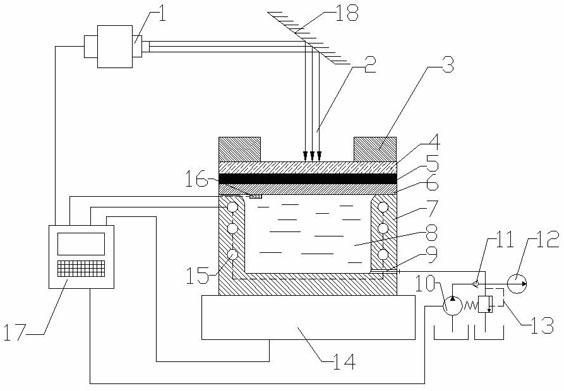

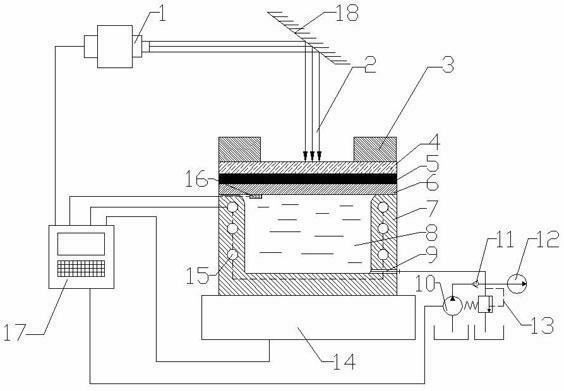

Laser impact warm forming method with uniform heat and constant pressure functions and device

A laser shock and warm forming technology, used in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of difficult to control stress distribution, uneven heating, small plastic deformation, etc., to improve fatigue life and stress resistance. Corrosion performance, improvement of formability, effect of improved formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] This example takes magnesium alloy sheet material as an example. combine figure 1 , after the pretreatment of the magnesium alloy sheet, paste aluminum foil on its surface as the energy absorbing layer 5, and then paste high-temperature-resistant glass on the outside of the aluminum foil as the constraining layer 4 to protect the sheet 6 from heat during the laser shock process , to reduce the thermal damage of the laser to the sheet 6; fix the magnesium alloy sheet to the figure 1On the shown device; in this example, water is used as the liquid in the cavity of the die 7, the pressure of the overflow valve 13 is set, and the water is sucked to the full cavity of the die 7 by the check valve 11 through the oil suction pump 10 (can be installed in the device A one-way air outlet is designed in the die to facilitate the discharge of gas in the die), so that the cavity of the die 7 reaches the set pressure, and the die 7 is heated by the heating coil 15, and the heat is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com