Lifting equipment of fire pump

A water pump and fire-fighting technology, which is applied in the direction of mechanical equipment, pumps, pump devices, etc., can solve the problems of water pump boosting effect, water flow direction change, etc., to achieve the effects of weakening the pumping effect, smooth water flow, and reducing mutual collisions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] as attached figure 1 to attach Image 6 Shown:

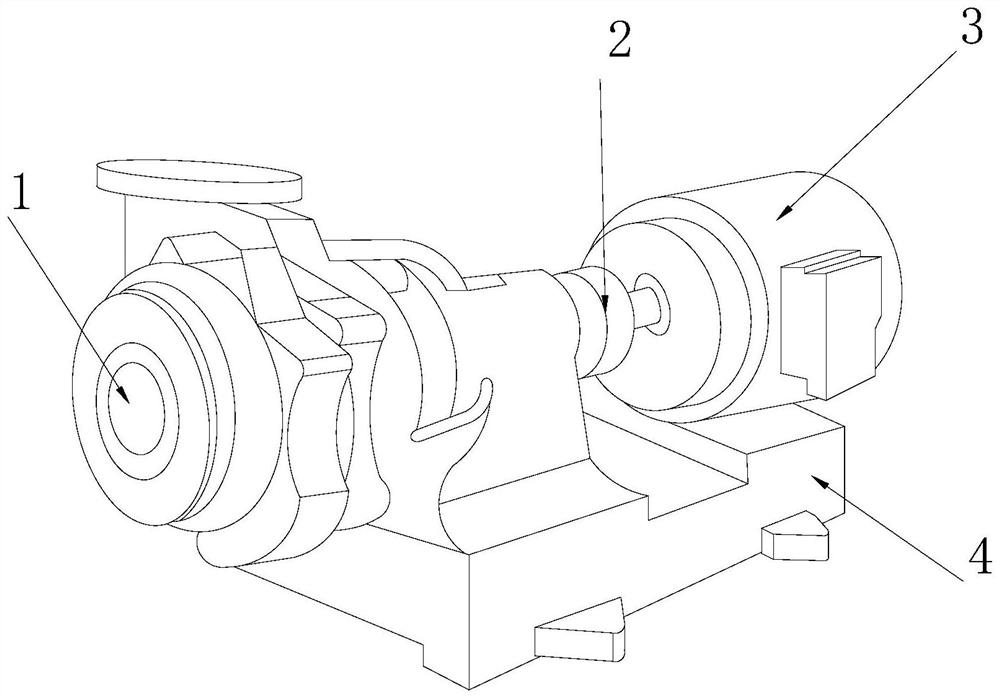

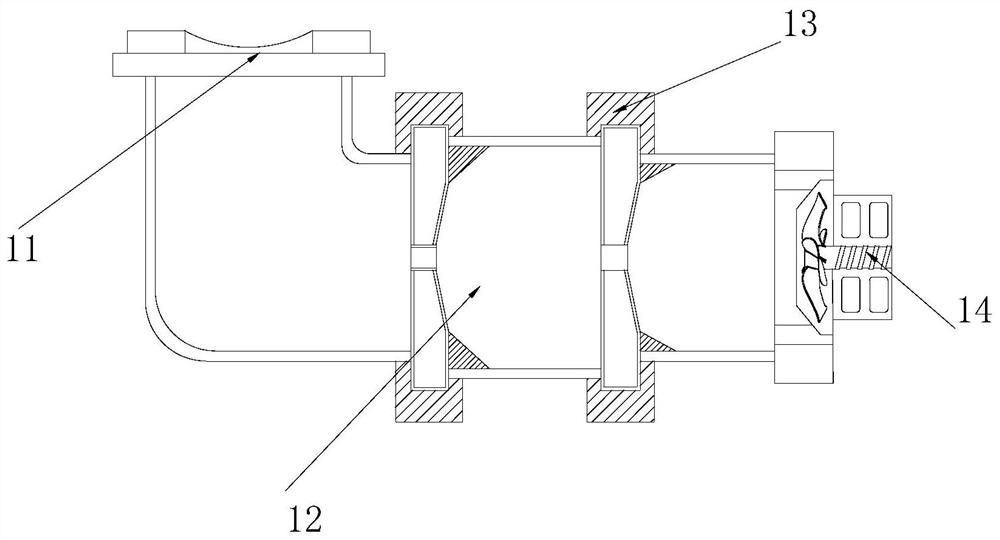

[0028] The invention provides a fire pump lifting device, the structure of which includes a pressurizing device 1, a power shaft 2, a motor 3, and a support seat 4. The pressurizing device 1 is installed on the left end surface of the power shaft 2 by welding, and the power The right end surface of the shaft 2 is inlaid with the motor 3, and the motor 3 is embedded and installed directly above the support base 4, and the support base 4 is located below the right side of the pressurizing device 1; the pressurizing device 1 includes an inlaid tube 11 , a pressurizing tube 12, an embedding ring 13, and a power paddle 14, the inlaying tube 11 is inlaid and mounted on the left side of the upper end of the pressurizing device 1, and the pressurizing tube 12 is nested and connected to the left side of the power paddle 14 , the embedding ring 13 is installed on the longitudinal outer end surface of the pressurizing pipe 12 by w...

