sterilizing once again; repeating the waiting and sterilizing processes after finishing the sterilization; finishing the sterilization. The sterilizing method is convenient to run, energy consumption is lowered greatly, and the original efficacy, characteristic and uniformity of the traditional Chinese medicine are kept; meanwhile, a plurality of bacteria such as molds and escherichia coli in traditional Chinese medicinal powder are killed fully, and a large amount of energy and material resource cost is saved; the sterilizing method is a novel and environment-friendly sterilizing method being worthy of wide popularization.

Owner:LIANYUNGANG YOUYUAN MEDICAL EQUIP MFG

Air energy storage system and method

PendingCN107842485ATake advantage ofWell formedVessel geometry/arrangement/sizeContainer filling methodsThermal energy storagePower grid

The invention discloses an air energy storage system and method. The air energy storage system comprises an air energy storage space, a pouring weight, a rubber air bag, a turbine and a compressor. When surplus electric energy drives the compressor to work through a compressor power source, air is injected into the rubber air bag through compression of the compressor, the pouring weight is gradually lifted, and energy reaches maximum till the pouring weight reaches the highest position; and when electric energy of a power grid needs to be supplemented by the energy storage system, a pressure regulating valve is opened, and the compressed air enters the turbine to push the turbine to do work. According to the air energy storage system and method, the form is simple, a novel air energy storage technology can more sufficiently utilize a storage space, large-scale energy storage can be effectively achieved, and the air energy storage system and method have the characteristics that the structure is simple, and implementation is easy, and can obtain obvious social and economic benefits.

Owner:NORTHWEST ELECTRIC POWER DESIGN INST OF CHINA POWER ENG CONSULTING GROUP

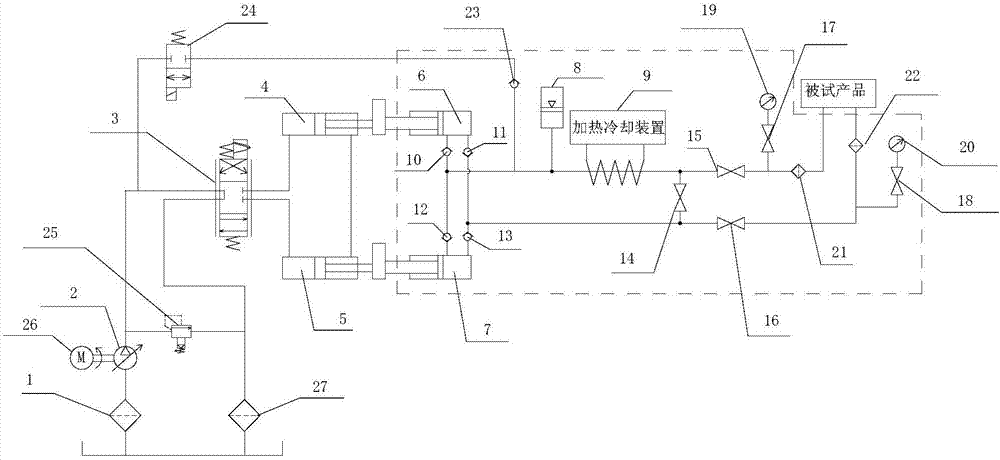

Hydraulic system for heating and cooling high-pressure oil liquid

ActiveCN107218260AAchieve isolationReduce usageServomotor componentsAccumulator installationsHydraulic cylinderHydraulic pump

The invention provides a hydraulic system for heating and cooling high-pressure oil liquid. The hydraulic system comprises a first hydraulic cylinder and a second hydraulic cylinder, and the first hydraulic cylinder and the second hydraulic cylinder are connected to a three-position four-way servo valve; the three-position four-way servo valve is connected to an oil tank through a hydraulic pump and an oil suction filter; the first hydraulic cylinder and the second hydraulic cylinder are connected to a hydraulic bridge through a first isolation cylinder and a second isolation cylinder respectively; one circuit of the hydraulic bridge is connected to a product to be tested through an energy accumulator and a heating and cooling device; and the other hydraulic circuit is connected to the product to be tested. The hydraulic system for heating and cooling the high-pressure oil liquid has the advantages that isolation of normal-temperature hydraulic oil from high-low-temperature oil can be realized, pressurizing and reversing of the system are carried out at the normal-temperature side, and therefore use of the hydraulic pump, the servo valve and other high-low-temperature hydraulic parts can be avoided, the high-low-temperature end is placed in the heating and cooling device, the heating and cooling power is small, safety and reliability can be achieved, and the cost is low.

