Patents

Literature

35results about How to "Reduced pumping effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

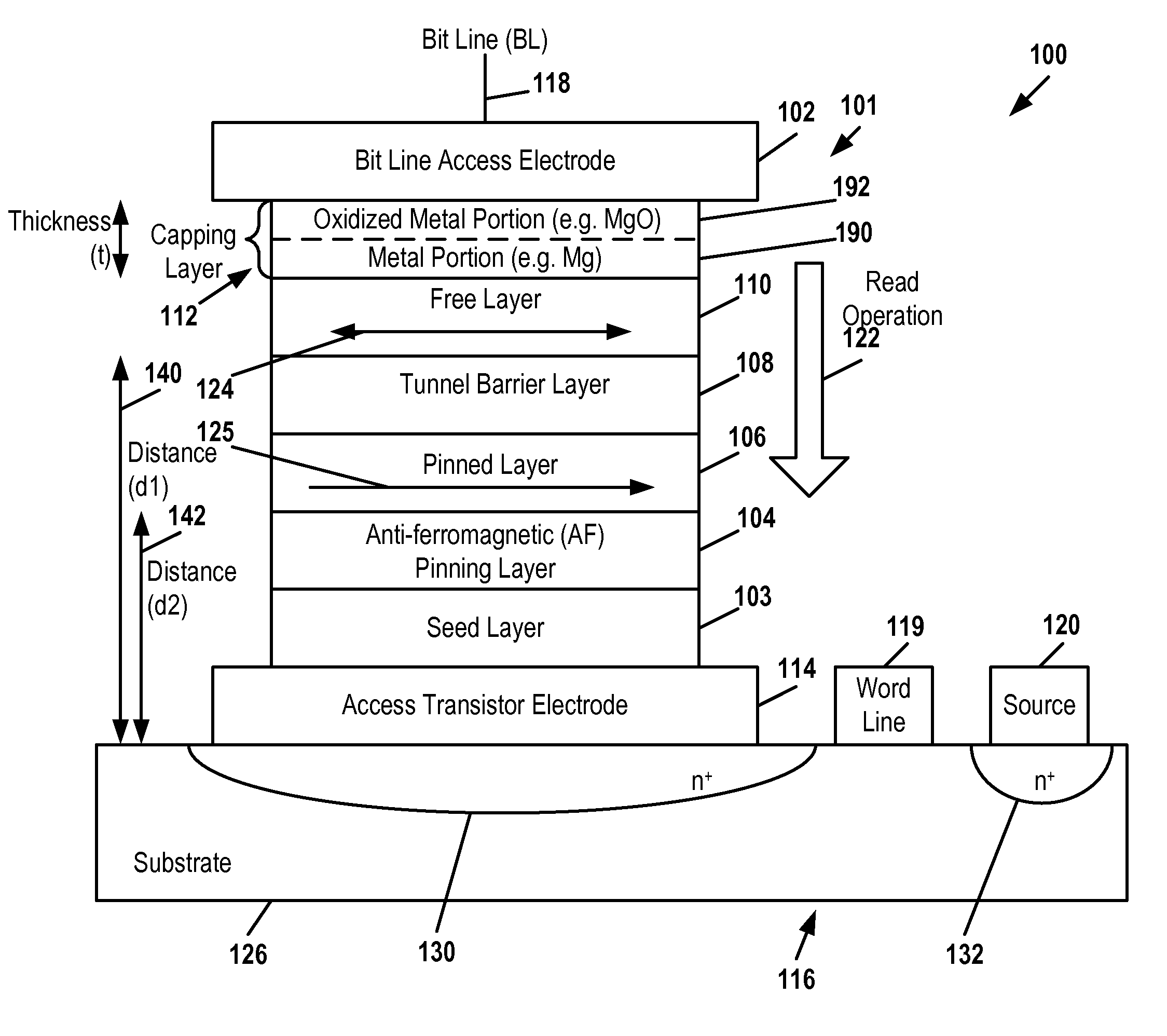

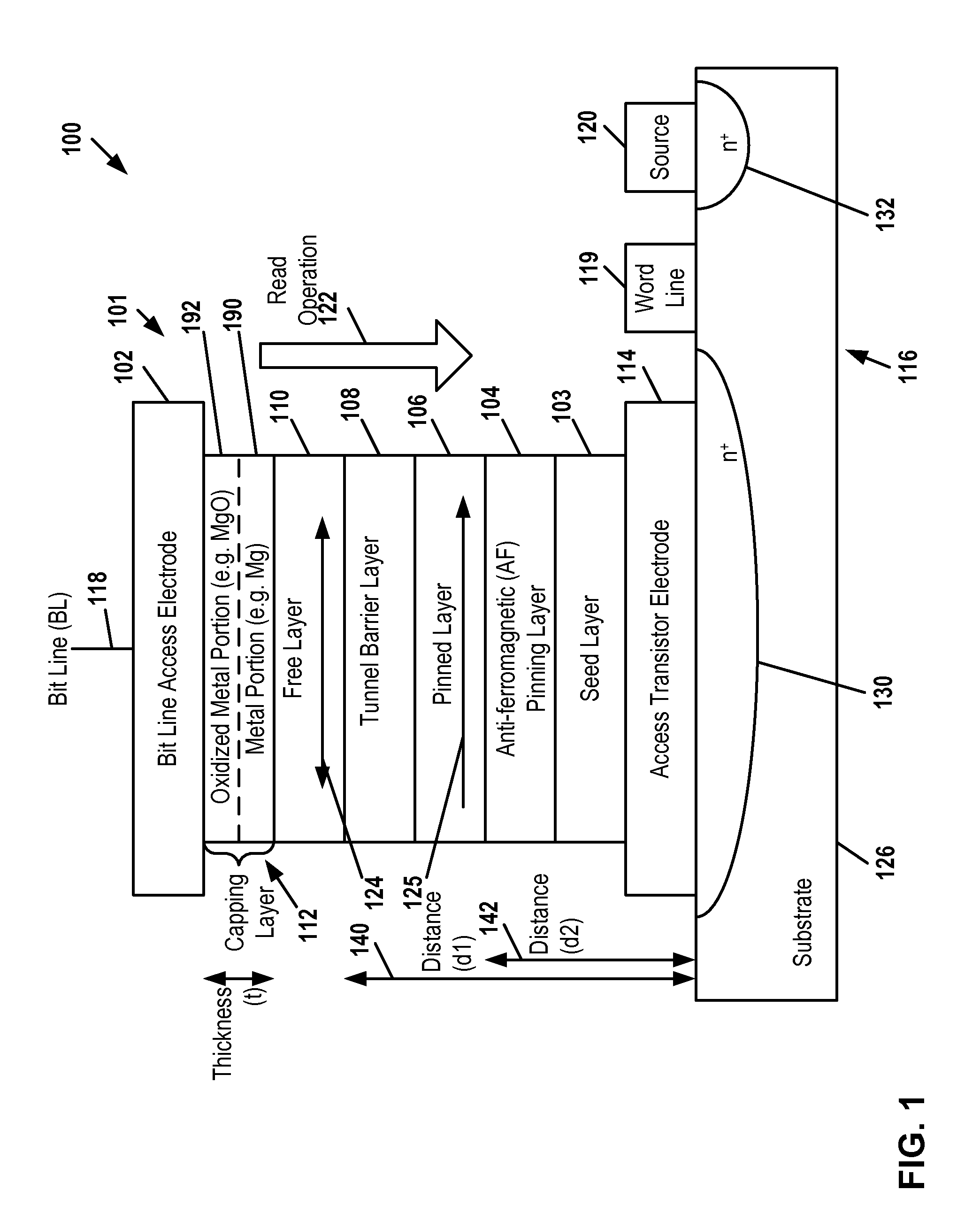

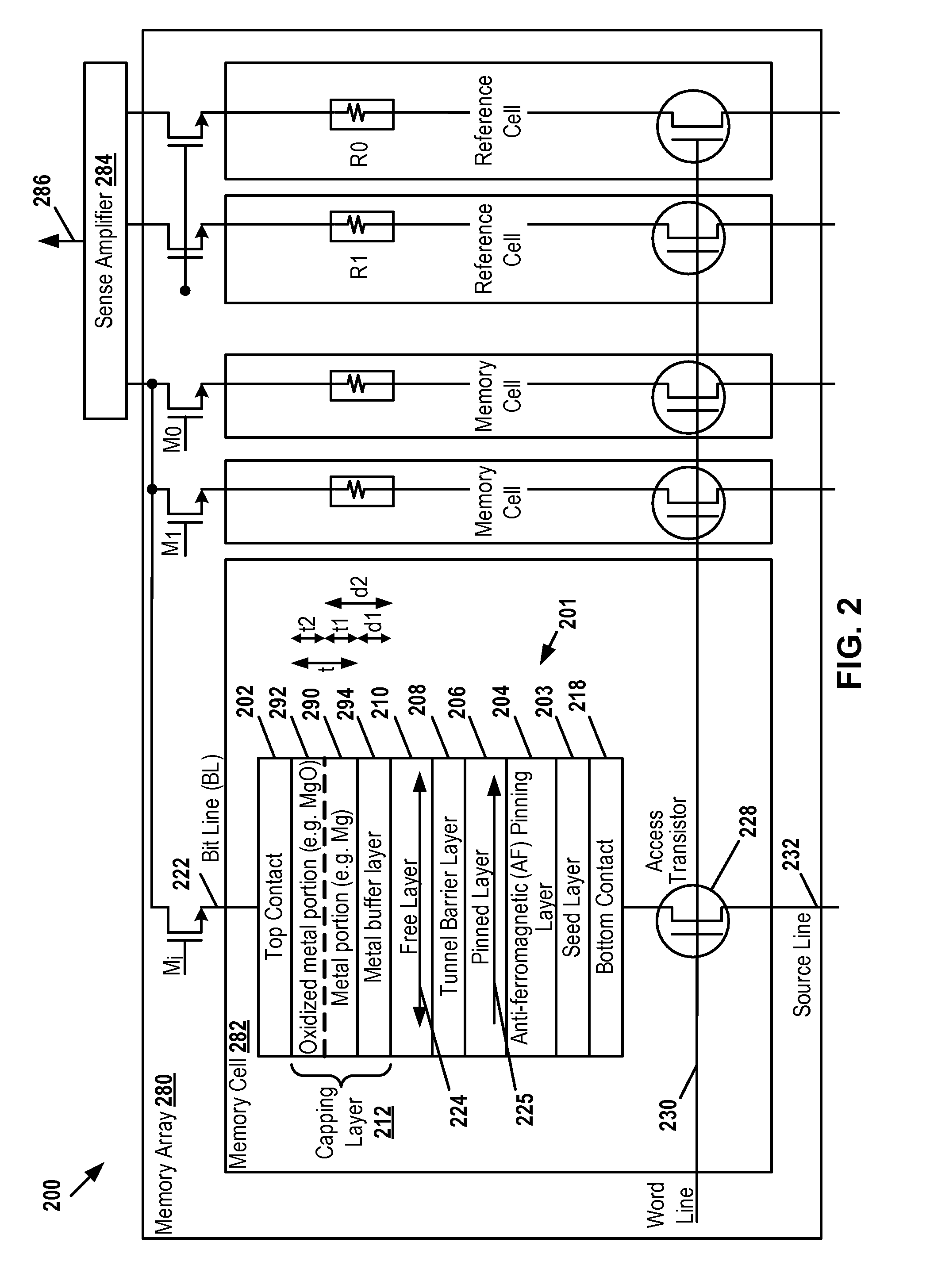

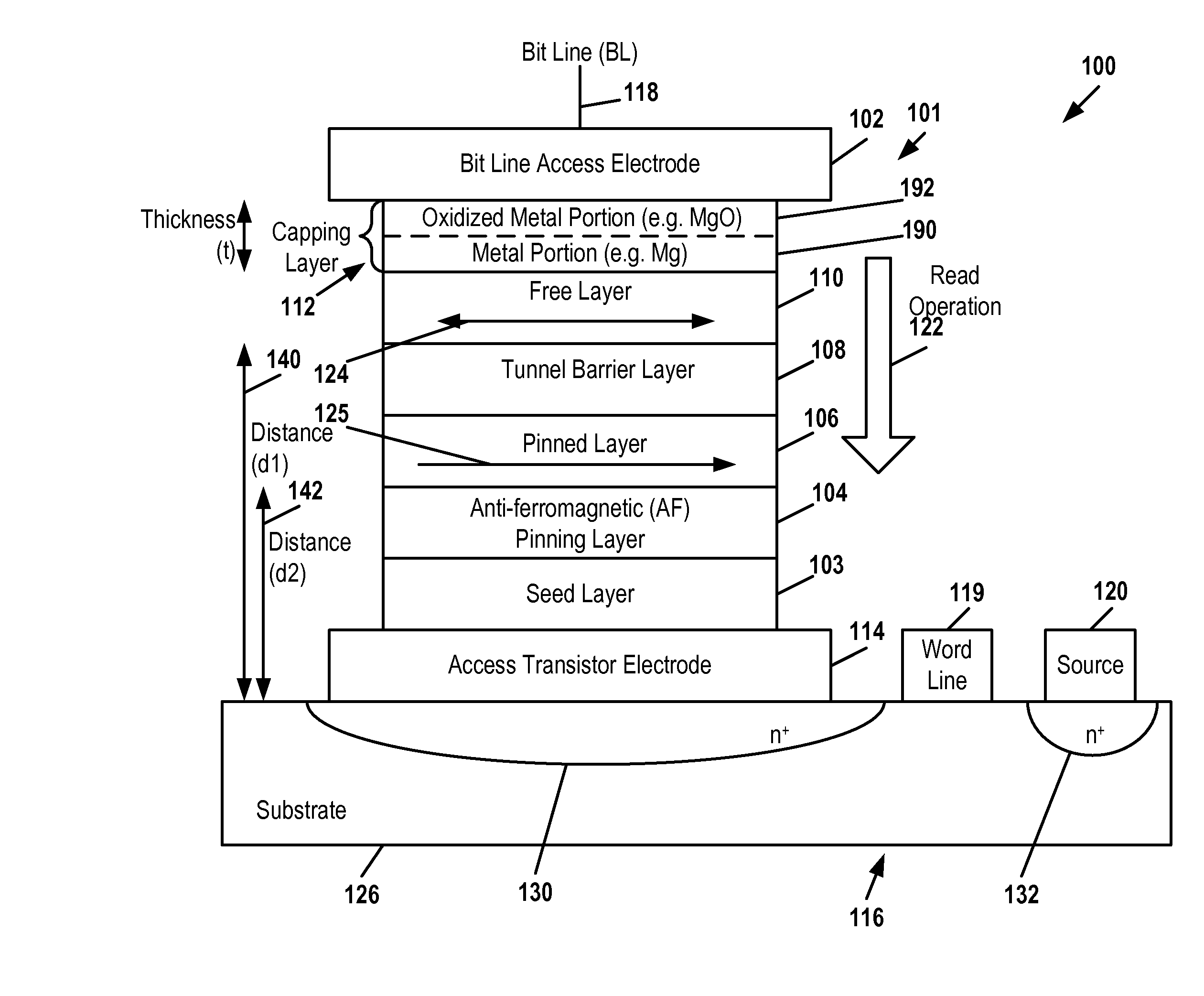

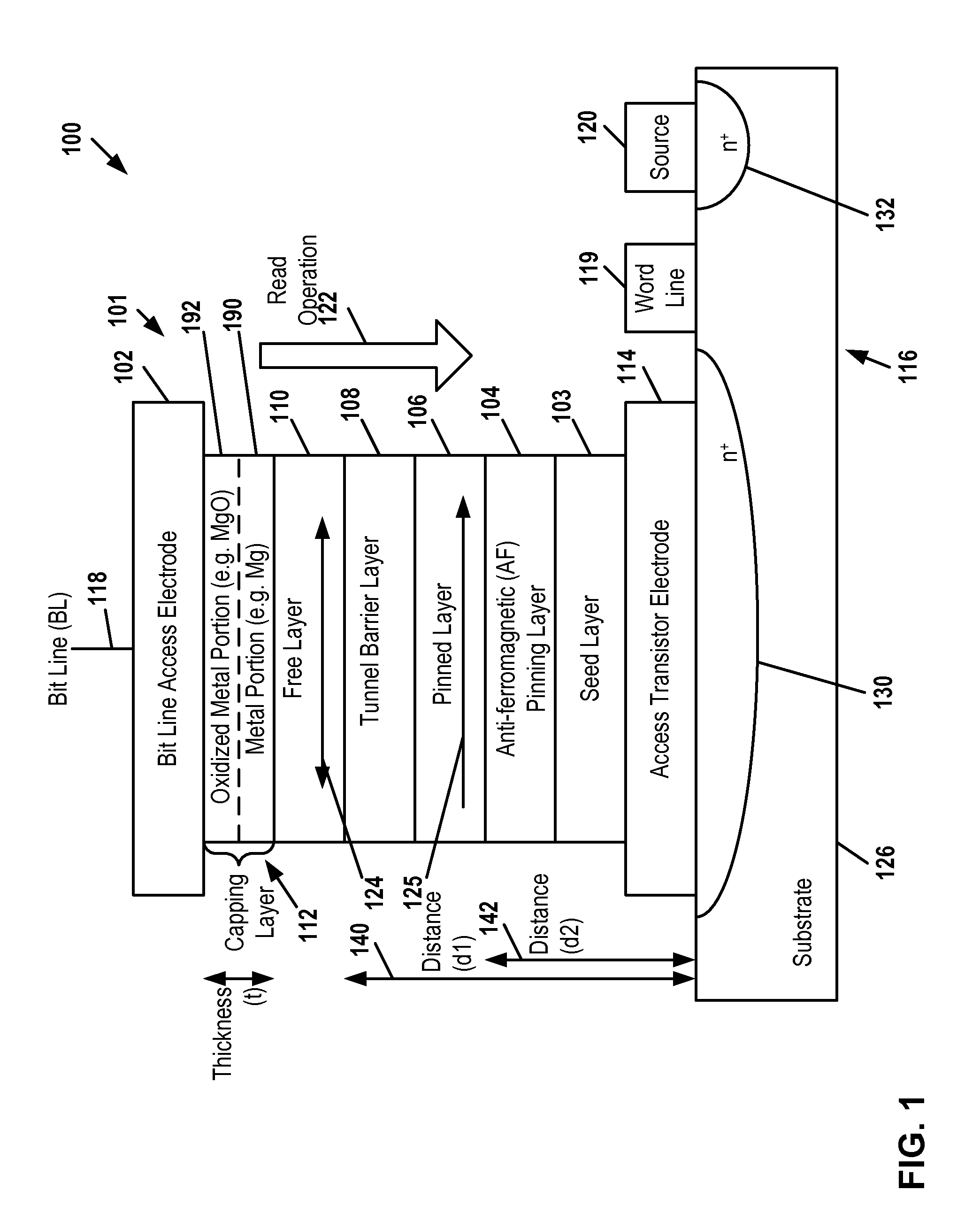

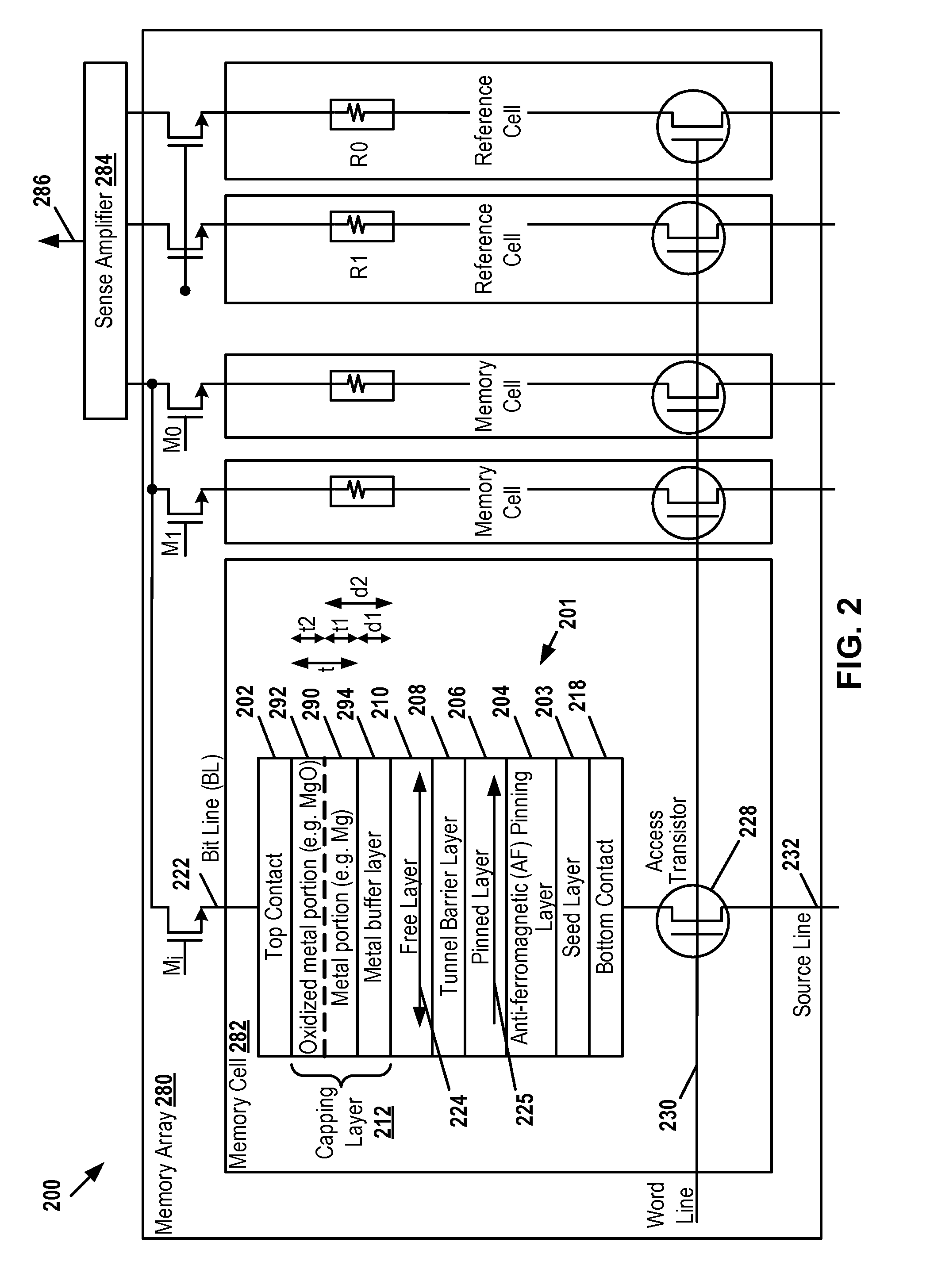

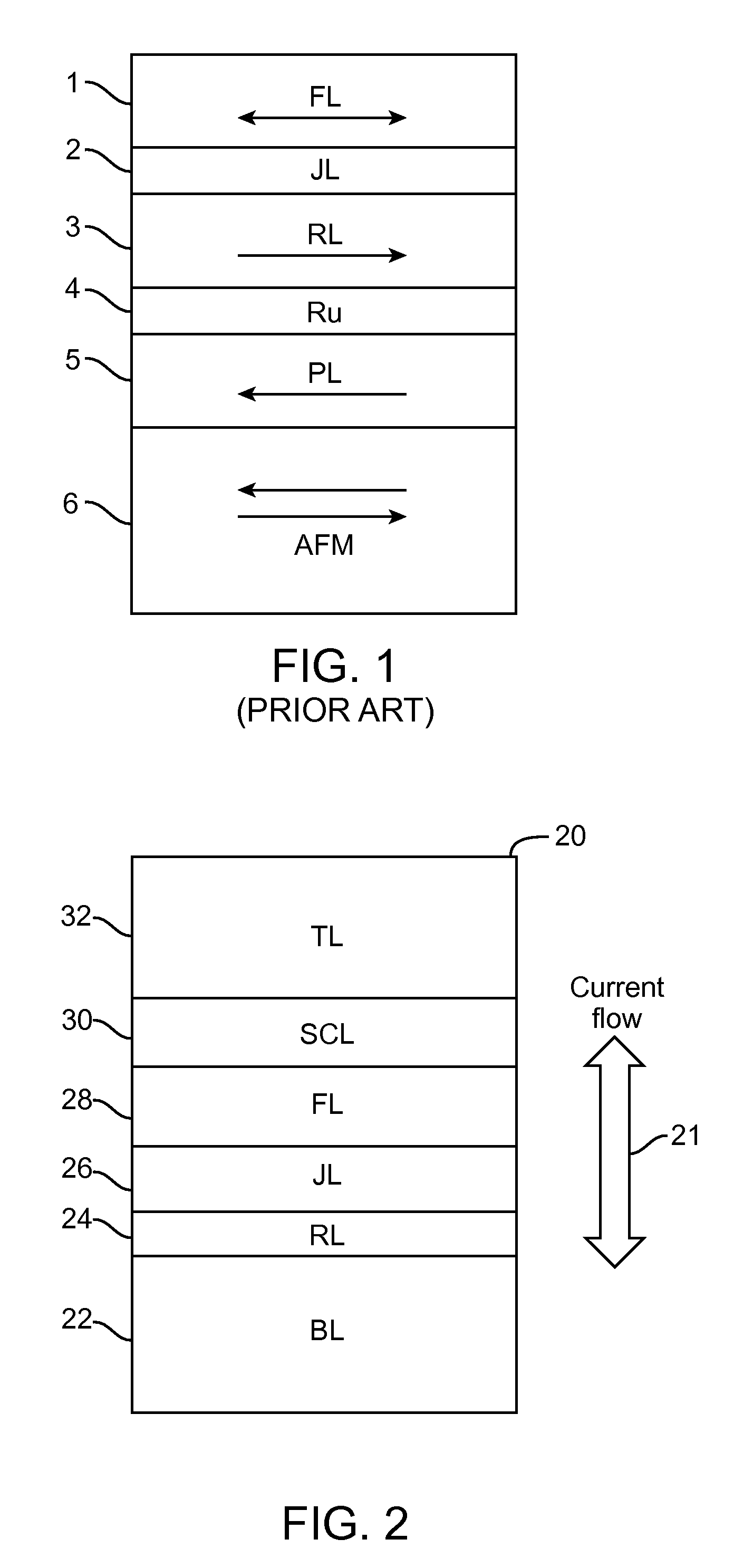

Magnetic Tunnel Junction Device and Fabrication

ActiveUS20100219491A1Low densityIncrease RANanomagnetismMagnetic-field-controlled resistorsEngineeringTunnel junction

