Patents

Literature

59 results about "Production packer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A production packer is a standard component of the completion hardware of oil or gas wells used to provide a seal between the outside of the production tubing and the inside of the casing, liner, or wellbore wall.

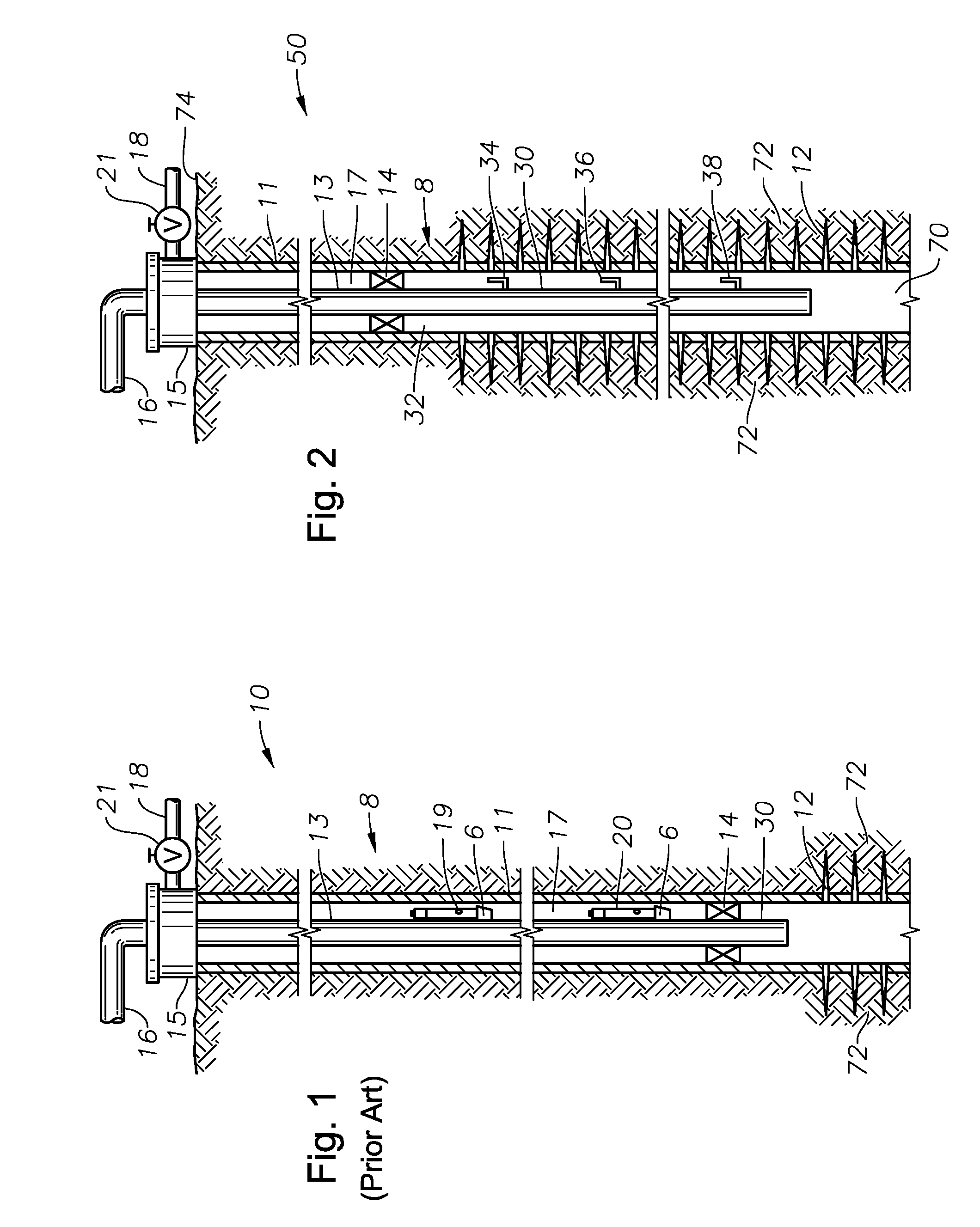

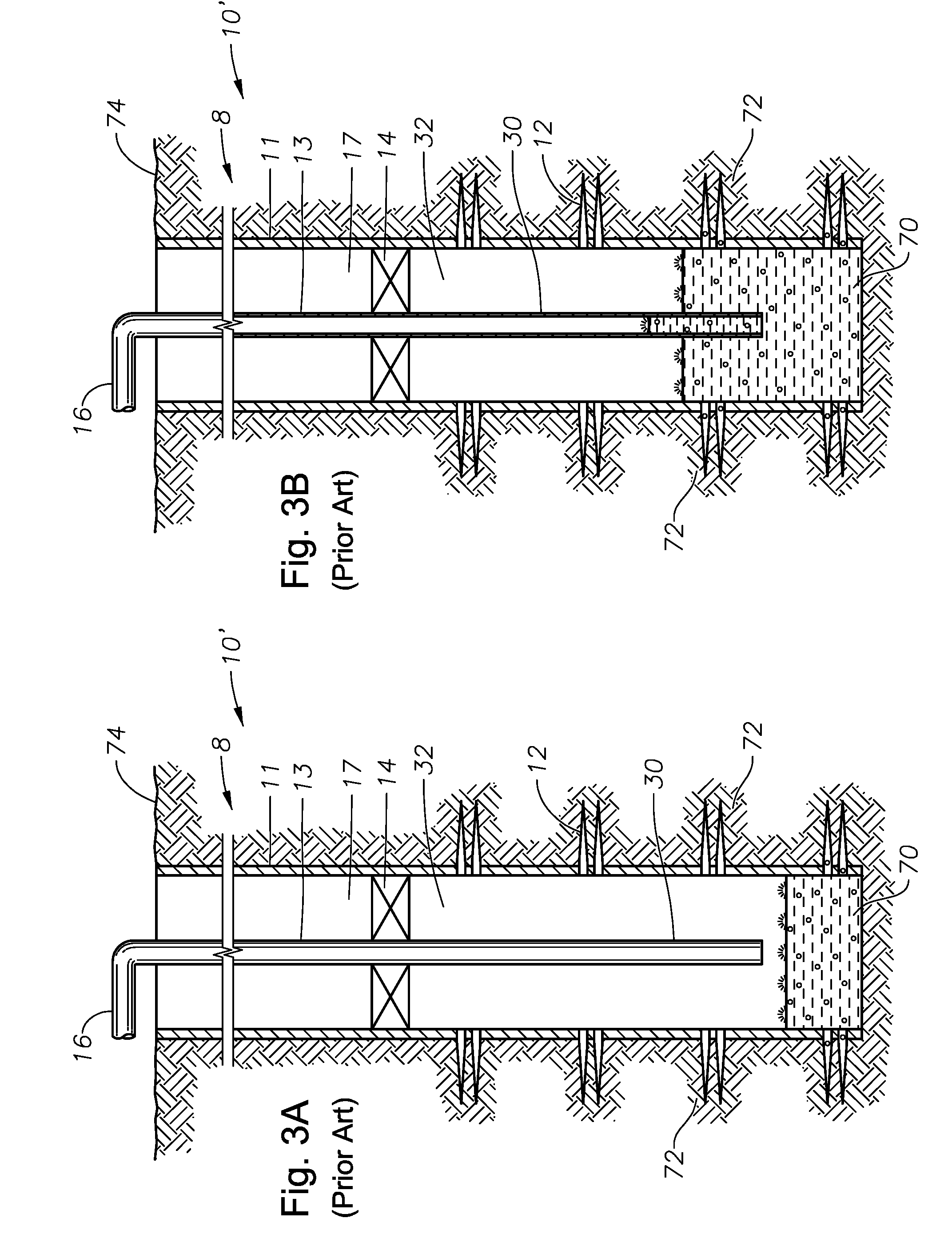

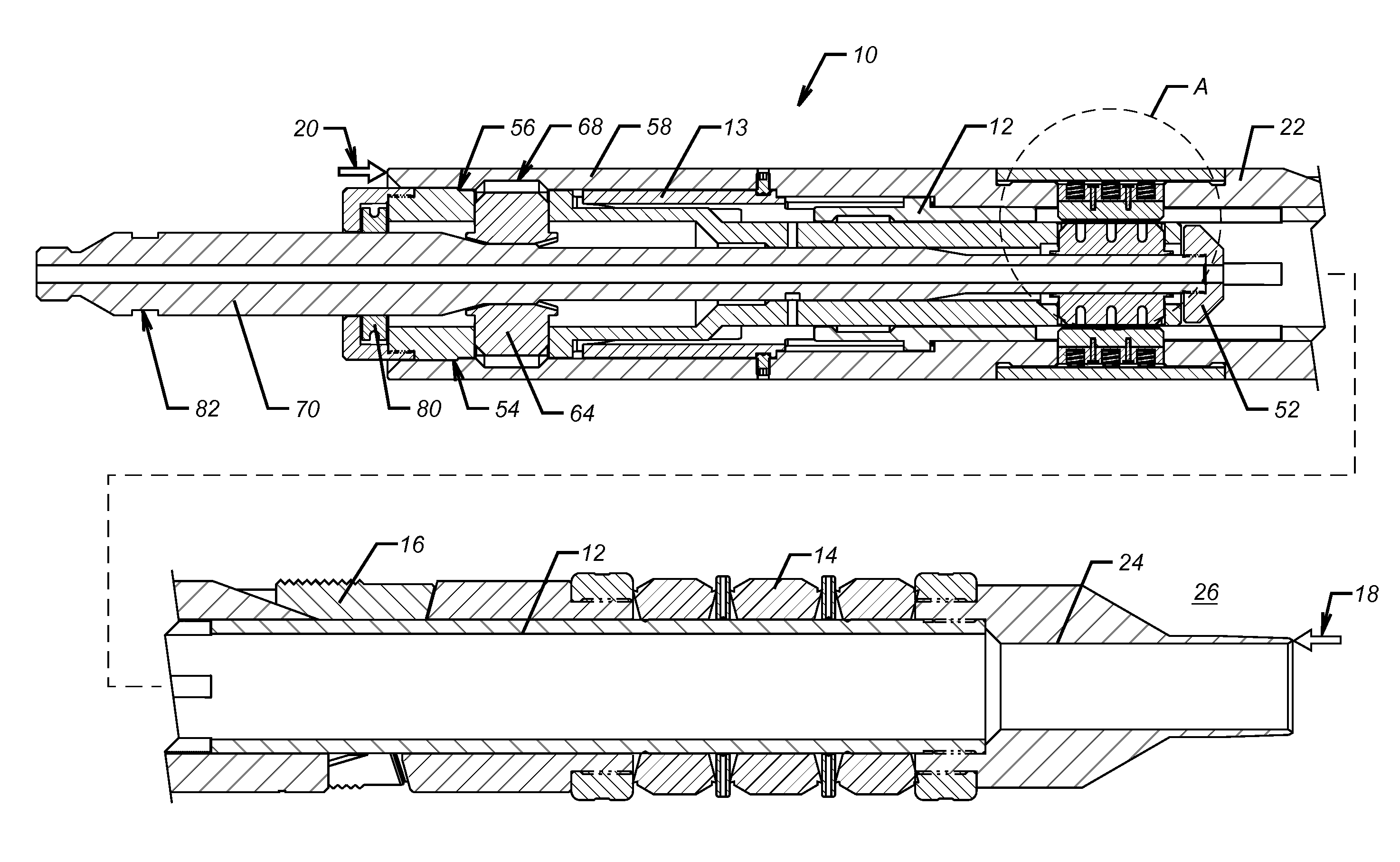

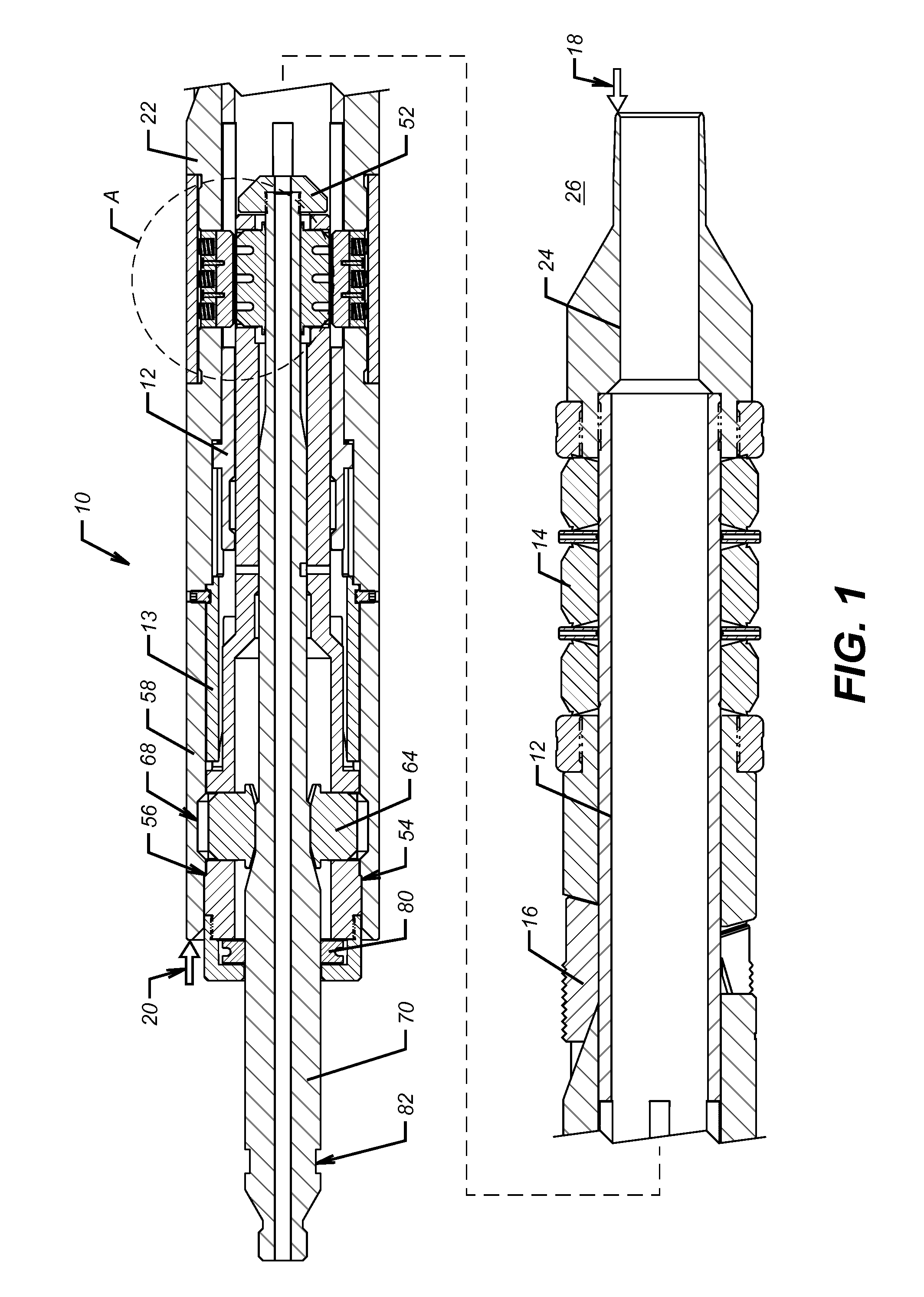

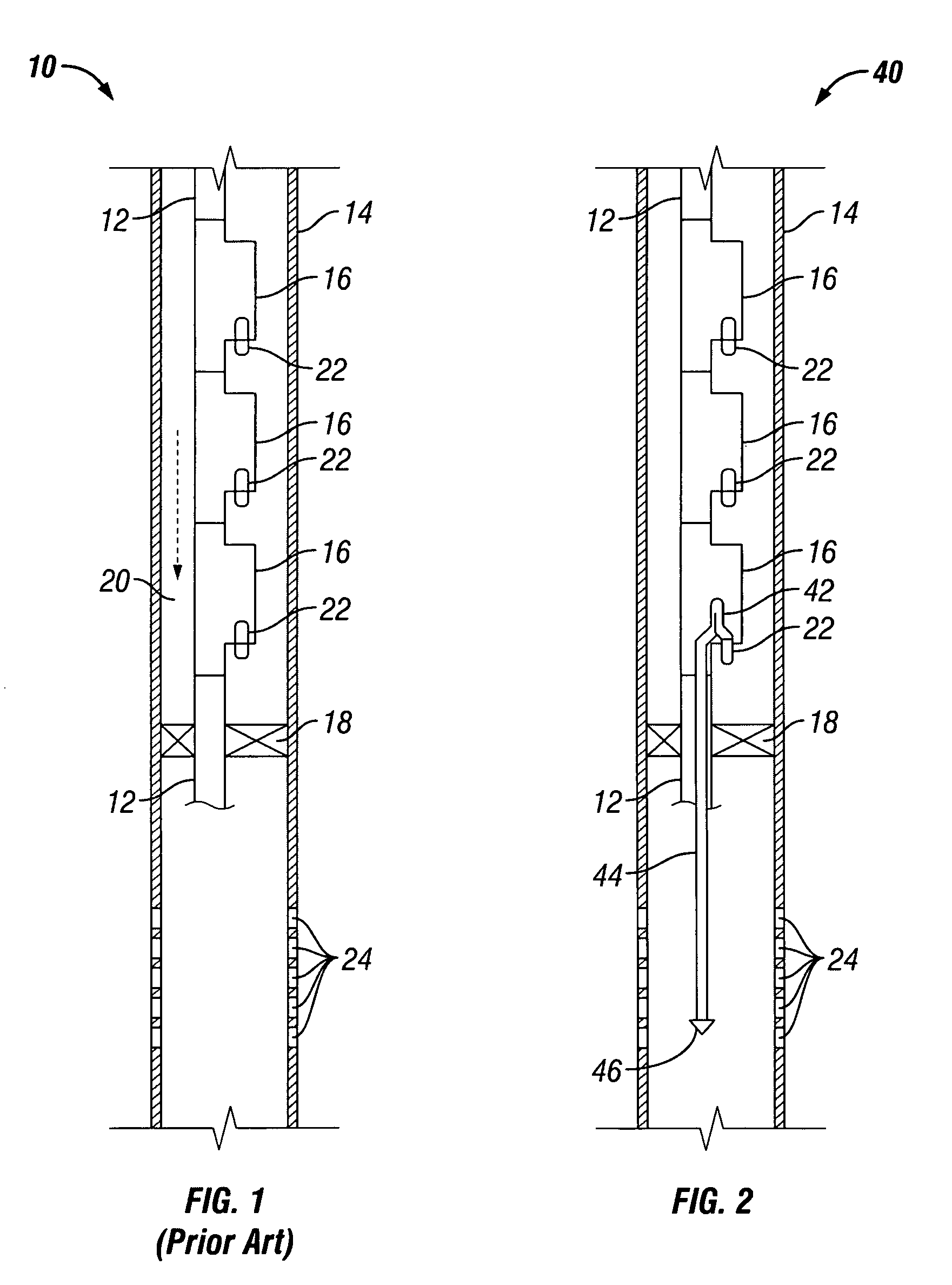

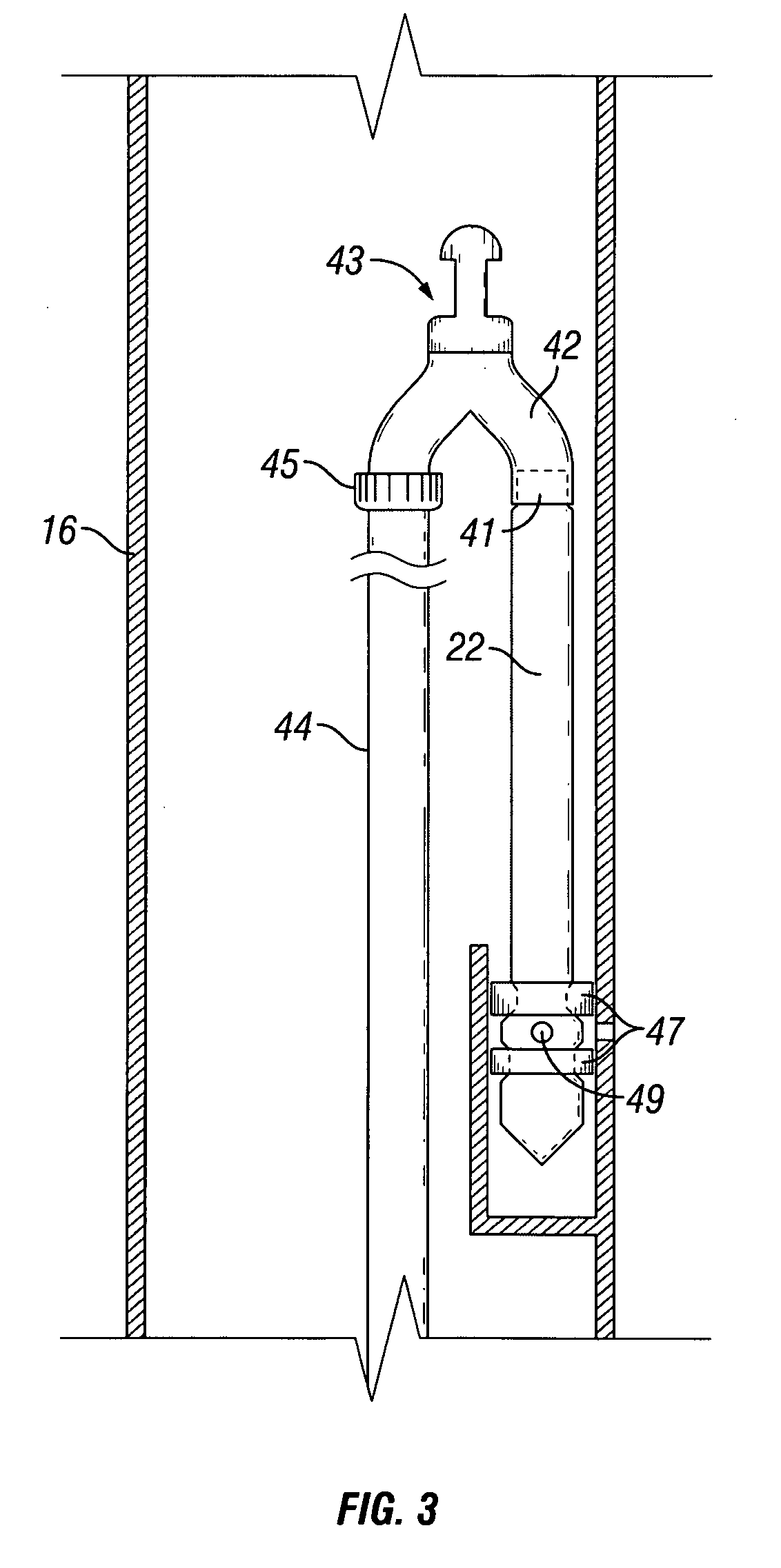

