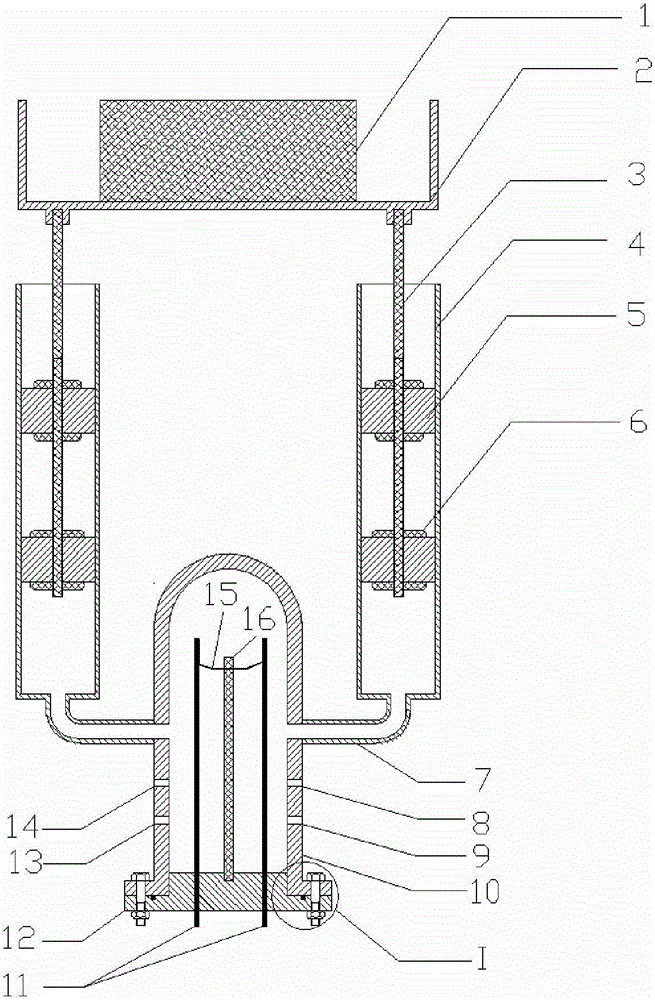

Constant-pressure apparatus used in testing of burning rate of solid propellant

A technology of solid propellant and constant pressure device, which is applied in the direction of using combustion for chemical analysis, etc. It can solve the problem of difficult constant pressure, and achieve the effect of easy cleaning, convenient maintenance, and getting rid of the use of nitrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