Owner:QUALCOMM INC

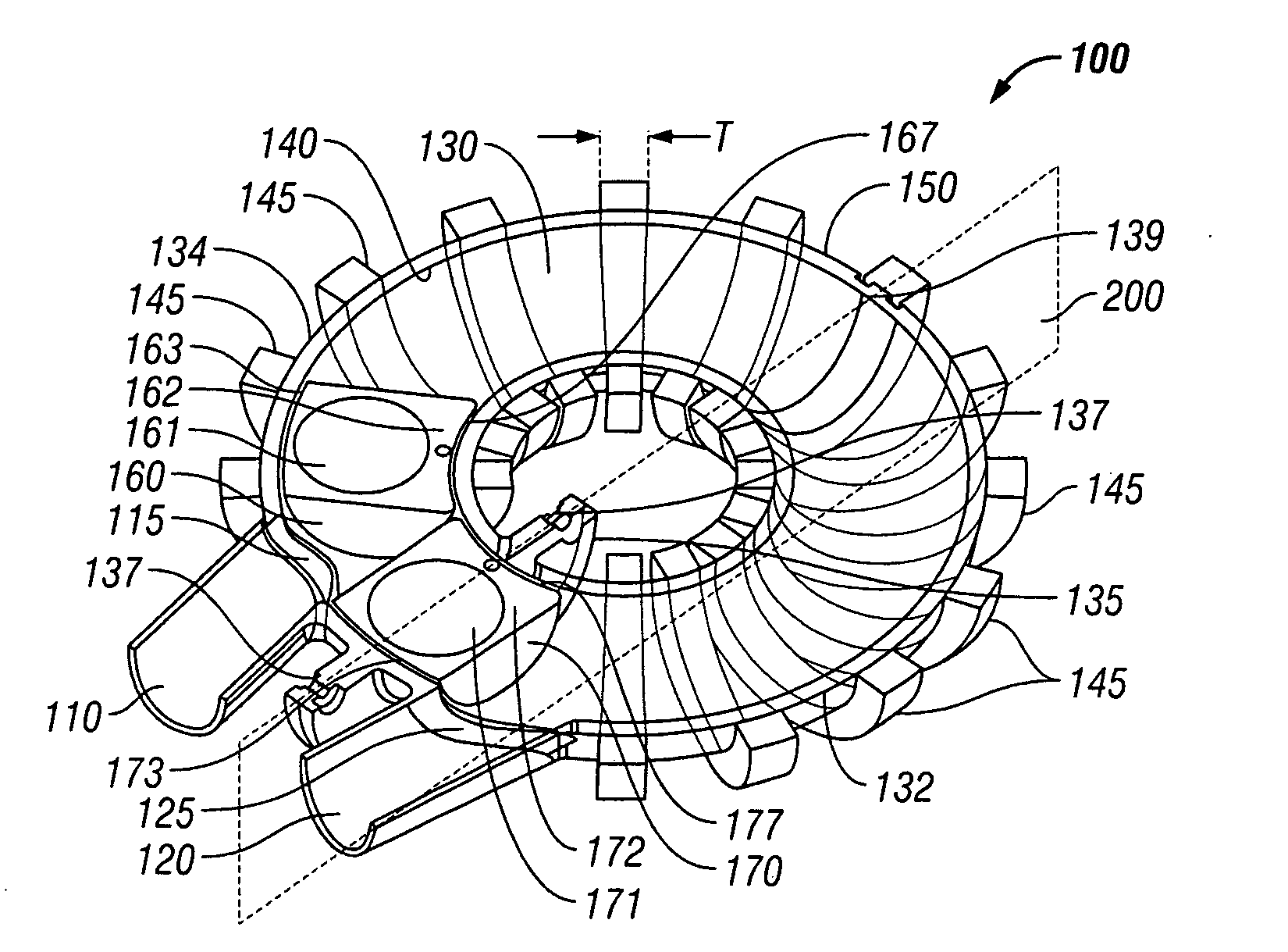

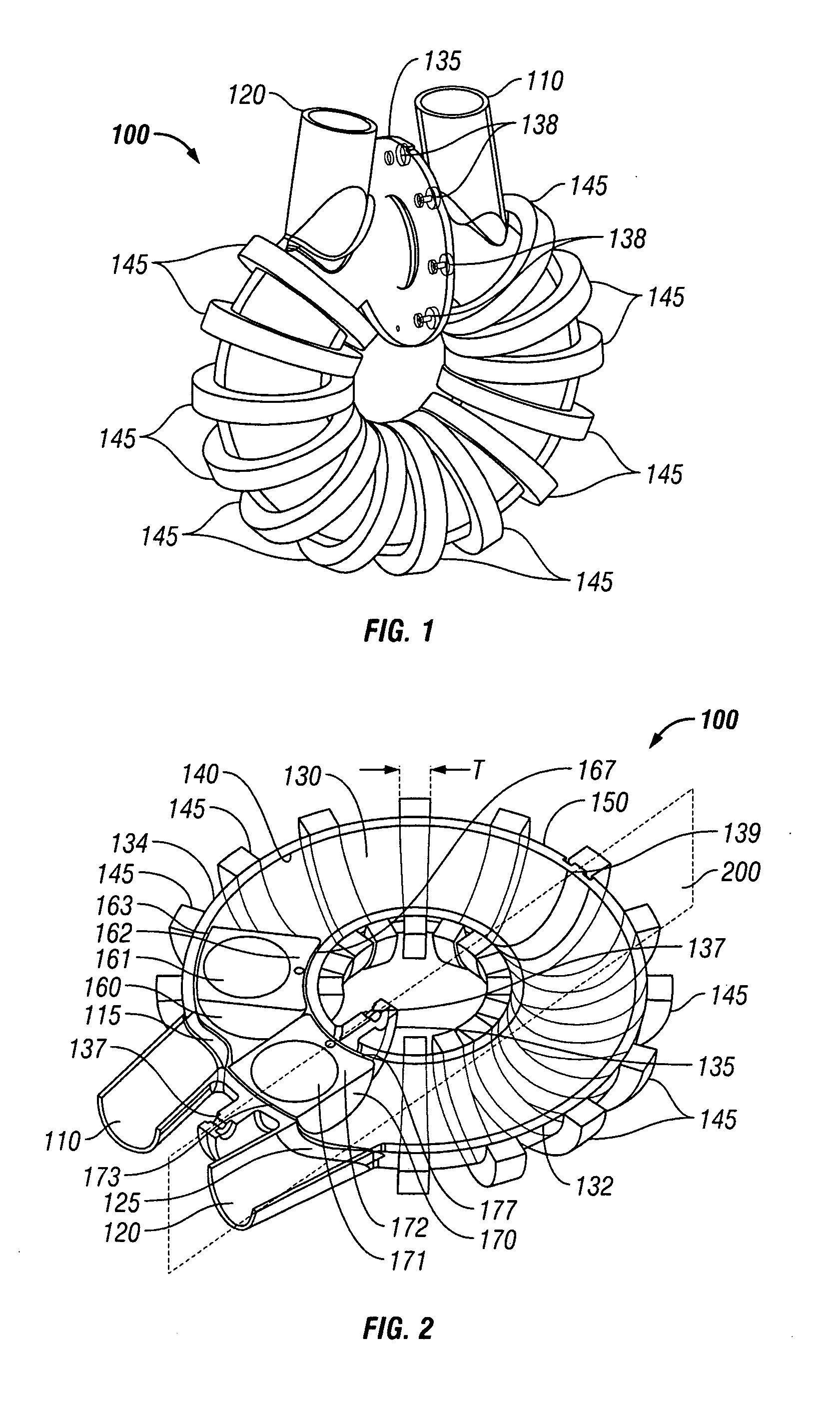

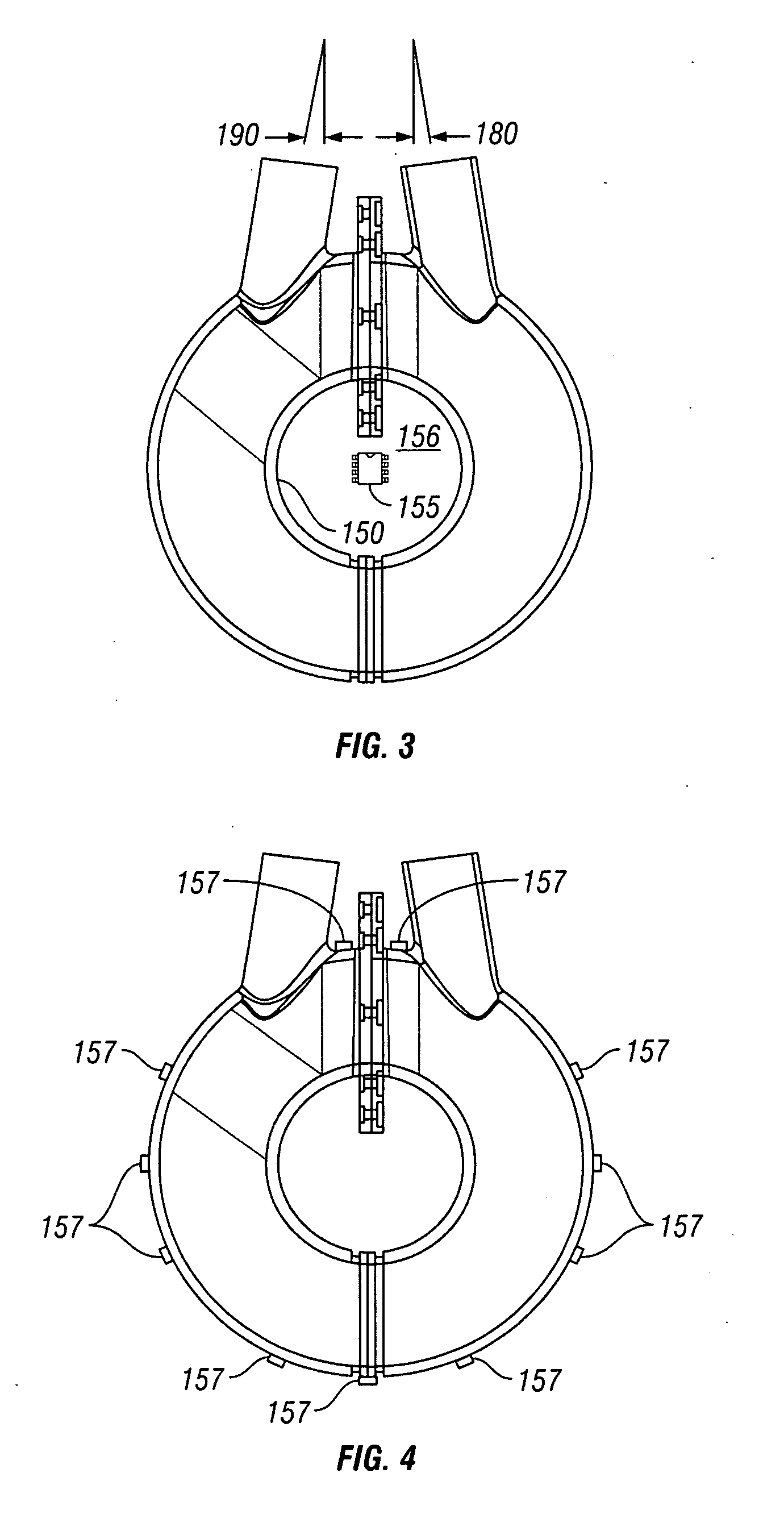

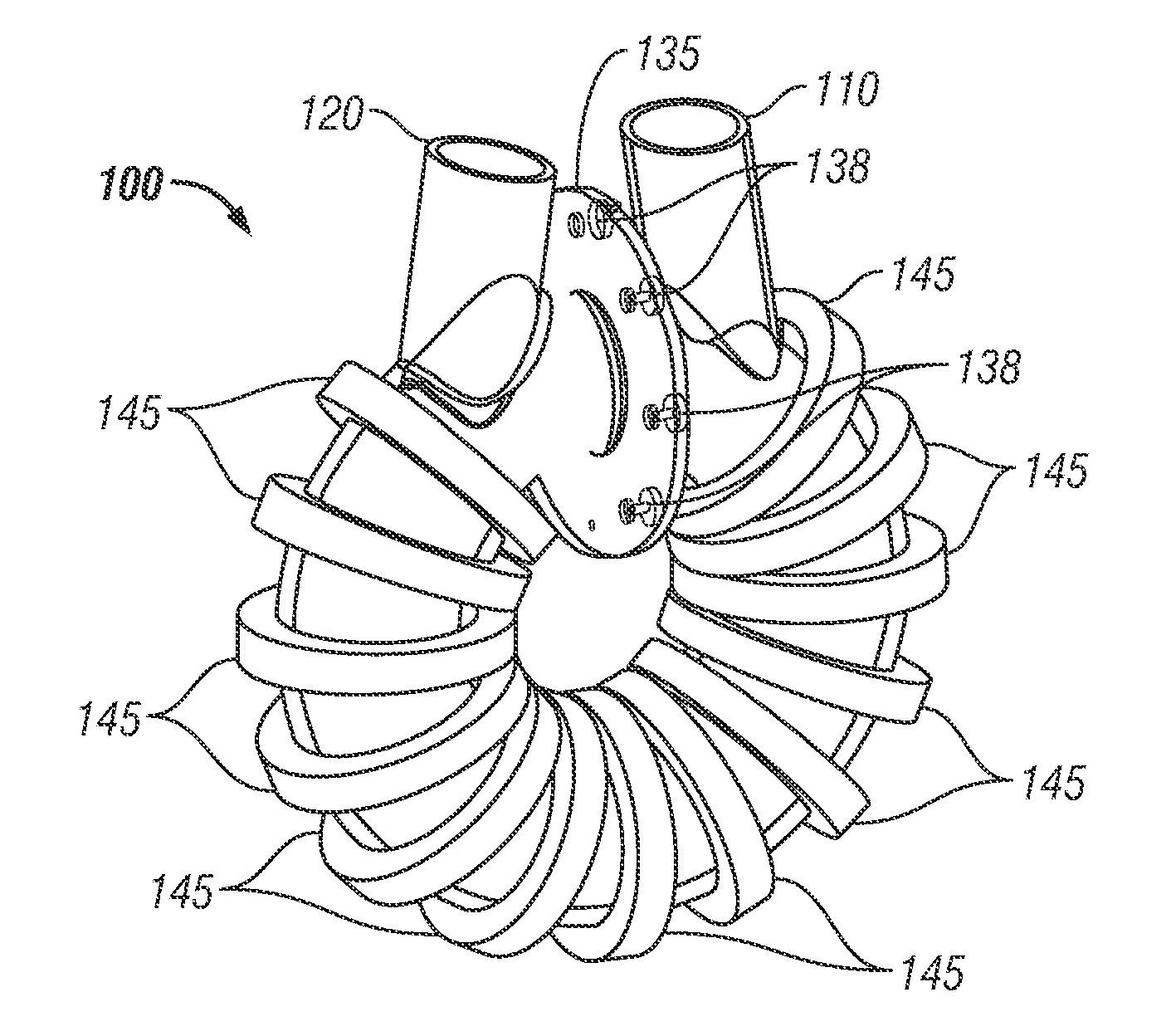

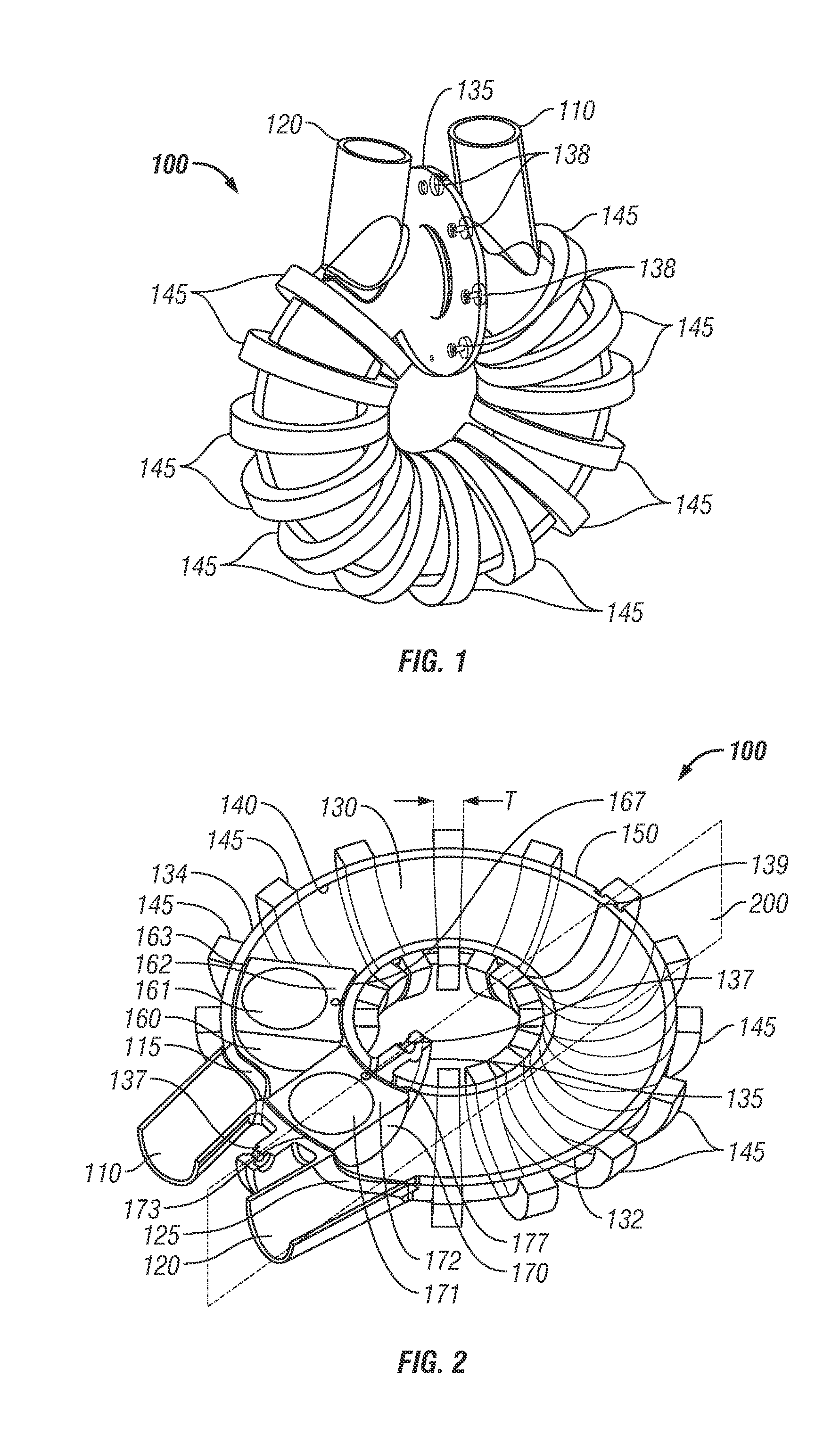

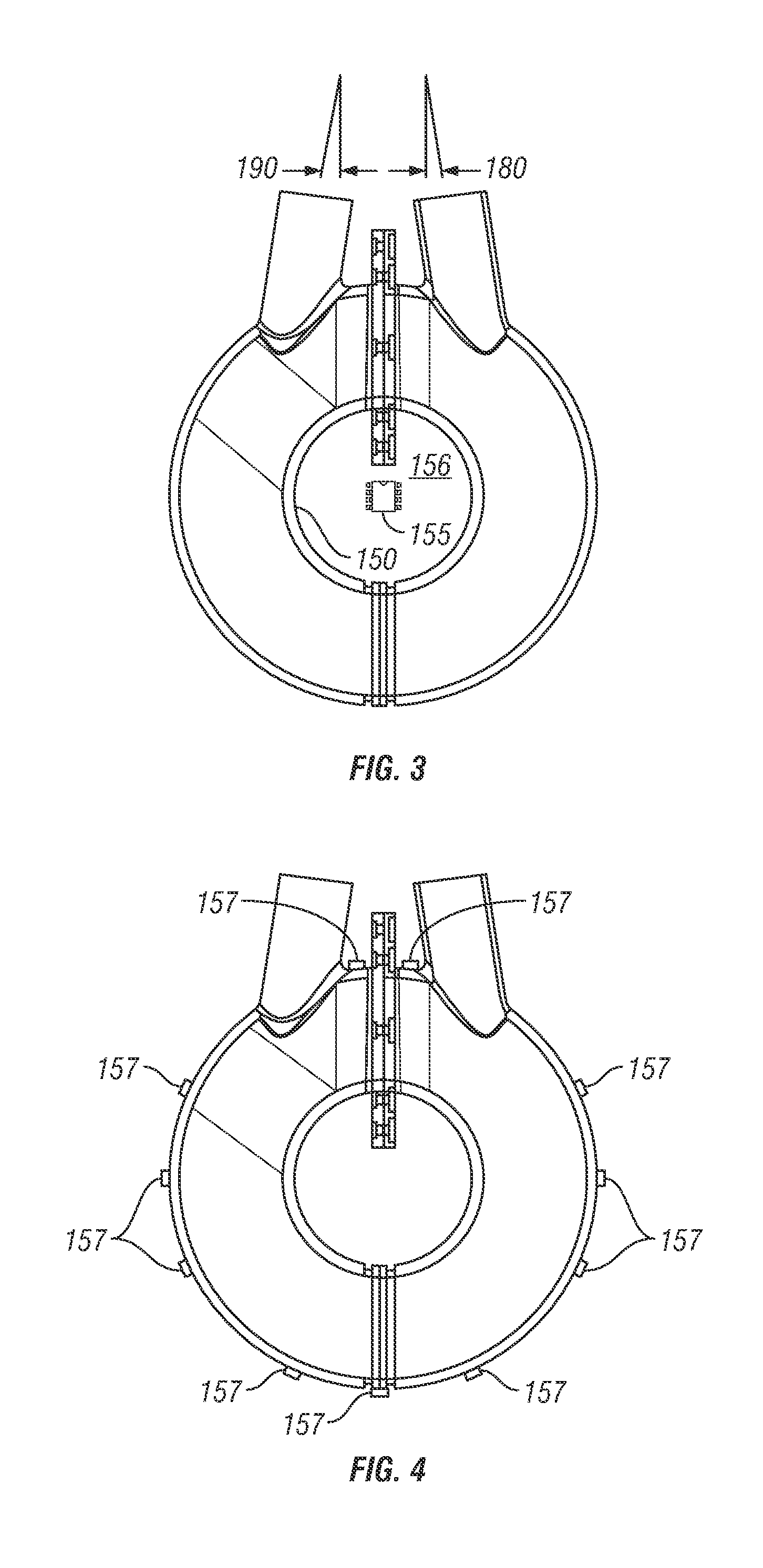

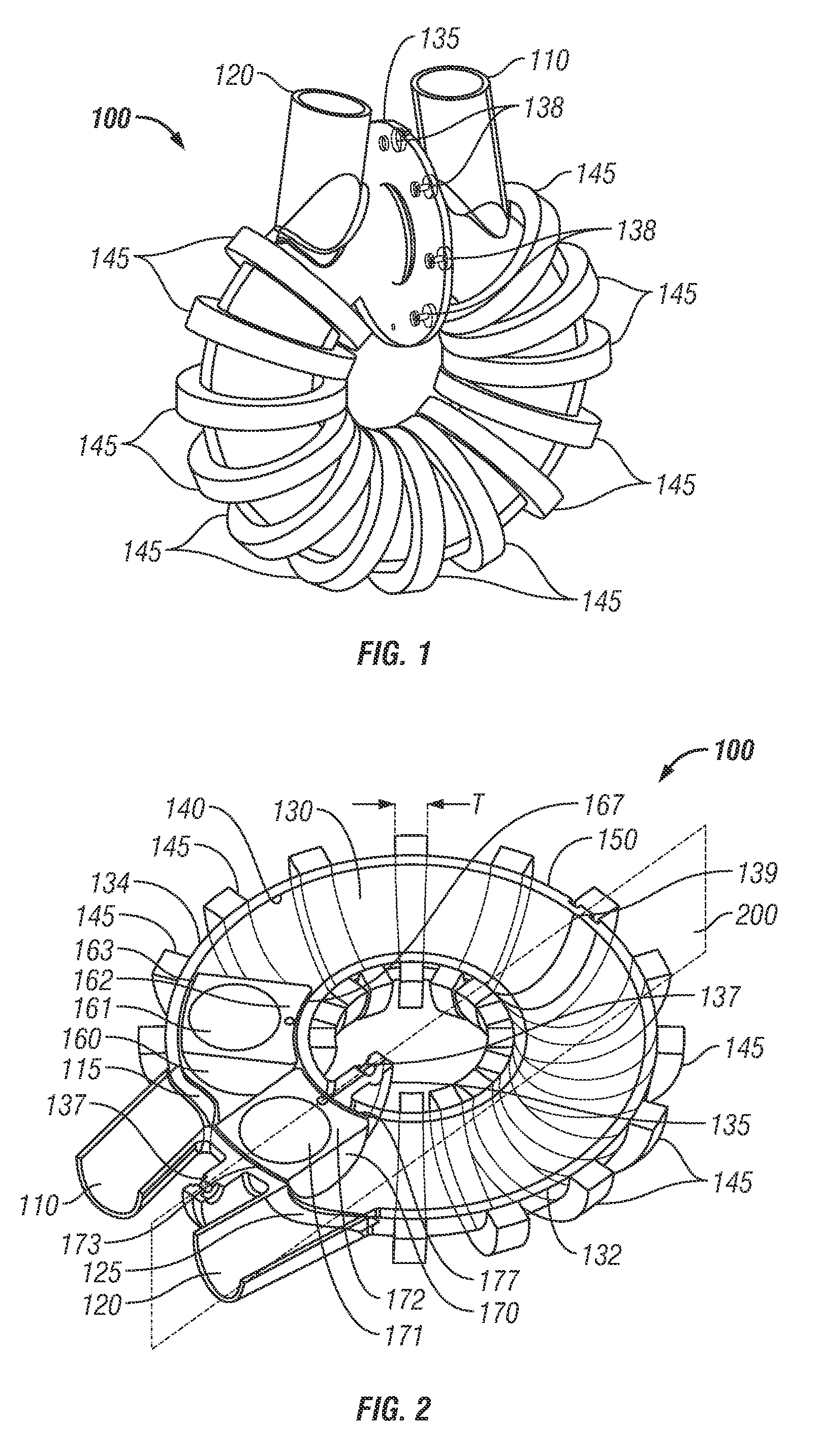

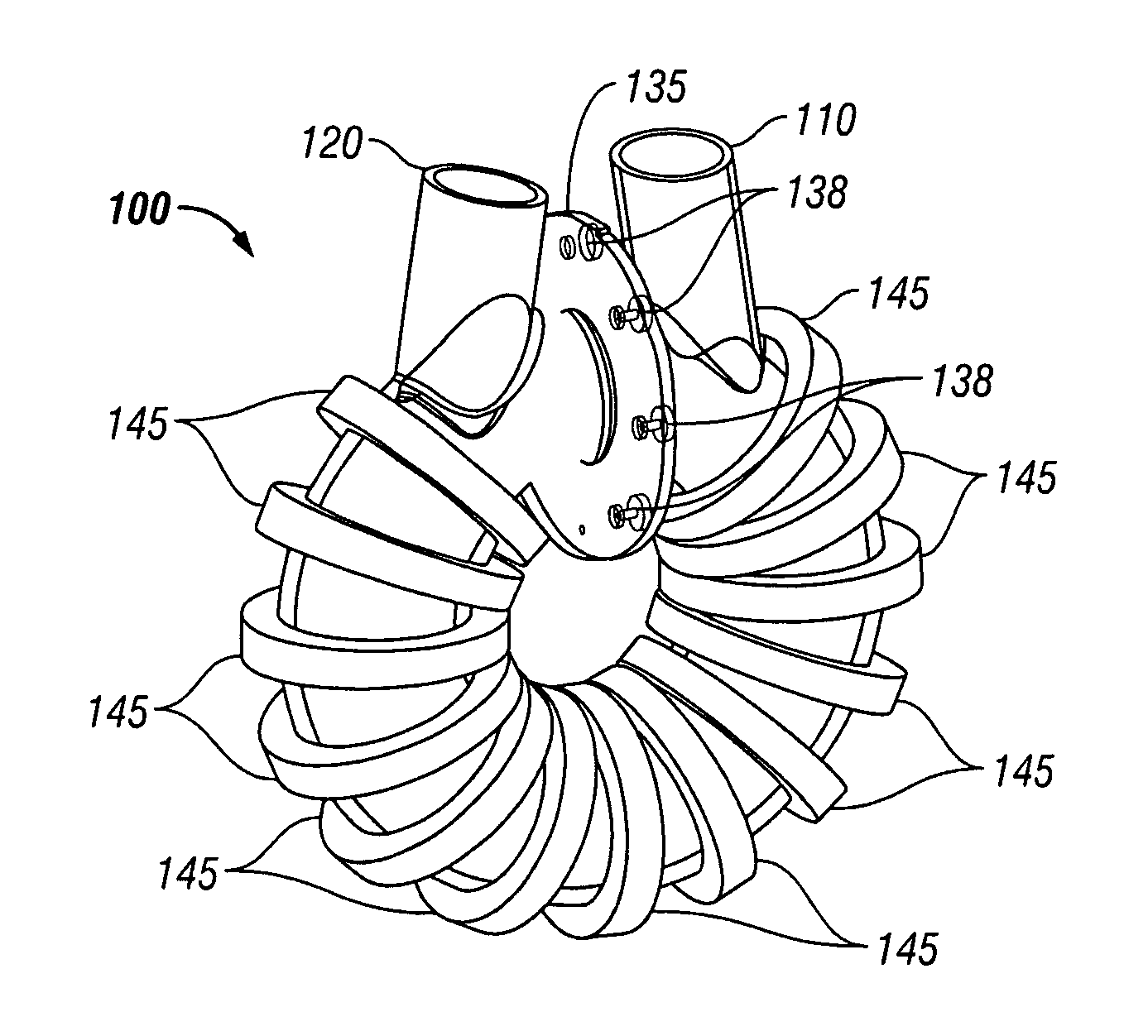

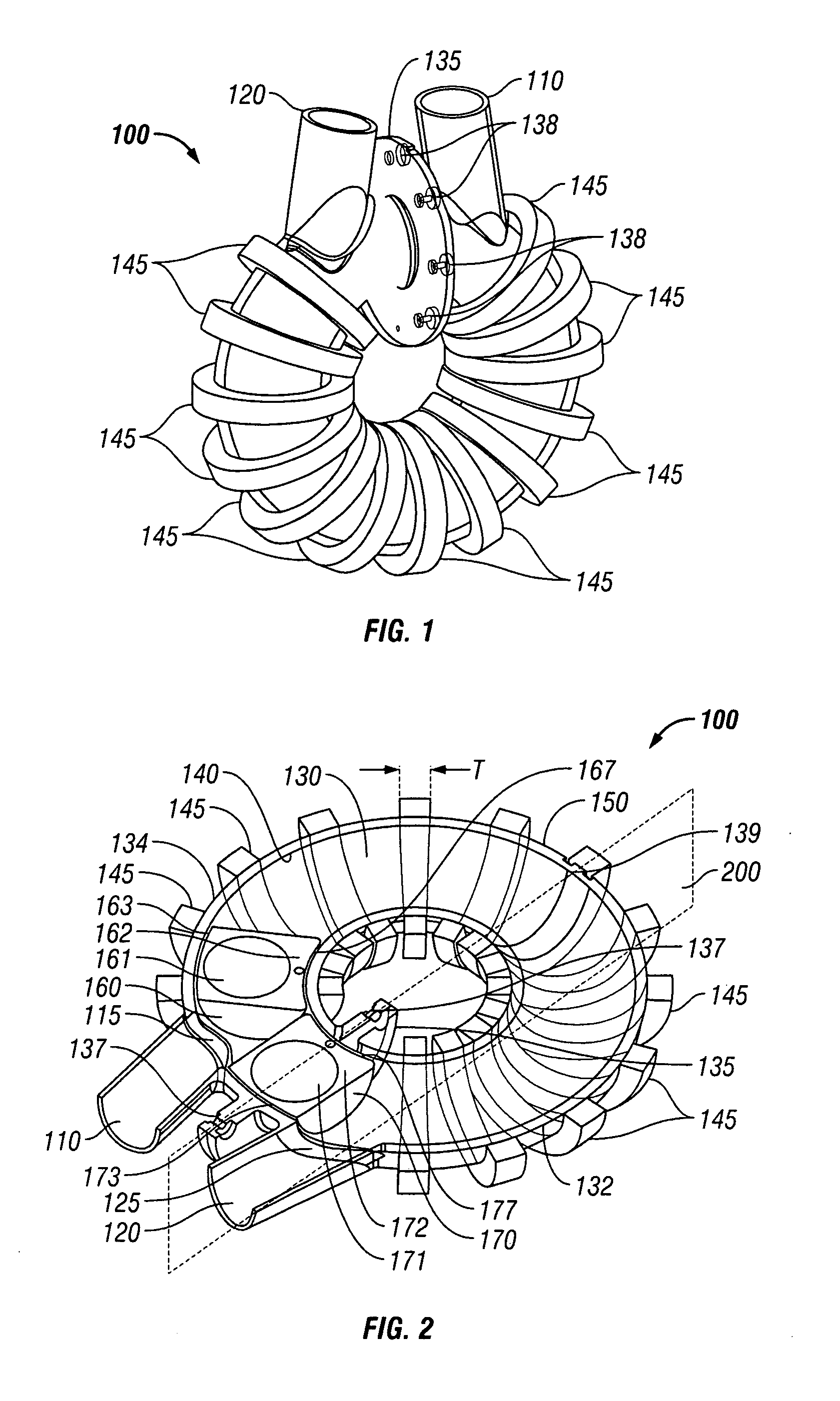

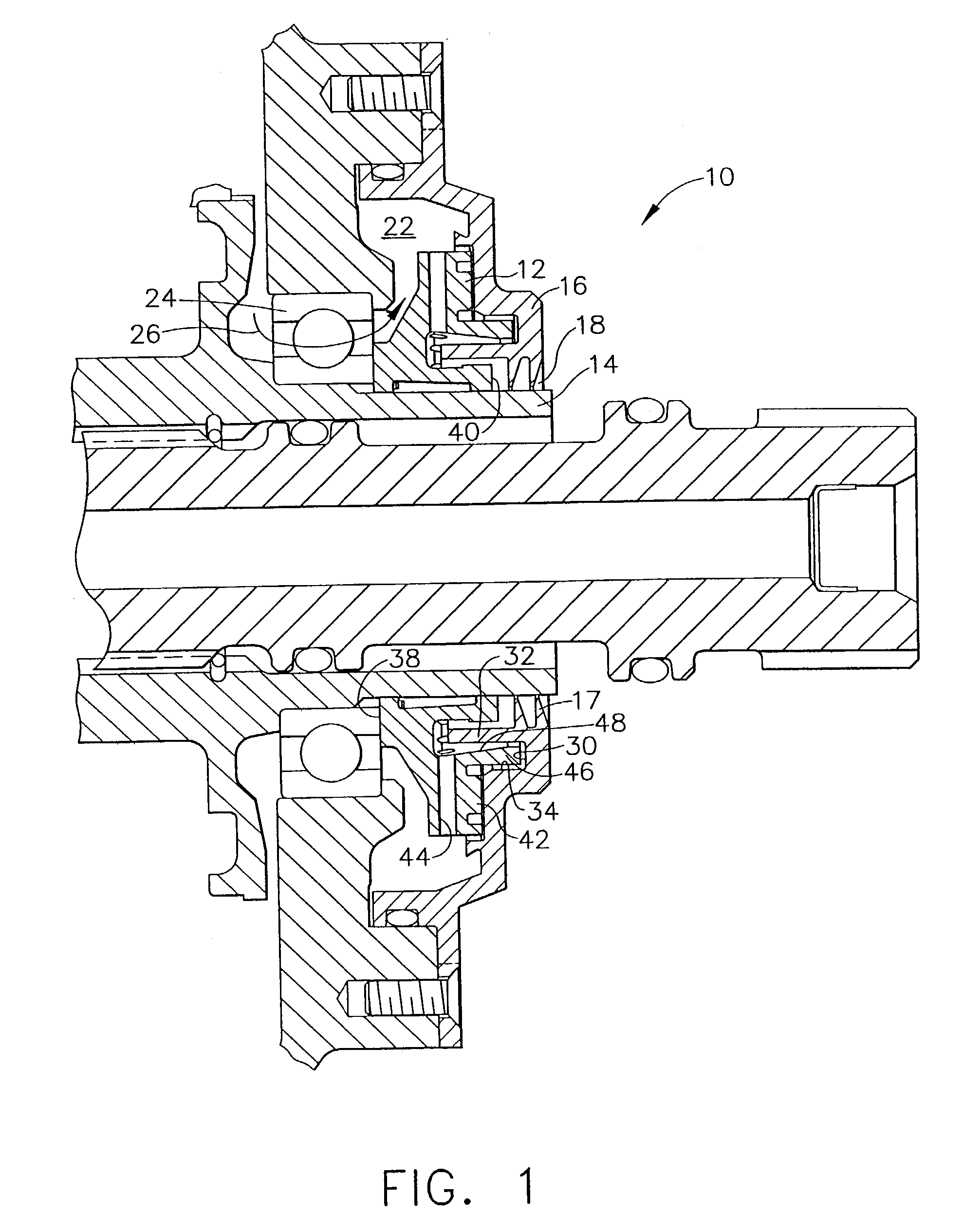

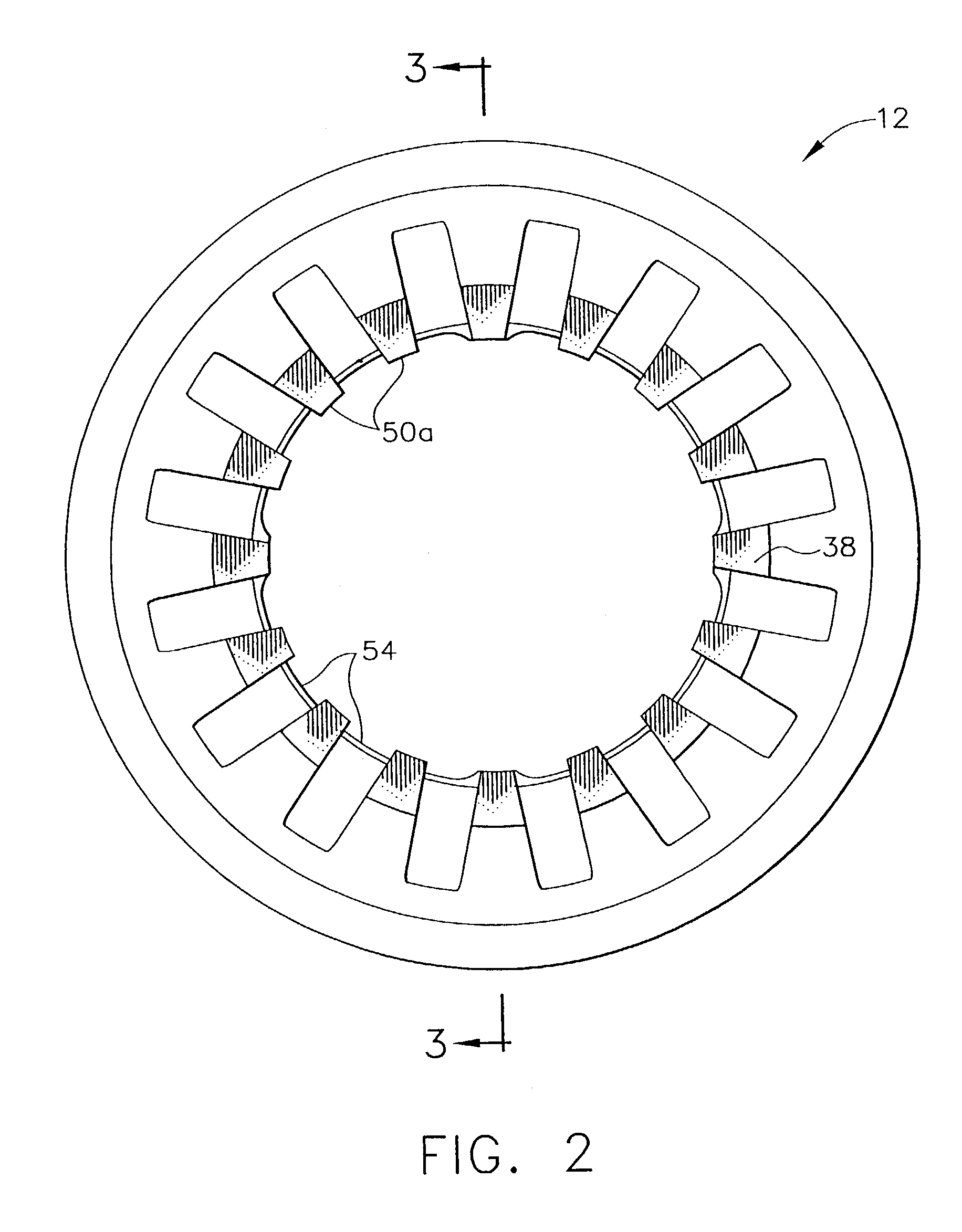

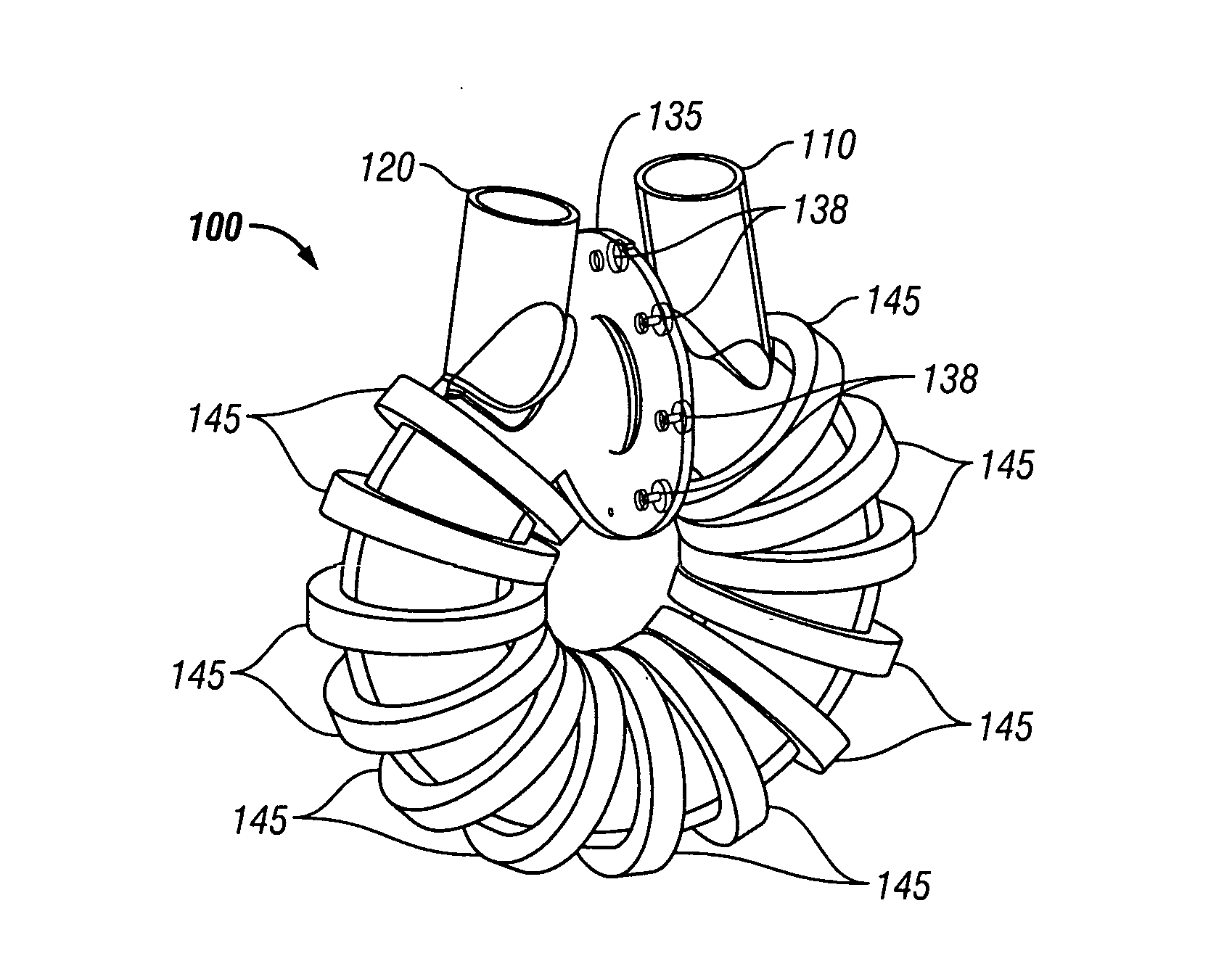

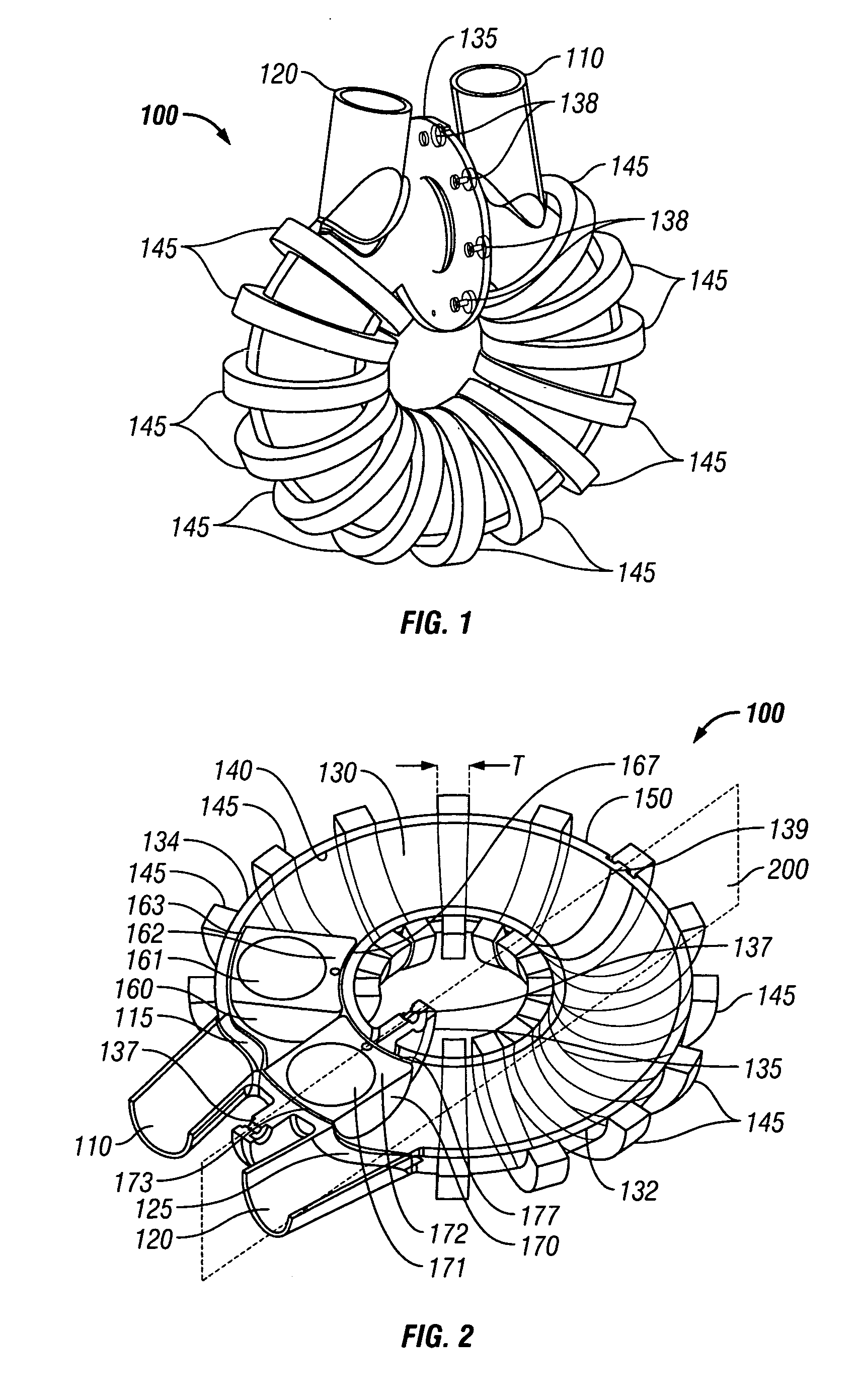

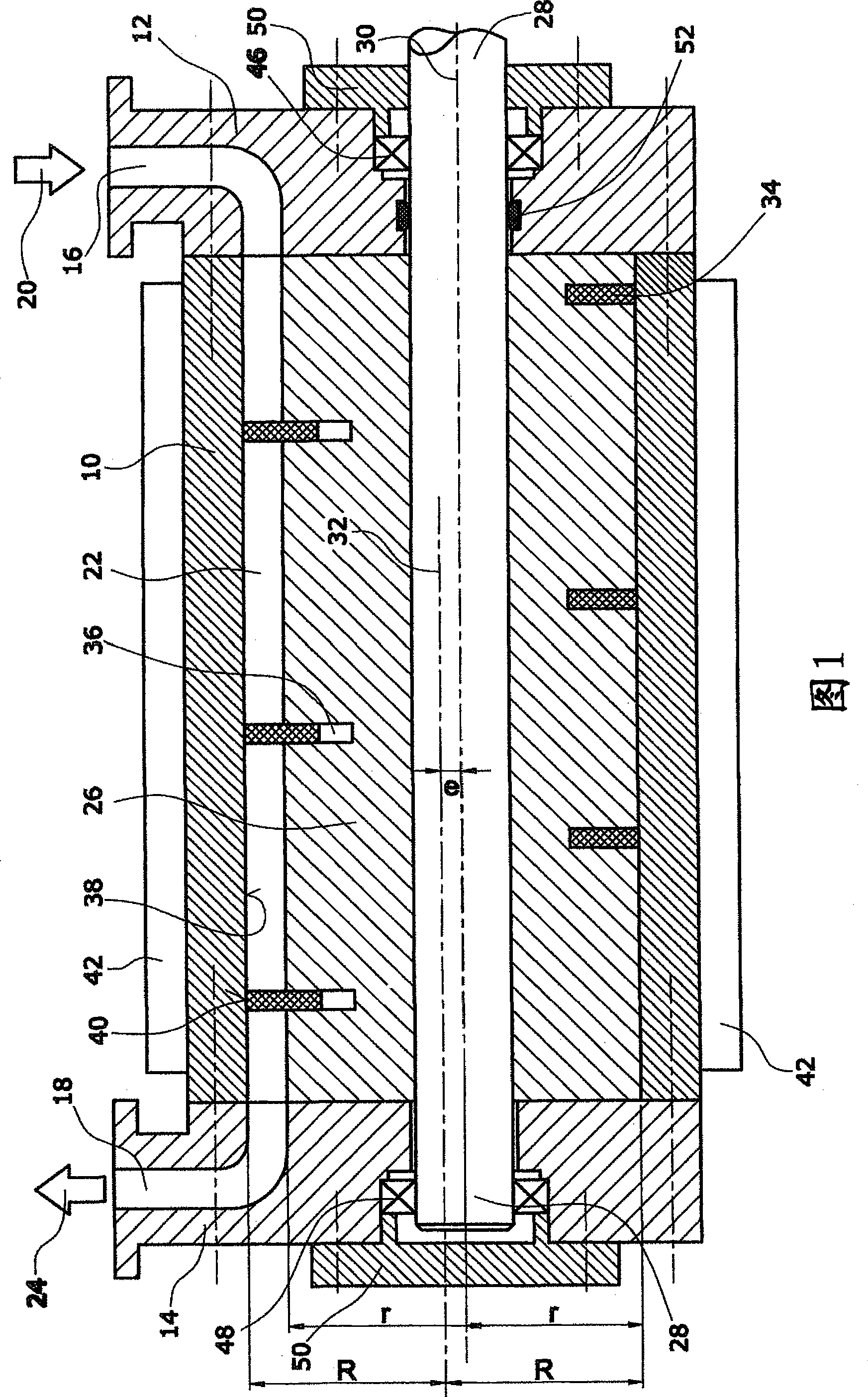

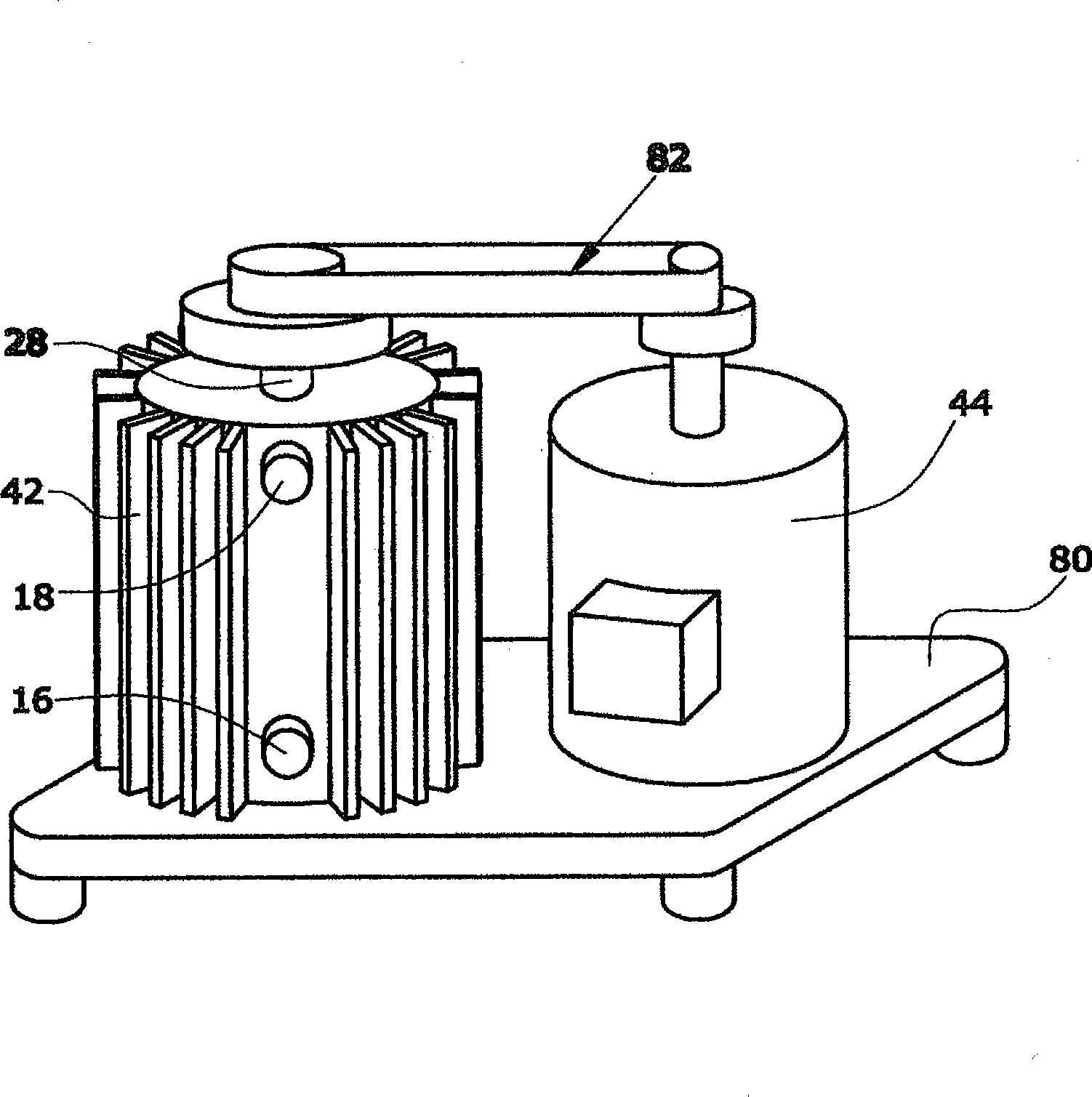

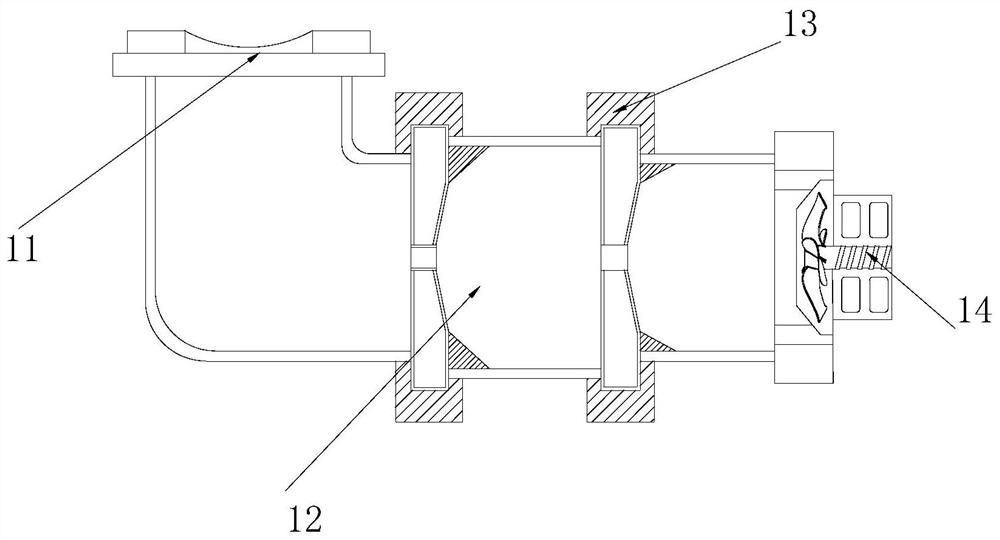

System and Method for Pump with Deformable Bearing Surface

ActiveUS20100266423A1Diminish performanceIncrease areaPositive displacement pump componentsFlexible member pumpsPistonBearing surface

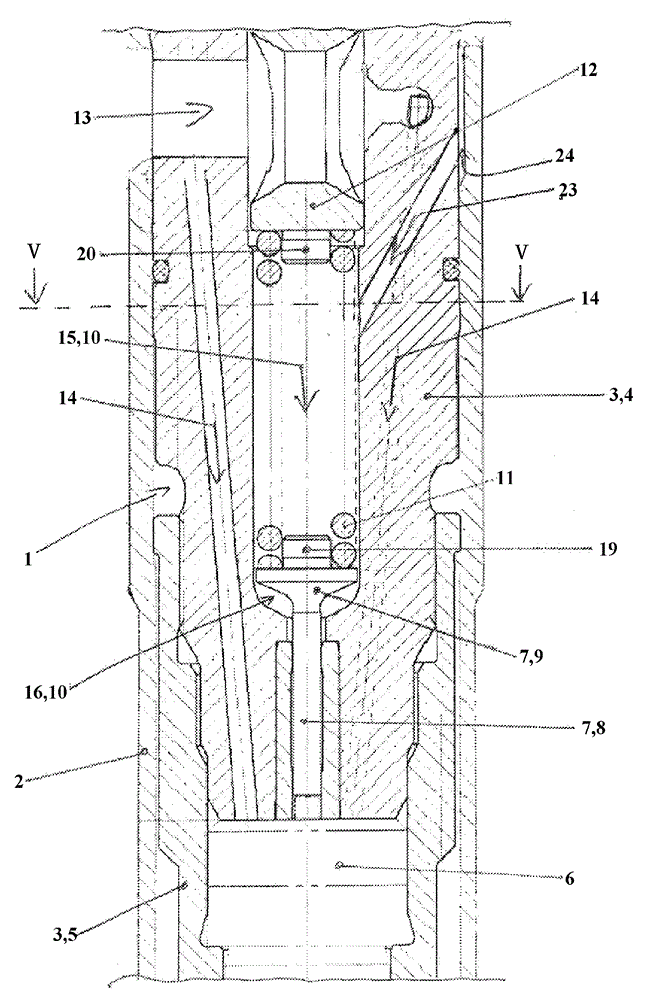

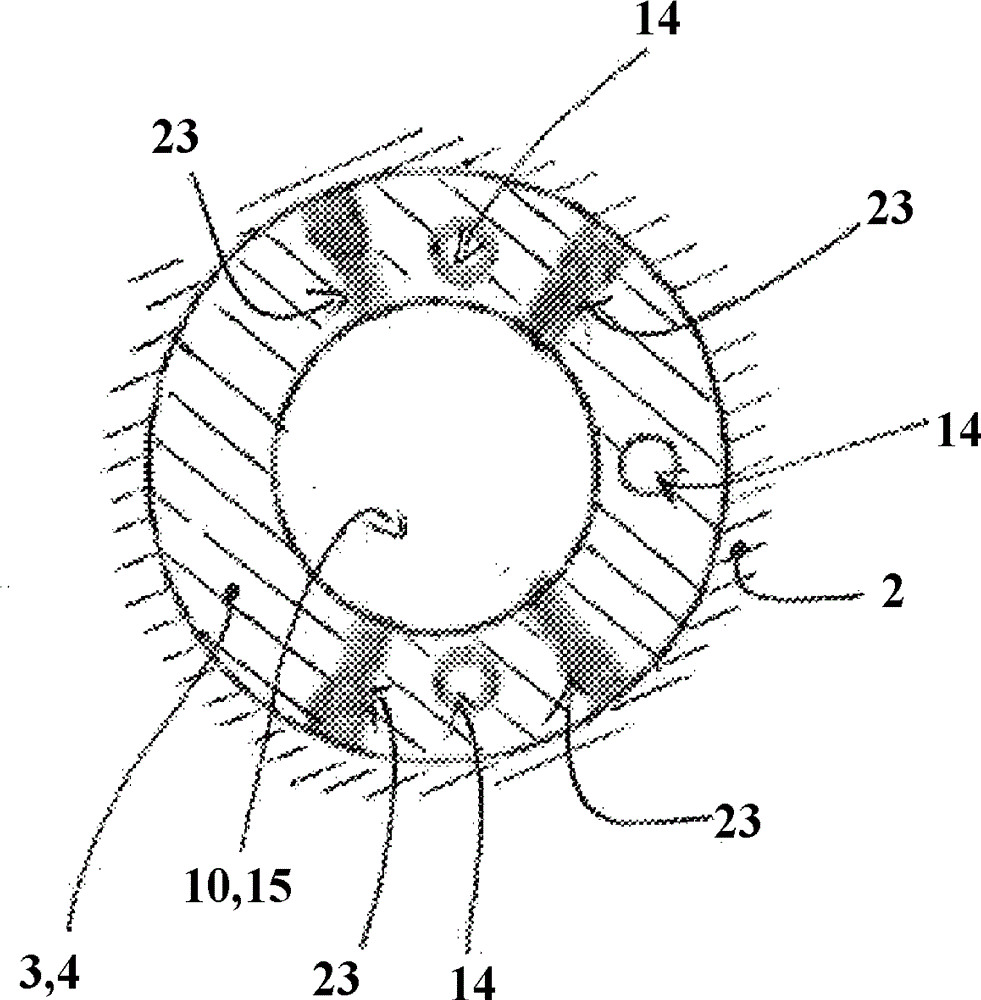

Systems and methods for pumping fluid comprising a pumping chamber, a pump inlet, a pump outlet, a valving mechanism, and a drive piston or pumping chamber wall including a deformable surface configured to provide elastohydrodynamic lubrication during operation.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