System and method for thru tubing deepening of gas lift

ActiveUS20090255684A1Blowout preventionFluid removalWell/borehole valve arrangementsProduction packerInjection point

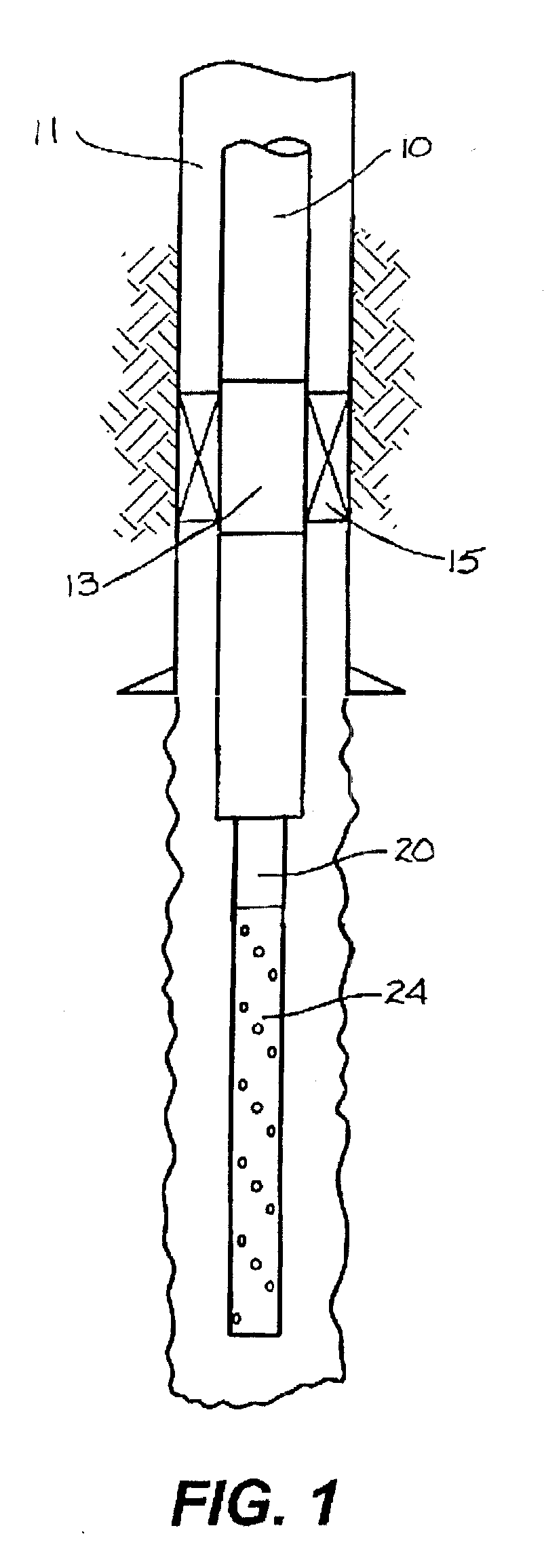

The present disclosure is directed to a gas lift system adapted to provide a gas injection point to a deeper location in a wellbore. A turn-over suspension mandrel can be landed inside a side pocket mandrel and connected to a gas lift valve on one end and a coil on the other end. A length of production tubing can extend from the side pocket mandrel. The production tubing can include a production packer to seal the annulus between the tubing and the well casing. The turn-over suspension mandrel can be constructed such that gas entering the gas lift valve is directed down through the coil and into the wellbore beneath the production packer. A plug can be placed at the bottom of the coil in order to prevent blowouts during installation of the gas lift system. An alternative embodiment of the present disclosure provides a coil and plug hung from a gas lift valve of a pack-off assembly.