Owner:LANDING GEAR ADVANCED MFG

Mass supply system

ActiveCN104244722ASmall inertiaEasy to replaceMeat processingRotary piston pumpsEngineeringMechanical engineering

Owner:GEA FOOD SOLUTIONS BAKEL

Convenient robot based on dining room cleaning

ActiveCN106923757AKeep the pressure constantWith vacuum functionAutomatic obstacle detectionTravelling automatic controlSuction forceEngineering

The invention belongs to the technical field of dining room cleaning robots and especially relates to a convenient robot based on dining room cleaning. The robot comprises a driving mechanism, a walking mechanism, a wiping device, a dust-collecting device, a first shell, an extension spring and an adjusting mechanism. The dining room cleaning robot designed by the invention is composed of the driving mechanism, the walking mechanism, the wiping device, the adjusting mechanism and the dust-collecting device and has a walking function, a dust-collecting function, a wiping function and an adjusting function. A plurality of dust-collecting holes are formed along the peripheral direction of the lower end of a dust-collecting box; the dust-collecting box is used for collecting the dust on the ground through a dust-collecting pump, a first dust-collecting pipe and a second dust-collecting pipe; the suction force of the dust-collecting box to the ground is averaged by the plurality of dust-collecting holes, so as to adjust the negative pressure in the dust-collecting box and keep constant pressure in the dust-collecting box.

Owner:JIANGSU XIYI HIGH NEW DISTRICT TECH DEV CO LTD

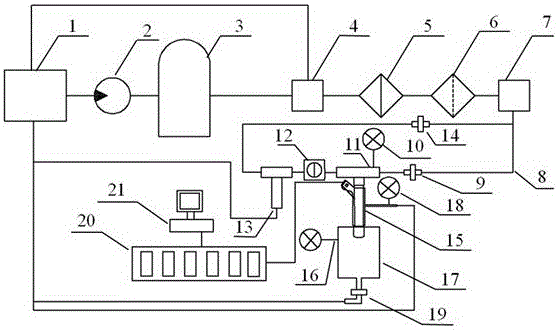

Fuel injector micro leakage test and seal test system

ActiveCN106153266AQuick responseImprove test accuracyMeasurement of fluid loss/gain rateInjectorLeakage test

The invention provides a fuel injector micro leakage test and seal test system and relates to the technical field of an engine part test device. A fuel tank is connected with an electric fuel pump, and provides fuel to an energy storage tank through the electric fuel pump, thereby ensuring sufficient fuel in a fuel path, and meanwhile, playing a certain pressure stabilization role; a pressure regulator is connected with an outlet of the energy storage tank; the pressure regulator carries with a fuel return system to ensure stable primary pressure in the fuel path and ensure the redundant fuel to the fuel tank; a heat exchanger is connected with the pressure regulator, and is used for ensuring change range of temperature of the fuel to be always kept within + / -1 degree in the test process; a fuel filter is connected with the heat exchanger, and is used for filtering impurities in the fuel; and a self-reliant pressure regulator is connected with the fuel filter, and is used for providing a certain pressure of fuel to a fuel rail and a standard pressure chamber, and controlling opening and closing of the fuel path between the self-reliant pressure regulator and the fuel rail through a solenoid valve A. The fuel injector micro leakage test and seal test system is fast in response speed, high in test precision, good in reliability and simple and quick to use.