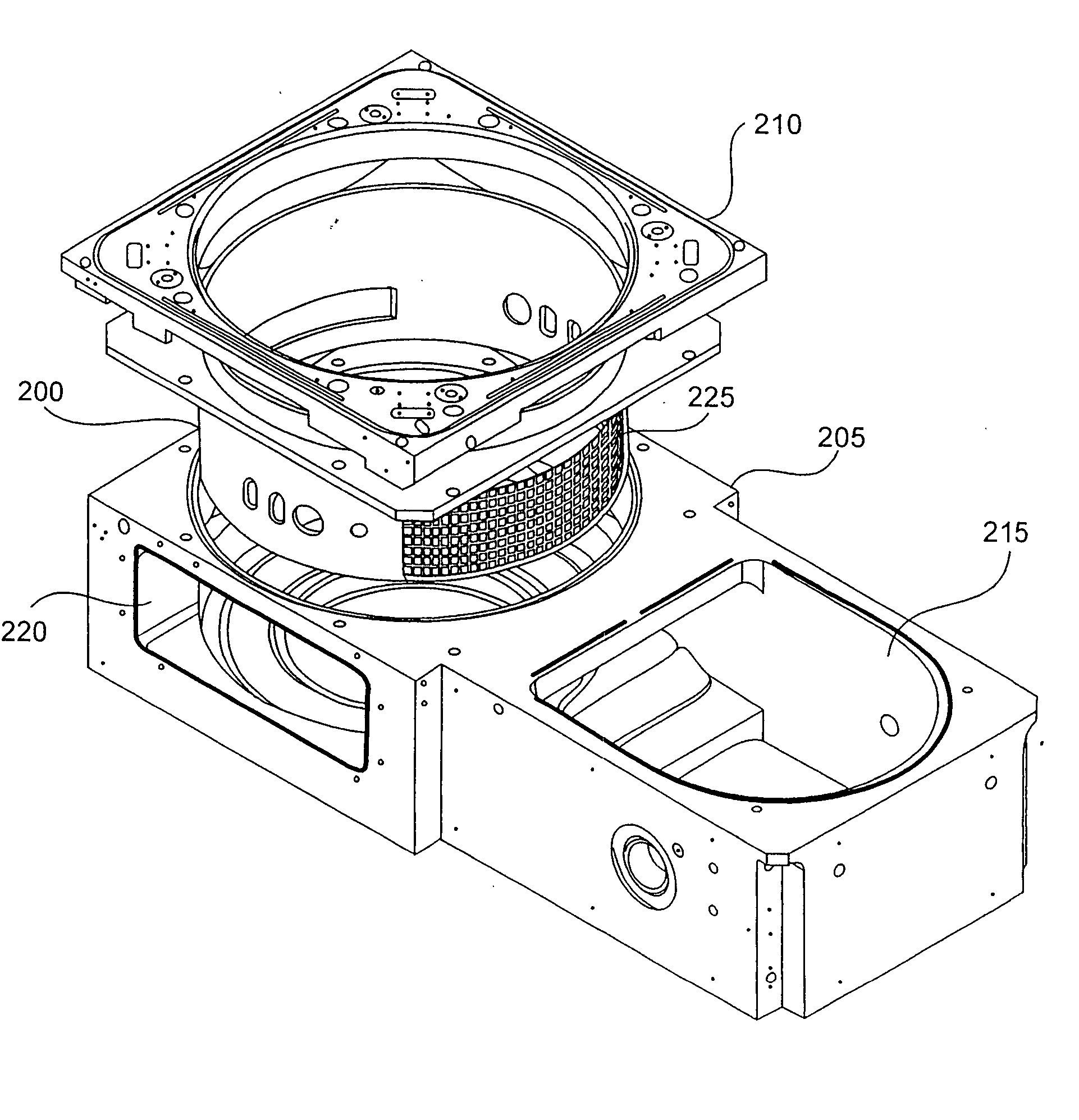

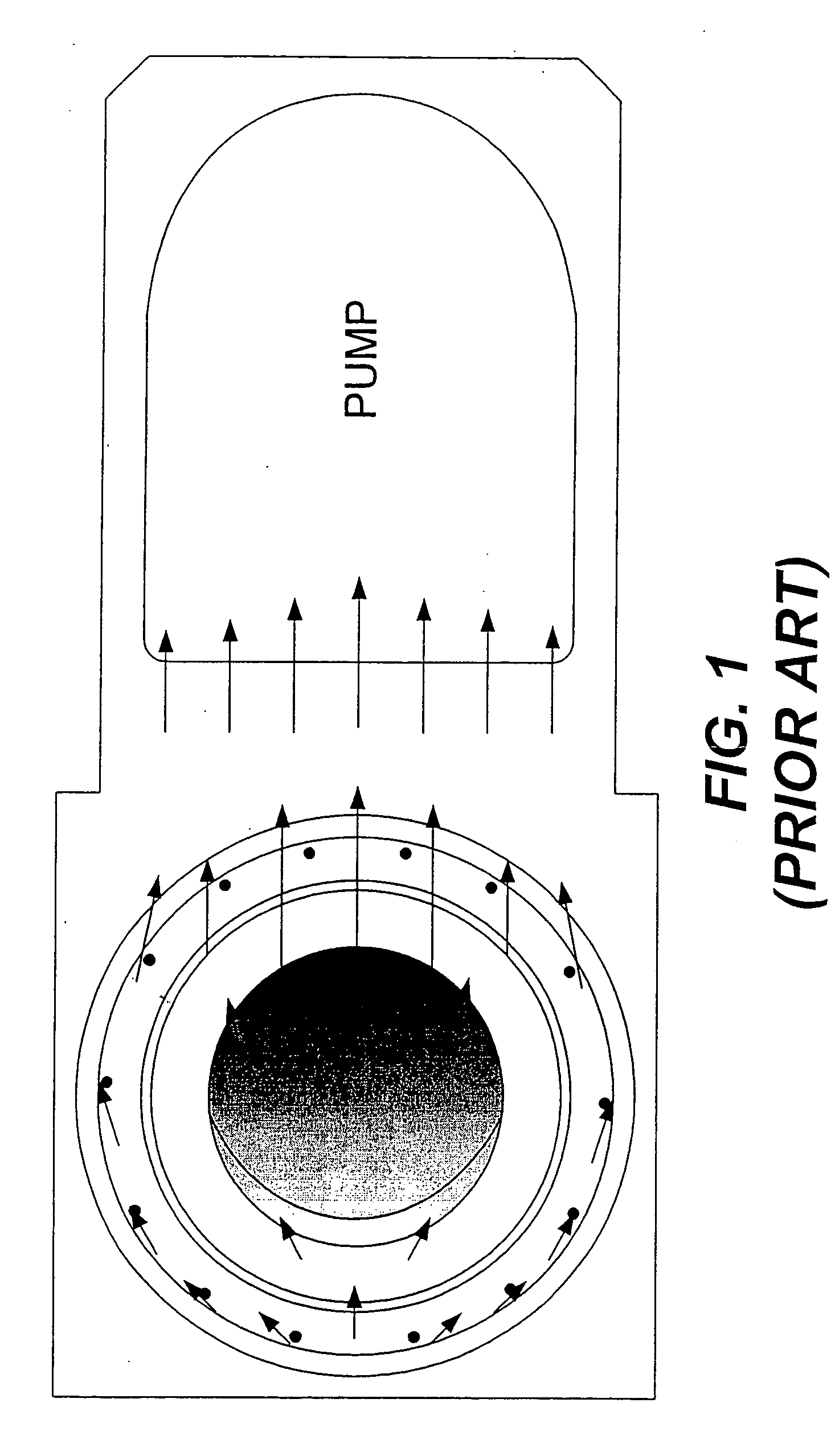

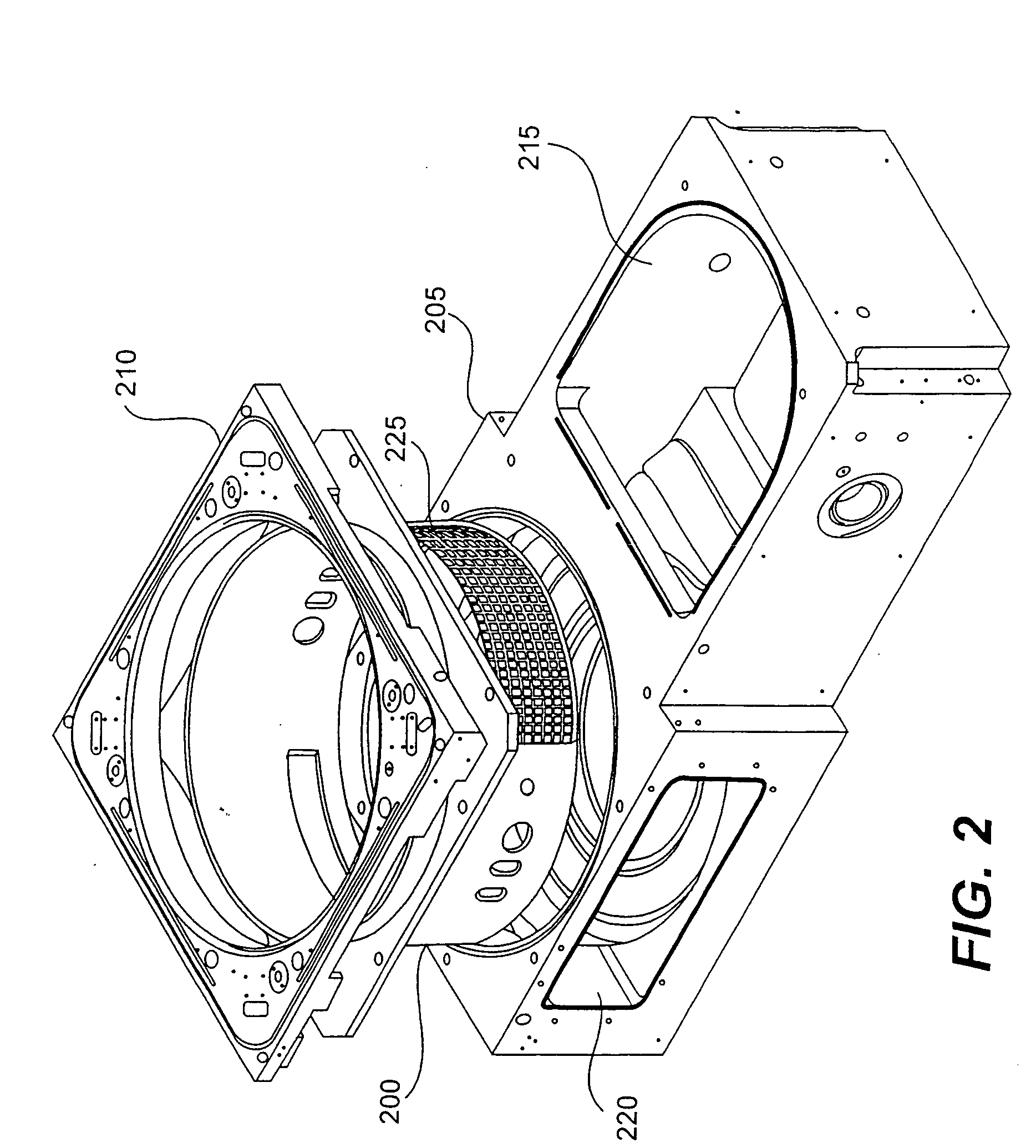

Pump baffle and screen to improve etch uniformity

InactiveUS20050121143A1Reduces asymmetric pumping effectReduce violationsElectric discharge tubesSemiconductor/solid-state device manufacturingDropout voltageGas concentration

A cylindrical pump baffle fitted to a semiconductor processing chamber is disclosed. The pump baffle contains a screen with bores therethrough to allow process gasses from the process chamber to be exhausted from the chamber at a reduced rate. This decreases process discrepancies to the wafer due to the prejudice of gas concentration as a result of the pressure differential imposed upon the gas and thereby the wafer brought about by the rapid and relatively unimpeded exit flow of process gasses when no restrictive member is in place. The pump baffle is also machined such that it does not block the placement and removal of wafers by the platform robot arm.