Owner:BAKER HUGHES INC

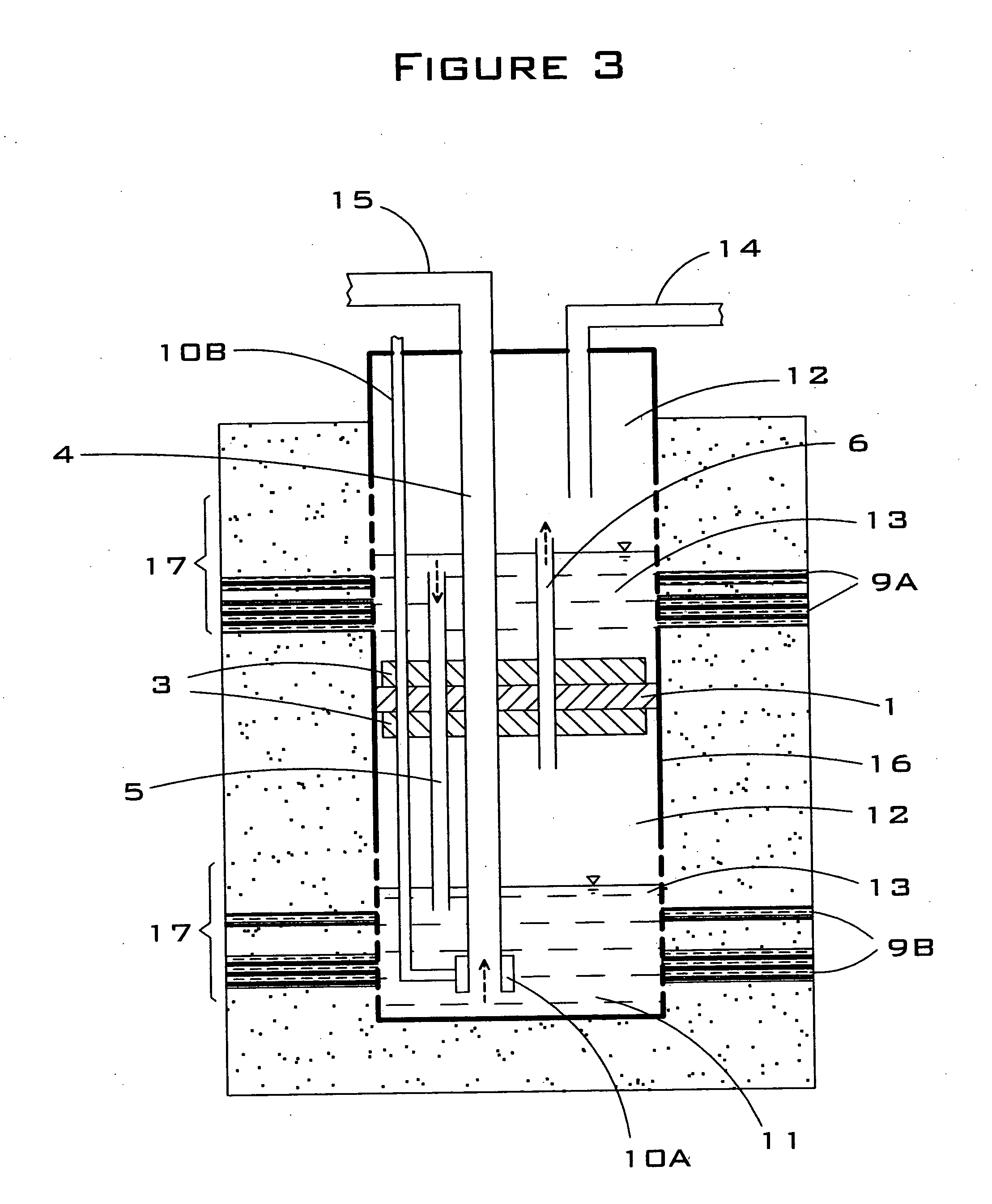

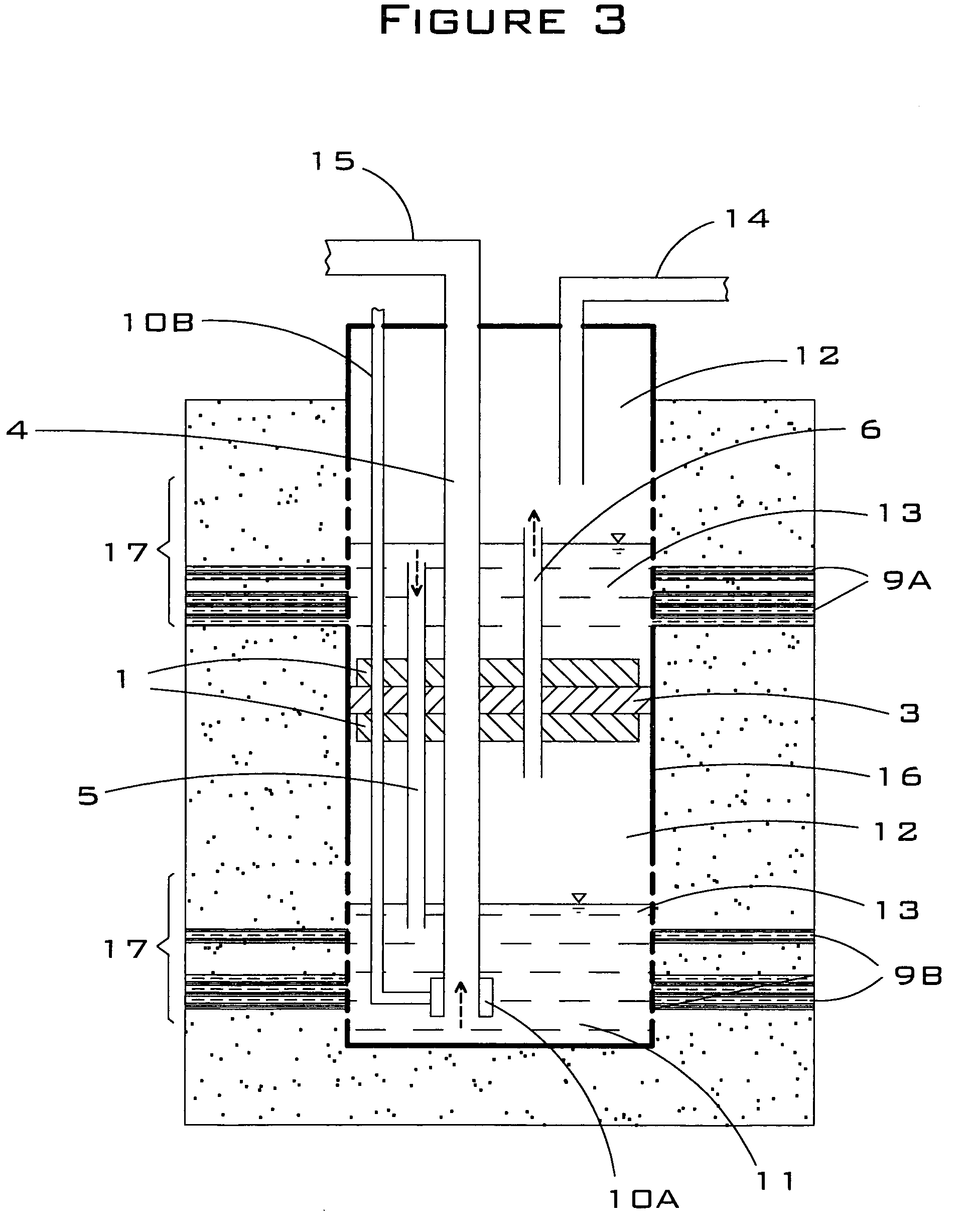

Multizone production monitoring system

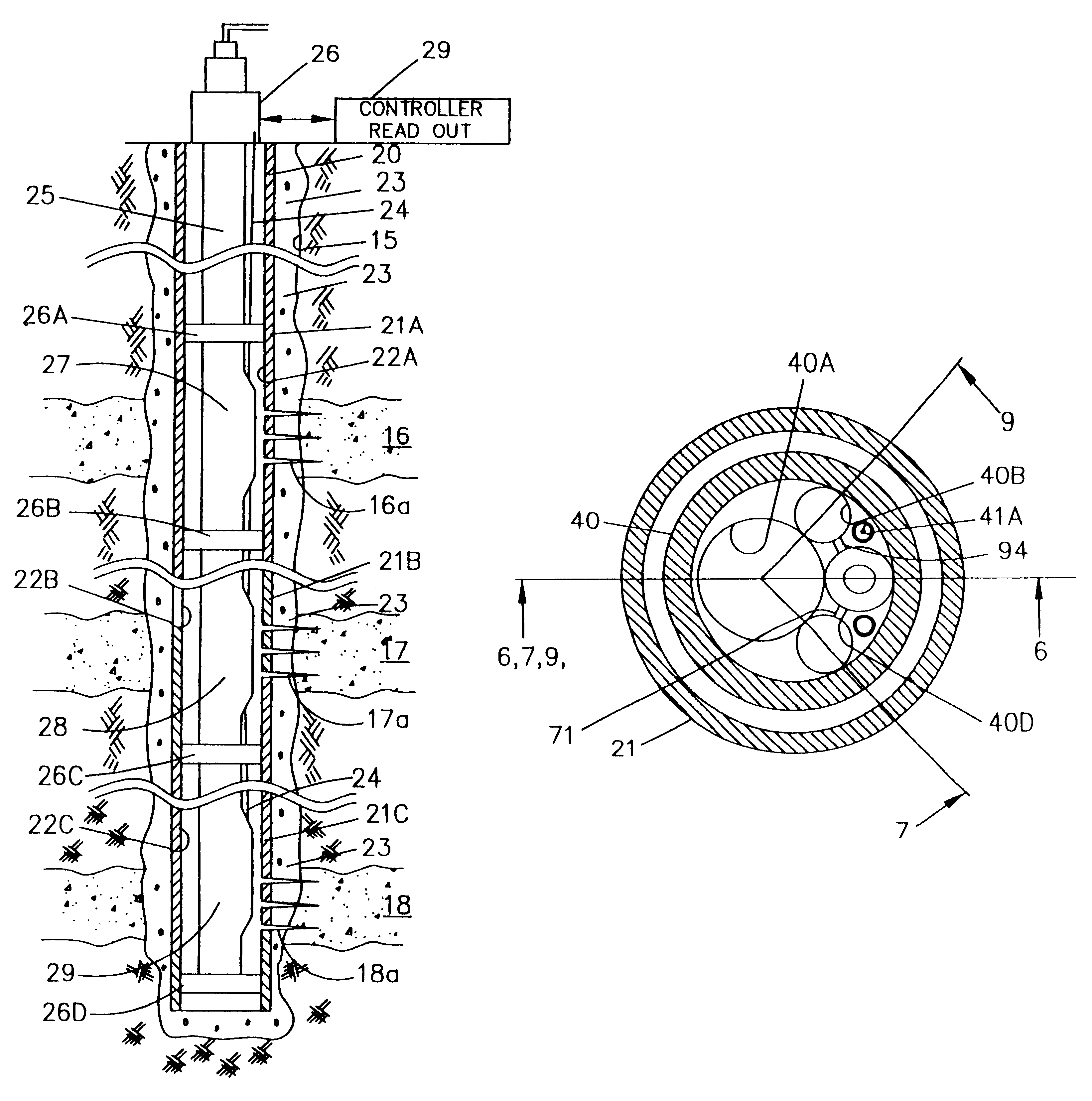

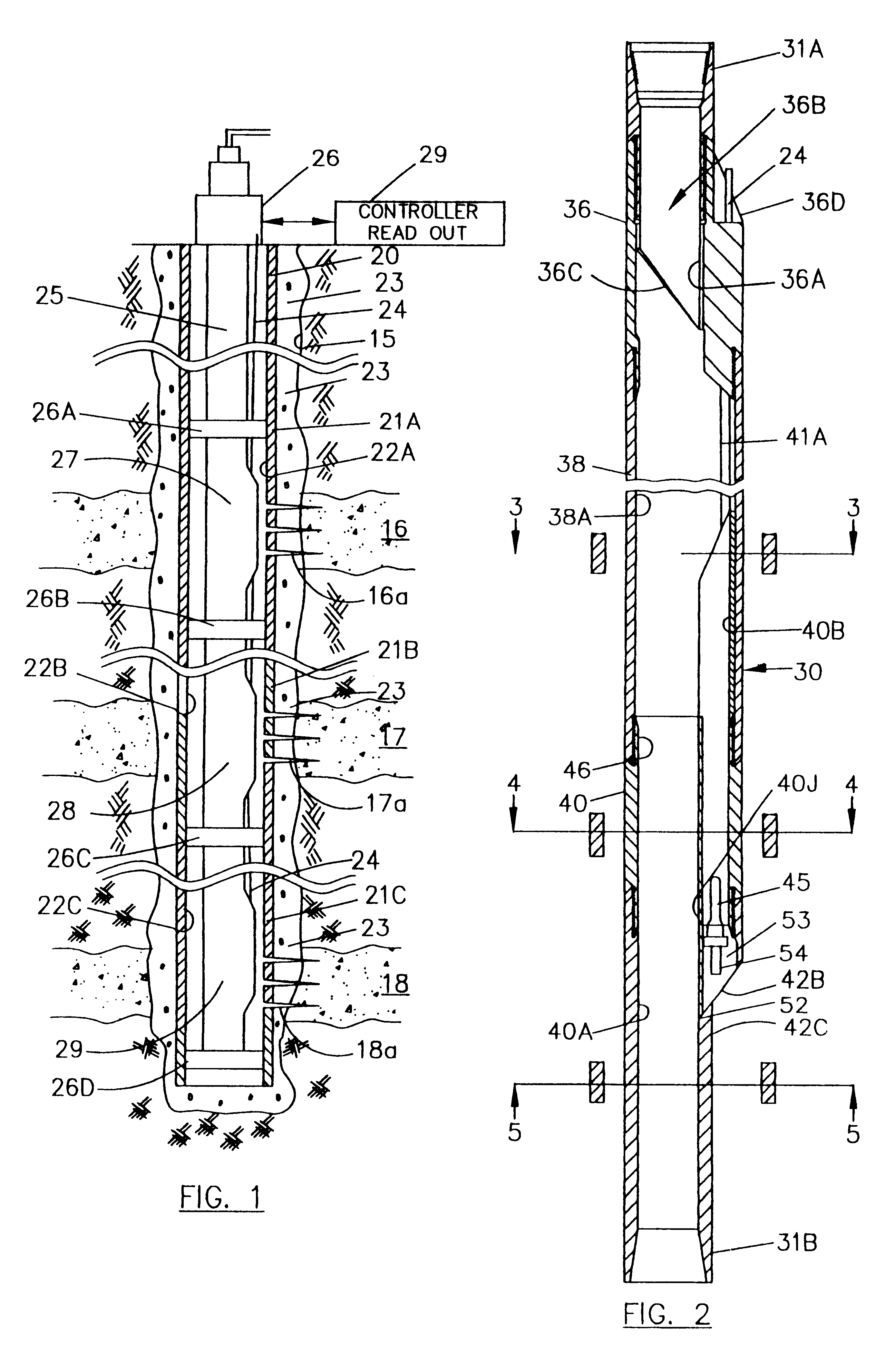

In a multiple well completion, spaced apart production packers isolate independent production zones from one another. In each isolated production zone, a side pocket mandrel with a full opening bore has lengthwise extending side by side elongated pockets (1) for receiving a static pressure measuring instrument or tool (static pressure pocket); (2) for providing a venturi flow passageway (flow passageway pocket); and (3) for receiving a differential pressure measuring tool (differential pressure pocket). The static pressure measuring tool and the differential pressure measuring tool or instrument are commonly connected by a data coupling means to a single electrical conductor line which is strapped to the string of tubing and extends to the earth's surface for transmission of control signals and data signals between the earth's surface and the various side pocket tools. The venturi flow passageway is connected for fluid communication with the static pressure pocket