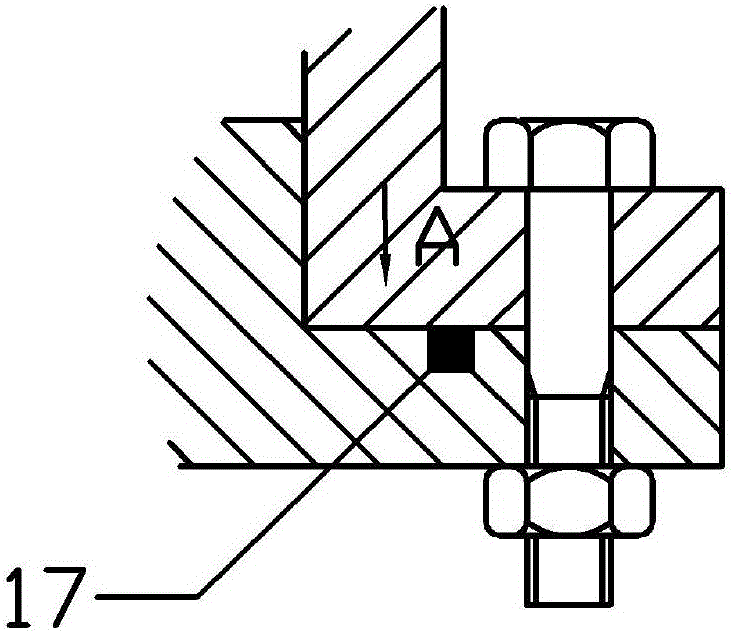

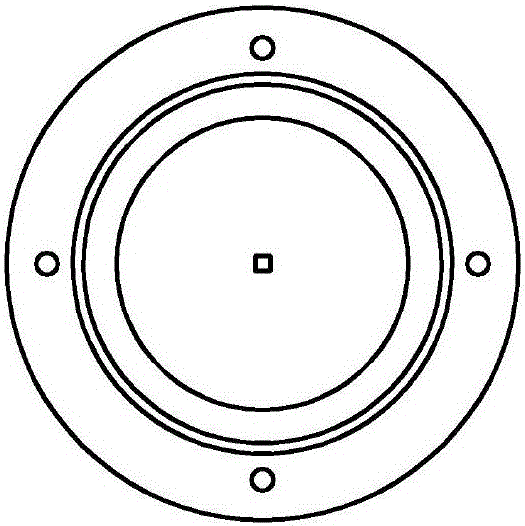

[0028] In this embodiment, a boron-containing fuel-rich propellant with a boron content of 35% is used as the test piece for the burning rate test. The size of the propellant rod is a cuboid of 4×4×150 mm, and the burning rate of the propellant under the test pressure is 0.2 MPa. . The diameter of the combustion chamber is 50mm, the height is 200mm, the number of cylinders is N=2, and the inner diameter of the cylinder is d 0 =65mm, cylinder length L 0 =1.5m, piston outer diameter D 1 =65mm, inner diameter of piston d 1 =30mm, piston length L 1 =40mm, the mass of the weight in the weight pan is 115kg.

[0029] The constant pressure device is installed on a special bench to ensure the stable operation of the device during the experimental test. After assembling the components of the combustion chamber, close the high-pressure nitrogen gas charging valve and exhaust valve of the combustion chamber, and at the same time, turn on the vacuum pump, and evacuate the combustion c...

example 2

[0031] In this embodiment, a boron-containing fuel-rich propellant with a boron content of 35% is used as the test piece. The propellant rod is a cuboid with a size of 4×4×150 mm, and the burning rate of the propellant is tested at a pressure of 5 MPa. The diameter of the combustion chamber is 50mm, the height is 200mm, the number of cylinders is N=2, and the inner diameter of the cylinder is d 0 =24mm, cylinder length L 0 =1.0m, piston outer diameter D 1 =24mm, inner diameter of piston d 1 =12mm, piston length L 1=40mm, the mass of the weight in the weight pan is 397kg.

[0032] After assembling the components of the combustion chamber, close the exhaust valve of the combustion chamber, and at the same time, turn on the vacuum pump to evacuate the combustion chamber to discharge the air in the combustion chamber. Then open the high-pressure nitrogen charging valve and charge nitrogen into the combustion chamber, and when the pressure in the combustion chamber reaches 5MPa...

example 3

[0034] In this embodiment, a composite propellant with an aluminum content of 17% is used as the test object. The size of the propellant rod is a cuboid of 4×4×150 mm. The mass is 52kg, and the burning rate is tested at 5MPa. The diameter of the combustion chamber is 50mm, the height is 200mm, the number of cylinders is N=4, and the inner diameter of the cylinder is d 0 =15mm, cylinder length L 0 =1.5m, piston outer diameter D 1 =15mm, inner diameter of piston d 1 =8mm, piston length L 1 =40mm, the mass of the weight in the weight pan is 342kg.

[0035] After assembling the components of the combustion chamber, close the exhaust valve of the combustion chamber, and at the same time, turn on the vacuum pump to evacuate the combustion chamber to discharge the air in the combustion chamber. Then open the high-pressure nitrogen charging valve and charge nitrogen into the combustion chamber, and when the pressure in the combustion chamber was 5MPa, close the high-pressure nitr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com