Owner:LAM RES CORP

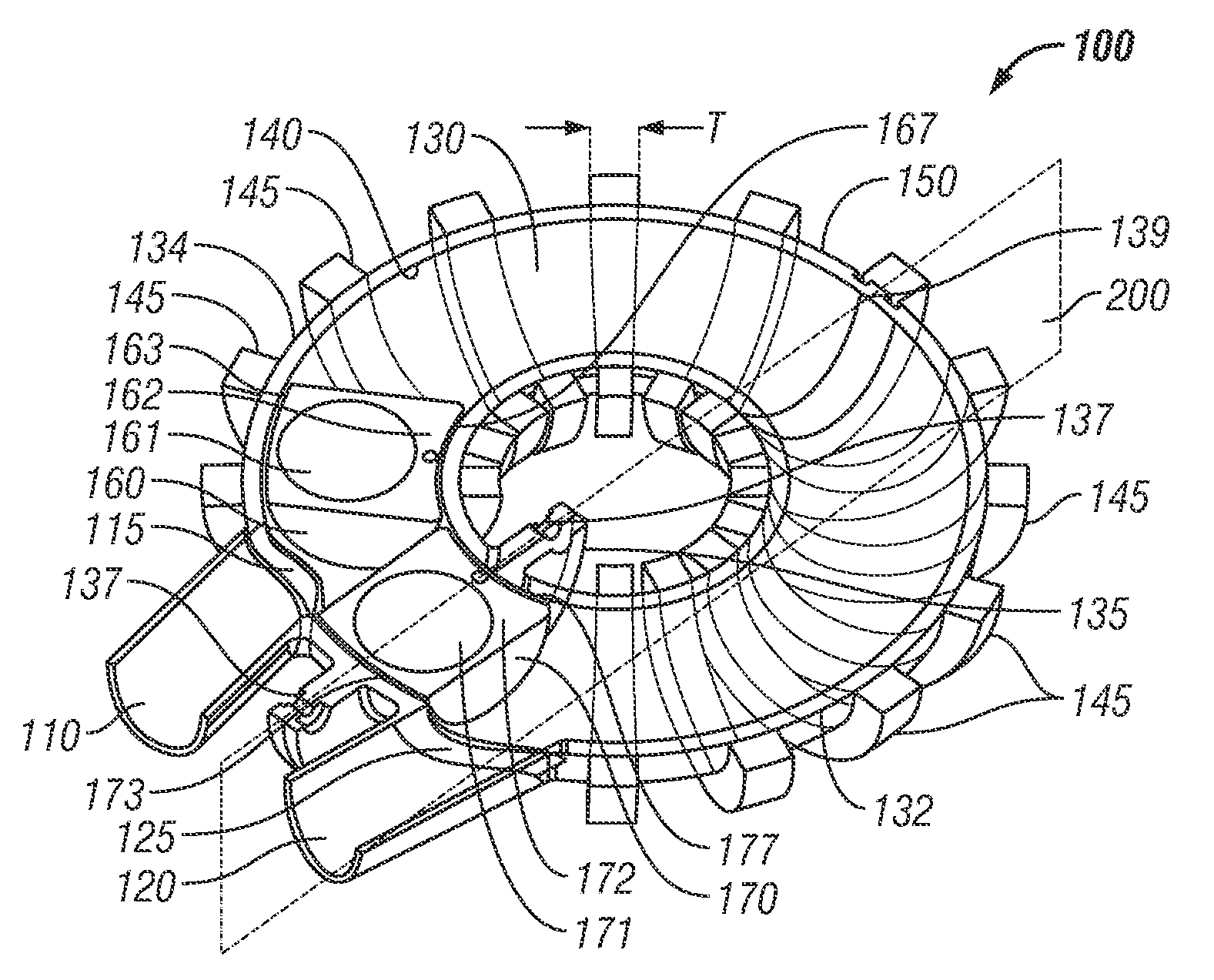

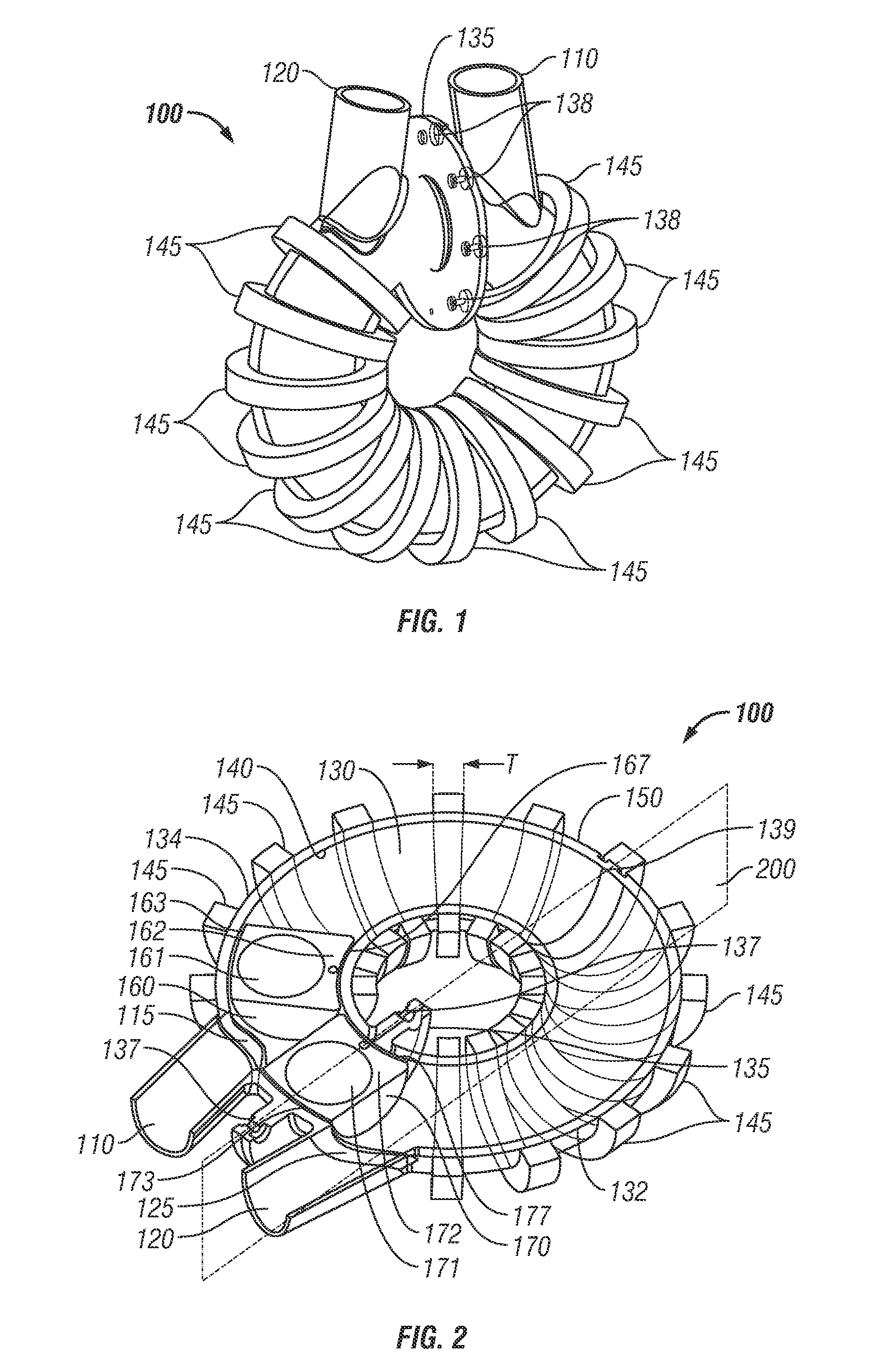

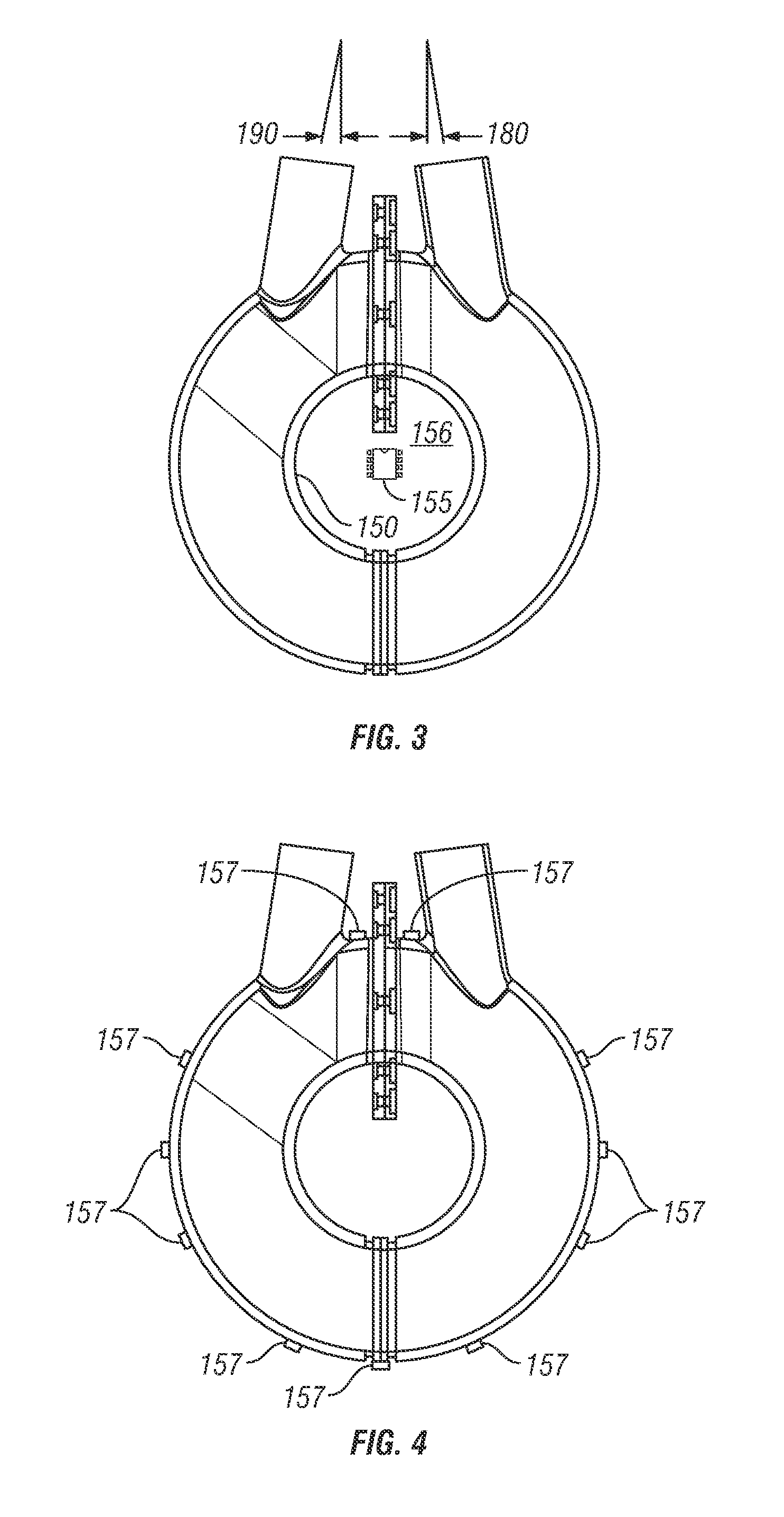

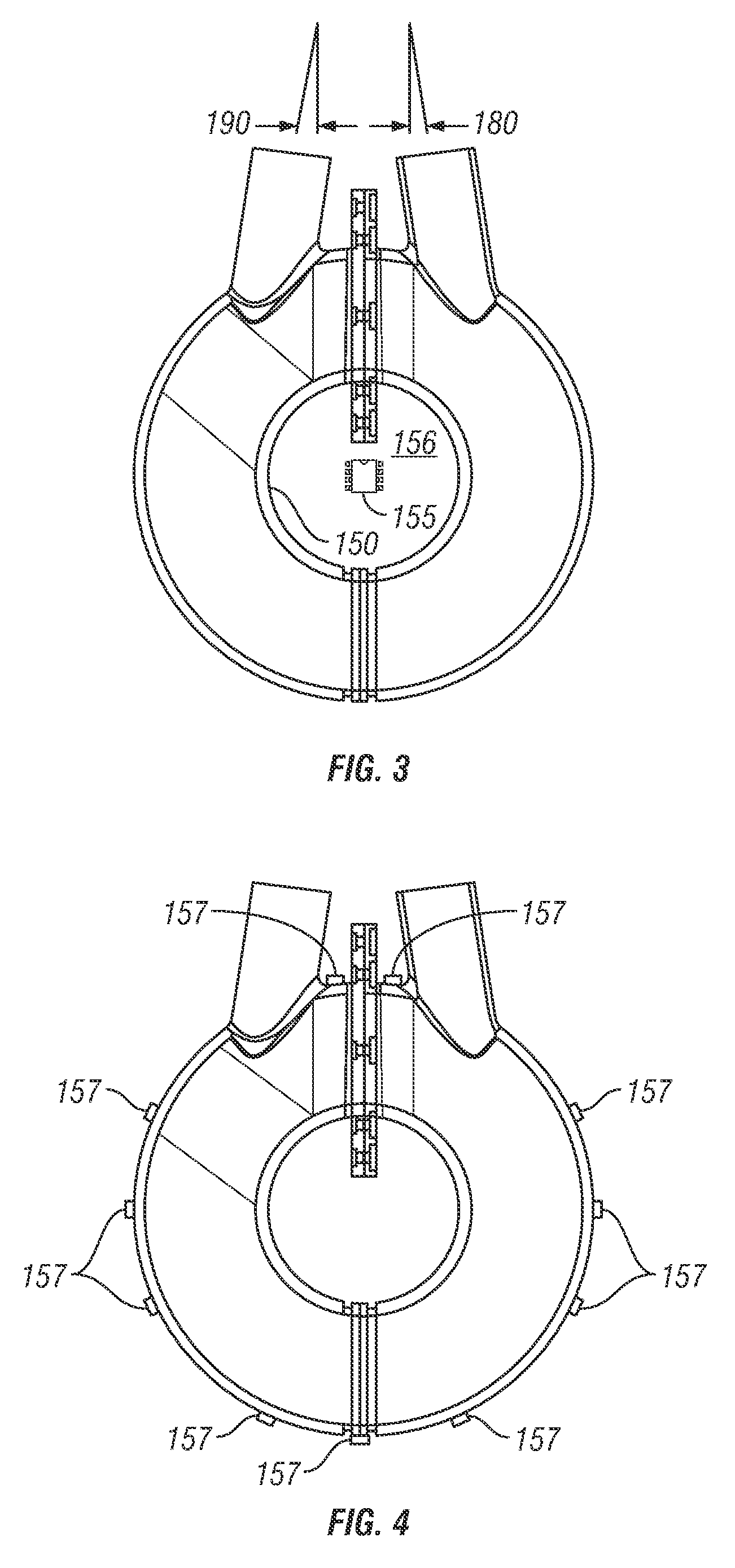

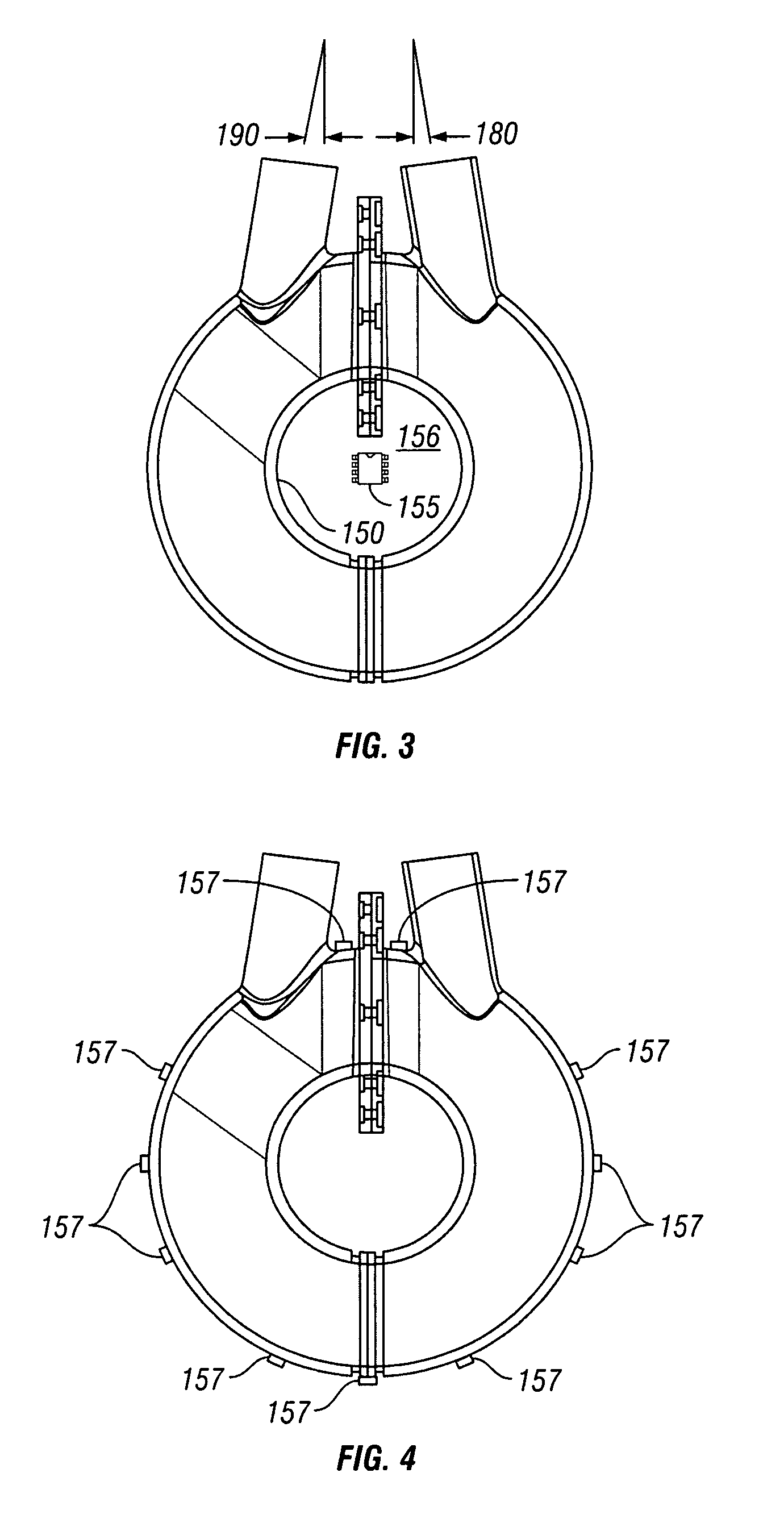

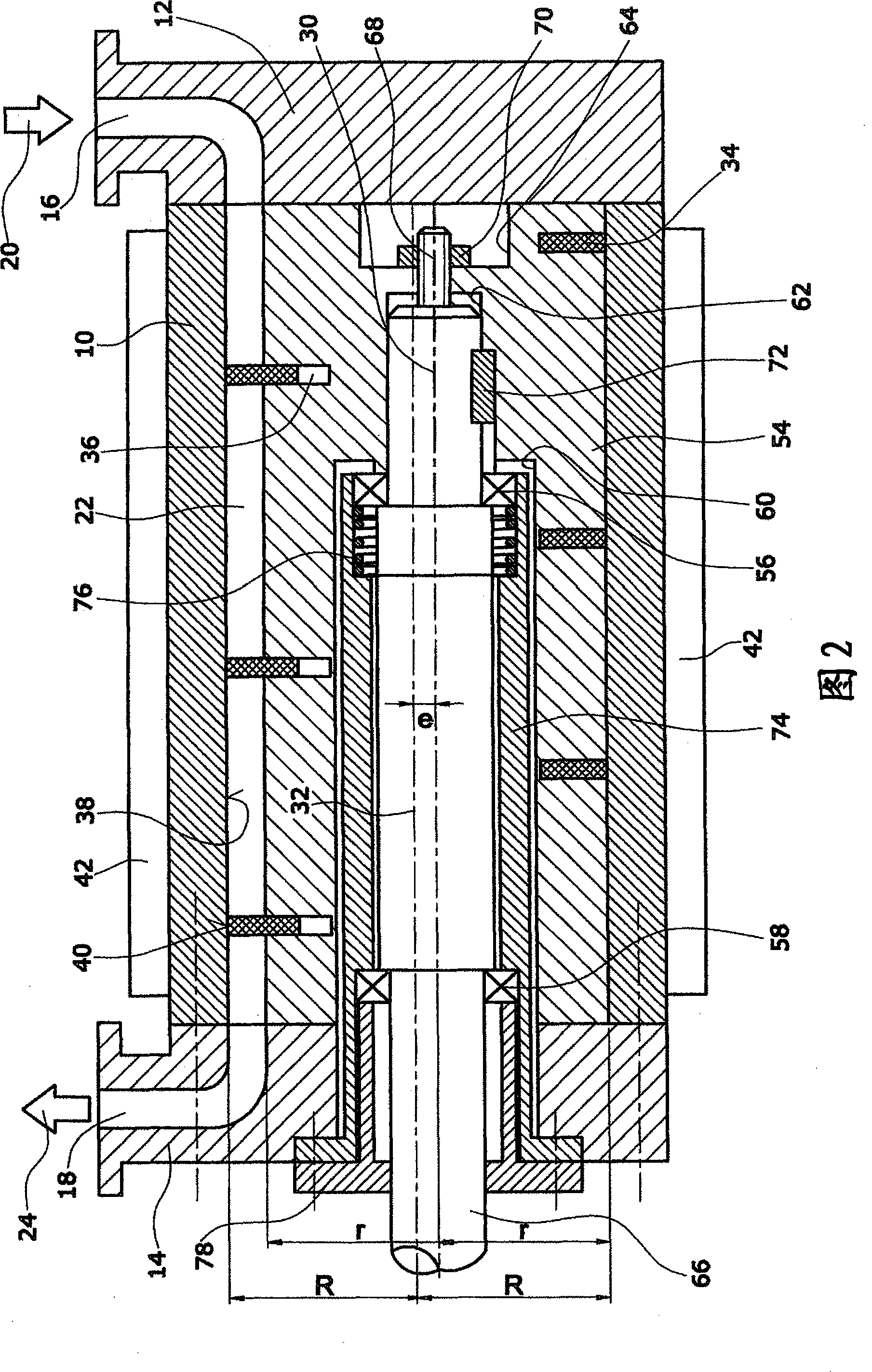

System and method for controlling pump

InactiveUS20100268333A1Reduce chanceImprove the immunityControl devicesBlood pumpsPump chamberEngineering

Systems and methods to control the movement of one or more pistons in a pumping chamber. The systems and methods may include a sensor to sense an external variable provide an output signal. The systems and methods may also include a microprocessor configured to receive the output signal from the sensor and to change an operating parameter of the pump in response to the output signal.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

System and method for controlling pump

InactiveUS20140058190A1Reduce chanceImprove the immunityFlexible member pumpsControl devicesPump chamberBearing surface

Systems and methods including a motor or electromagnets to control the movement of one or more pistons in a pumping chamber. The pumping chamber may include a pump inlet and a pump outlet in fluid communication with the pumping chamber. Surfaces on a piston or pumping chamber may include hydrodynamic bearing surfaces.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Magnetic tunnel junction device and fabrication

Owner:QUALCOMM INC

System and method for pump variable stroke

ActiveUS8386040B2Reduce chanceImprove the immunityControl devicesFlexible member pumpsPump chamberRisk stroke

Systems and methods for providing a variable pumping stroke from a pump comprising a pumping chamber, a pump inlet, a pump outlet, a valving mechanism, and a drive piston. In one embodiment, the pump inlet is in fluid communication with the pumping chamber regardless of the location of the drive piston within the pumping chamber, and the pump outlet is similarly in fluid communication with the pumping chamber regardless of the location of the drive piston within the pumping chamber.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

System and method for pump with deformable bearing surface

ActiveUS8167593B2Reduce chanceImprove the immunityPositive displacement pump componentsFlexible member pumpsPump chamberBearing surface

Systems and methods for pumping fluid comprising a pumping chamber, a pump inlet, a pump outlet, a valving mechanism, and a drive piston or pumping chamber wall including a deformable surface configured to provide elastohydrodynamic lubrication during operation.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