and the differential pressure pocket in the side pocket mandrel. Fluid flow from a particular production zone is channeled through the respective venturi flow passageway to the full opening bore and the fluid flow parameters are communicated to the static pressure measuring tool and to the differential pressure tool. The flow passageway is constructed and arranged to develop a differential pressure which is measured by the differential pressure measuring tool. At the same time, the static pressure of the production fluid in the production zone is measured by the static pressure measuring tool. Both the differential pressure measurements and the static pressure measurements may be transmitted to the surface and recorded as a function of real time.

Owner:RETRIEVABLE INFORMATION SYST +1

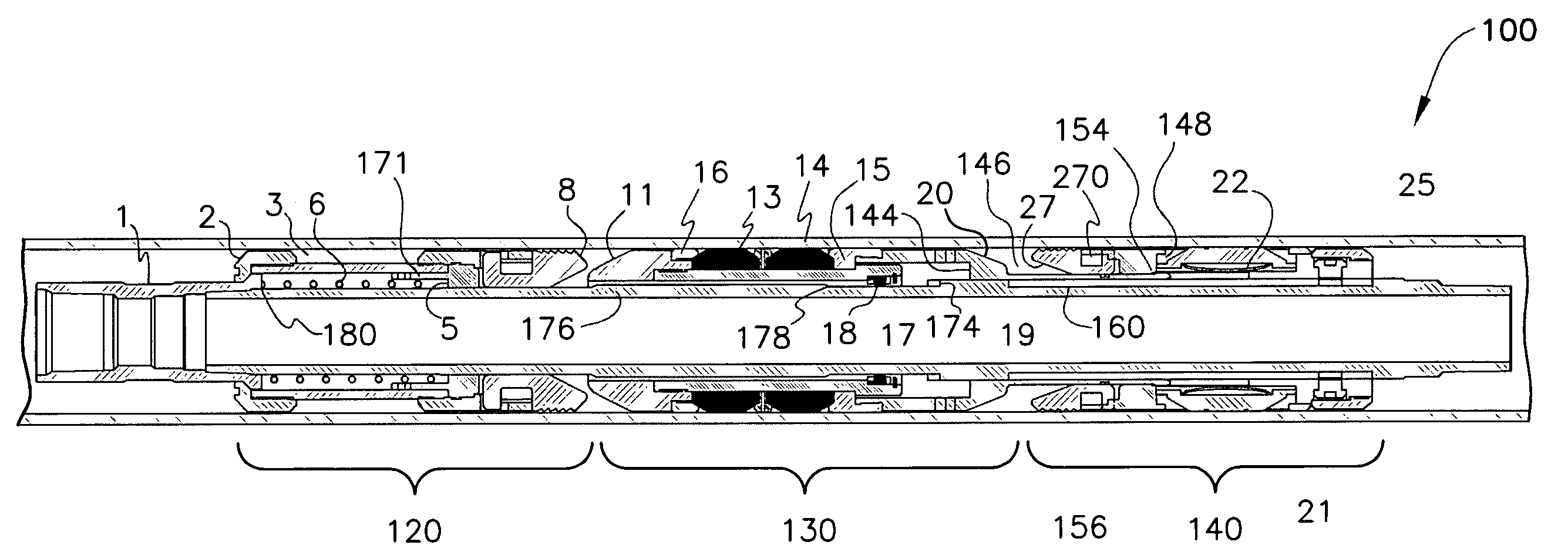

Spoolable coiled tubing completion system

InactiveUSRE36723E1Avoid interferenceLongitudinal flexibilityDrilling rodsFluid removalProduction packerCoiled tubing

Owner:CAMCO INT

Spoolable flexible hydraulically set, straight pull release well packer

InactiveUSRE36525E1Avoid interferenceLongitudinal flexibilityDrilling rodsFluid removalProduction packerCoiled tubing