Owner:WUXI VOCATIONAL & TECHN COLLEGE

Load limiter on roads

InactiveCN101629412AKeep the pressure constantAvoid manual operationTraffic restrictionsPistonHuman control

The invention discloses a load limiter on the roads, comprising a top plate, a load bearing apparatus and a spray apparatus, wherein the top plate is positioned on the upper part of the load bearing apparatus and is in fit connection with the load bearing apparatus against press; the spray apparatus is connected with the load bearing apparatus; the load bearing apparatus consists of a plurality of cylinder bodies arranged vertically; pistons are arranged in and in sliding fit with the cylinder bodies; compression springs are installed between the bottom surfaces of the pistons and the bottoms of the cylinders, the tops of the pistons are in fit connection with the top plate against press. The invention is characterized by reasonable design, simple structure, low cost and good endurance for use, which is used for cautioning that vehicles can not be overloaded, otherwise, serious consequences can be caused. Moreover, without being artificially controlled, the invention can achieve the satisfactory effect of automatically cautioning and punishing the overloaded vehicles as long as the maximum loading capacity is preset, thus having favorable utility value and being easily popularized and applied.

Owner:邢天恩

Self-liquid-supply pneumatic hydraulic pump having liquid return function

InactiveCN104819122AAvoid complicated procedures such as connectionEfficient use ofPositive displacement pump componentsPiston pumpsHydraulic cylinderReturn function

The invention relates to a self-liquid-supply pneumatic hydraulic pump having a liquid return function. A pneumatic body, a gas piston, an extrusion piston rod, an oil pressure body and an oil outlet one-way valve are positioned in an oil storage box; a pedal is fixed at the right side of a separation plate through a hinge; a high-pressure oil through hole is formed in the oil pressure body, and is connected with the internal of a cylinder and an oil outlet; the oil outlet one-way valve and an oil absorbing one-way valve are mounted in the middle of the high-pressure oil through hole; an oil return through hole is formed in the right end of the upper side of the oil outlet one-way valve, and is connected with an oil outlet hole and the internal of the oil storage box; an oil return valve is arranged in the middle position of the oil return through hole; and an oil return control thimble is arranged above the oil return valve, and is positioned at the left side of the pedal. The pump uses the technical breakthrough for integrating functions of the hydraulic pump and the hydraulic oil storage box to prevent such complex procedures as connection between a traditional hydraulic cylinder power source hydraulic pump and the hydraulic oil storage box and to synchronously realize the liquid supply and liquid return functions of the hydraulic cylinder.