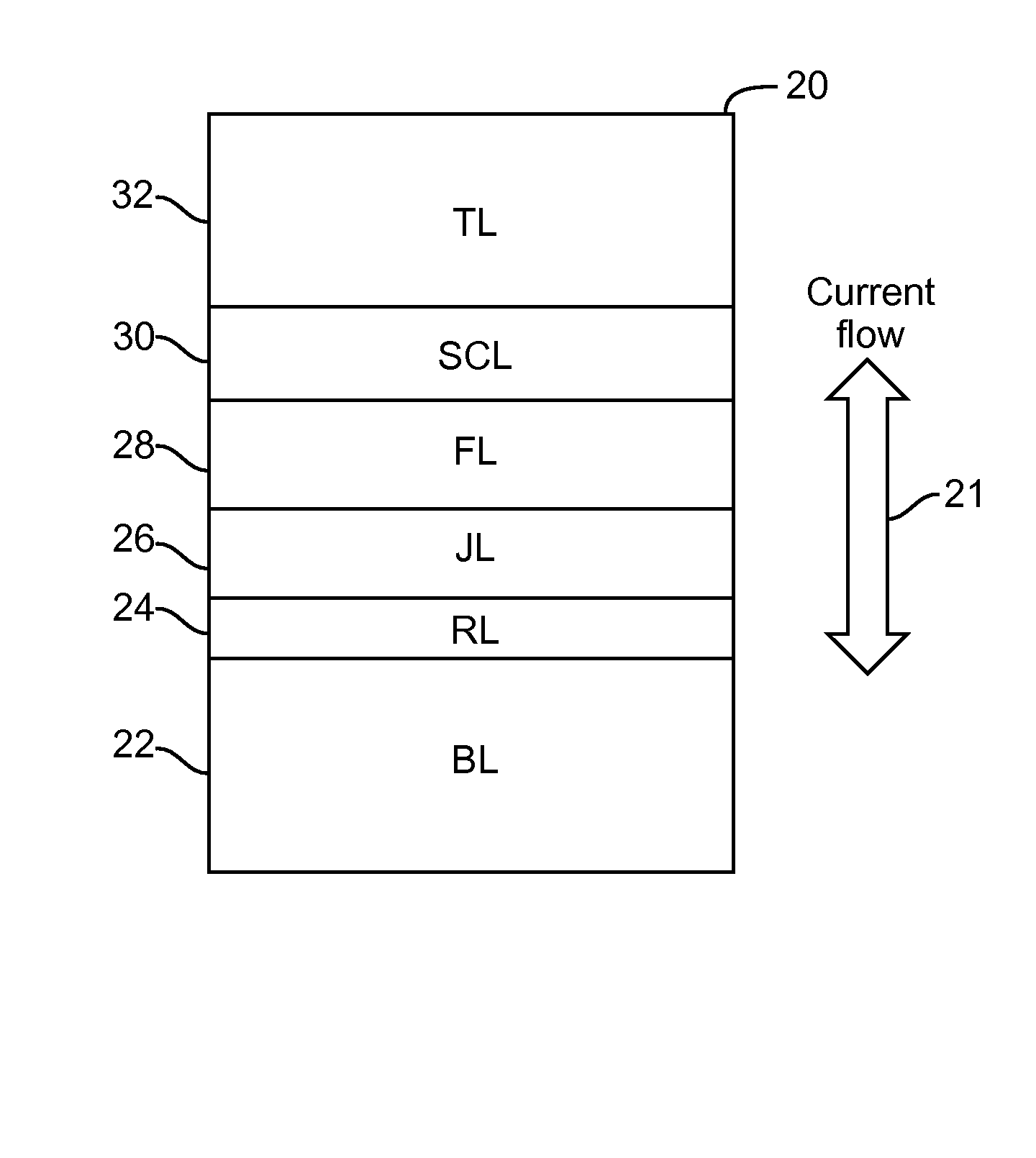

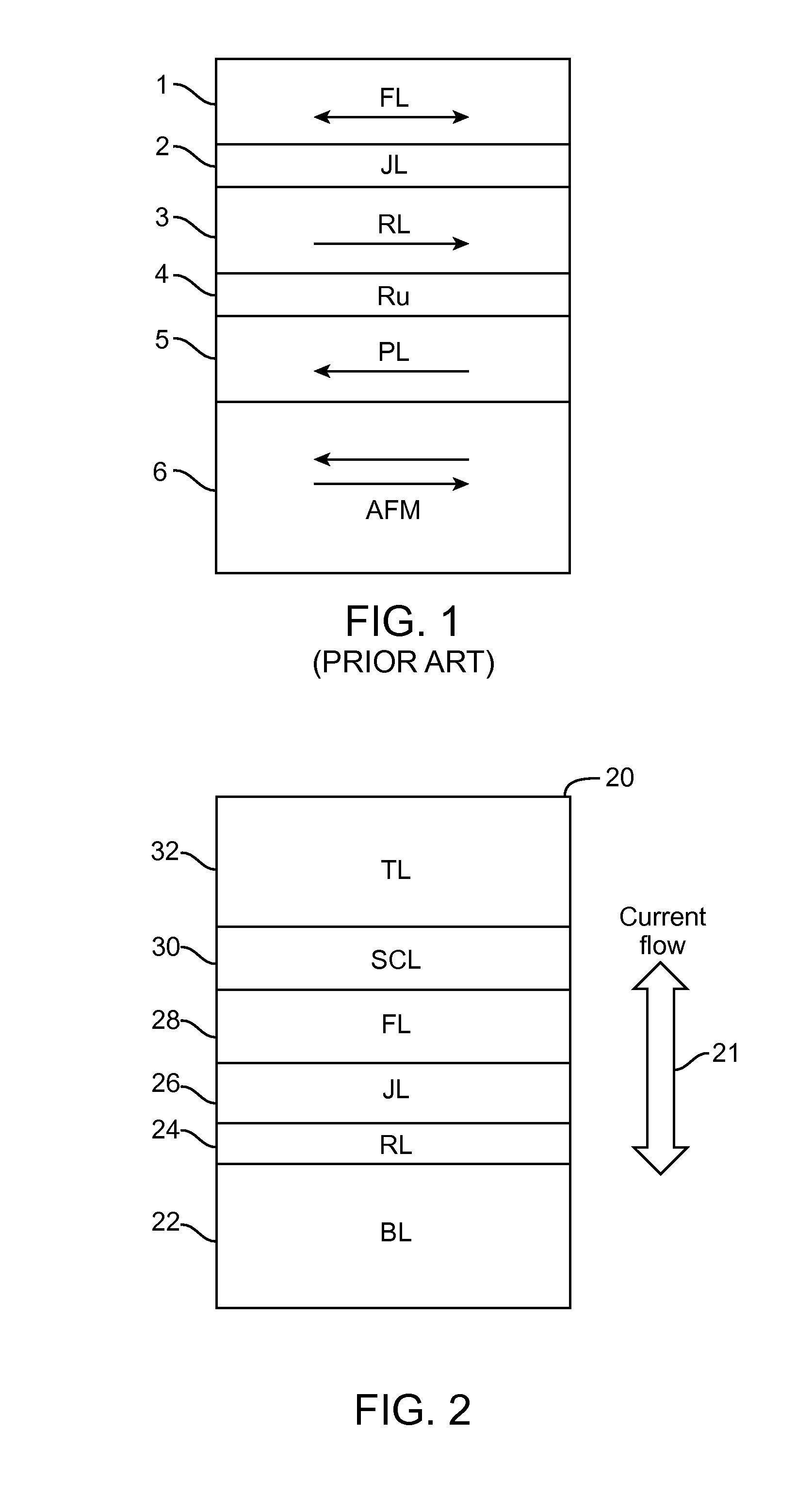

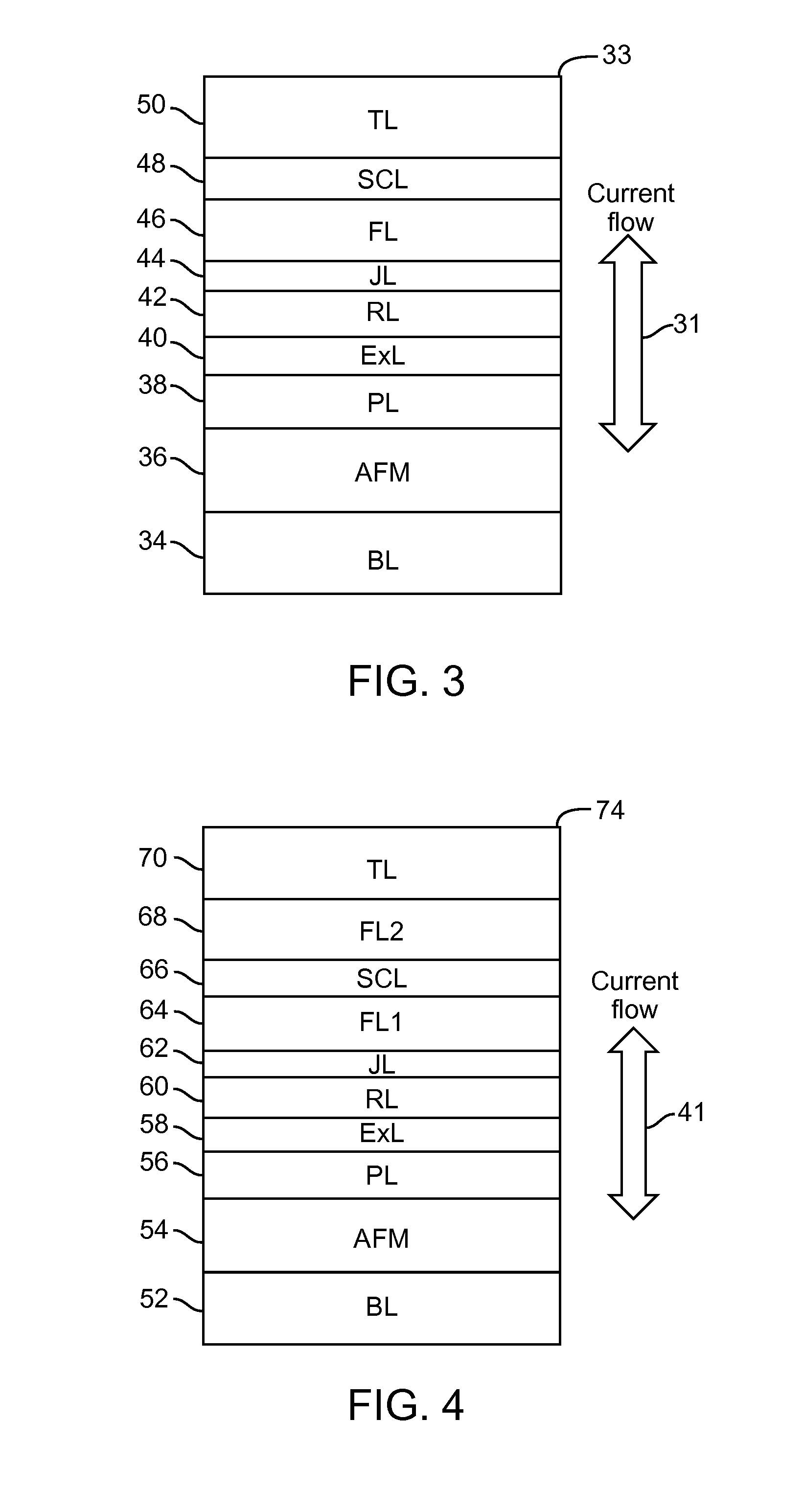

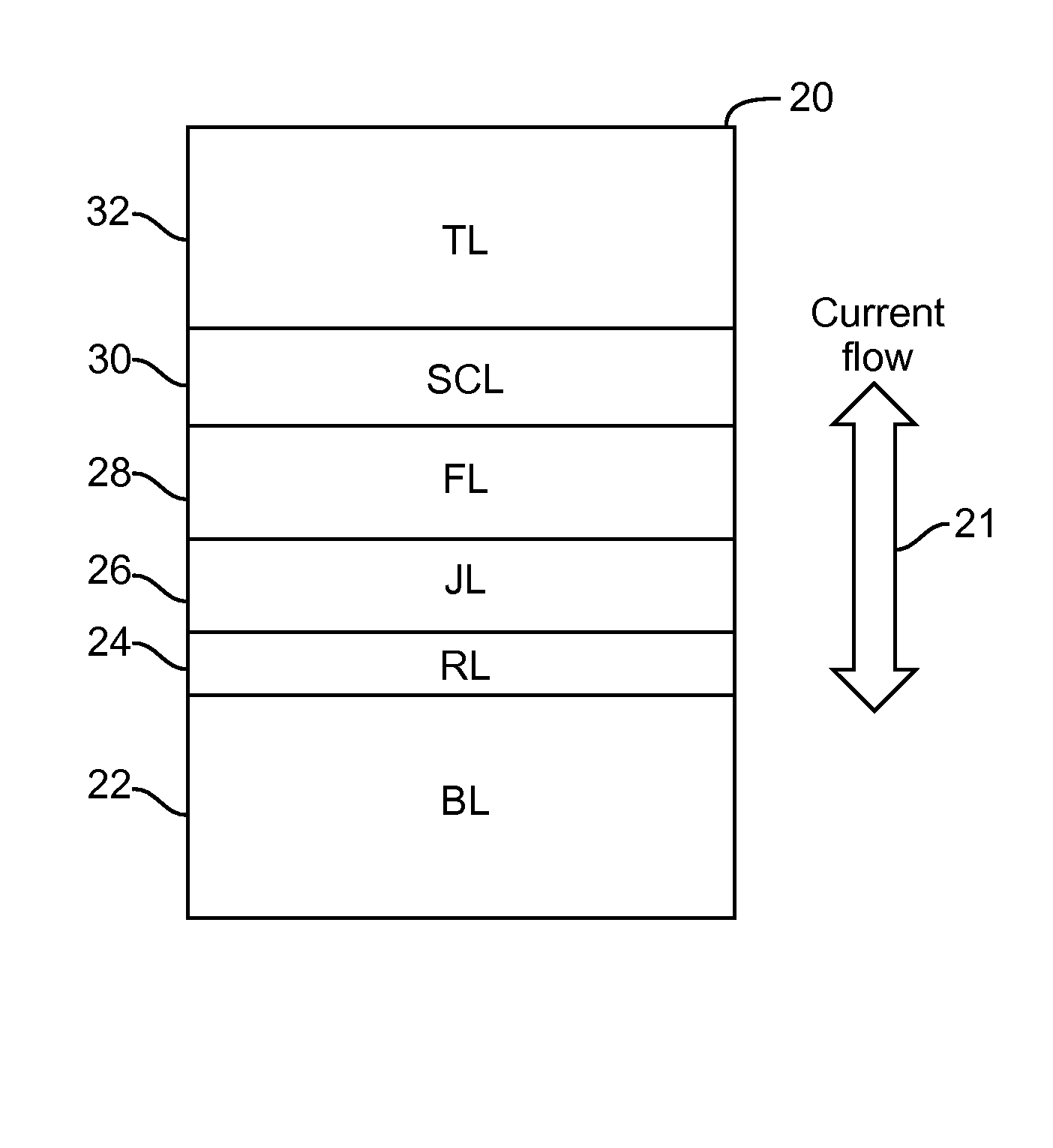

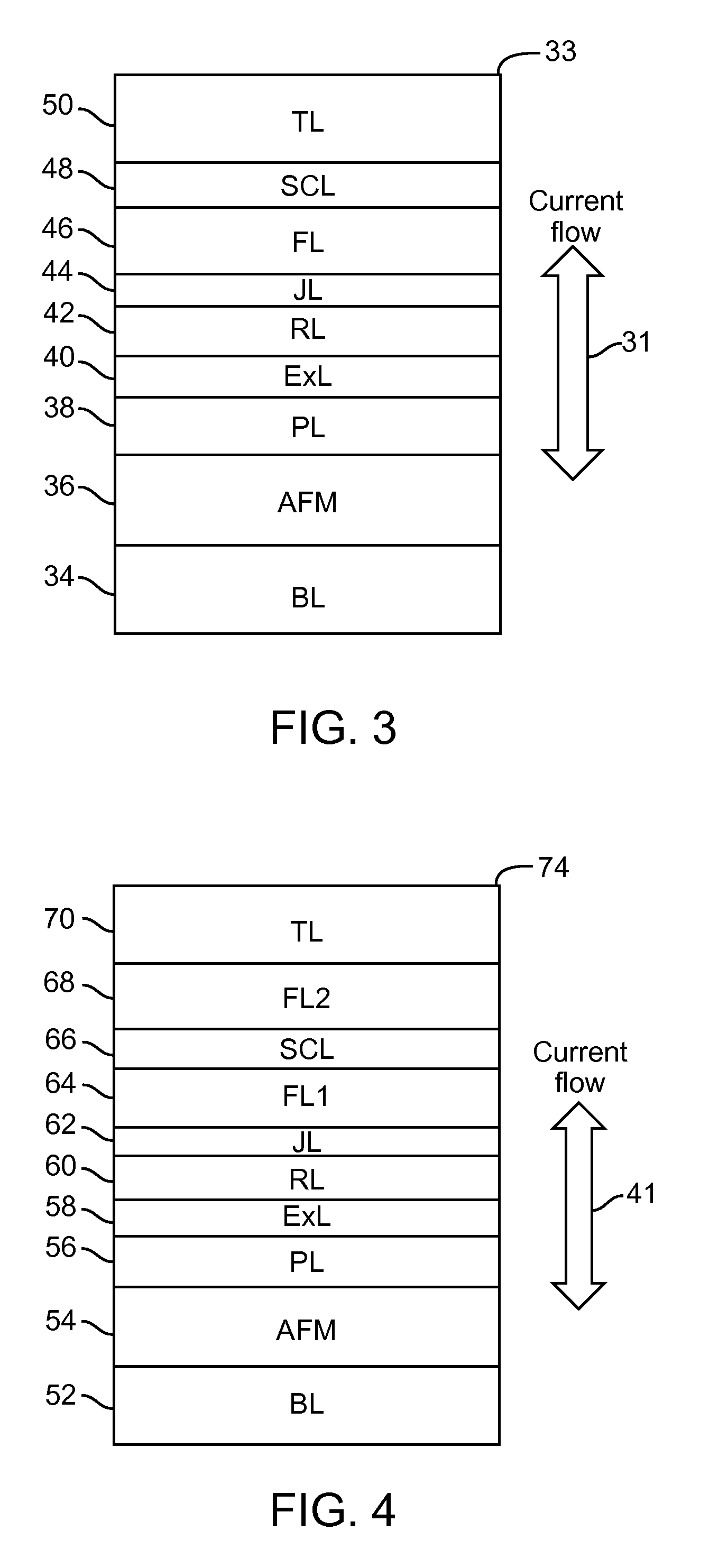

Magnetic Tunnel Junction With Non-Metallic Layer Adjacent to Free Layer

ActiveUS20130334633A1Reduce resistanceReduce spin pumping effectGalvano-magnetic material selectionSemiconductor devicesSpin-transfer torqueRandom access memory

A spin transfer torque magnetic random access memory (STTMRAM) magnetic tunnel junction (MTJ) stack includes layers to which when electric current is applied cause switching of the direction of magnetization of at least one of the layer. The STTMRAM MTJ stack includes a reference layer (RL) with a direction of magnetization that is fixed upon manufacturing of the STTMRAM MTJ stack, a junction layer (JL) formed on top of the RL, a free layer (FL) formed on top of the JL. The FL has a direction of magnetization that is switchable relative to that of the RL upon the flow of electric current through the spin transfer torque magnetic random access memory (STTMRAM) magnetic tunnel junction (MTJ) stack. The STTMRAM MTJ stack further includes a spin confinement layer (SCL) formed on top of the FL, the SCL made of ruthenium.

Owner:AVALANCHE TECH

Non-contacting clearance seal for high misalignment applications

InactiveUS7055827B2Reducing negative pumping actionEliminating oil leakageEngine sealsBall bearingsMechanical engineeringEngineering

Owner:HONEYWELL INT INC

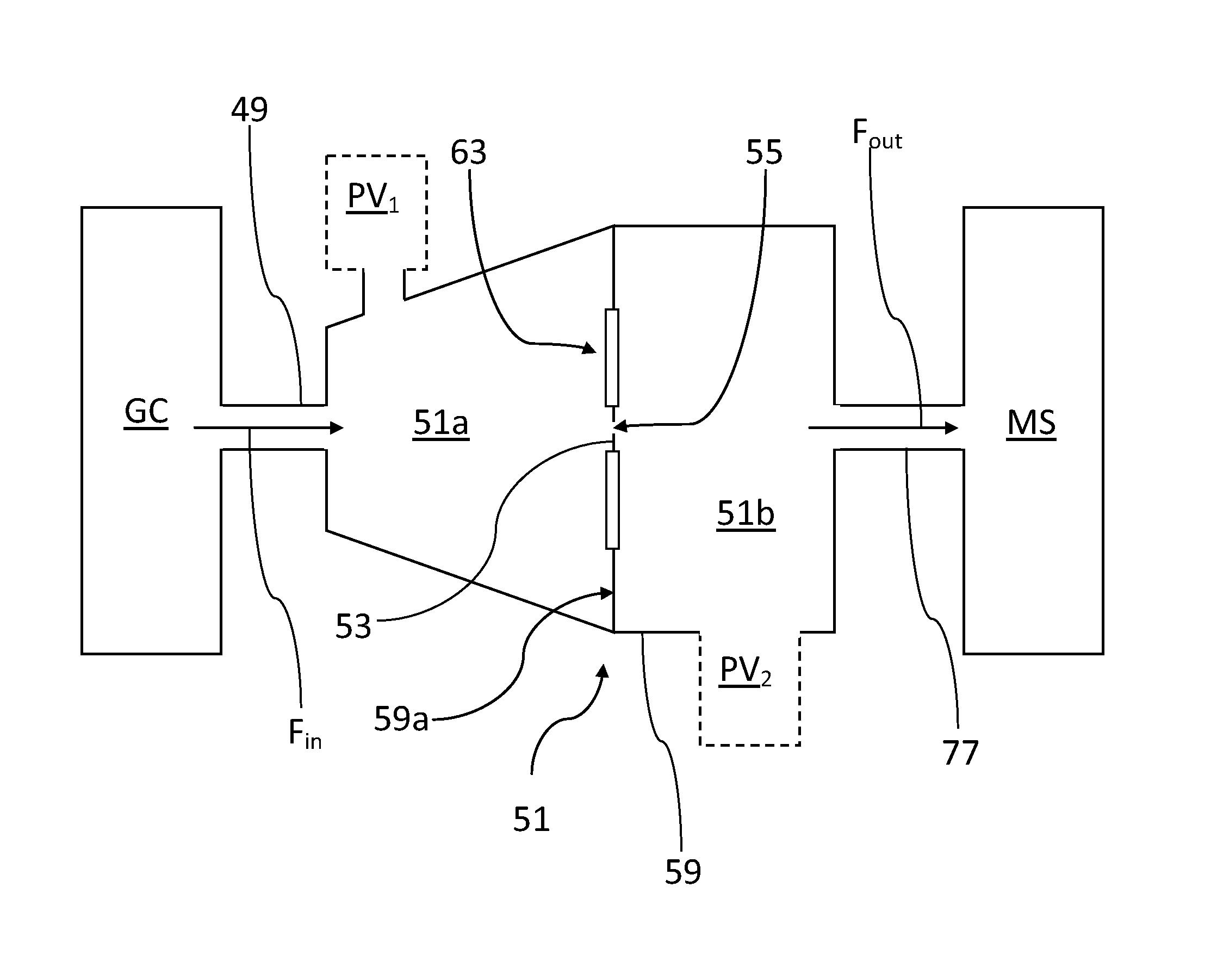

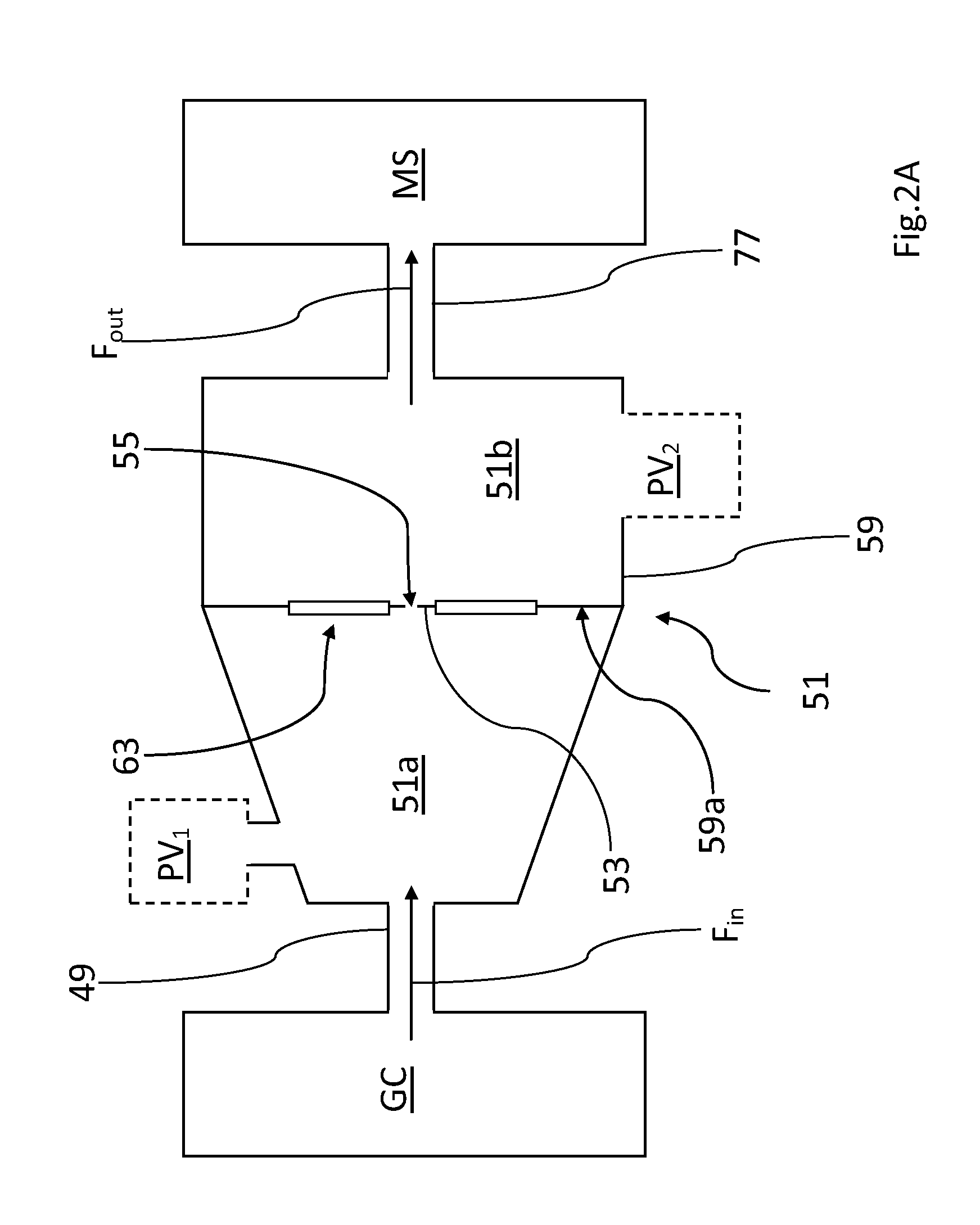

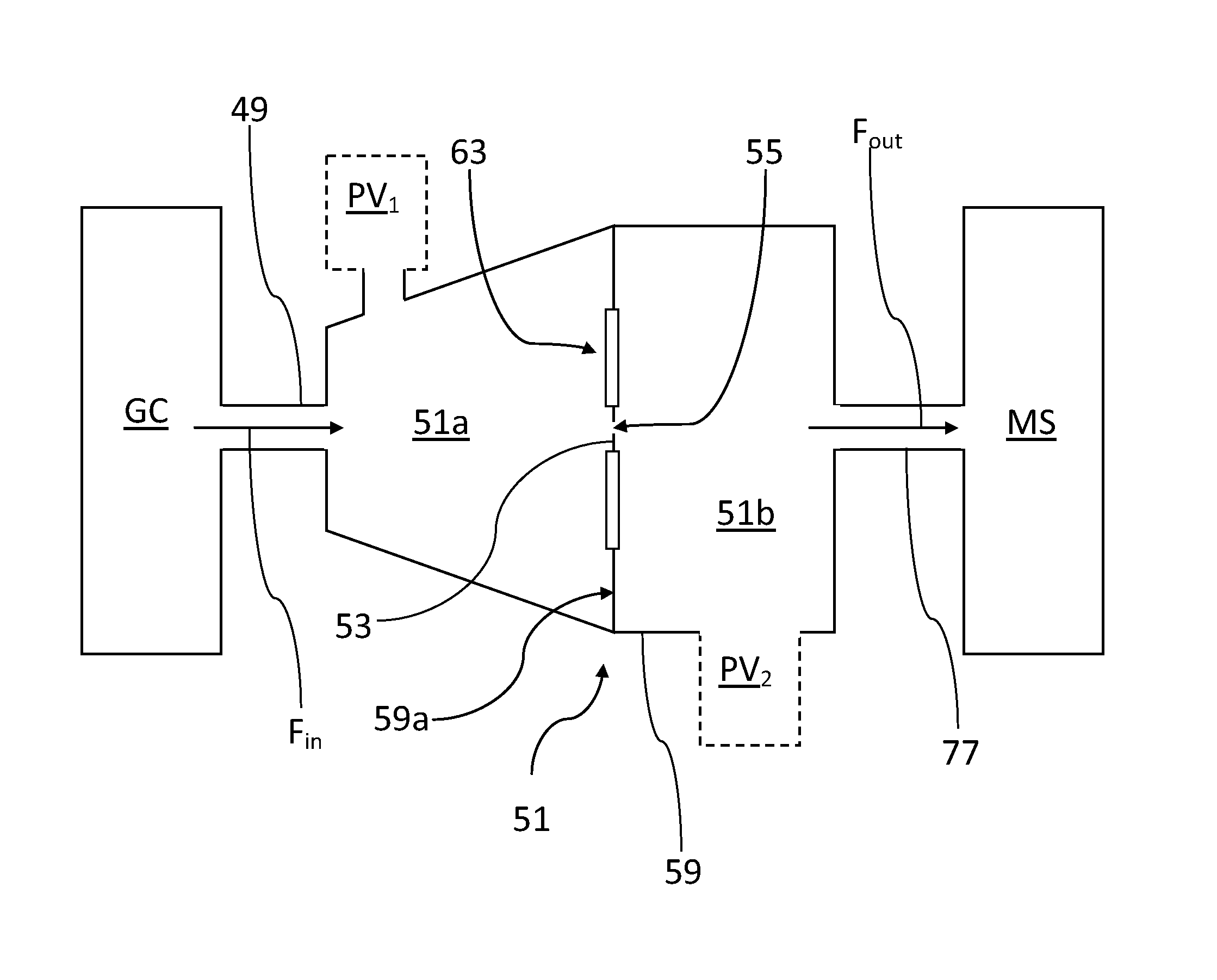

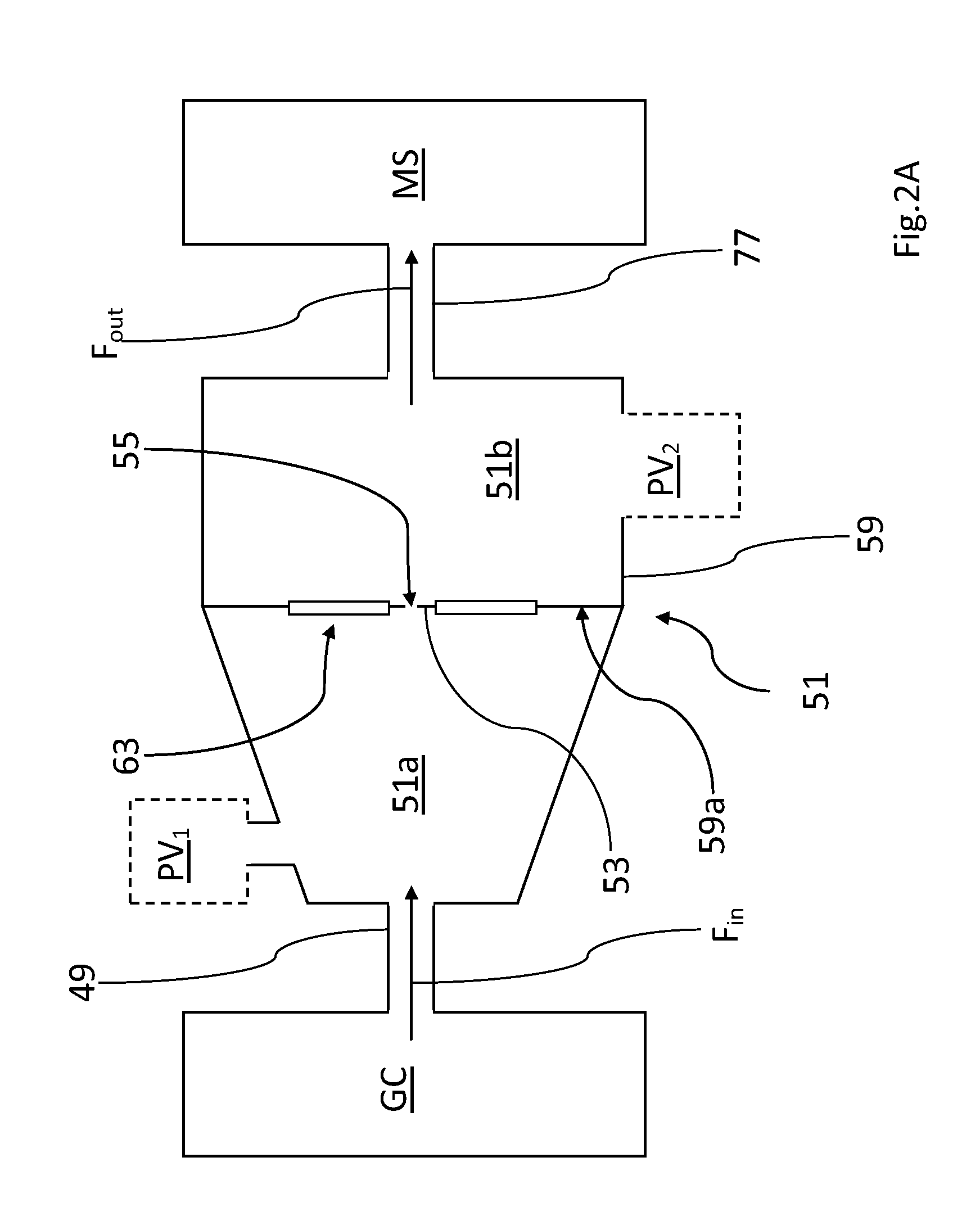

GC-MS analysis apparatus

InactiveUS8237116B2Structurally more simplifiedReduce weightAnalysing fluids using sonic/ultrasonic/infrasonic wavesParticle separator tubesAnalytePressure difference

Owner:AGILENT TECH INC

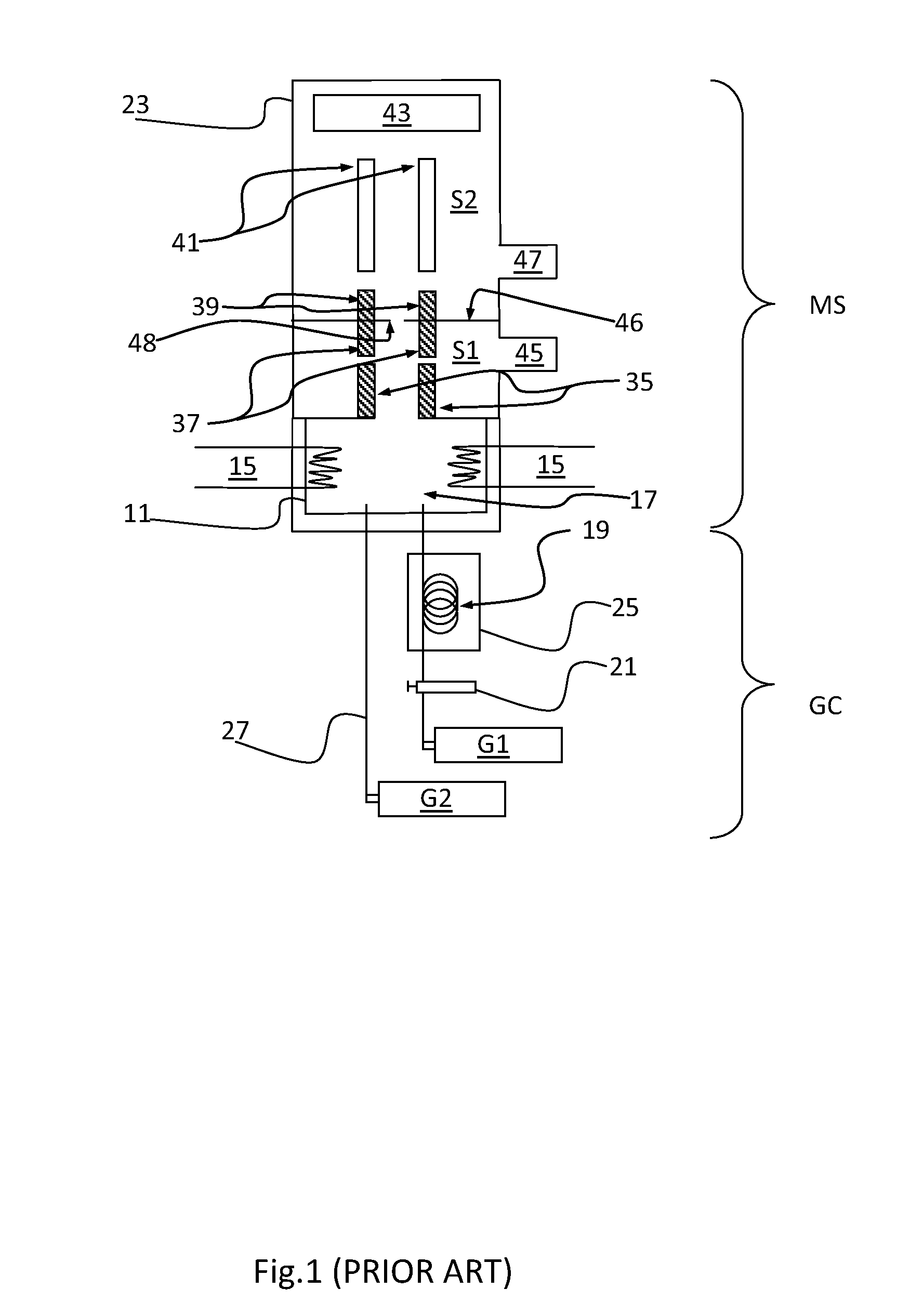

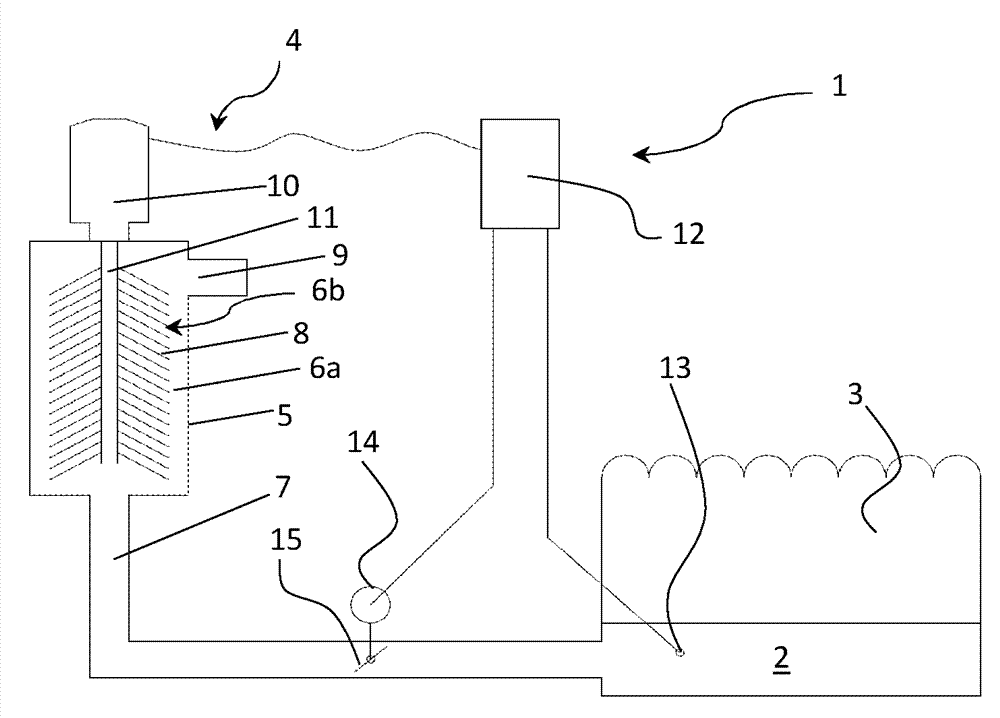

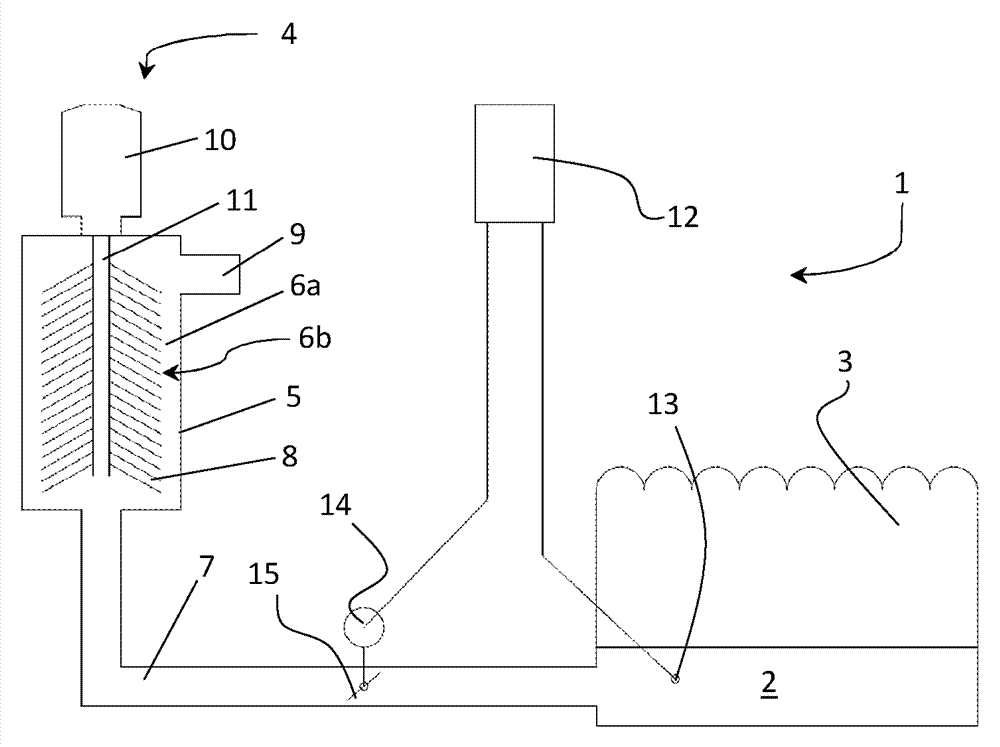

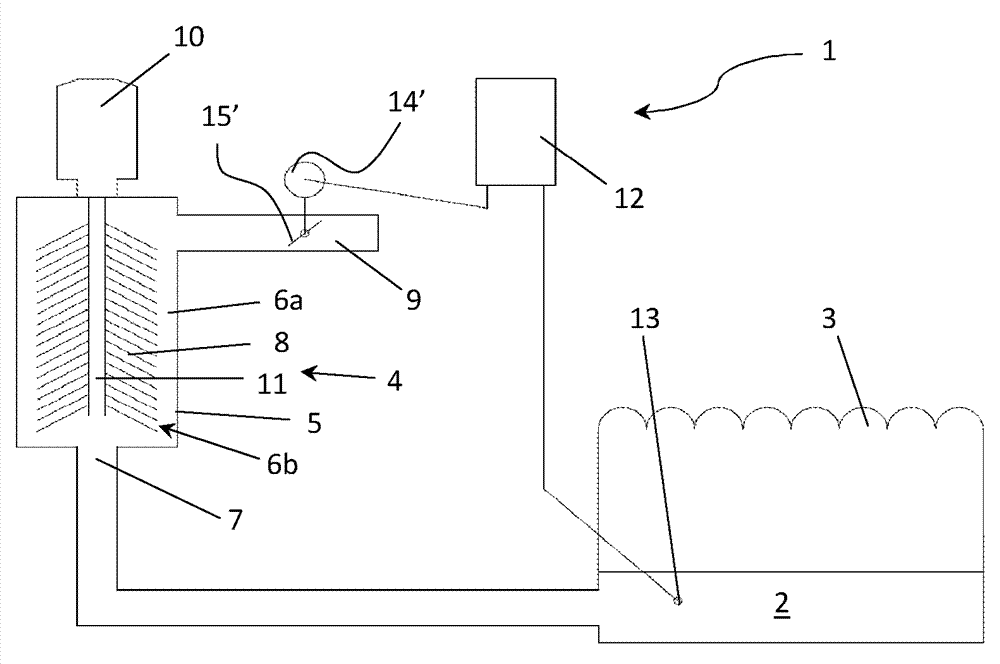

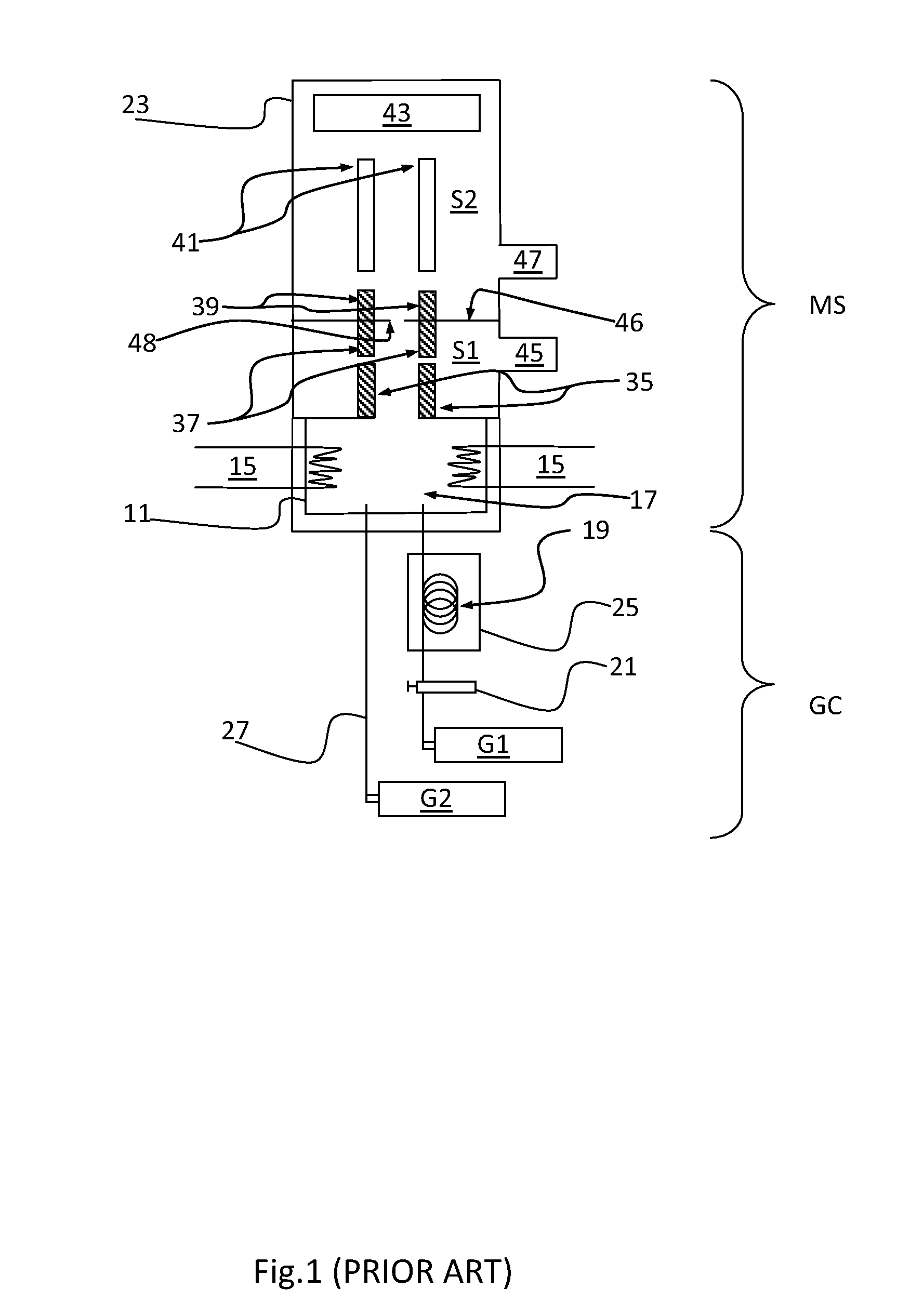

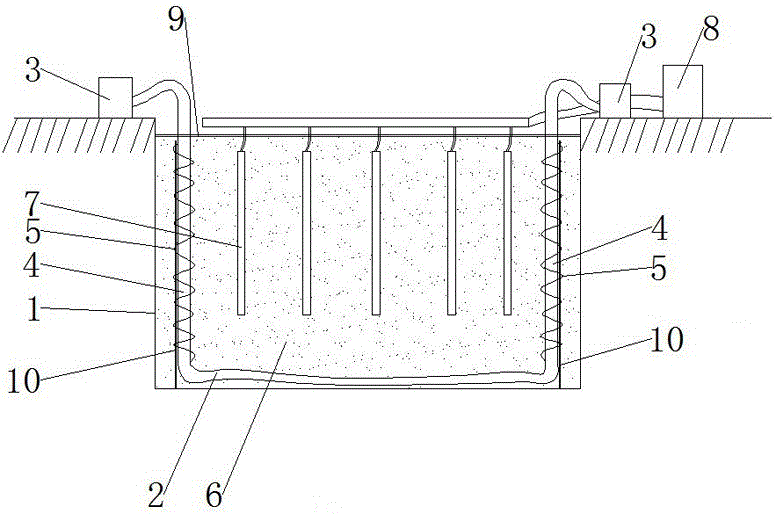

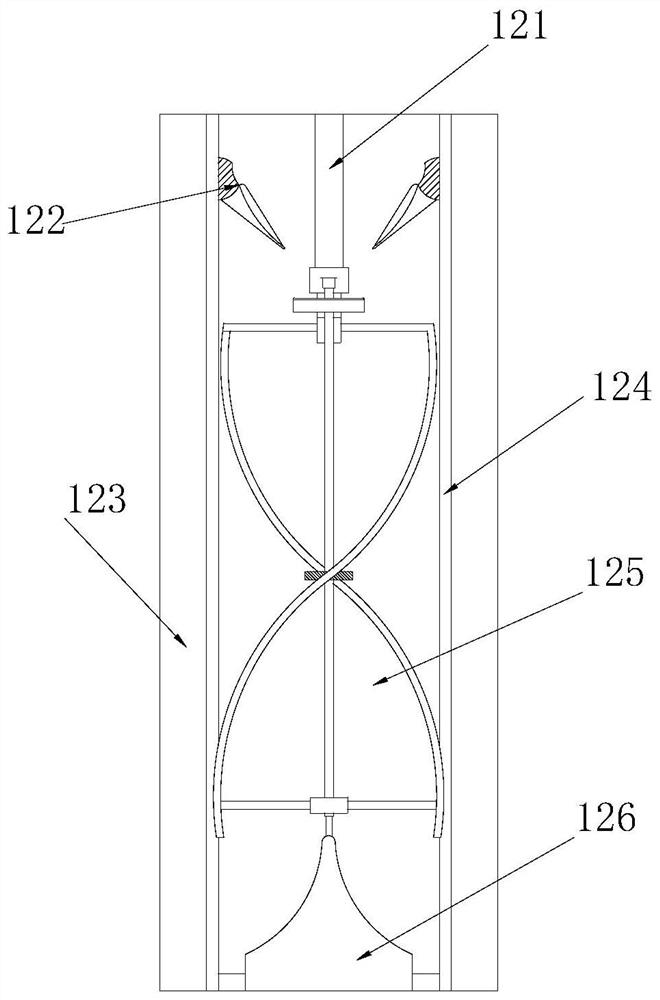

A device and method for cleaning crankcase gas

ActiveCN103097674AHigh speed rotationImprove separation efficiencyMachines/enginesCrankcase ventillationCombustionCrankcase