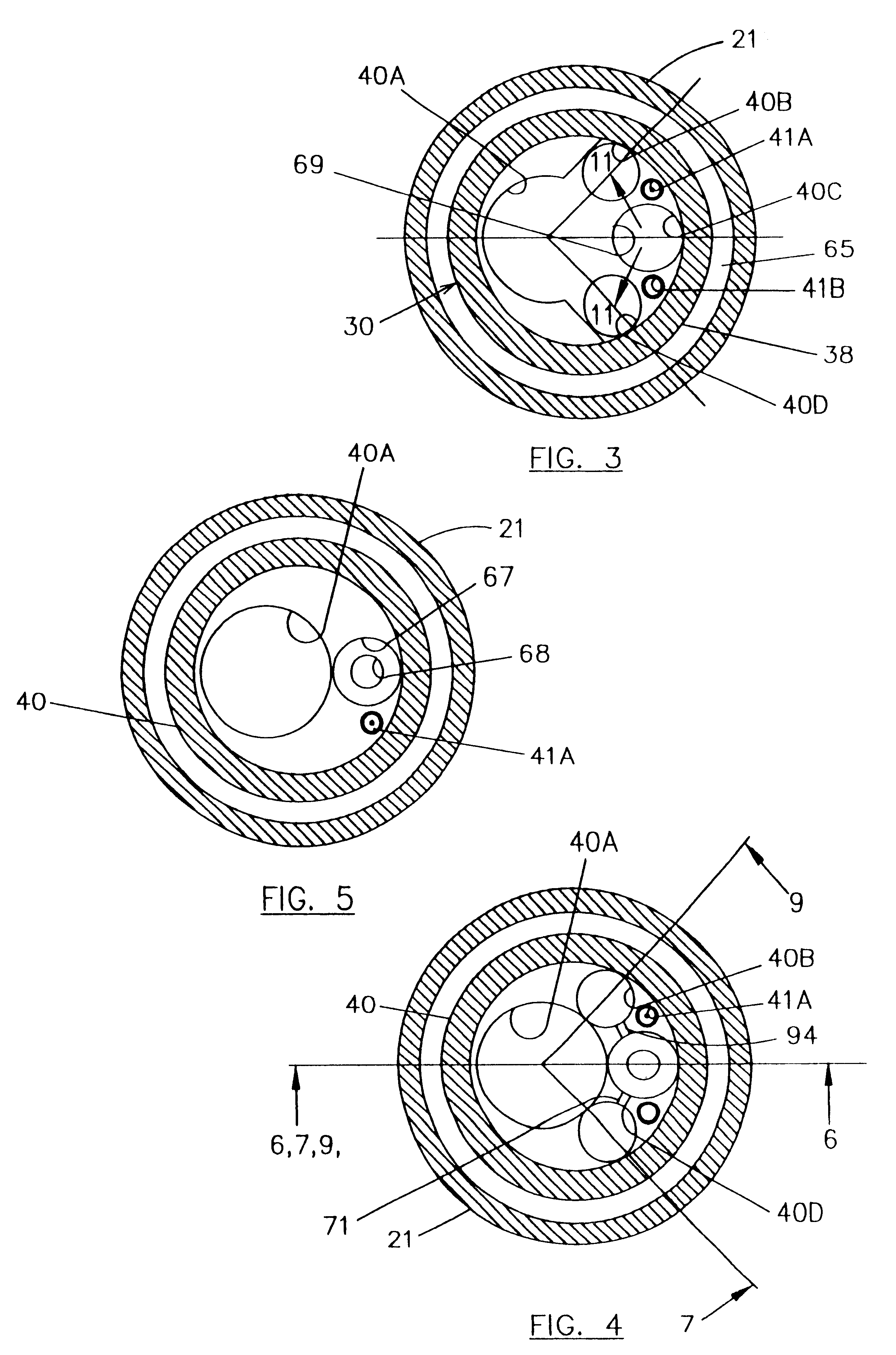

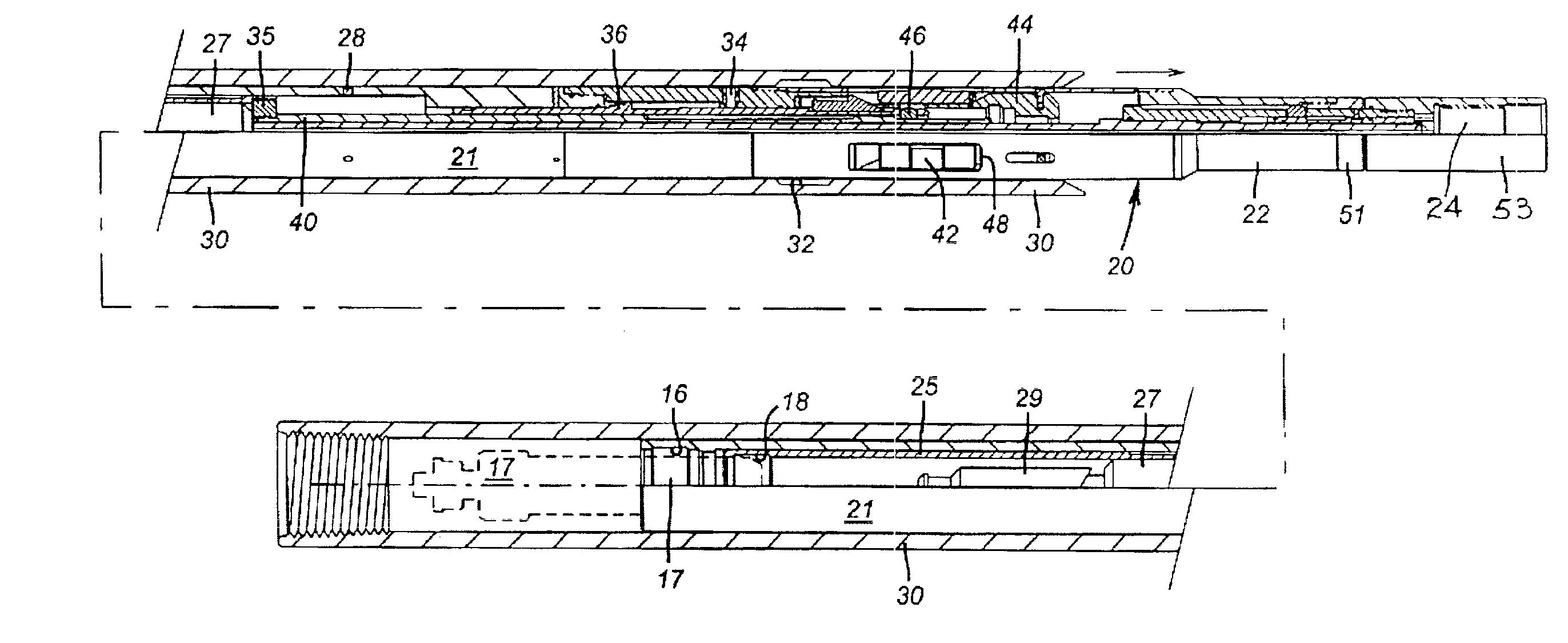

A coiled tubing completion system is provided with a plurality of completion apparatus, all of which is designed flush with the diameter of the coiled tubing outside diameter for avoiding upsets and are flexible, spoolable on a coiled tubing reel and having through bores large enough to pass wireline tools for performing other operations. The spoolable coiled tubing system may use standard coiled tubing well control equipment and can be used in live wells. The flush, flexible, spoolable and through bore completion equipment may include a tubing retrievable safety valve, an annular control valve, concentric gas lift valves, a zone packer, a landing nipple, a sliding sleeve, and may include at the end a non-flexible but flush and open bore production packer and pump out plug. The completion system may be retrieved through a retrieval system.