Owner:大大科技(宁国)有限公司

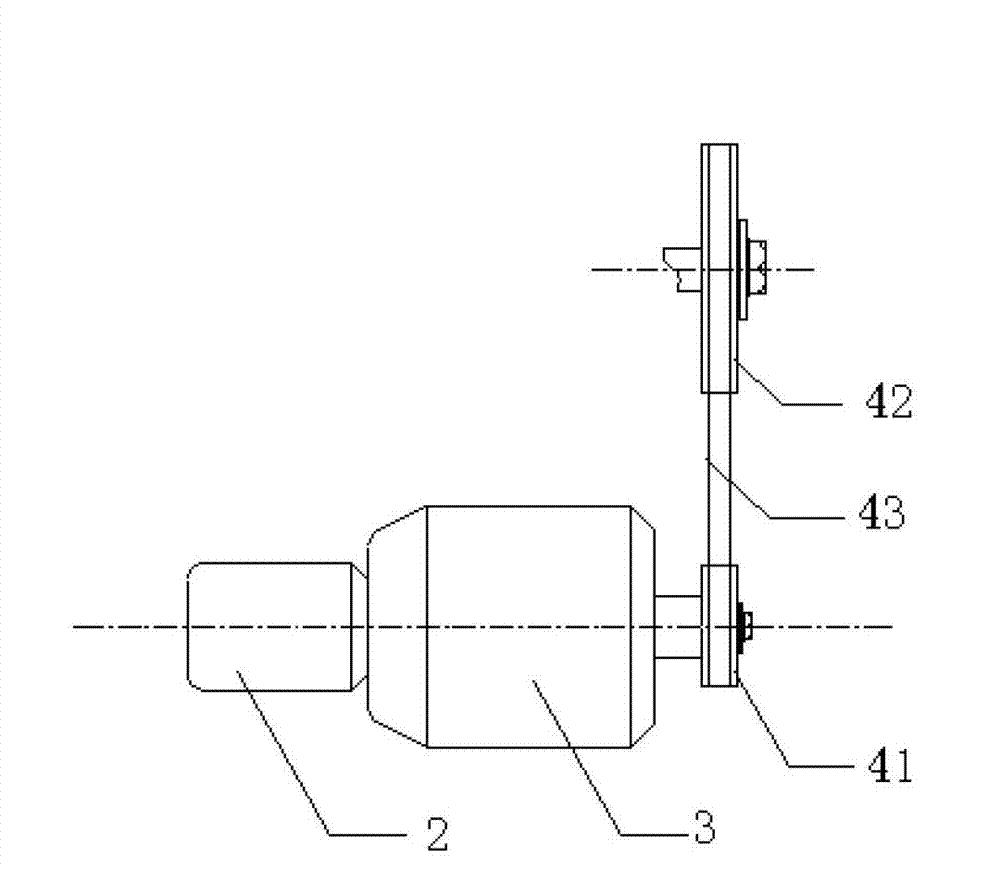

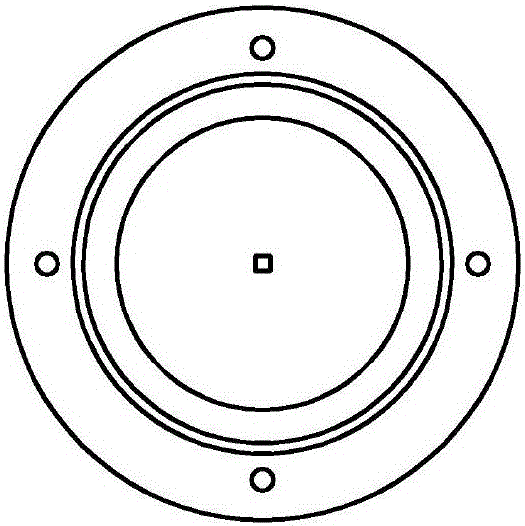

Polishing machine tool and constant-pressure device thereof

InactiveCN109176226AExhaust stableKeep the pressure constantOptical surface grinding machinesGrinding feed controlPull forceContact pressure

The invention discloses a constant-pressure device of a polishing machine tool. The constant-pressure device comprises a sealed gas cylinder and a polishing module which is in contact with a polishingworkpiece and can vertically move, wherein a piston platform is arranged in the gas cylinder; the piston platform can vertically move in the gas cylinder, is connected with the polishing module through a connector to transmit tensile force; a through hole for allowing the connector to pass through is formed in the gas cylinder; a gas outlet of the gas cylinder is used for stably discharging gas;a gas inlet of the gas cylinder is equipped with an inlet adjustable pressure-stabilizing valve; and the inlet adjustable pressure-stabilizing valve adjusts gas inlet amount according to the positionof the piston platform, so that pressure in the gas cylinder is kept constant. Real-time automatic compensation for contact pressure is realized through gas pressure change rule, so that constant-pressure polishing is realized, the polishing process for the workpiece is improved, the structure is simple, the control process is simplified, influences, on polishing, of a complex structure are reduced, and problems such as low workpiece polishing precision and a great rejection rate caused by conventional manual polishing equipment operation are avoided. The invention further discloses the polishing machine tool comprising the constant-pressure device.

