A full-wall heating double-speed helical pseudoplastic fluid pumping device and method

A pseudoplastic fluid and pumping device technology, which is applied to parts of pumping devices for elastic fluids, pump devices, axial flow pumps, etc., can solve problems such as poor thermal conductivity, long time consumption, and inhomogeneity , to achieve the effect of improving pumping performance, improving pumping effect and reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

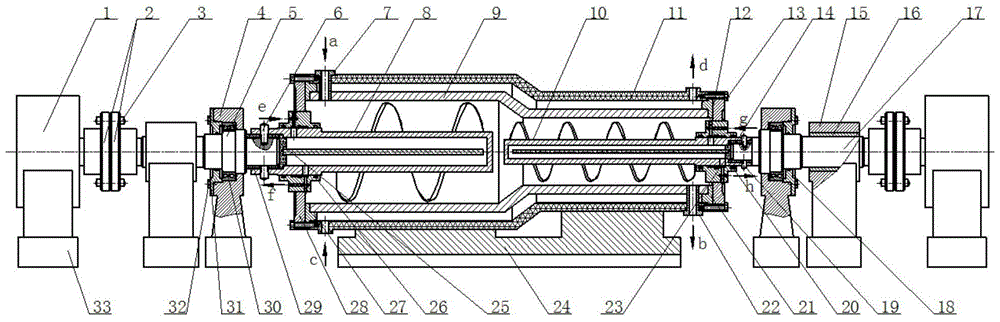

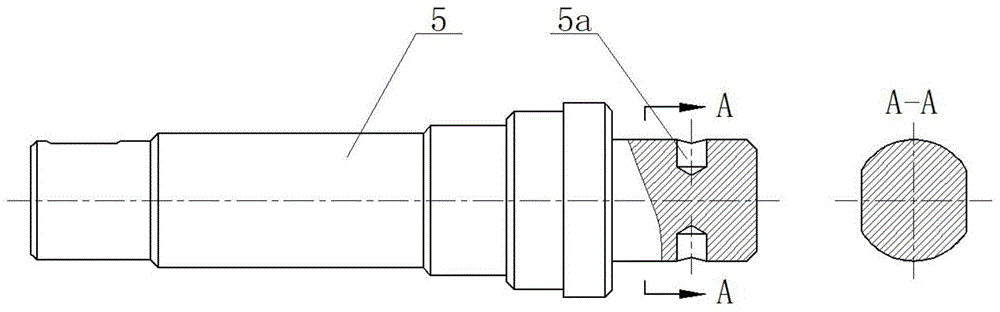

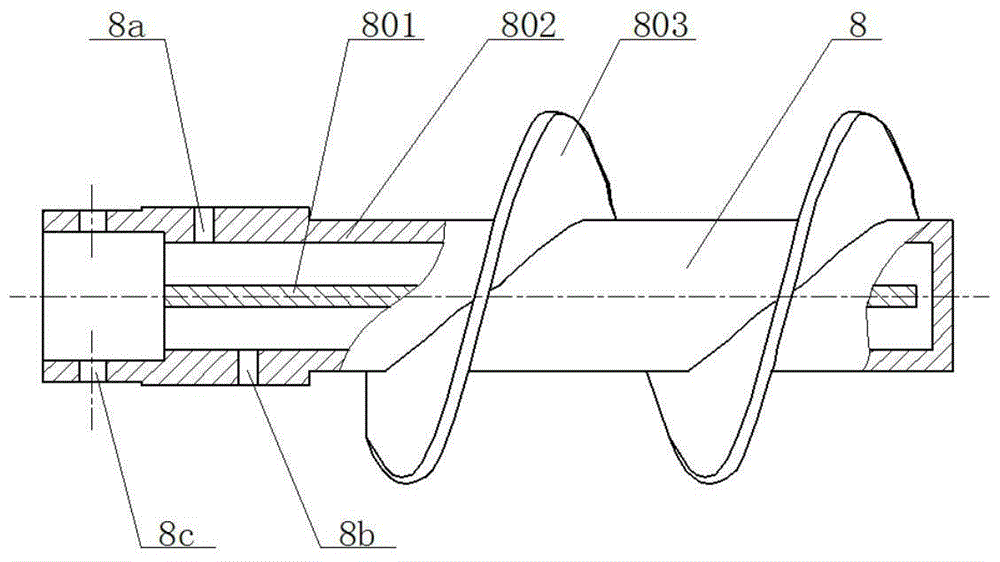

[0052] A full-wall heating double-speed spiral pseudoplastic fluid pump device of the present invention includes: a cylinder body 9 and a power and power transmission module. Such as figure 1 , figure 2 As shown, the power and power transmission module includes a hydraulic motor 1 at both ends, a motor base 33, a coupling 2, a cylindrical pin 3, a bearing housing 15, a bearing housing 16, a bearing housing 4, a double-row tapered roller bearing 30, and a low-speed input shaft 5. The high-speed input shaft 17, the large screw device 8 and the small screw device 10 are composed of the hydraulic motor 1 at both ends through the coupling 2 to drive the large screw device 8 and the large screw device 8 by the low-speed input shaft 5 and the high-speed input shaft 17 respectively. The small screw device 10 rotates, the input shafts 5, 17 and the screw devices 8, 10 are connected by profiles, and are positioned by pins 6, 19, and the connection parts of the two need to be provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com