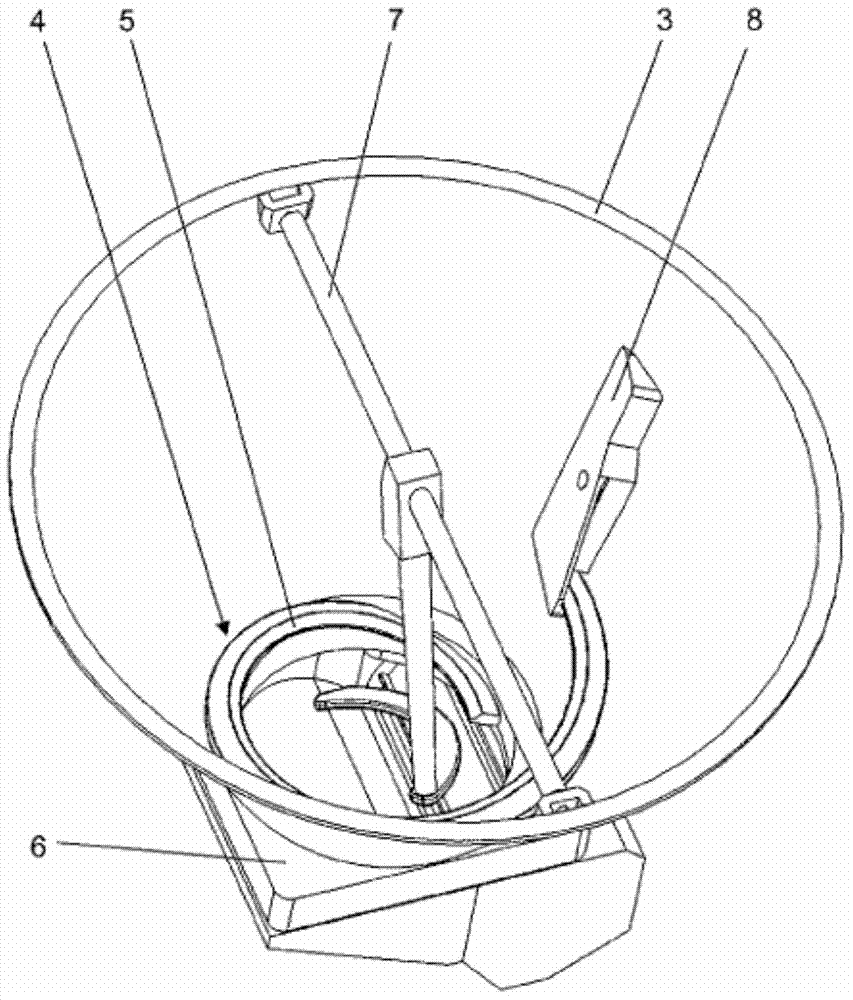

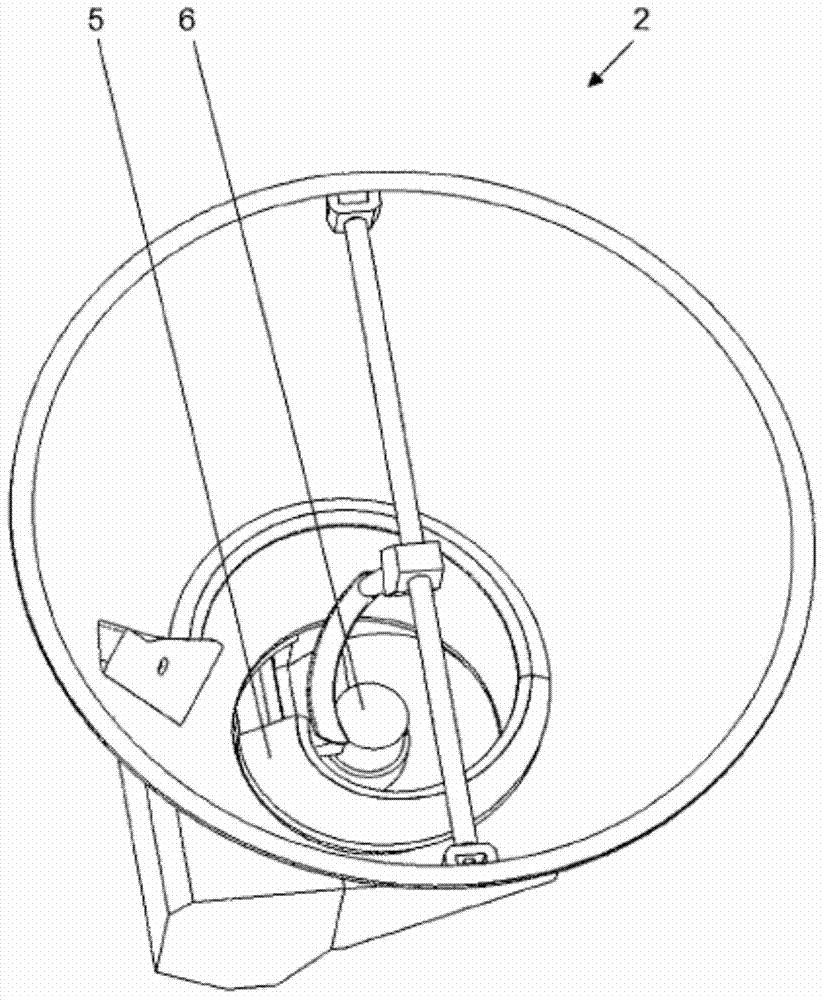

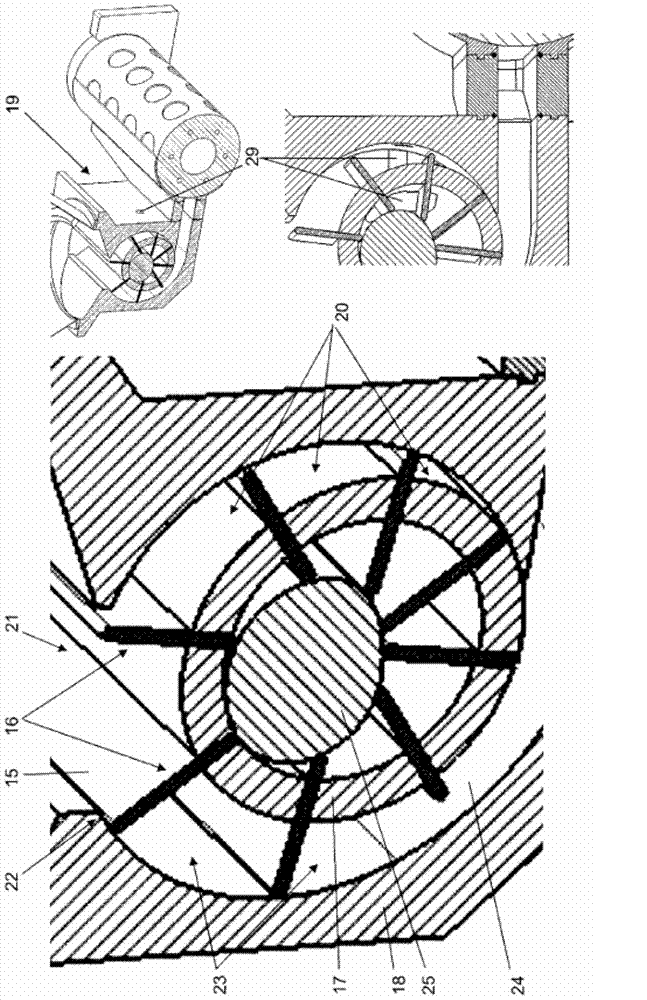

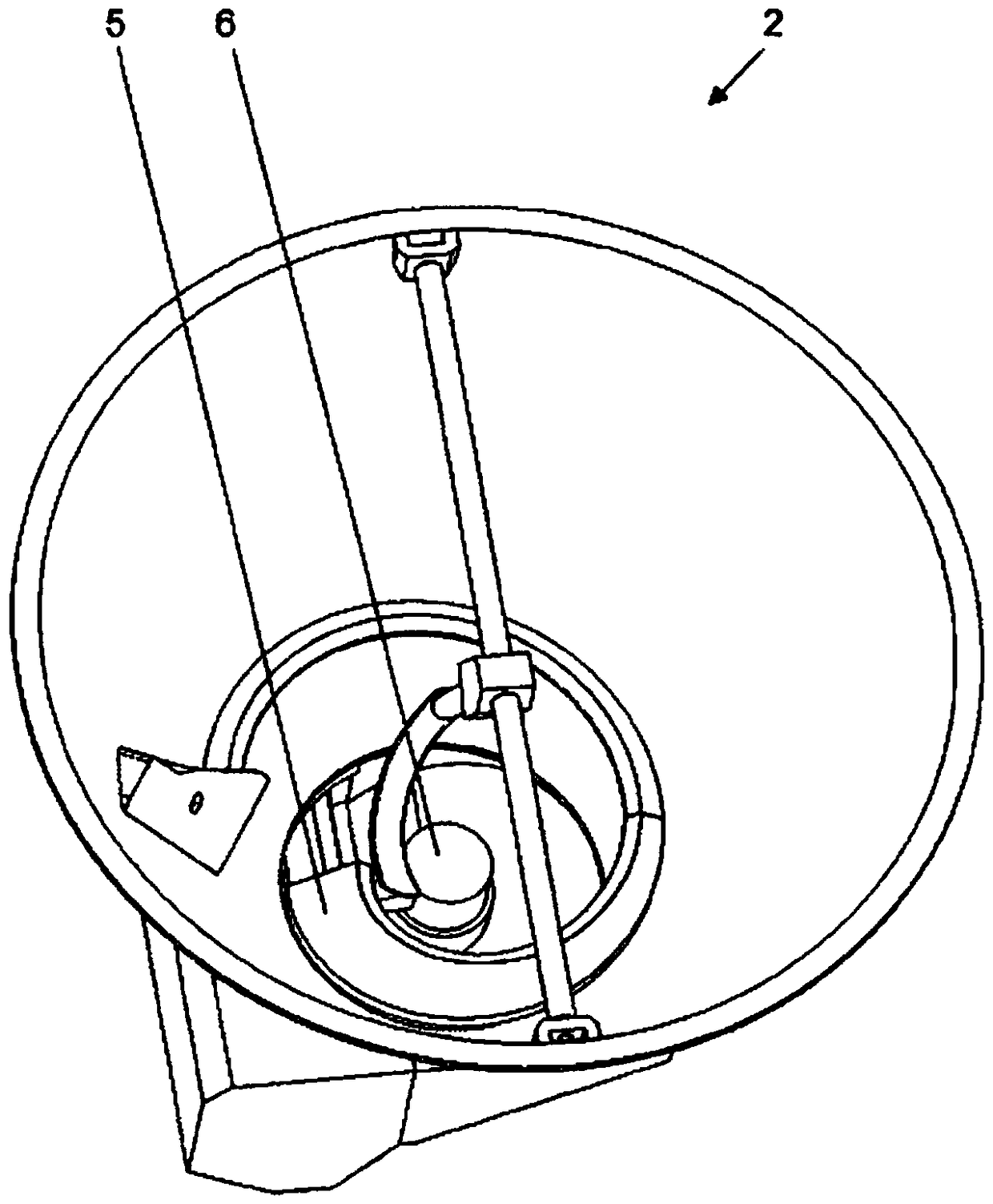

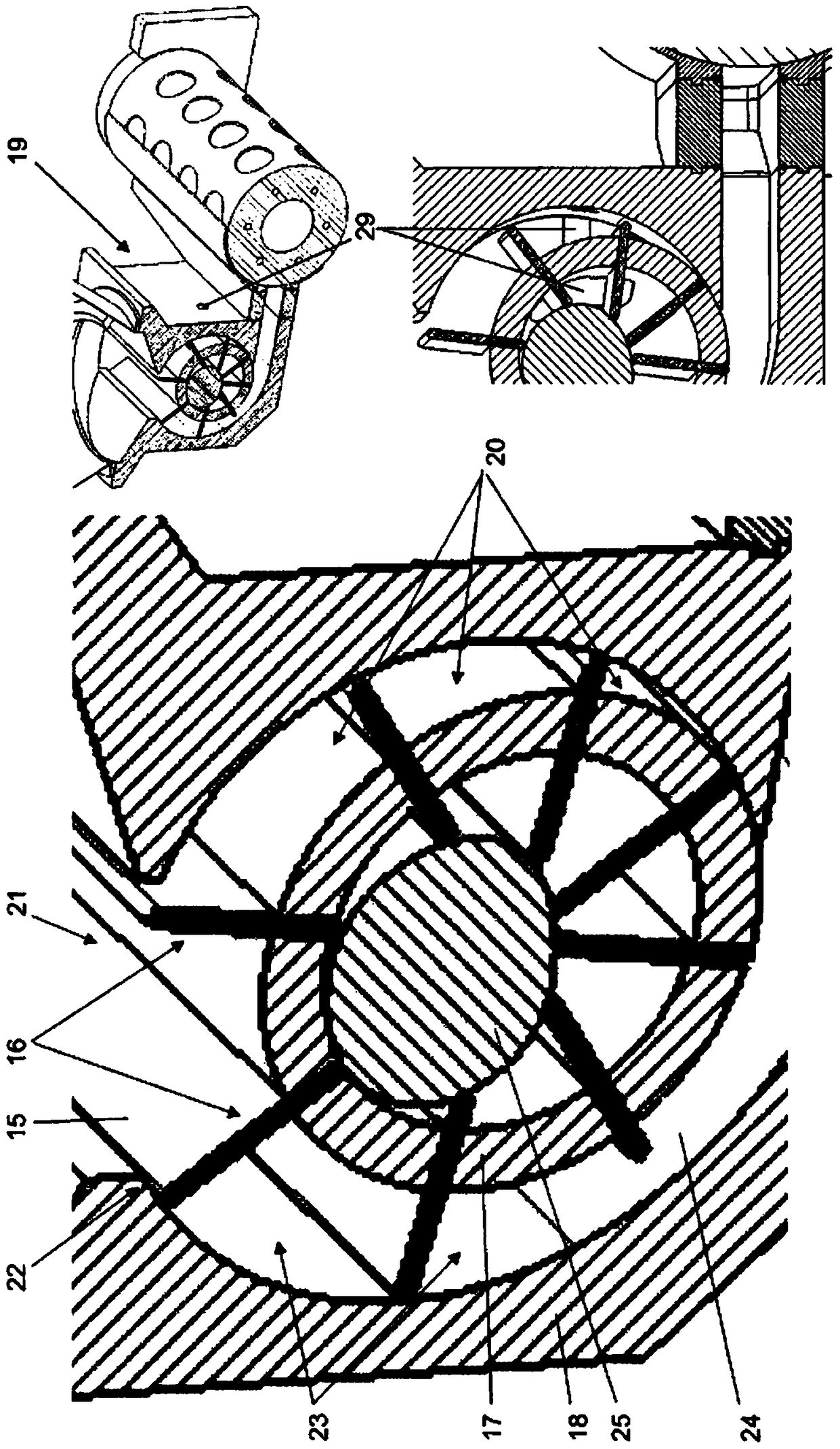

The present invention relates to a device (1) and method for cleaning of crankcase gas being produced in a crankcase (2) during operation of an internal combustion engine (3). The device (1) comprises a centrifugal separator (4) having a housing (5) and a separation chamber (6a) in which a centrifugal rotor (6b) is arranged for cleaning of said crankcase gas. The separator (4) is connected to a gas inlet (7) for conducting crankcase gas from the crankcase (2) to the centrifugal separator (4) and a gas outlet (9) for conducting the cleaned gas from the separator (4). A motor (10) is arranged to rotate the centrifugal rotor (6b) with control equipment (12) for changing the rotational speed of the centrifugal rotor (6b). A sensor (13) is provided for detection of a parameter, the magnitude of which is related to a gas pressure in the crankcase (2). The sensor (13) is arranged to communicate with the control equipment (12) of the motor, the control equipment (12) being operatively connected to a valve (15, 15') which is arranged for adjusting the flow of gas through the centrifugal separator (4). The control equipment (12) is arranged to change the position of the valve (15, 15') in response to a detected change of said parameter in a way such that the gas pressure in the crankcase (2) is maintained at a predetermined value, or at a predetermined pressure interval, during operation of the combustion engine.

Owner:ALFA LAVAL CORP AB

Mass supply system

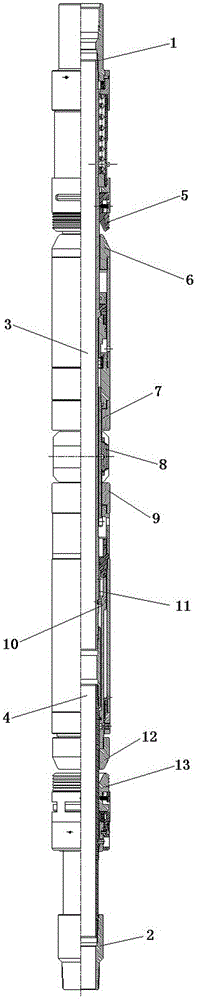

ActiveCN104244722ASmall inertiaEasy to replaceMeat processingRotary piston pumpsEngineeringMechanical engineering

Owner:GEA FOOD SOLUTIONS BAKEL

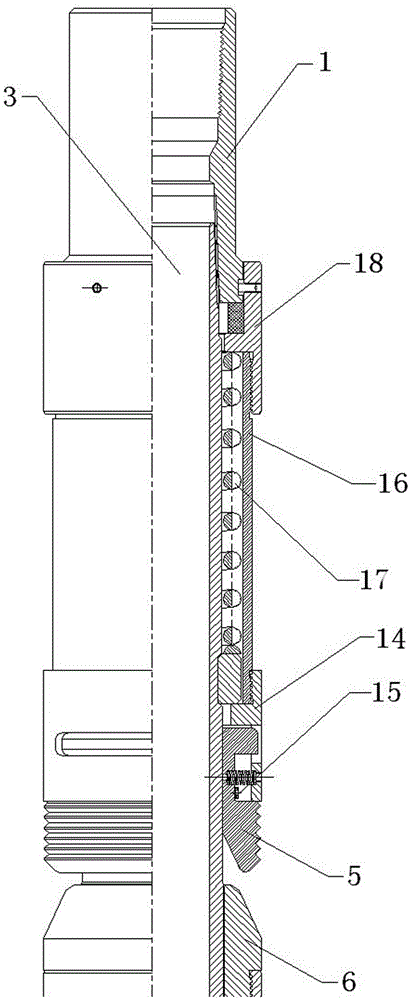

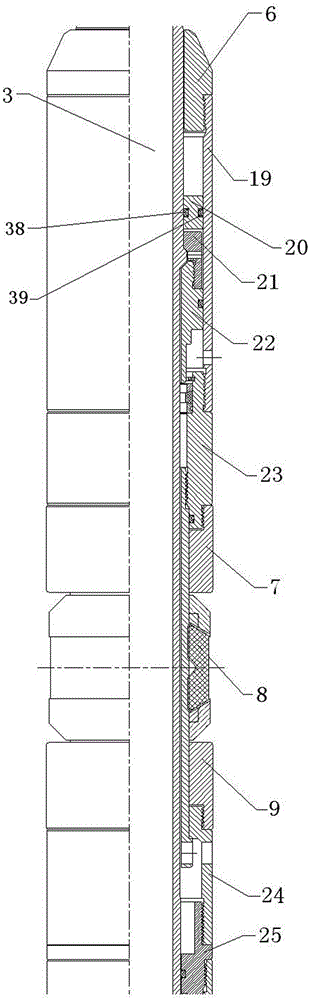

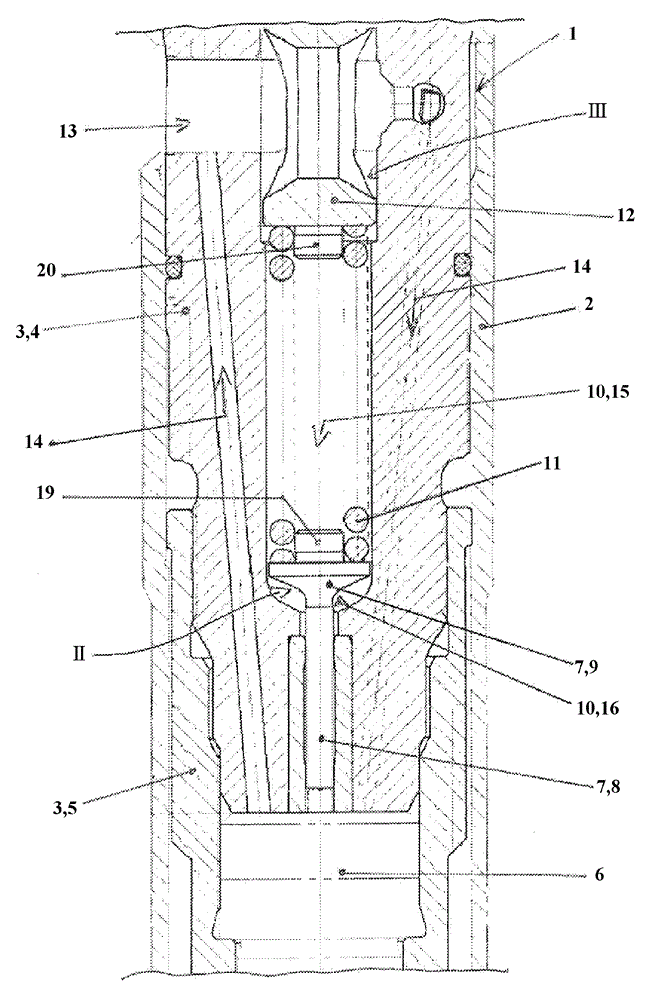

Recyclable hydraulic production packer

A recyclable hydraulic production packer is provided with bi-directional slips, can be used for setting at stretching, retracting or neutral states, and also can bear pressure differences form above and below. With the design of large bypass openings inside the packer, swabbing effects during lowering and retracting can be reduced, and the large bypass openings are automatically closed during setting. When the packer is unset, the bypass openings are first opened, up-down pressure is balanced, when the packer bears a lower pressure, a compensation piston can further ensure that an upper slip bits tightly, the setting is reliable, and resistance during retraction of tools can be reduced through an upper slip release device of the packer. The packer provided by the present invention is characterized by being excellent in pressure bearing capability, capable of setting in various working conditions, and recyclable.

Owner:四机赛瓦石油钻采设备有限公司

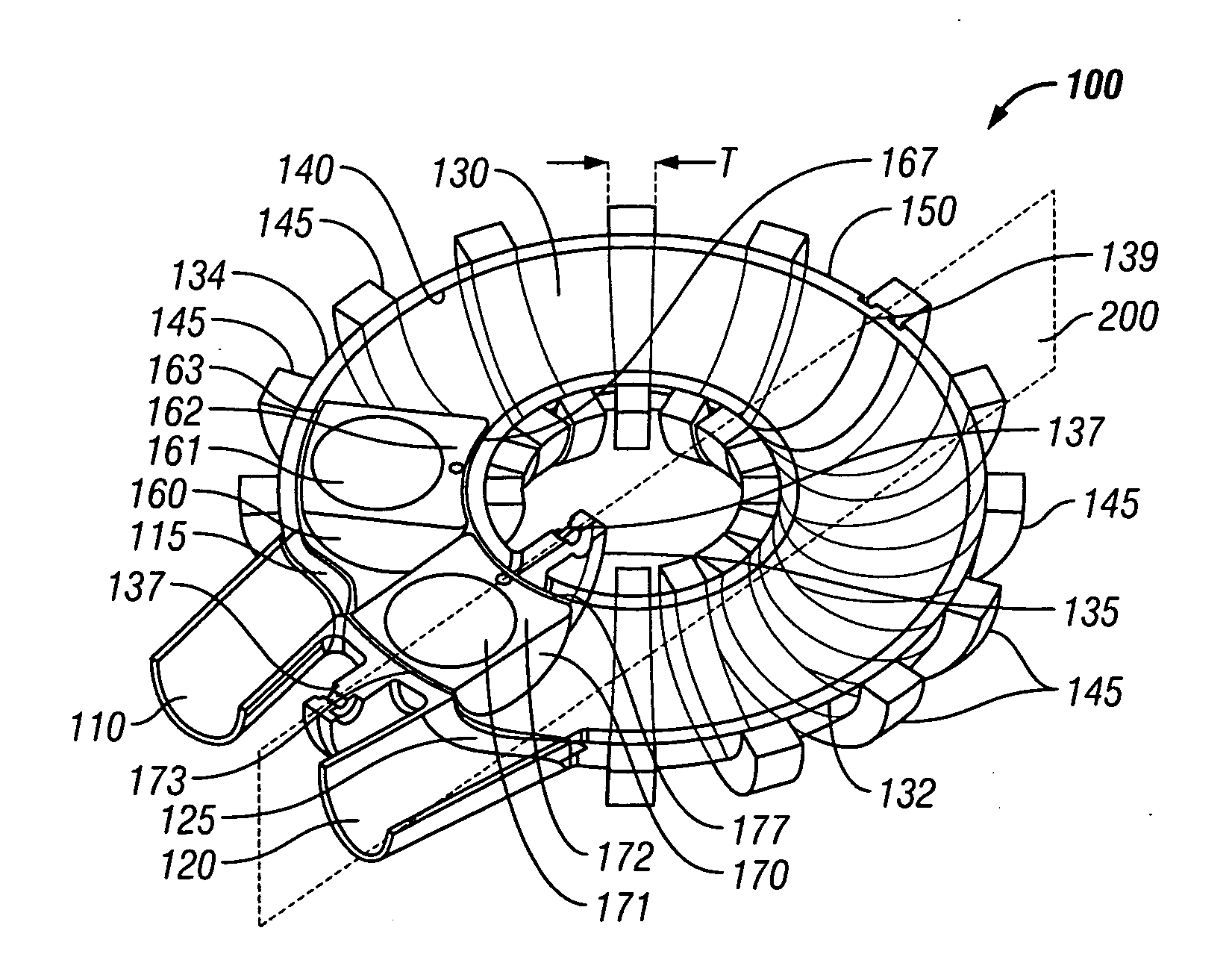

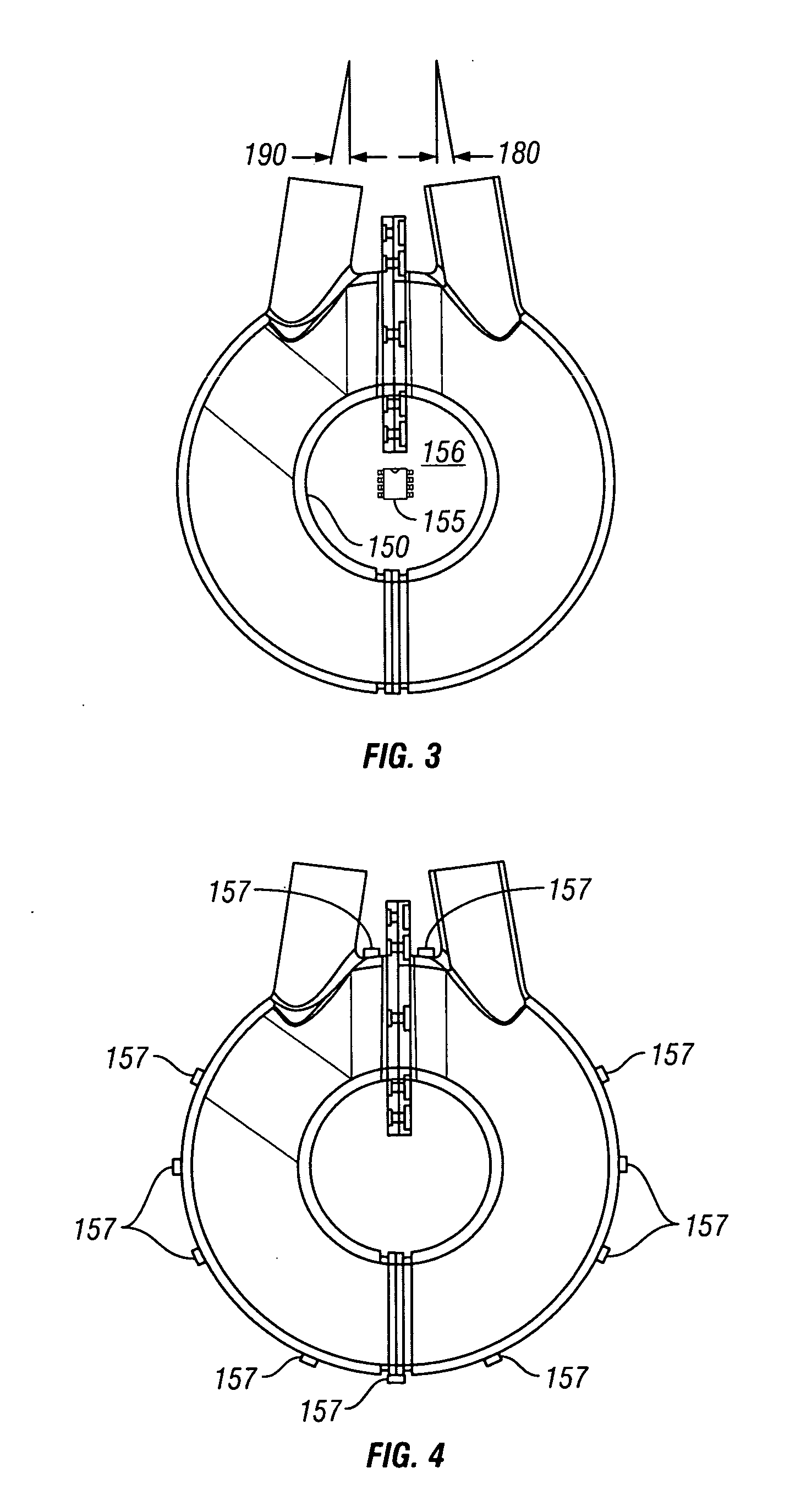

Positive displacement pump system and method with rotating valve

ActiveUS8366401B2Reduce chanceImprove the immunityFlexible member pumpsPump controlPistonPositive displacement pump

Systems and methods including a valve piston in a pumping chamber. The pumping chamber may include a pump inlet and a pump outlet in fluid communication with the pumping chamber. The valve piston may be configured to rotate between a first position within the pumping chamber and a second position outside of the pumping chamber.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

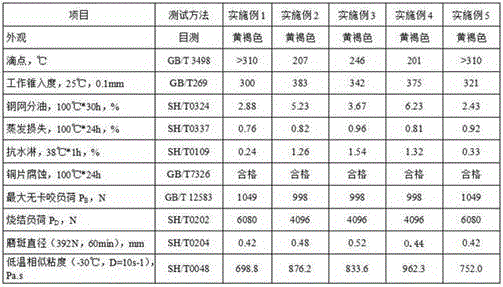

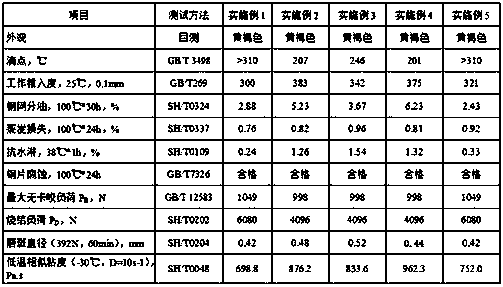

Automobile seat sliding rail lubrication grease and preparation method thereof

The invention discloses an automobile seat sliding rail lubrication grease. The lubrication grease is prepared from the following components in percentage by weight: 52%-65% of base oil, 26%-33% of sulfonate, 6%-10% of a structure improving agent and 3%-5% of a thickening agent. The lubrication grease adopts food-grade base oil, is free of smell, free of damage to human body and excellent in high-and-low temperature performance, and can meet the application of an automobile seat sliding rail in extreme environment; the high-alkali synthetic calcium sulphonate has excellent extreme-pressure antiwear property and is free of damage to human body; the effects of resisting wearing, reducing friction and reducing noise can be achieved by not adding high-cost solid lubricant; the structure improving agent is capable of effectively improving the thickening capability of the product and shortening the production time; the thickening agent is capable of greatly improving the antiwear property and the antifriction property of the product and also has excellent pumpability; the raw materials are cheap and easily available; the preparation method is simple and easily controllable; the production efficiency of the product is greatly improved.