Owner:GUANGDONG UNIV OF TECH

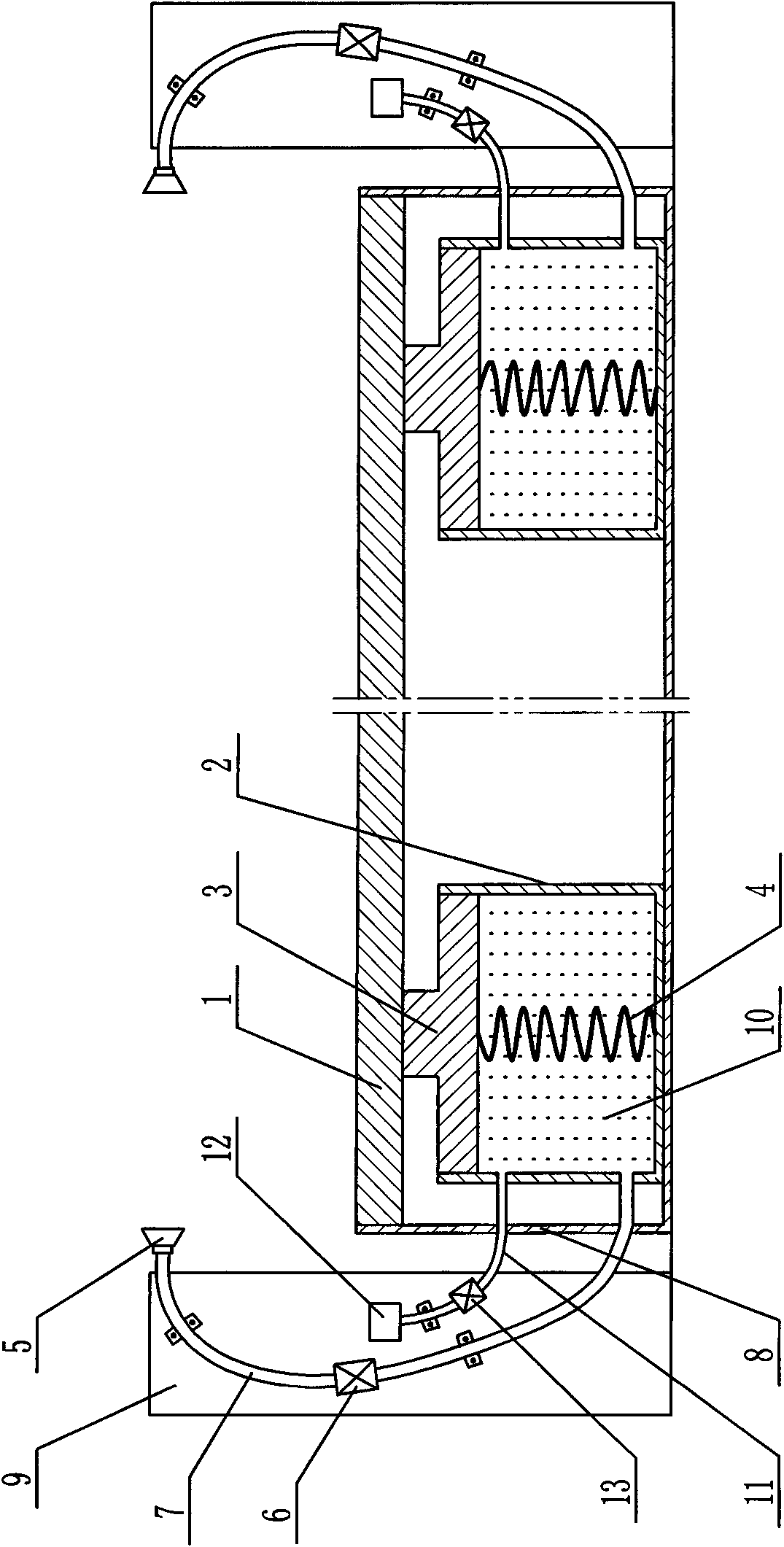

Constant-pressure apparatus used in testing of burning rate of solid propellant

InactiveCN105911213AKeep the pressure constantReduce volumeChemical analysis using combustionCombustion chamberExhaust valve

The invention discloses a constant-pressure apparatus used in testing of the burning rate of a solid propellant. The constant-pressure apparatus is composed of a combustion chamber, a pedestal, a plurality of cylinders and a weight disk, wherein the combustion chamber is fixedly connected with the pedestal; a sealing ring is installed at the joint of the pedestal and a flange of the sidewall of the combustion chamber; two cylindrical cylinders are symmetrically installed at two sides of the combustion chamber, and two same rubber pistons are arranged in the cylinders; one end of a support bar is connected with a groove located on the outer bottom of the weight disk, and the other end of the support bar is connected with the two rubber pistons in the cylinders; the distance between the two rubber pistons is adjustable; the combustion chamber is connected with the cylinders through arc circular pipes; the side wall of the combustion chamber is provided with a nitrogen filling hole, a gas vent, a sensor connection hole and a vacuum pump connection hole which are respectively connected with a high-pressure nitrogen cylinder, an exhaust valve, a pressure sensor and a vacuum pump; and a propellant strip is fixed in a groove located on the pedestal in the combustion chamber. The constant-pressure apparatus is simple in structure and convenient to dismount; combustion products in a cleaning device are easy to clean, which is beneficial for maintenance of the apparatus; and testing precision is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com