Silica gel vacuum sealing drainage dressing

A silicone gel and negative pressure technology, applied in dressings, adhesive dressings, non-adhesive dressings, etc., can solve the problems of poor sealing of the transmission layer, unsatisfactory drainage effect, and slow wound healing speed, so as to prevent wound bleeding and reduce eczema and the occurrence of dermatitis, and the effect of improving the quality of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

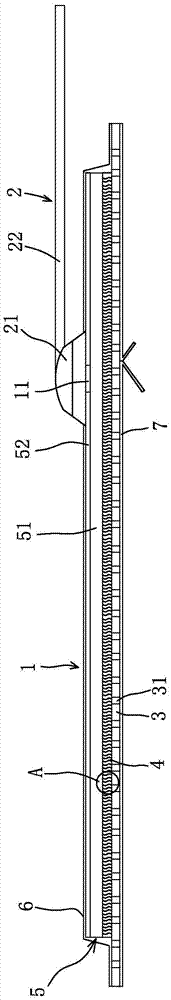

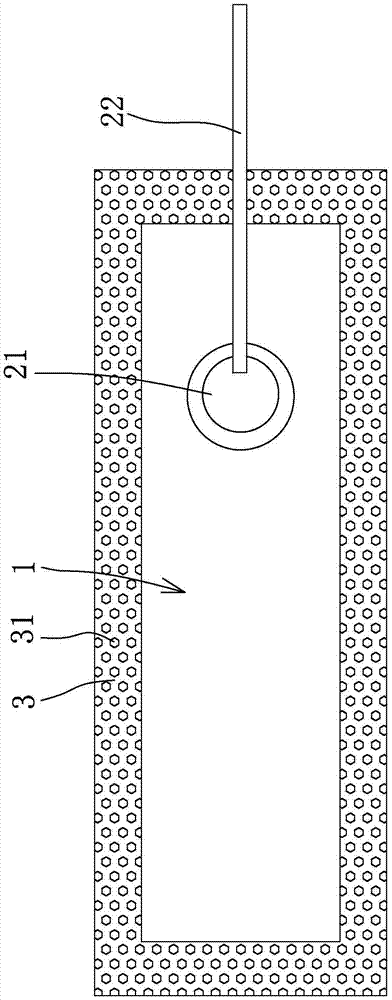

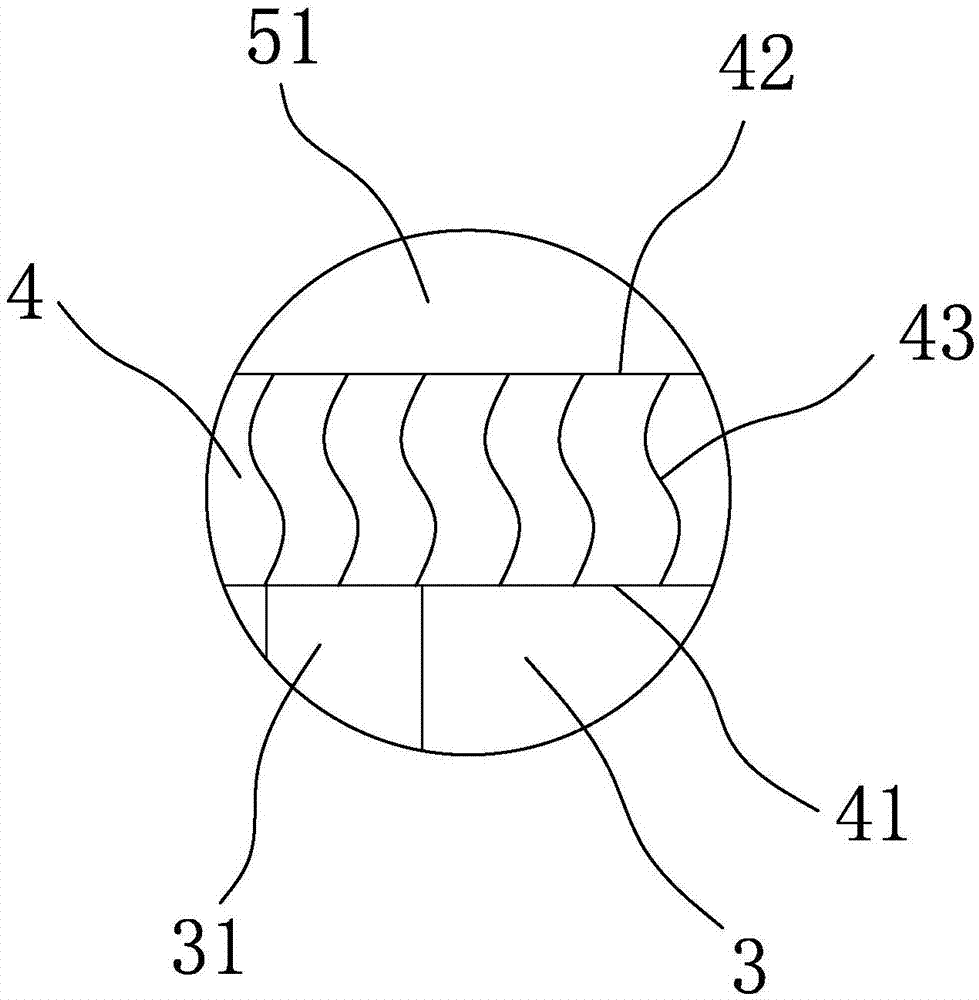

[0025] Such as figure 1 , figure 2 and image 3 As shown, the silicone gel negative pressure sealing drainage dressing in this program includes a dressing body 1, and the dressing body 1 is connected with a drainage structure 2 that can discharge the exudate under the action of negative pressure. It is characterized in that the dressing body 1 includes a silicone gel layer 3 that can adhere to the human body, with through holes 31 evenly distributed on the silicone gel layer 3, and a liquid storage filter layer 4 with storage and filtration functions and an absorption filter layer are arranged on the silicone gel layer 3 in sequence. The absorbent structure 5 with exudate function, the side of the silicone gel layer 3 that can adhere to the human body is provided with two pieces of release paper 7 that can cover the surface, and the adjacent sides of the two pieces of release paper 7 overlap each other . In this solution, the silicone gel layer 3 is used to fix the dressin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com