Embodiment 2

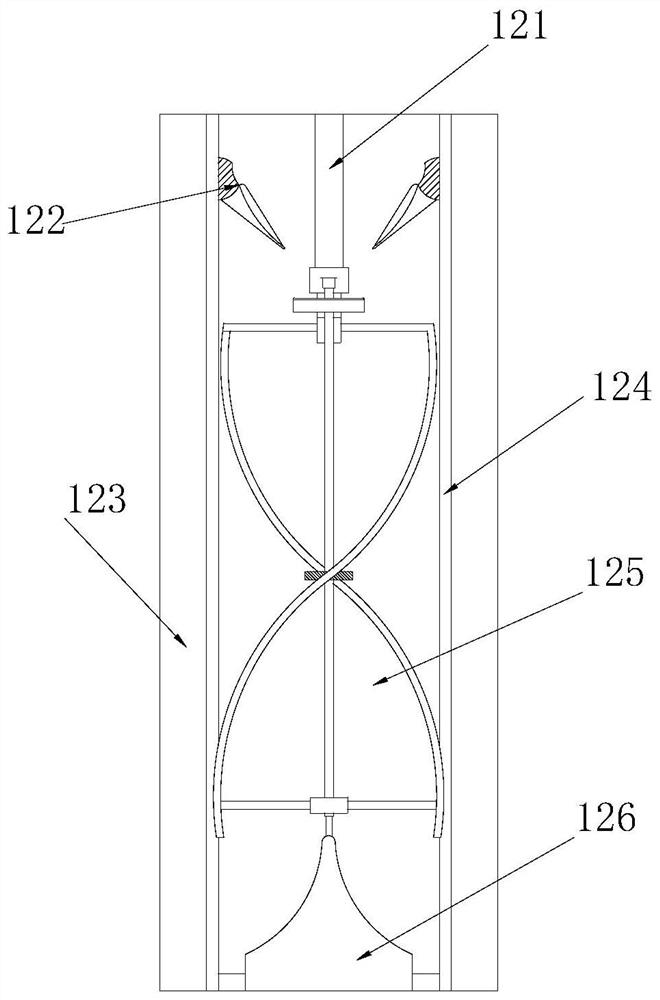

[0036] as attached Figure 7 to attach Figure 8 As shown: the circulation block 126 includes a cone 261, an inlay column 262, a fixed ring 263, a water seepage piece 264, and a connecting plate 265. The outer end surface of the column 262 is inlaid with a fixed ring 263, and the fixed ring 263 is installed on the inner end surface of the pipe wall 123 by welding. The water seepage sheet 264 wraps around the lateral outer end surface of the cone 261. The fixing ring 263 is at the center, and the cone 261 has a conical arc outer contour, which can effectively slow down the impact force of the water flow when the water flow hits from above and below.

[0037] Wherein, the water seepage sheet 264 includes an airtight patch 641, an inlay block 642, a fitting opening 643, and a diagonal flow block 644. connected, the mosaic block 642 is embedded and installed on the inner end surface of the water seepage sheet 264, the fitting opening 643 is set on the upper right side of the dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com