Improvement to a fuel-injection system for an internal-combustion engine

A fuel injection system and the technology of the injection system, which are applied in the directions of fuel injection pump, fuel injection device, low-pressure fuel injection, etc., can solve the problems of interference and delay of the restart effect of solenoid valve, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

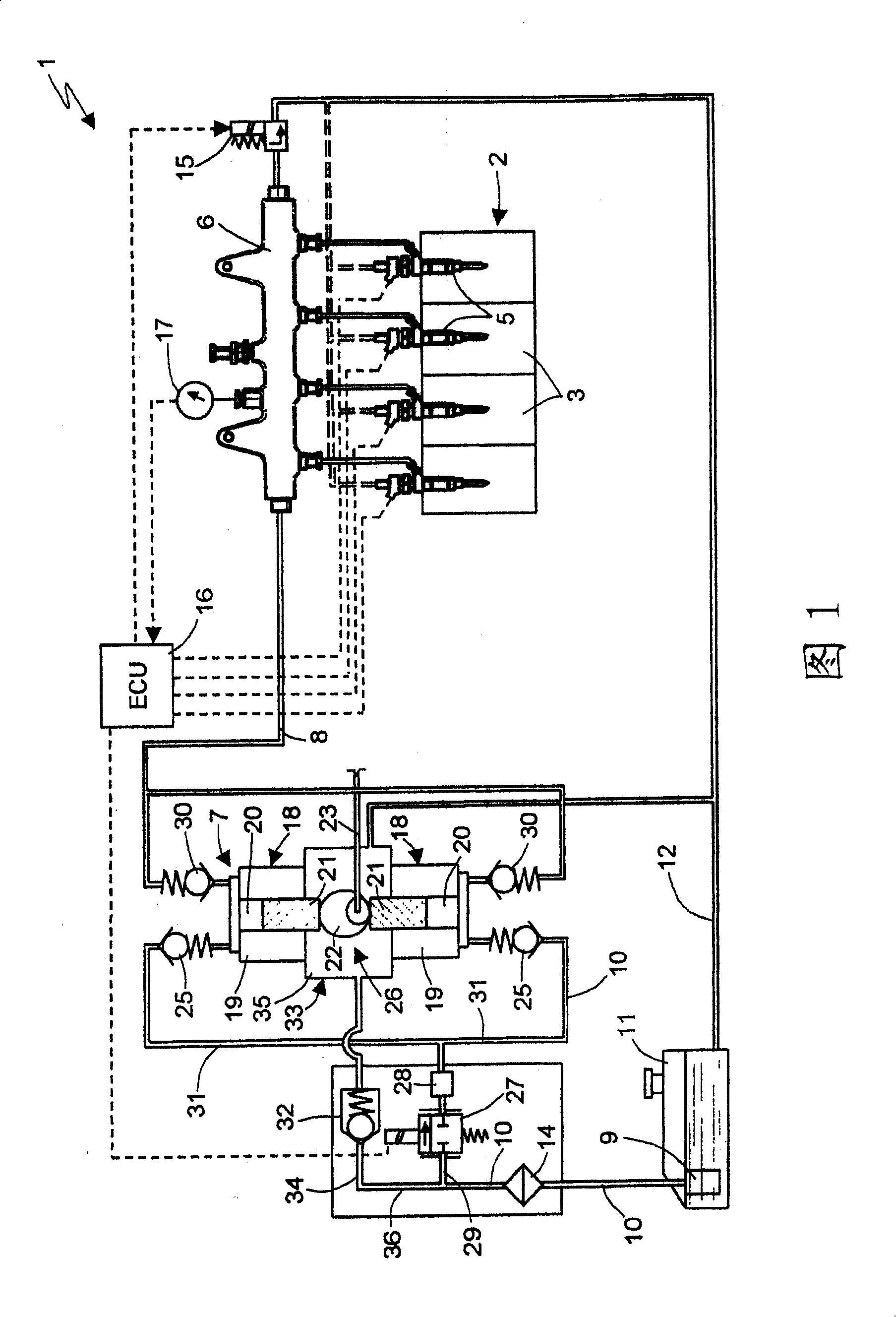

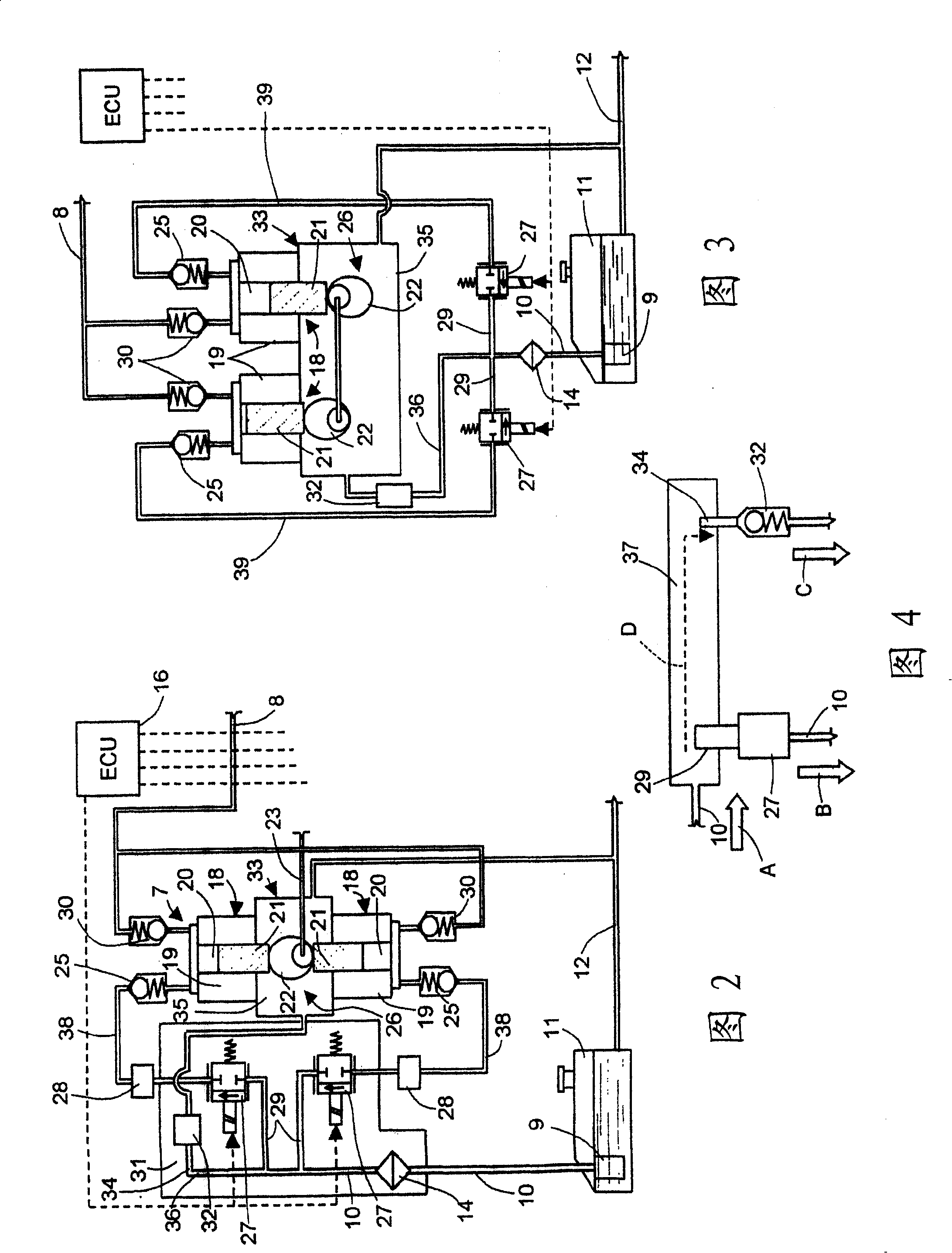

[0011] Referring to FIG. 1 , the entire fuel injection system for an internal combustion engine (which may be, for example, a four-stroke diesel engine) 2 is indicated by the reference numeral 1 . The internal combustion engine 2 includes a plurality of cylinders 3, for example four cylinders. The injection system 1 comprises a plurality of electronically controlled injectors 5 associated with the cylinders 3 , these injectors 5 being designed to inject high pressure fuel into the cylinders 3 . The injectors 5 are connected to an accumulation volume of pressurized fuel, which is formed, for example, by a common common rail 6 to which all the injectors 5 are connected.

[0012] The common rail 6 is supplied with high-pressure fuel via an oil outlet pipe 8 by a high-pressure pump, generally designated by the reference numeral 7 . In turn, the high pressure pump 7 is supplied by a low pressure pump (eg, the electric pump 9 ) through the oil inlet pipe 10 of the pump 7 . The ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com