Owner:CAMCO INT

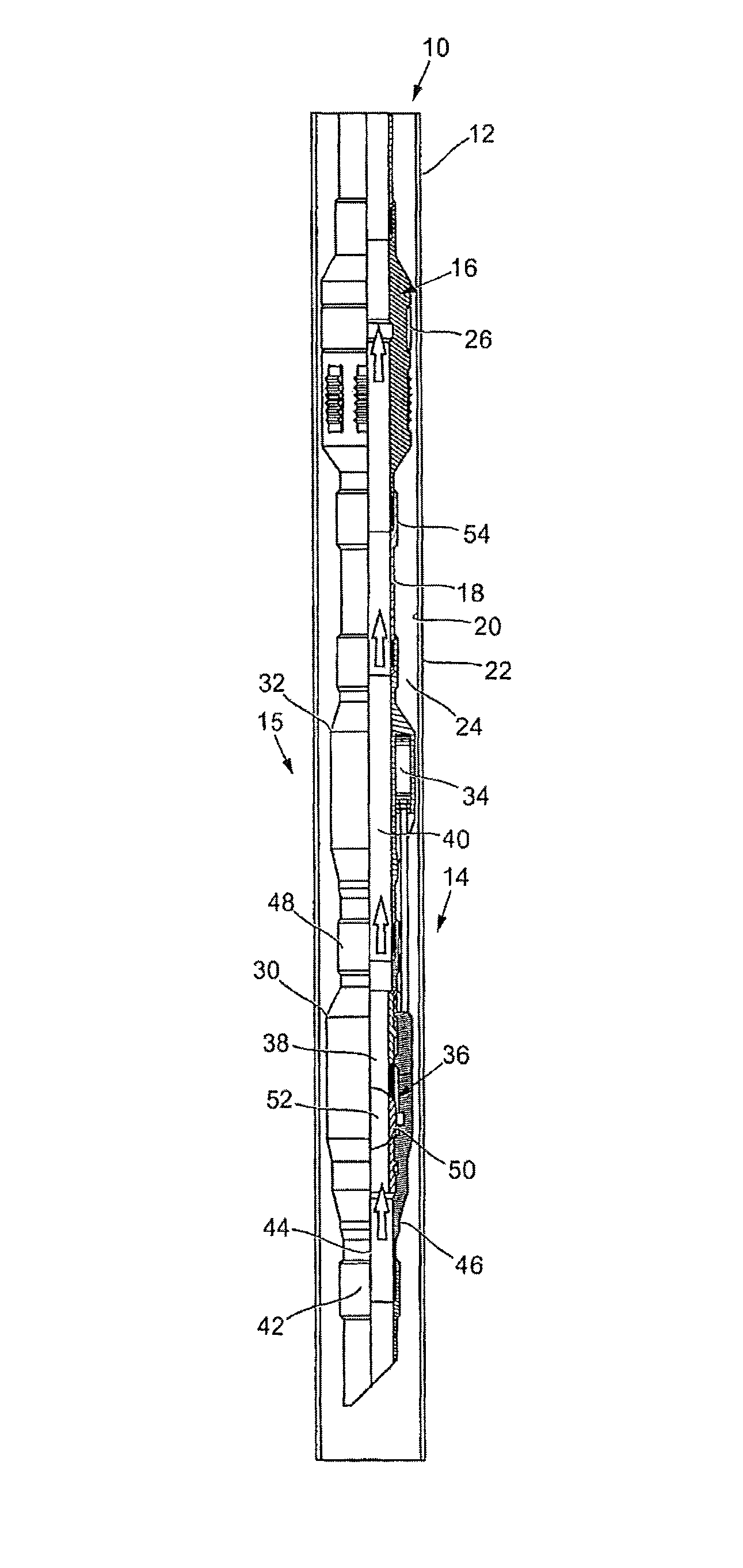

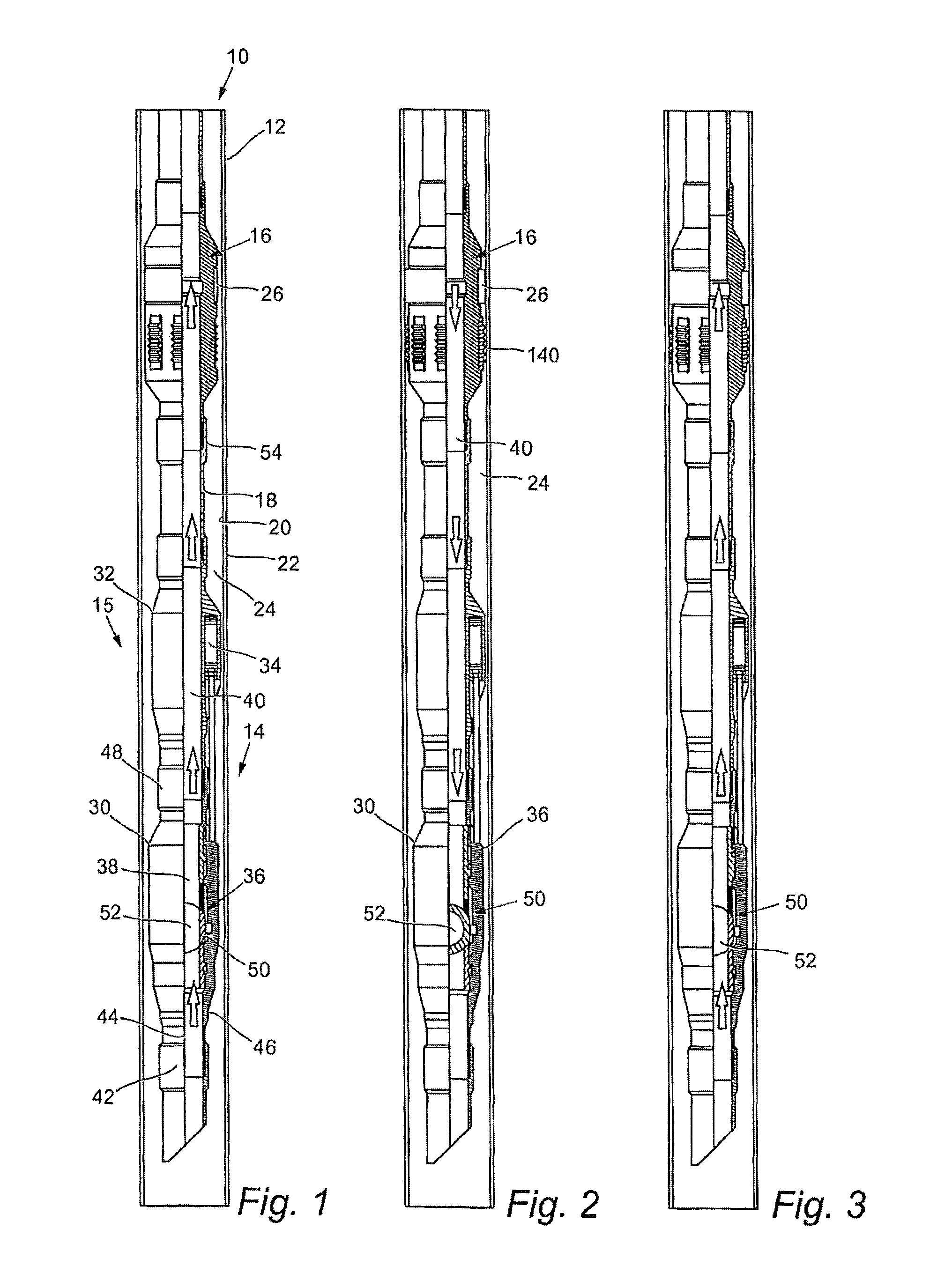

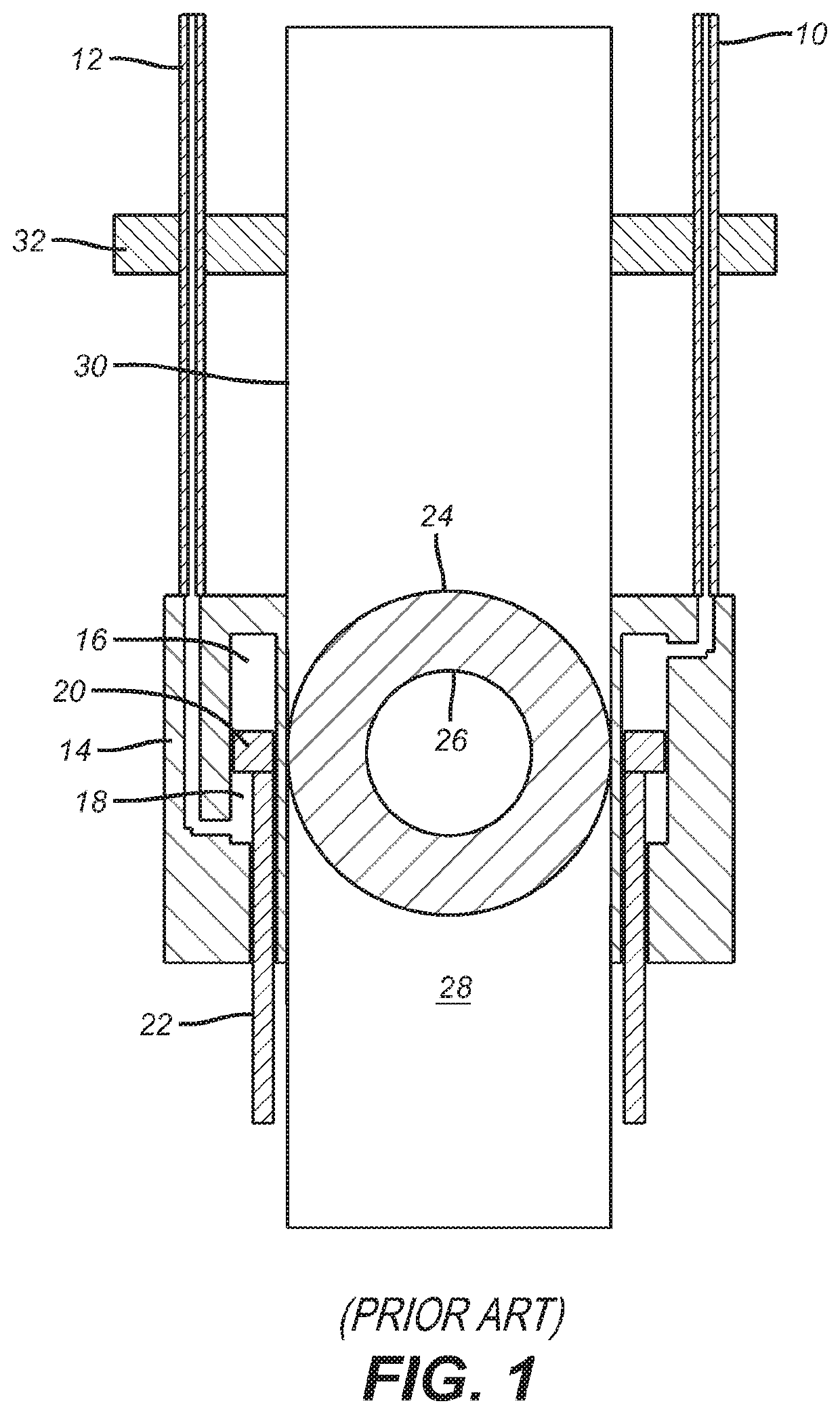

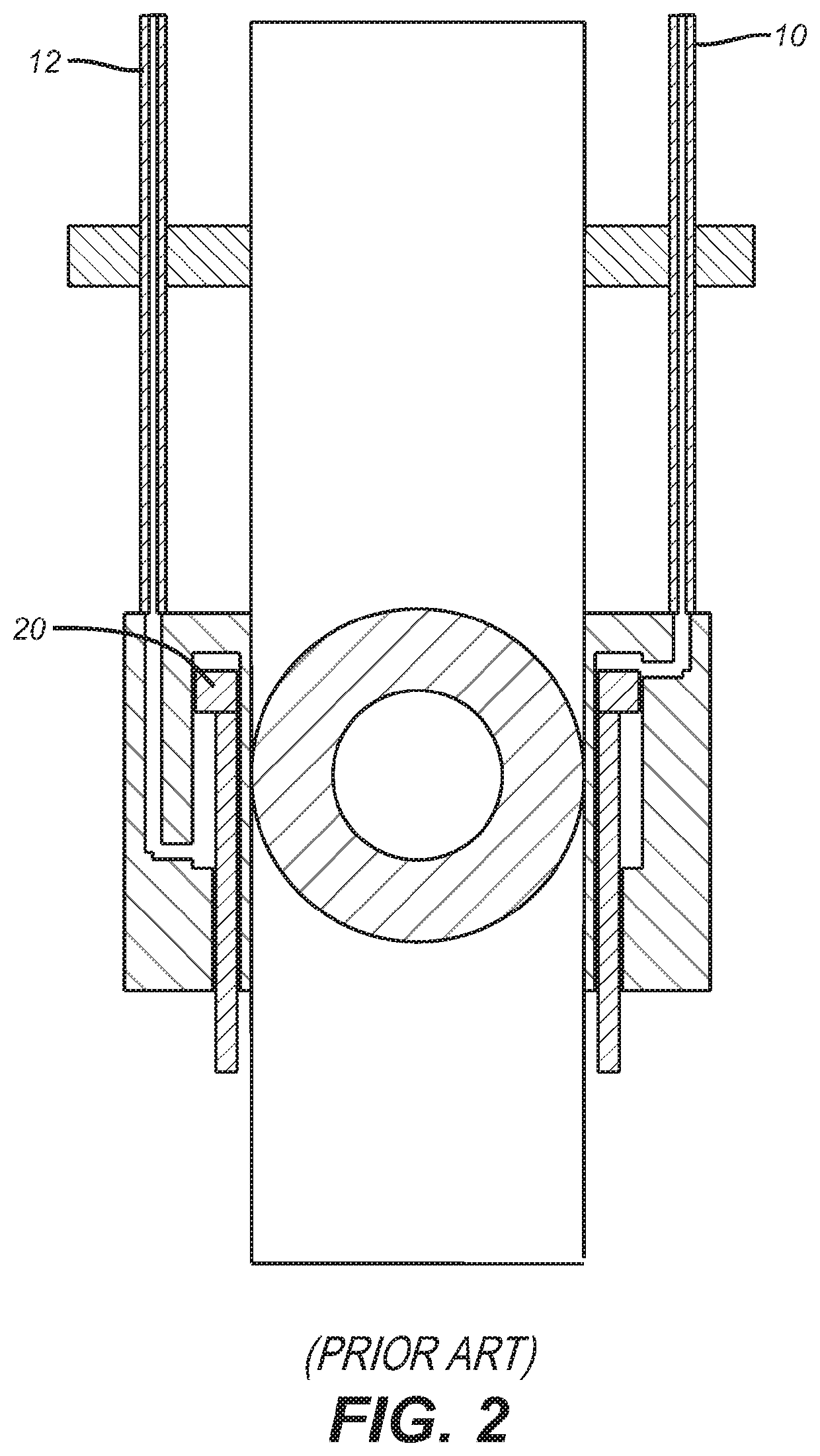

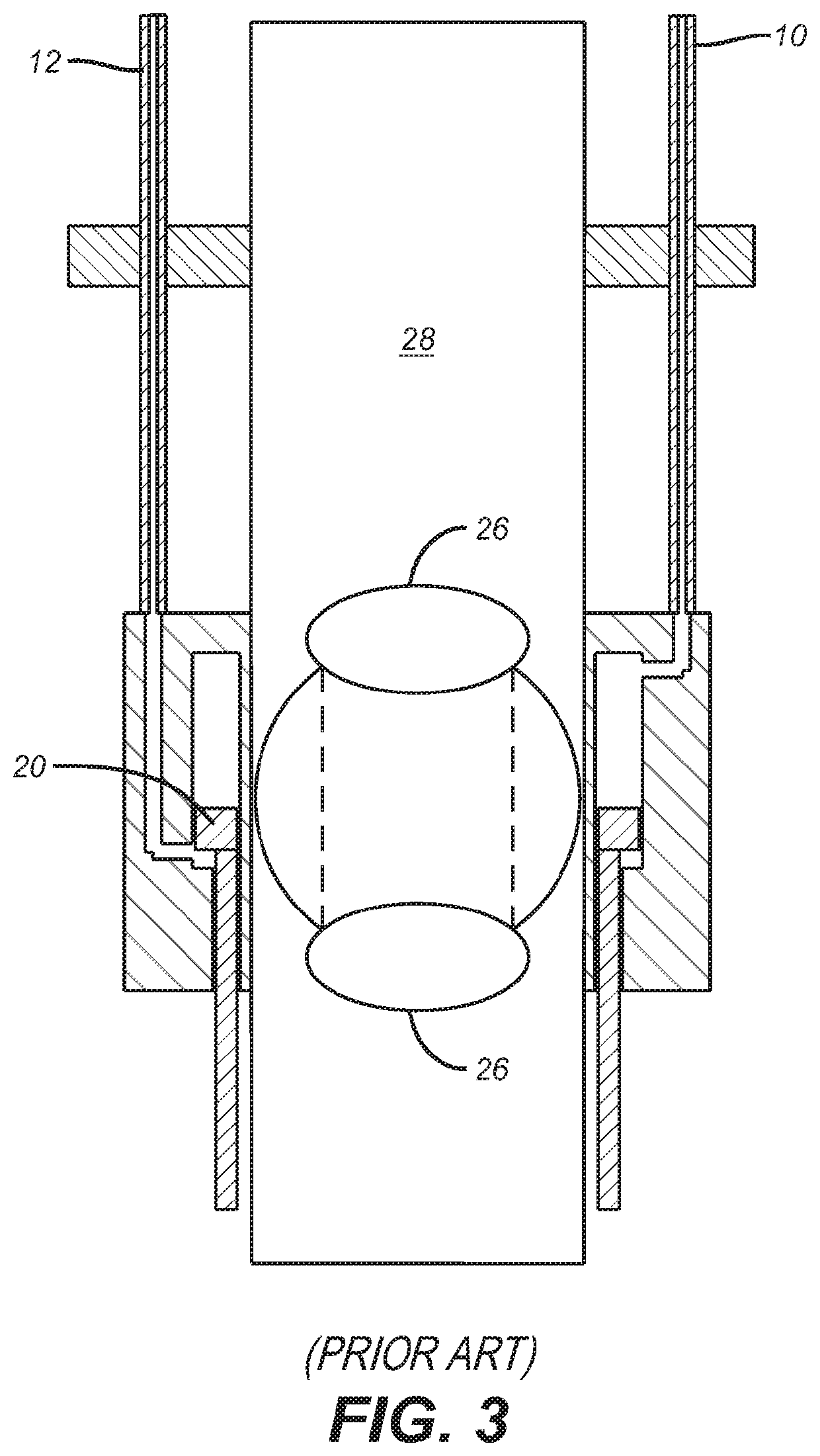

