Bottom uniform booster-type vacuum preloading treatment method

A treatment method and preloading technology, which is applied in the fields of soil protection, construction, and infrastructure engineering, etc., can solve the problems of poor pumping and drainage effects and affecting soil treatment effects, and achieve enhanced drainage effects, high hardness, and soil dense effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

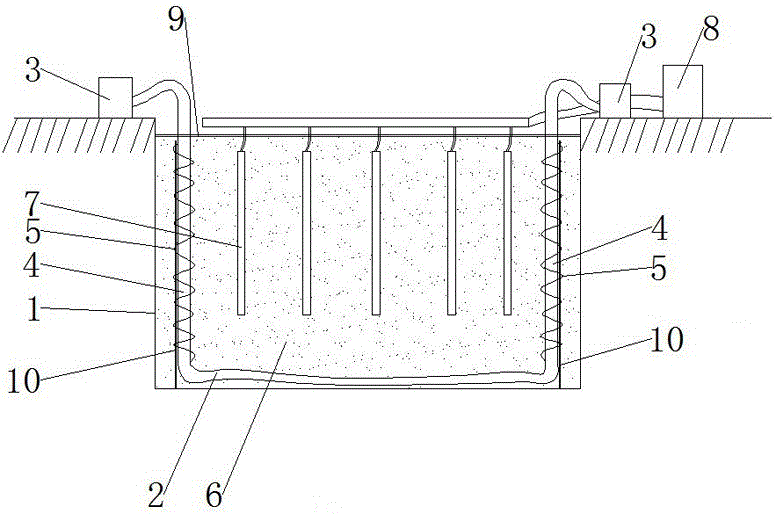

[0009] The accompanying drawings show the technical solution of the present invention and its embodiments, and the relevant details and working principles of the embodiments will be further described below in conjunction with the accompanying drawings.

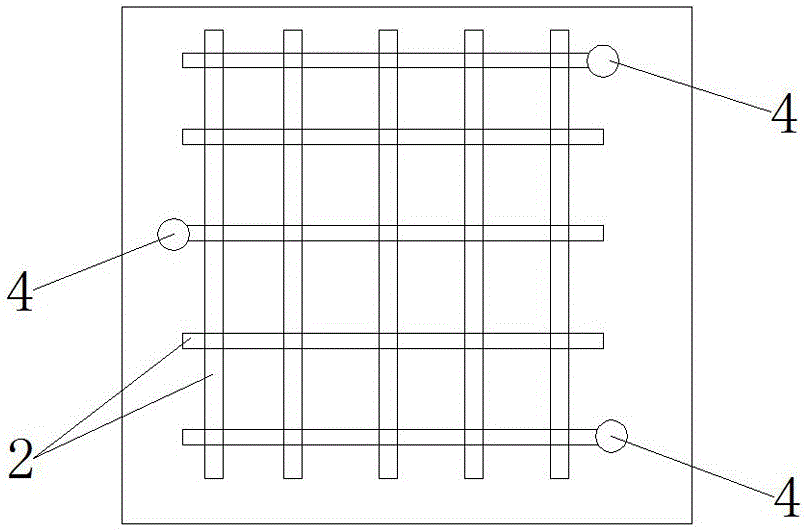

[0010] refer to figure 1 As shown, the bottom uniform pressurized vacuum preloading treatment method provided by the present invention includes A, excavating a preloading pit 1; The bottom inflation pipe 2 at the bottom and the vertical inflation pipe 4 connected vertically upward to the inflation device 3 outside the pre-pressing pit, the bottom inflation pipe 2 is densely covered with exhaust holes on the upward side, and the bottom inflation pipe 2 is connected to the vertical Leading to the inflatable tube 4, the vertical inflatable tube 4 is covered with a spring 5, and the vertical inflatable tube 4 can be covered with the spring 5 to maintain a vertical state while having elastic expansion and contraction performance, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com