Owner:NATOR LUBRICATION TECH JIANGSU CO LTD

Gc-ms analysis apparatus

InactiveUS20110006201A1Affordable costStructurally more simplifiedAnalysing fluids using sonic/ultrasonic/infrasonic wavesSamplingChemistryAnalyte

GC-MS analysis apparatus has an interface section between GC and MS sections, which is located with respect to the direction of an analyte flow downstream of the GC section and upstream of the MS section. The interface section comprises at least one membrane with at least one orifice capable of establishing a molecular flow condition in the analyte passing between the GC and MS sections through the membrane. The membrane is subjected to a pressure differential such that the pressure pa in a region located upstream of the membrane is higher than the pressure pb in a region located downstream of the membrane.

Owner:AGILENT TECH INC

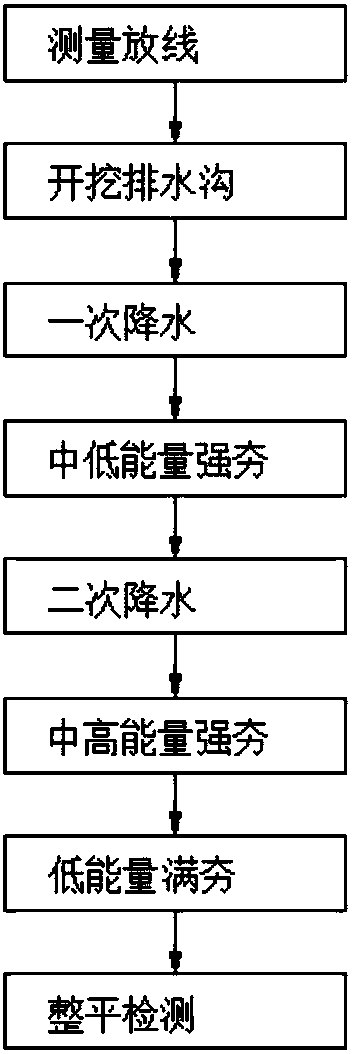

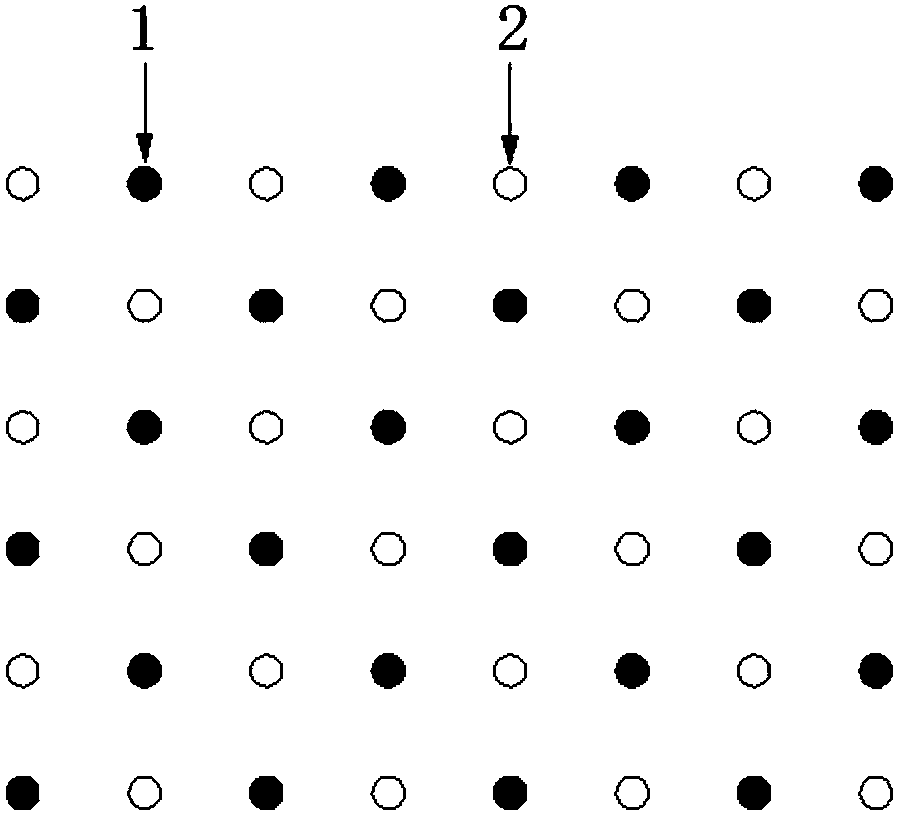

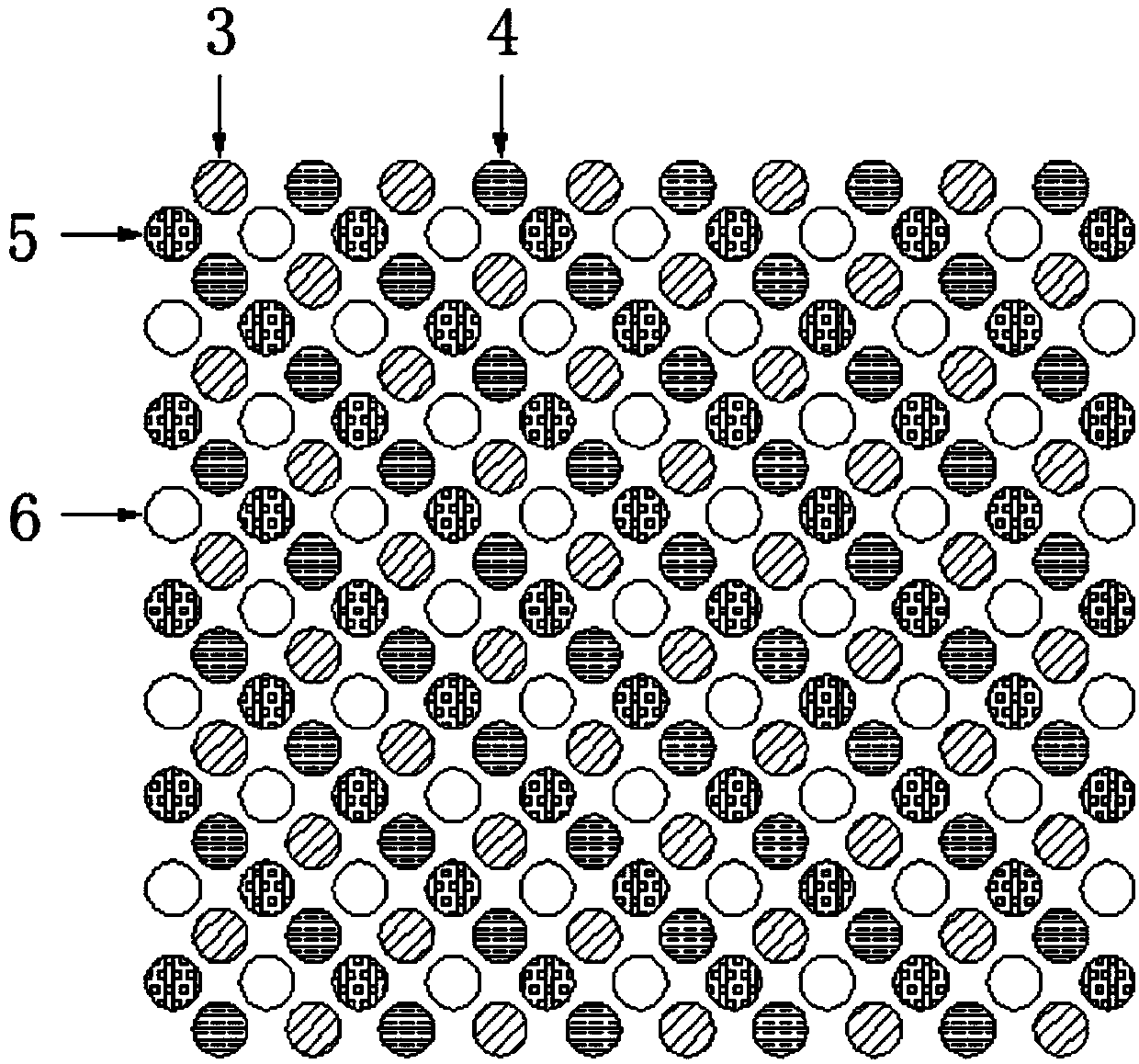

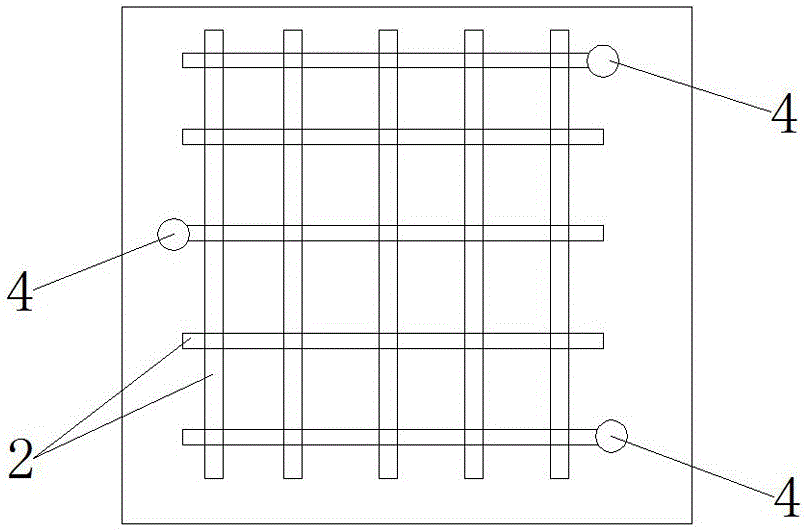

Soft foundation treatment method based on combination of two-time precipitation and dynamic consolidation

The invention discloses a soft foundation treatment method based on combination of two-time precipitation and dynamic consolidation. The soft foundation treatment method comprises following construction steps shown as figure 1: firstly, measuring and setting-out are performed, and a construction area range and a position of a tube well are determined; a drainage ditch is excavated to isolate phreatic water outside the construction area from entering the construction area; a shallow tube well is constructed, and primary precipitation is performed; medium-low energy dynamic compaction is executed, soil mass is consolidated, and phreatic water is extruded to the shallow tube well and pumped out; and vacuum tube well construction and secondary precipitation are performed; medium-high energy dynamic compaction is executed, drainage of pore water in soil mass is accelerated, and reconsolidation of the soil mass is accelerated; finally, low-energy full compaction is adopted to compact soil mass on the surface, the field is leveled, and detection is performed after a rest period.

Owner:ZHONGYIFENG CONSTR GRP

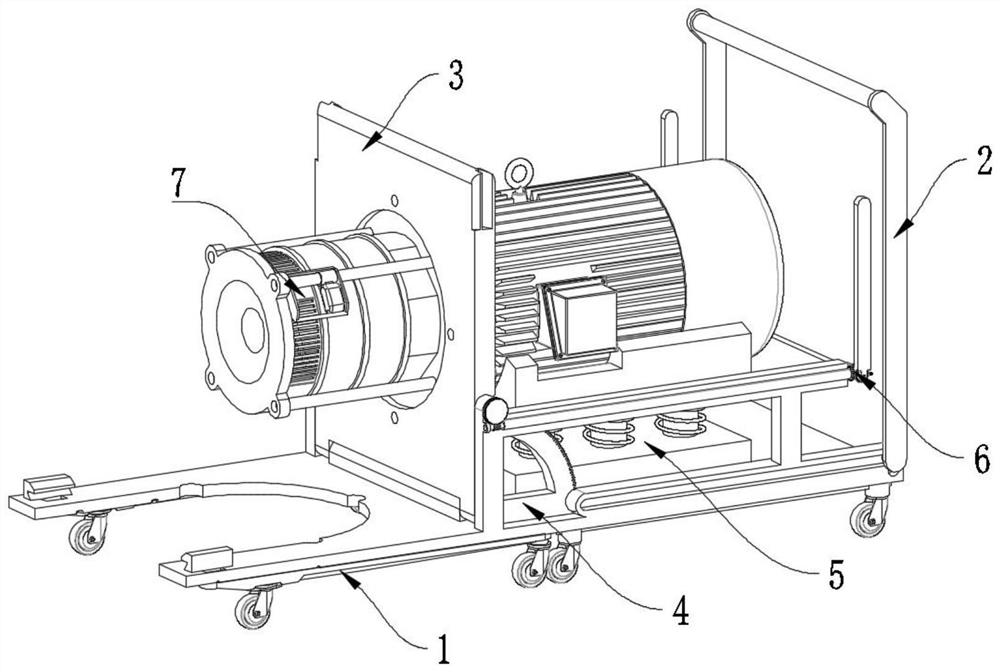

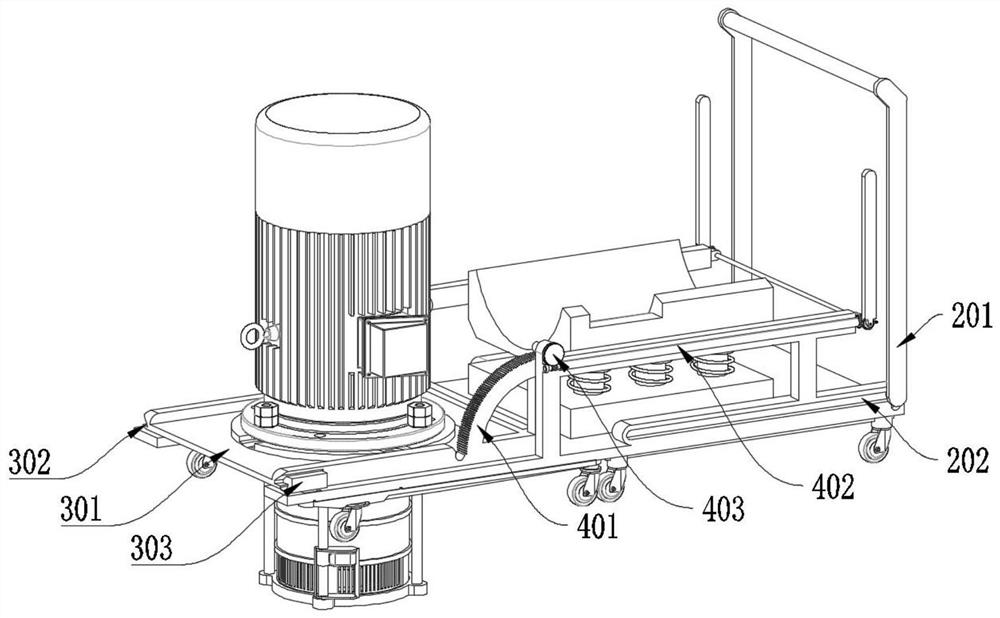

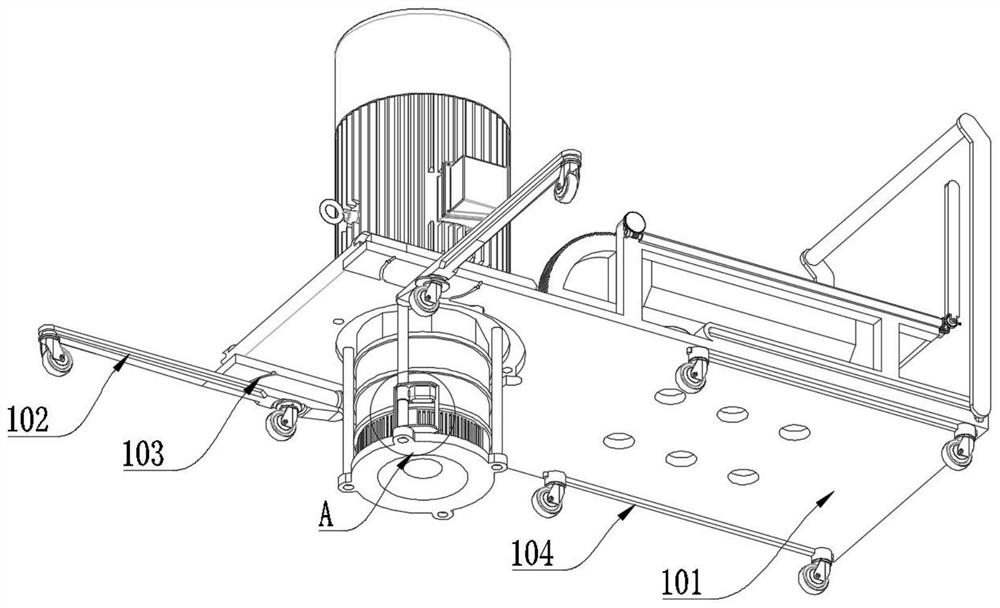

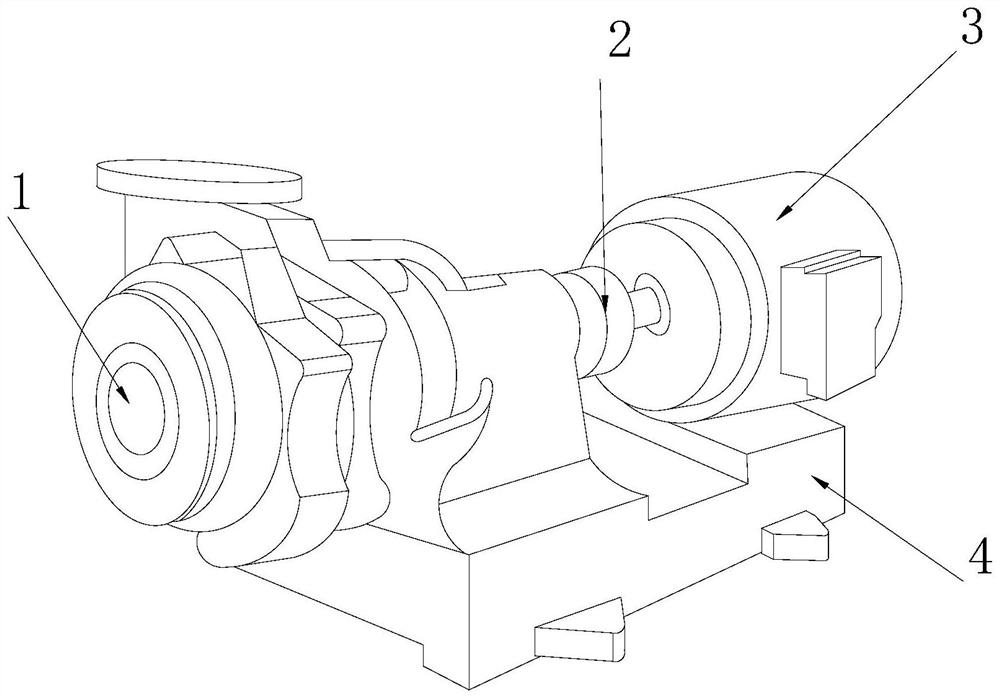

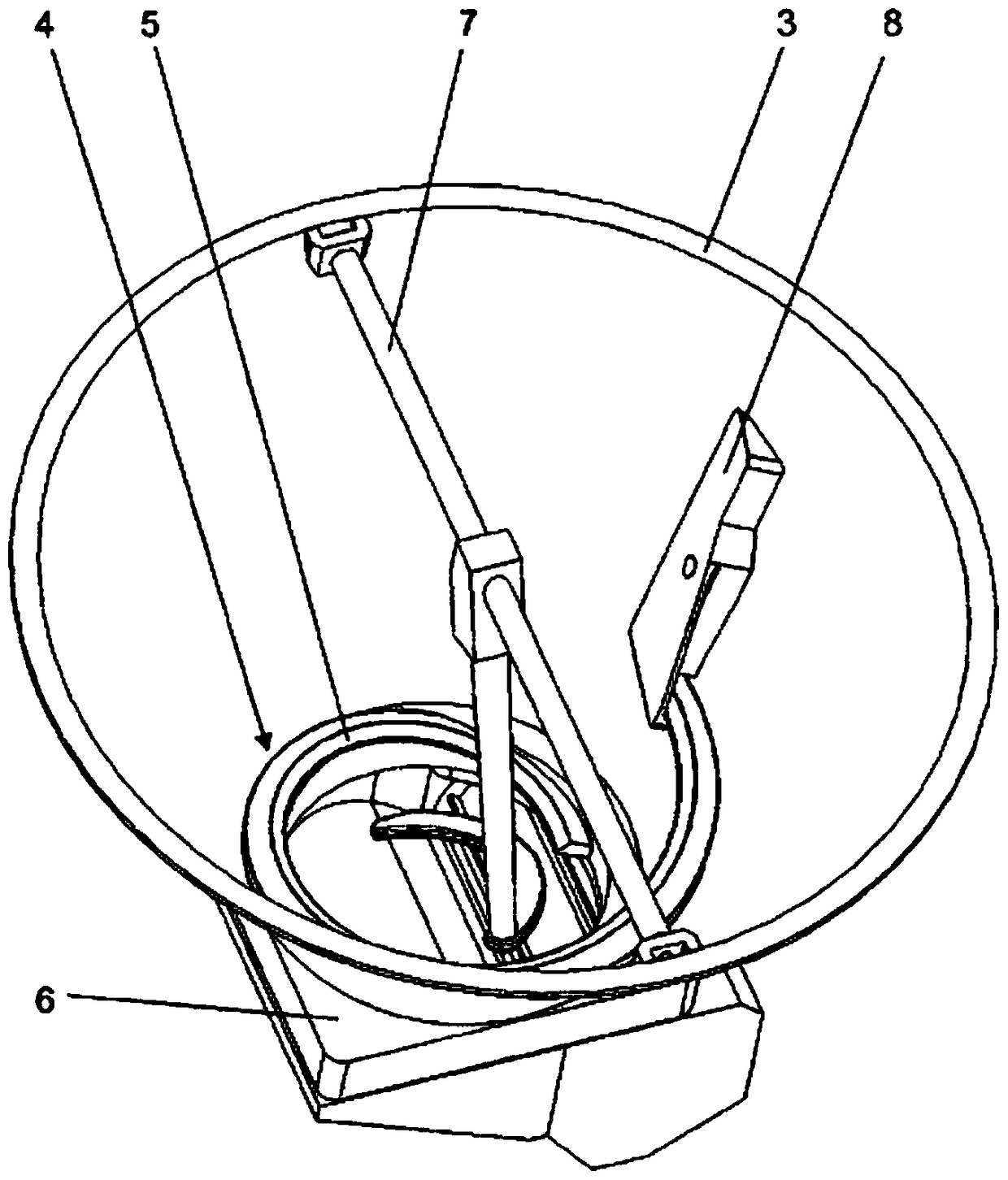

Portable centrifugal vertical water pump

PendingCN113236569AImprove stabilityGood bearing effect and stabilityPortable framesPump componentsPhysicsEngineering

The invention provides a portable centrifugal vertical water pump. The portable centrifugal vertical water pump comprises a bottom plate structure; an auxiliary structure is mounted at the right end of the bottom plate structure; a supporting structure is mounted at the left end of the auxiliary structure; a fixing structure is hinged to the upper end of the bottom plate structure; a detection structure is mounted at the lower end of the fixing structure; transmission structures are mounted at the front end and the rear end of the bottom plate structure; and one-way structures are mounted at the right ends of the transmission structures. The bottom plate structure further comprises a mounting plate and supporting rods, the two sets of supporting rods are rotationally mounted at the bottom of the mounting plate, wheels are rotationally mounted at the hinged positions and the tail ends of the supporting rods, bottom grooves are formed in the positions close to the mounting positions of the supporting rods, the supporting rods are mounted at the bottom, close to the left end, of the mounting plate, and the bottom grooves are formed in the rotating mounting positions of the supporting rods. The supporting rods can be clamped with the bottom grooves so that the mounting plate can be fixed at any angle of the bottom groove, and the overall stability of the mounting plate is improved.

Owner:张青军

Magnetic tunnel junction with non-metallic layer adjacent to free layer

ActiveUS8836061B2Reduce resistanceReduced pumping effectMagnetic-field-controlled resistorsSolid-state devicesSpin-transfer torqueRandom access memory

Owner:AVALANCHE TECH

Bottom uniform booster-type vacuum preloading treatment method

Owner:WENZHOU UNIVERSITY

Positive Displacement Pump System and Method with Rotating Valve

ActiveUS20100266422A1Reduce chanceImprove the immunityFlexible member pumpsPump controlPump chamberRotary valve

Systems and methods including a valve piston in a pumping chamber. The pumping chamber may include a pump inlet and a pump outlet in fluid communication with the pumping chamber. The valve piston may be configured to rotate between a first position within the pumping chamber and a second position outside of the pumping chamber.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

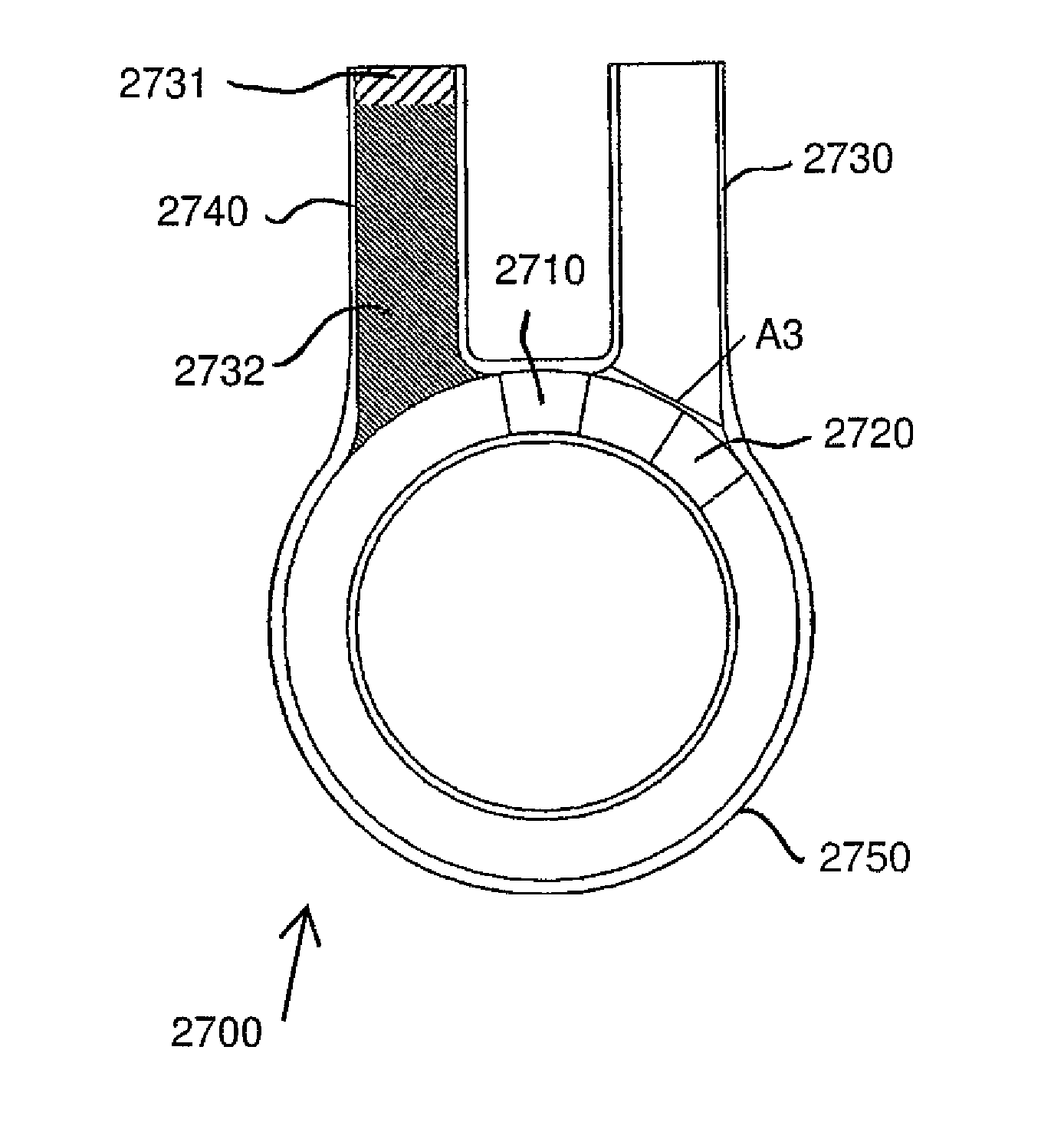

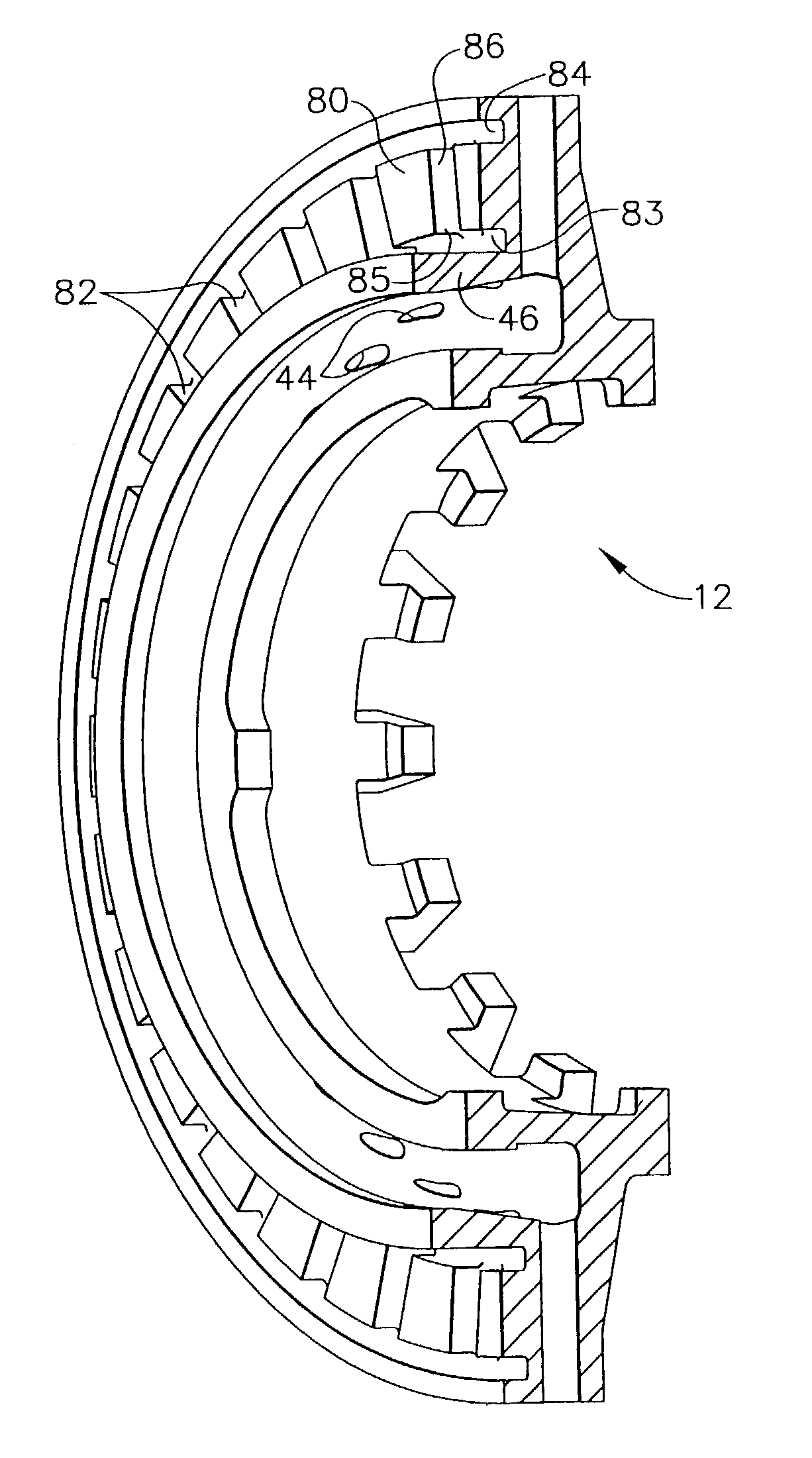

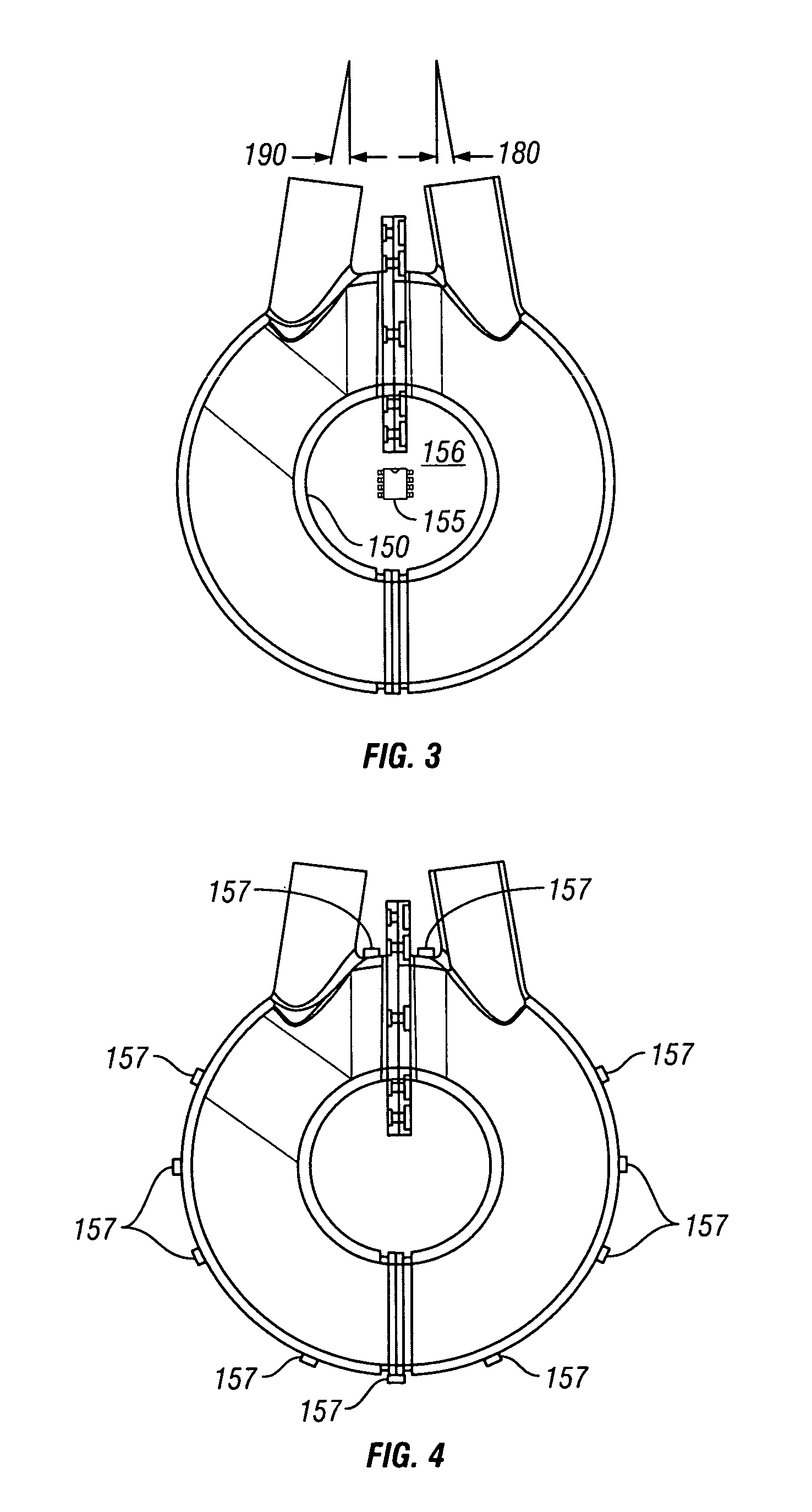

Vacuum pump

InactiveCN101371044AImprove suction performanceCheap constructionRotary piston pumpsRotary piston liquid enginesInterior spaceEngineering

A vacuum pump for producing a vacuum in a space which is to be evacuated has a housing (10) having a cylindrical inner space (22). An expeller (26) is arranged eccentrically in the inner space (22). A helical sealing element (34) is provided between the expeller (26) and an inner wall (38) of the housing (10) for forming at least one crescent-shaped conveying space. The housing (10) or the expeller (26) are connected to a drive device (44) for producing a relative rotary movement between the housing (10) and the expeller (26). According to the invention, the vacuum pump is configured as a dry-running vacuum pump.

