Movable asphalt mixture forming machine

An asphalt mixture and molding machine technology, applied in the preparation of test samples, etc., can solve the problems of rolling force fluctuation, high labor intensity, complicated operation, etc., to meet the shape size and structure, meet equipment functional requirements, process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

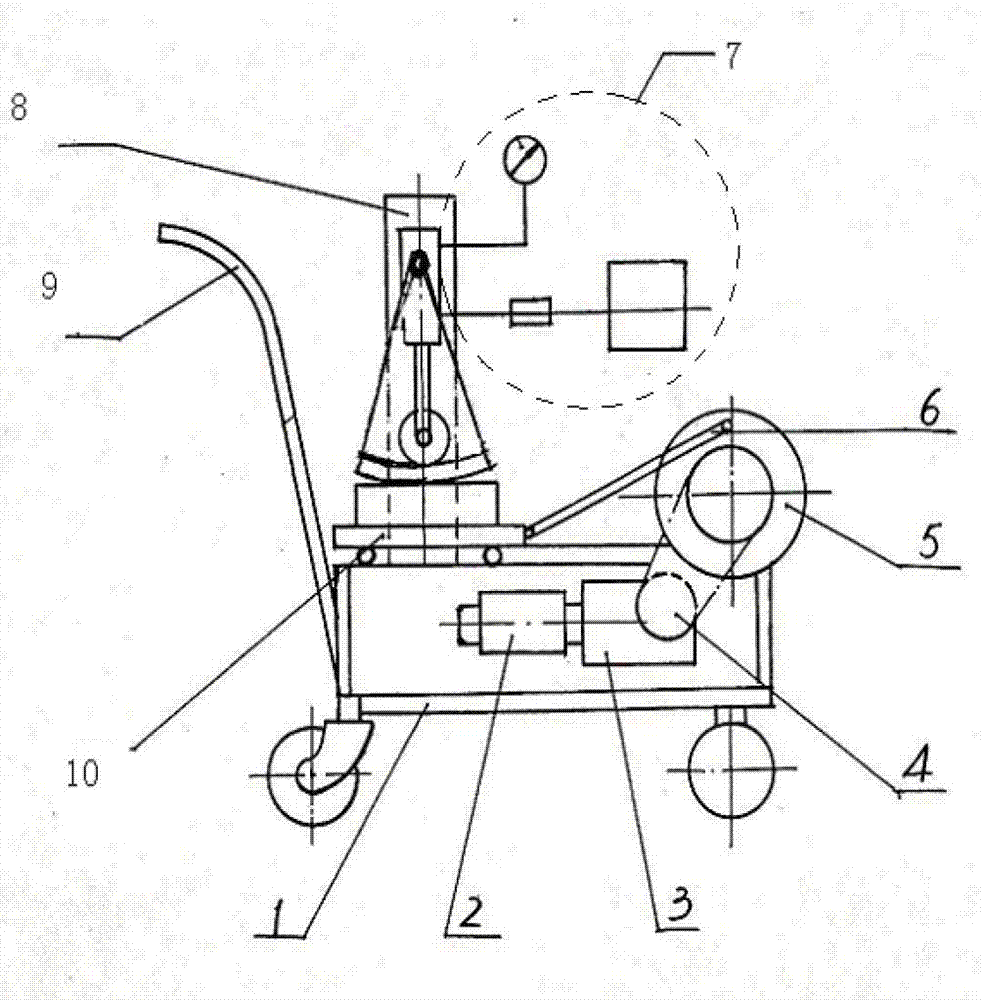

[0022] The invention provides a mobile asphalt mixture on-site wheel mill forming machine. The structure of the mobile asphalt mixture on-site wheel milling machine is as follows: figure 1 shown.

[0023] The forming machine includes a car body, a speed reduction mechanism, a trial mold frame, a hydraulic loading system and a wheel mill support assembly. The car body includes a vehicle frame 1, wheels and handlebars. Below the frame, it is easy to move the frame. The vehicle frame is a box body structure, and the speed reduction mechanism is installed in the vehicle frame box body.

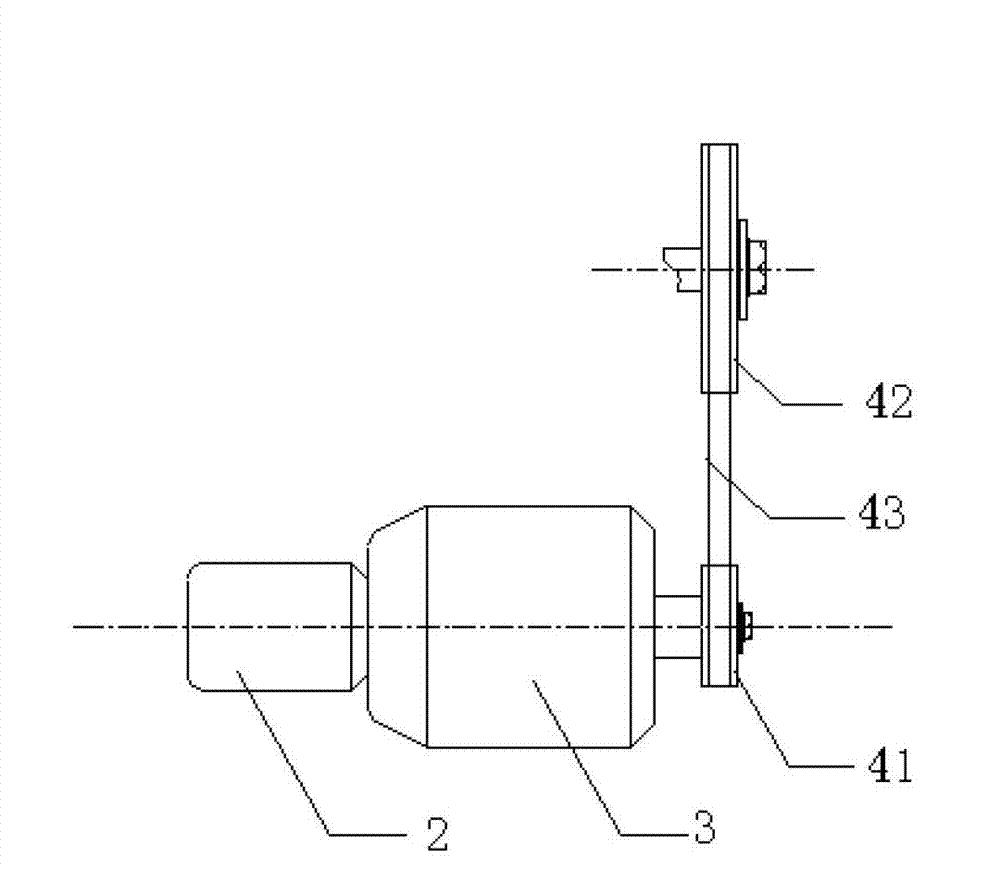

[0024] Such as figure 2 As shown, the reduction mechanism includes a first motor (2), a reducer (3), a small sprocket (41), a large sprocket (42), a transmission chain 43, and a turntable 5. The reducer is a cycloidal pin wheel planetary reducer, which applies the principle of planetary transmission, adopts cycloidal pin-tooth meshing, has a large reduction ratio, and the meshing parts adopt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com