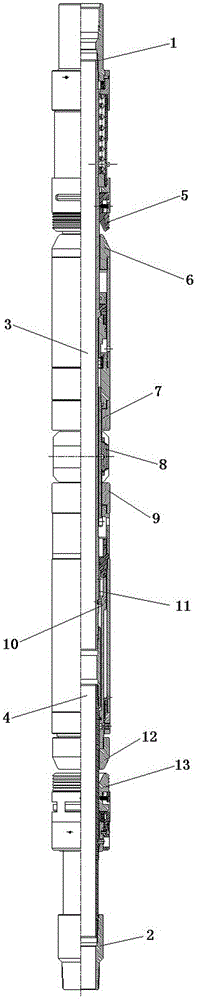

Recyclable hydraulic production packer

A packer and hydraulic technology, applied in the directions of sealing/packing, earth-moving drilling, wellbore/well components, etc. Reliable sealing, long service life, and the effect of reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

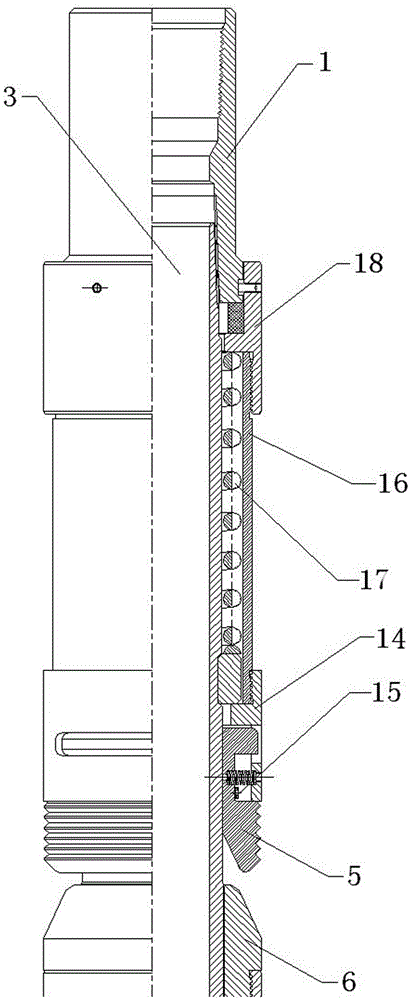

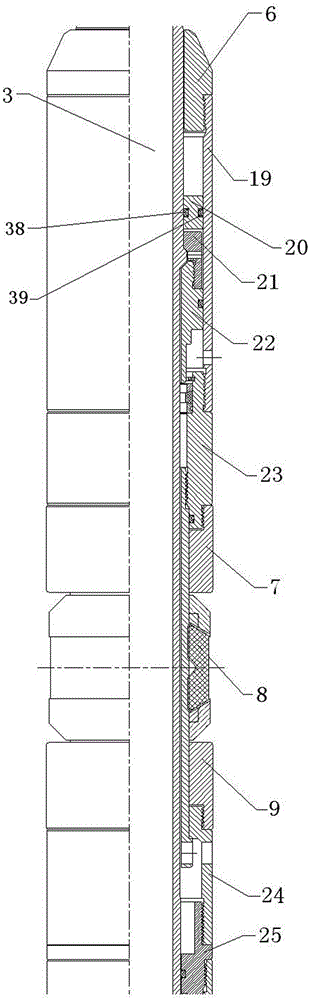

[0043]When the packer is running into the well, the design of the large bypass hole on the valve casing can reduce the swabbing effect when running and recovering. Use the supporting cannula or ball seat to form a seal at the inner hole of the packer, pressurize from the oil pipe, and the liquid passes through the pressure transmission hole 34 of the upper center pipe 3 to generate an axial downward thrust on the setting piston 10, and the pressure reaches When the unsealing force is applied, the setting piston 10 cuts off the first shear pin 32, and moves downward to push the lower cone 12 to squeeze the lower slip 13. When the extrusion force reaches the breaking force of the slip retaining ring 15, the lower slip 13 radial tension bites into sleeve pipe. The pressure of the pressure transmission hole 34 is transmitted upwards at the same time, pushing the connecting sleeve 25 to move upward. After the setting piston 10 gives way to the radial space, the pawl body 11 is driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com