Owner:OERLIKON LEYBOLD VACUUM

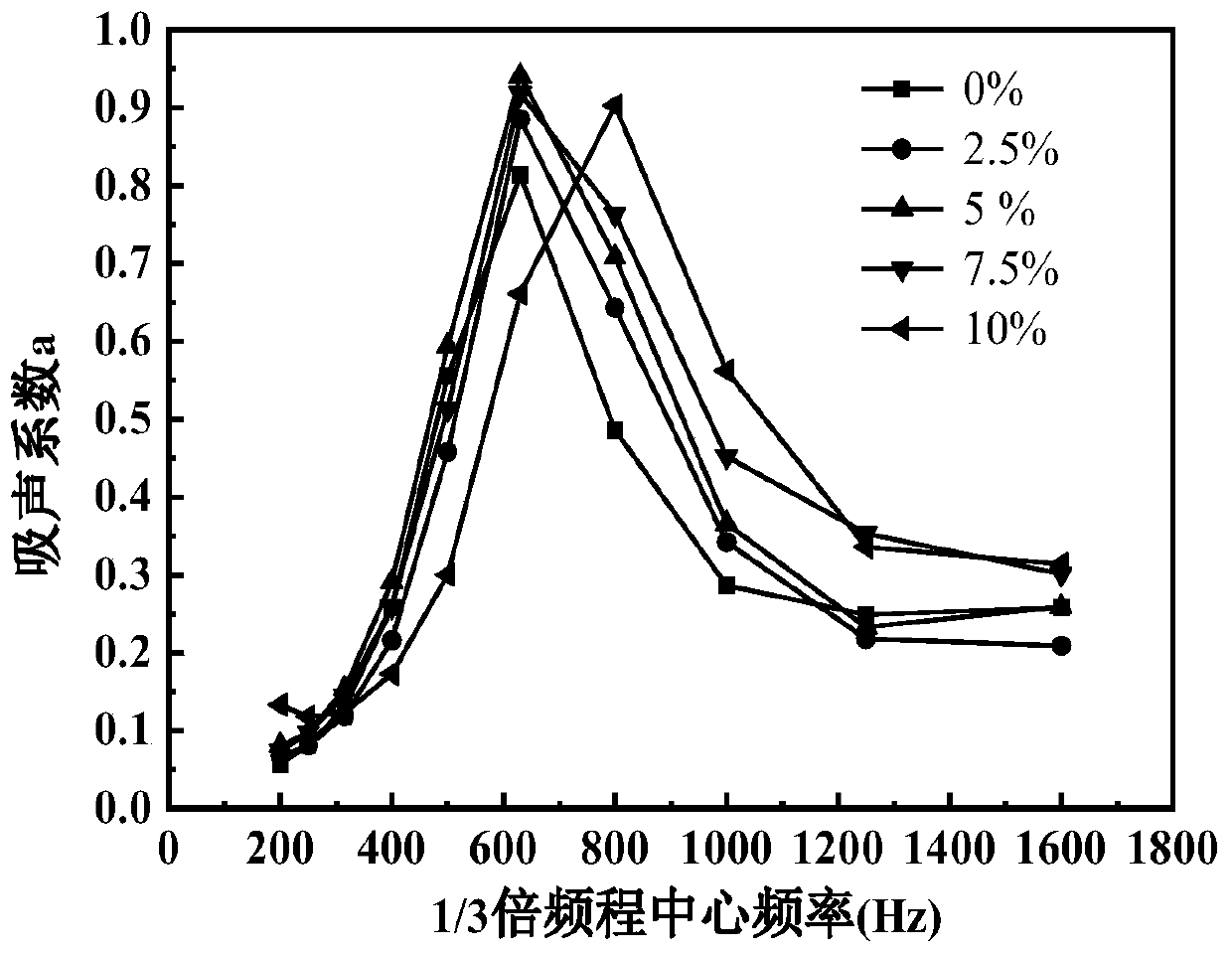

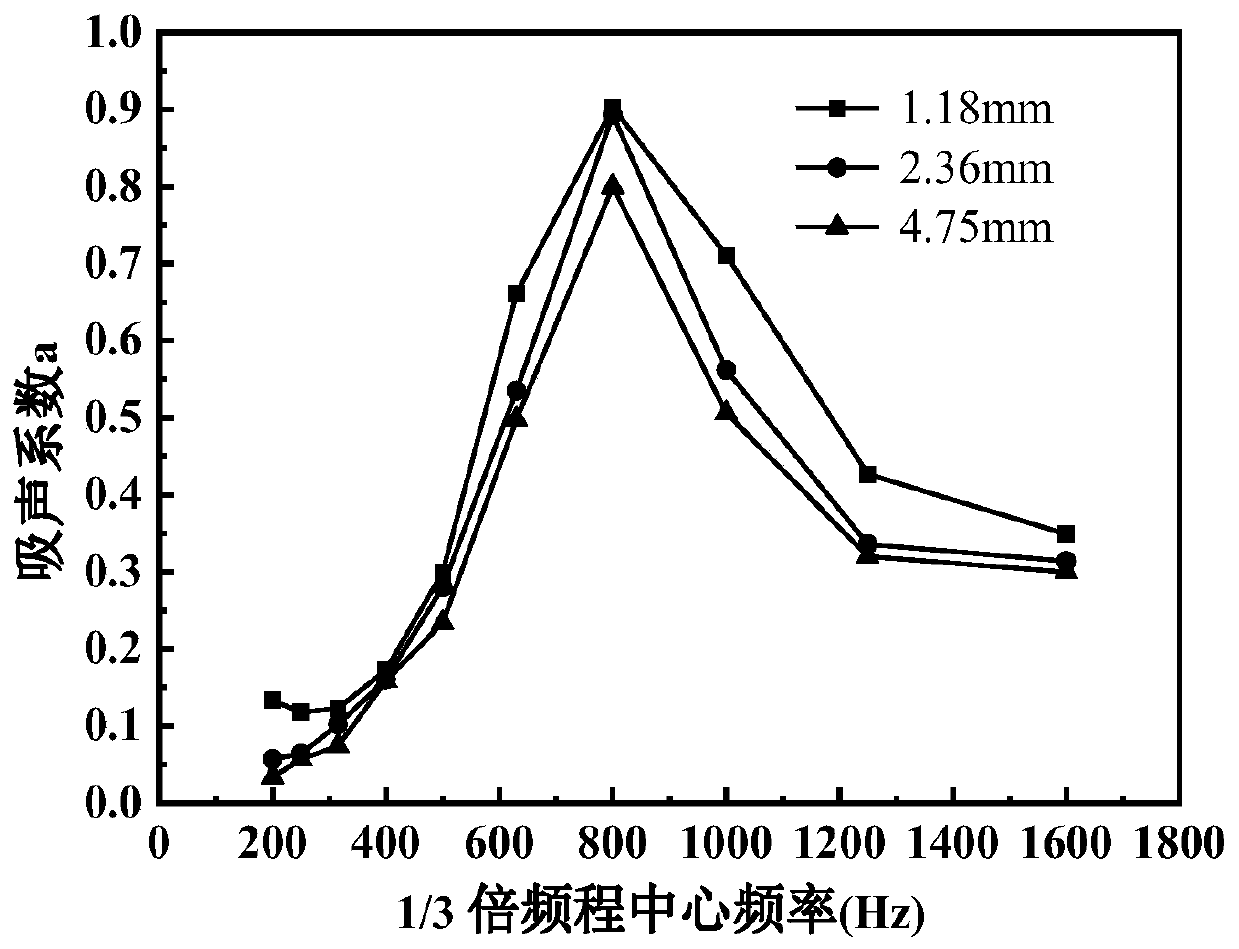

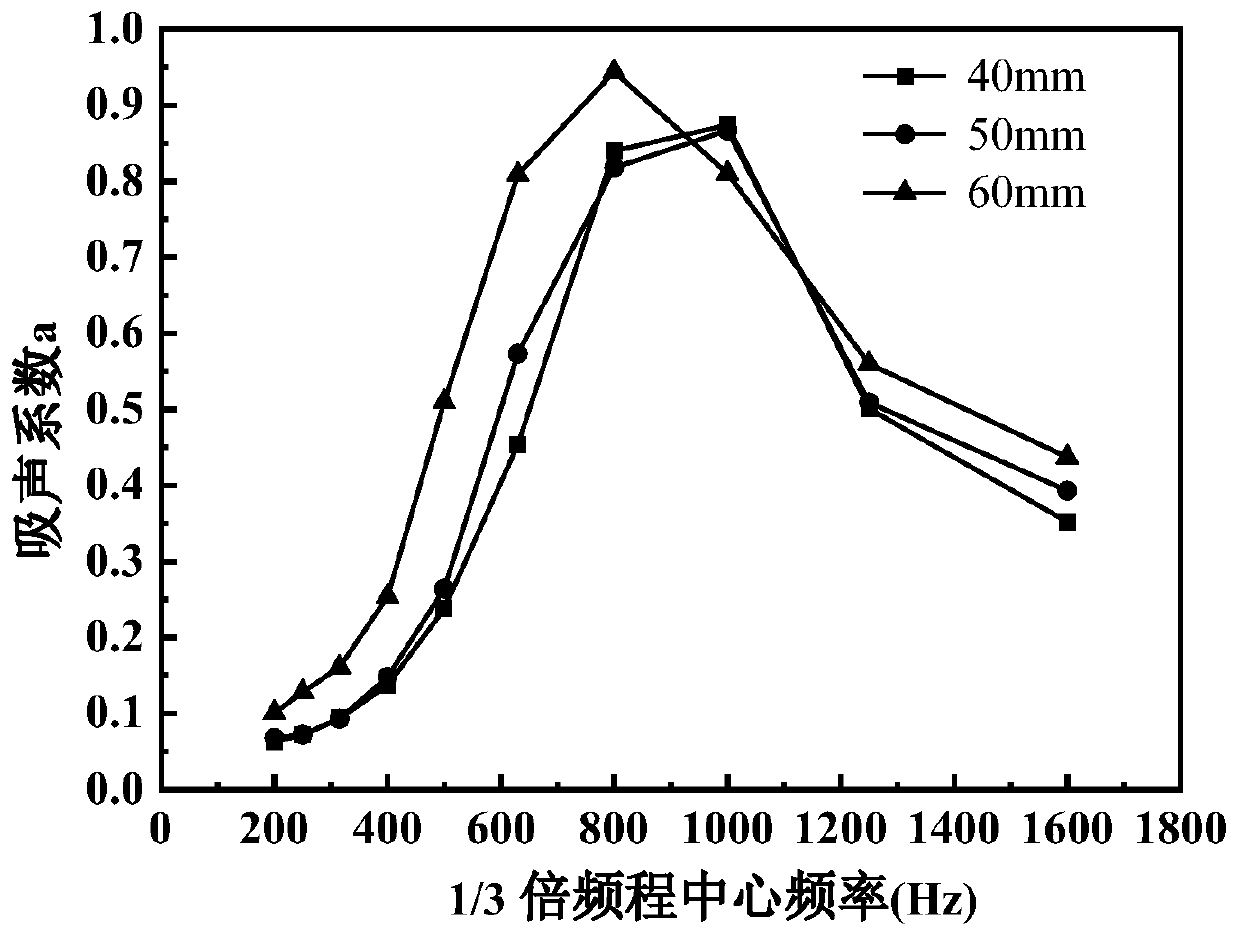

Ultra-quiet pavement paving material and application

InactiveCN110683791ASolve traffic noiseTraffic noise improvementIn situ pavingsCeramicwareEpoxyPolymer science

The invention relates to an ultra-quiet pavement paving material and application. The ultra-quiet pavement paving material comprises an aggregate, rubber and a two-component solvent-free polyurethanebinder, wherein the mass percentage of the two-component solvent-free polyurethane binder is 5.0-6.0%; the mass percentage of the rubber is 4-12%; the balance is the aggregate; and the two-component solvent-free polyurethane binder is synthesized by an epoxy resin and a polyurethane binder prepolymer according to a mass ratio of 1:(3-6). According to the pavement paving material which is providedby the invention, cubic rubber particles are adopted to be in contact with the aggregate to form connected pores, play good roles in sound absorption and noise reduction, and are easy to form stone-rubber-stone skeleton structures and can be in good contact with the aggregate, and thus the stability and the durability of the mixture can be ensured.

Owner:CHANGAN UNIV

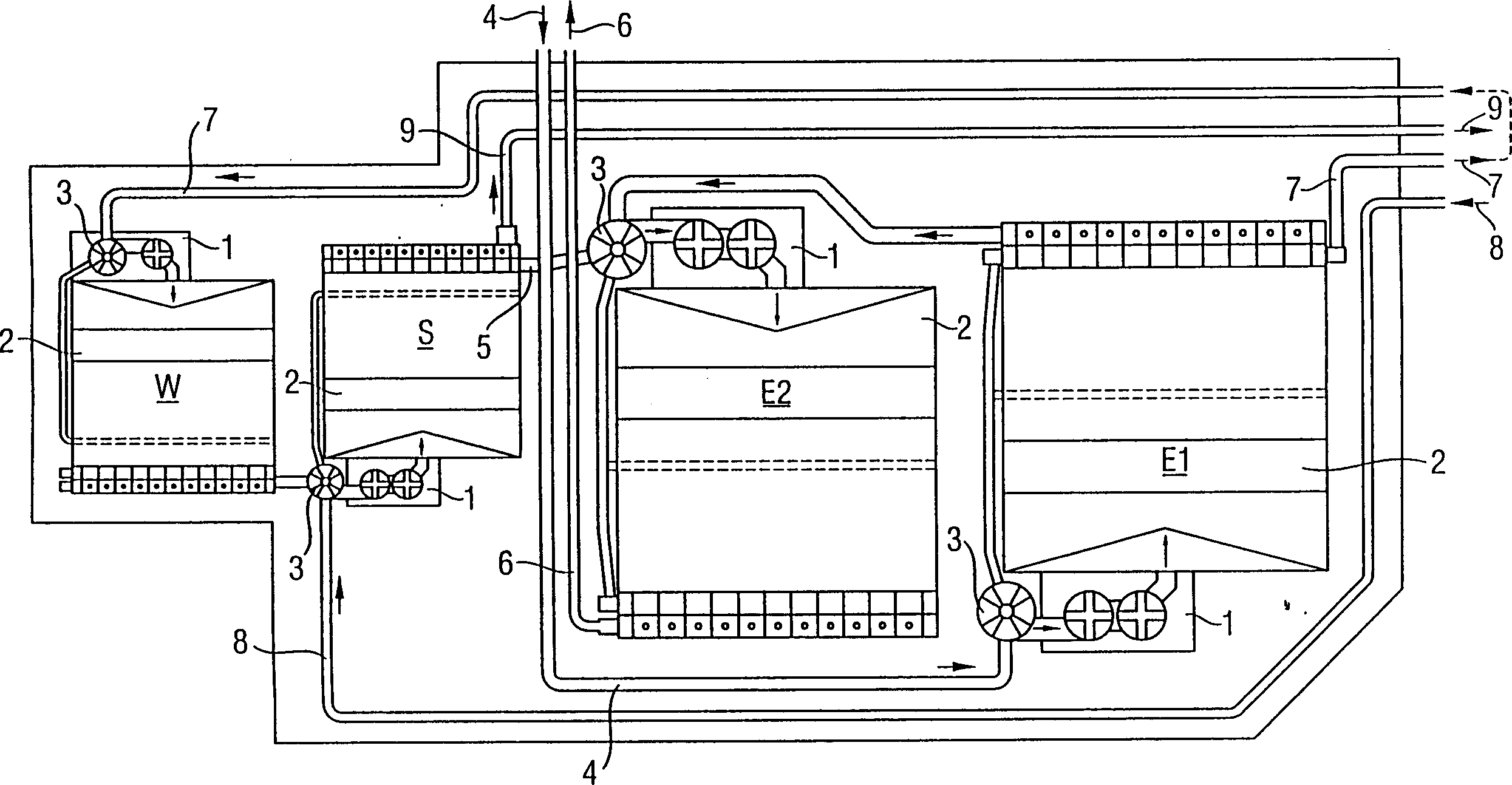

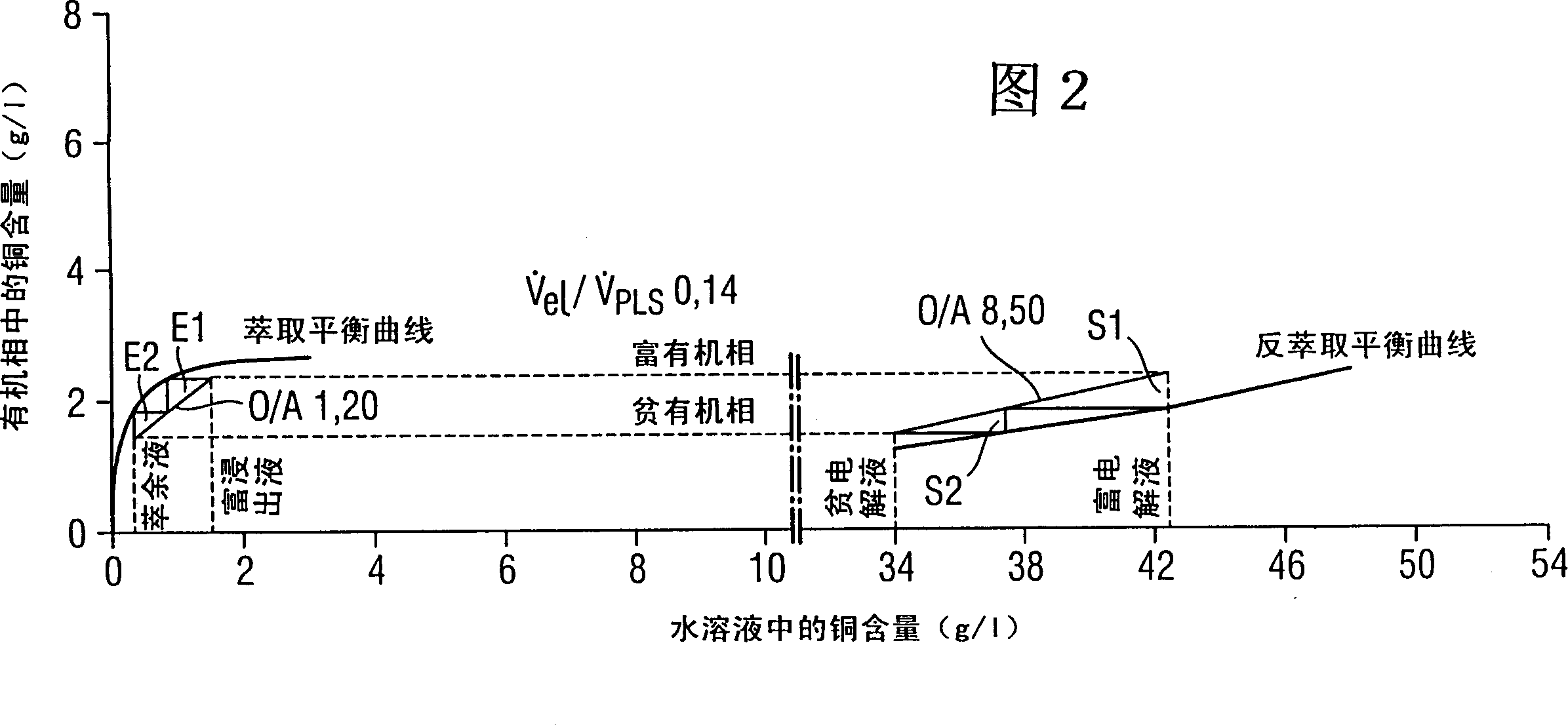

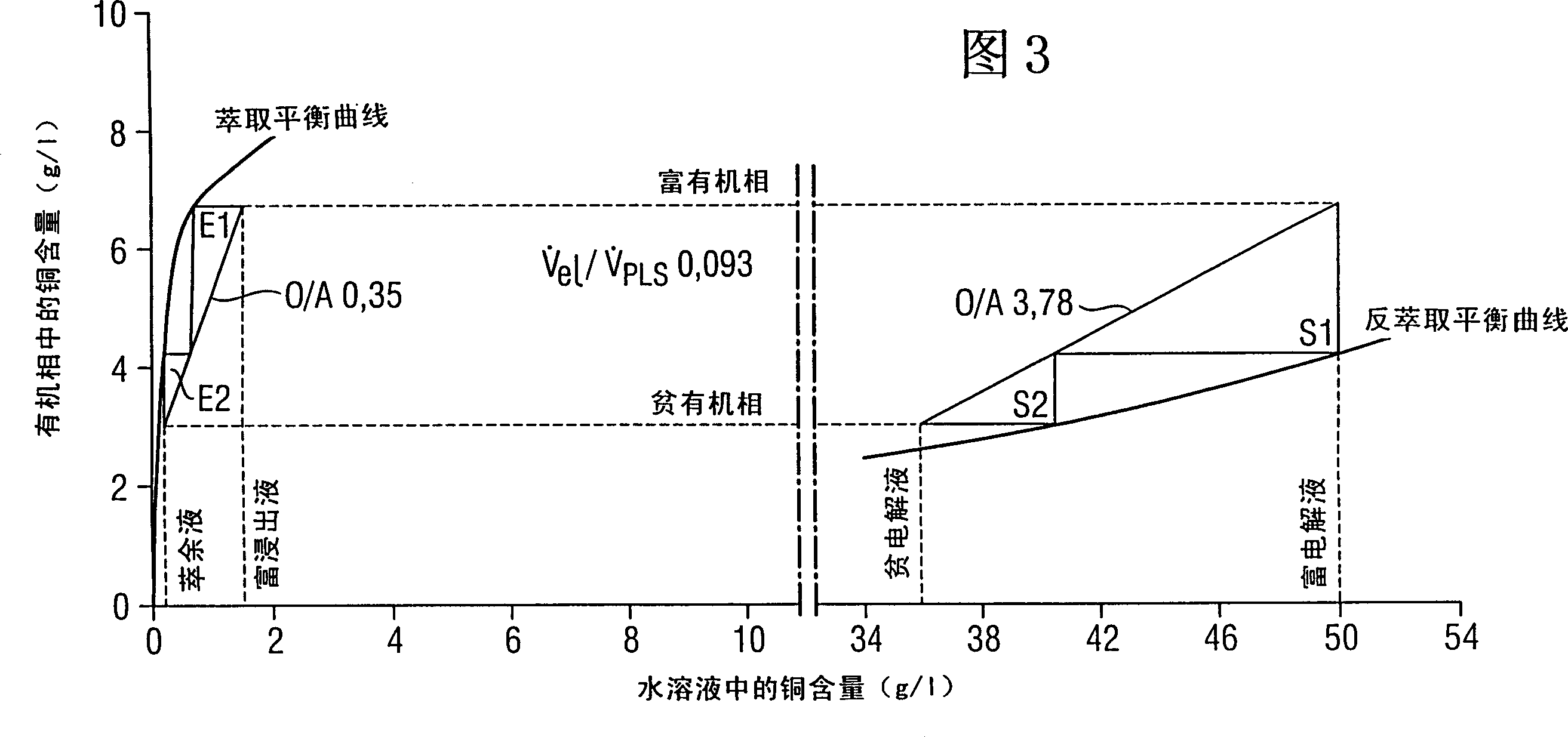

A method for extracting copper from an aqueous solution

InactiveCN1142004CHigh viscosityIncrease contentLiquid solutions solvent extractionProcess efficiency improvementChemistryAqueous solution

The invention relates to a method for extracting copper in liquid-liquid solvent extraction from aqueous solutions with a high sulphate content, by raising the viscosity of the extraction solution and by dispersing the aqueous solution into drops, achieving a dense drop aggregation. The viscosity of the extraction solution may be raised either by increasing the content of the actual extractant, the extraction reagent, in the extraction solution or by using a diluting agent with a higher viscosity than that of the diluting agent normally used. By raising the viscosity of the extraction solution the mixing durability of the extraction dispersion can be increased and resulting of that the amount of residual drops is decreased. Other advantages are that the extraction solution flow of the extraction process decreases in relation to the flow of the aqueous solution acting as the copper source and that the size of the extraction equipment needed is reduced.

Owner:OUTOTEC OYJ

Lifting equipment of fire pump

InactiveCN111894859AImprove liquidityIncrease rotation speedPump componentsPump installationsBalancing machineElectric machine

The invention discloses lifting equipment of a fire pump. The lifting equipment structurally comprises pressurized equipment, a power shaft, a motor and a supporting seat. The pressurized equipment ismounted on the end face of the left side of the power shaft in a welded manner, the end face of the right side of the power shaft is connected with the motor in an inlaid manner, the motor is mountedover the supporting seat in a build-in manner, the supporting seat is located below the right side of the pressurized equipment, when spiral strips rotate, moving blocks mounted on the inner end faces of the spiral strips in a build-in manner can drive currents to converge and flow to an intermediate point, and the rotating speed of a movable blade is increased; and by means of the lifting equipment, the effect of the stable liquidity of the currents is achieved through the cooperation of the liquidity of the currents and a balance mechanism while flow of the currents can be effectively guaranteed, and the situation that power is dissipated due to mutual collisions in flow of the currents, and the water pumping effect of the pump is weakened can be effectively avoided.

Owner:成都常瑞满郎商贸有限公司

A kind of automobile seat slide rail lubricating grease and preparation method thereof

Owner:NATOR LUBRICATION TECH JIANGSU CO LTD

Block supply system and method

ActiveCN104244722BSmall inertiaEasy to replaceMeat processingRotary piston pumpsEngineeringMechanical engineering

Owner:GEA FOOD SOLUTIONS BAKEL

Valve of liquid operation

ActiveCN104863766AReduce risk of damageReduced pumping effectMachines/enginesStress reducing fuel injectionSpring forceBody positions

The present invention relates to a valve of liquid operation, especially a fuel injection valve. The valve has a valve shell, wherein in the valve shell, on one hand, a valve body interacted with a valve seat is guided, especially a nozzle needle, on the other hand, an operating element interacted with the valve body is guided, i.e., the operating element causes the valve body to be pressed into a closed position facing the valve seat through a spring force of a spring element attaching to a spring plate position of the operating element, while fluid pressure at the valve body position raises the valve body from the valve seat against the spring force of the spring element, wherein fluid leaks and gathers in a spring cavity of the valve shell for containing the spring element and can be outputted from the valve through a leakage pipeline, and wherein, at least one hole is leaded in the spring plate of the operating element for connecting a sub-cavity of the spring cavity arranged at a first side of the spring plate with a sub-cavity of the spring cavity arranged at a second side of the spring plate.

Owner:MAN ENERGY SOLUTIONS SA

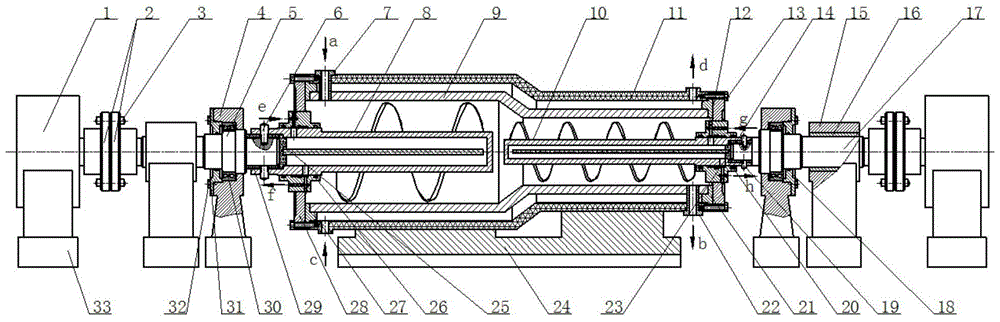

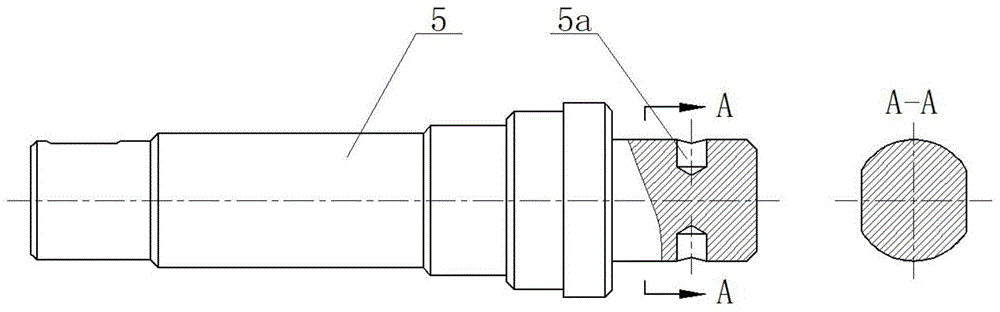

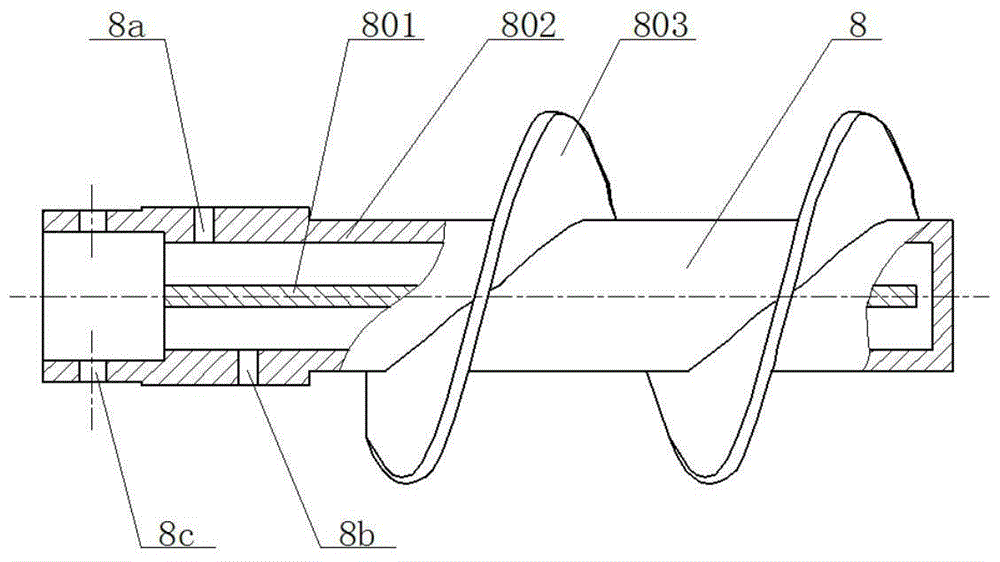

A full-wall heating double-speed helical pseudoplastic fluid pumping device and method

InactiveCN104632639BLow viscosityFully heatedPump componentsPump installationsInsulation layerLow speed

Provided are a full-wall-face heating double-speed spiral pseudoplastic fluid pumping device and method. Three parts of a power and power transmission module, a heating module and a spiral shearing and conveying module are included. The heating module carries out heating on fluid from the surface of a spiral device, another high-temperature heat conducting oil branch enters into the position between a cylinder body wall face and a cylinder body heat insulation layer, heating on the fluid on the cylinder body wall face is achieved, accordingly, the effect of full-wall-face efficient heating is achieved, the heating efficiency of pseudoplastic fluid is greatly improved, and the viscosity of the pseudoplastic fluid is lowered. A spiral shearing and conveying device can achieve fluid conveying and apply shearing speeds on the fluid at the same time, and shear thinning effect is achieved. Different shearing speeds can be achieved on the pseudoplastic fluid through a low-speed spiral vane and a high-speed spiral vane, meanwhile, by matching of a large spiral device and a small spiral device, certain negative pressure is formed in a cavity in a forced mode, flowing of the pseudoplastic fluid is achieved, and the pumping effect of the pseudoplastic fluid is improved.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com