System and method for creating a fluid seal between production tubing and well casing

InactiveUS6854521B2Low costImprove sealingFluid removalSealing/packingProduction packerProduction tubing

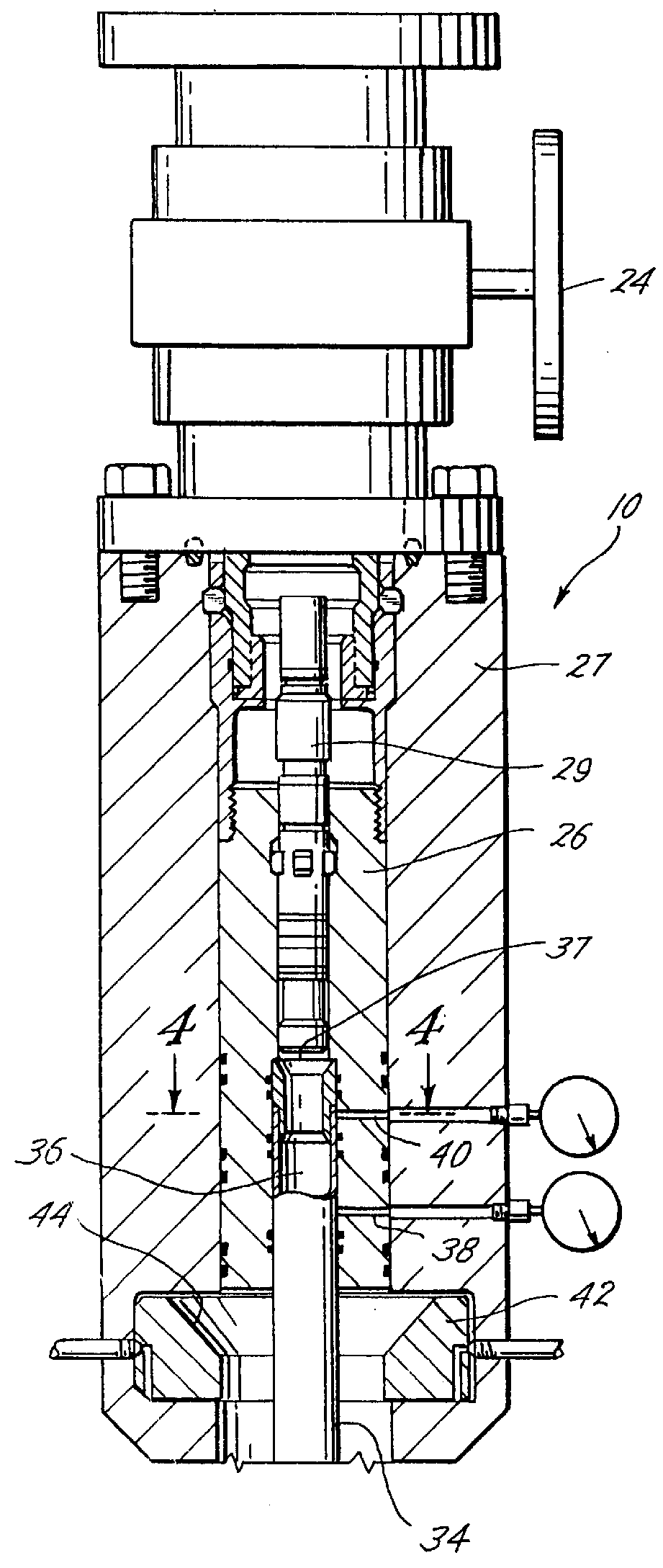

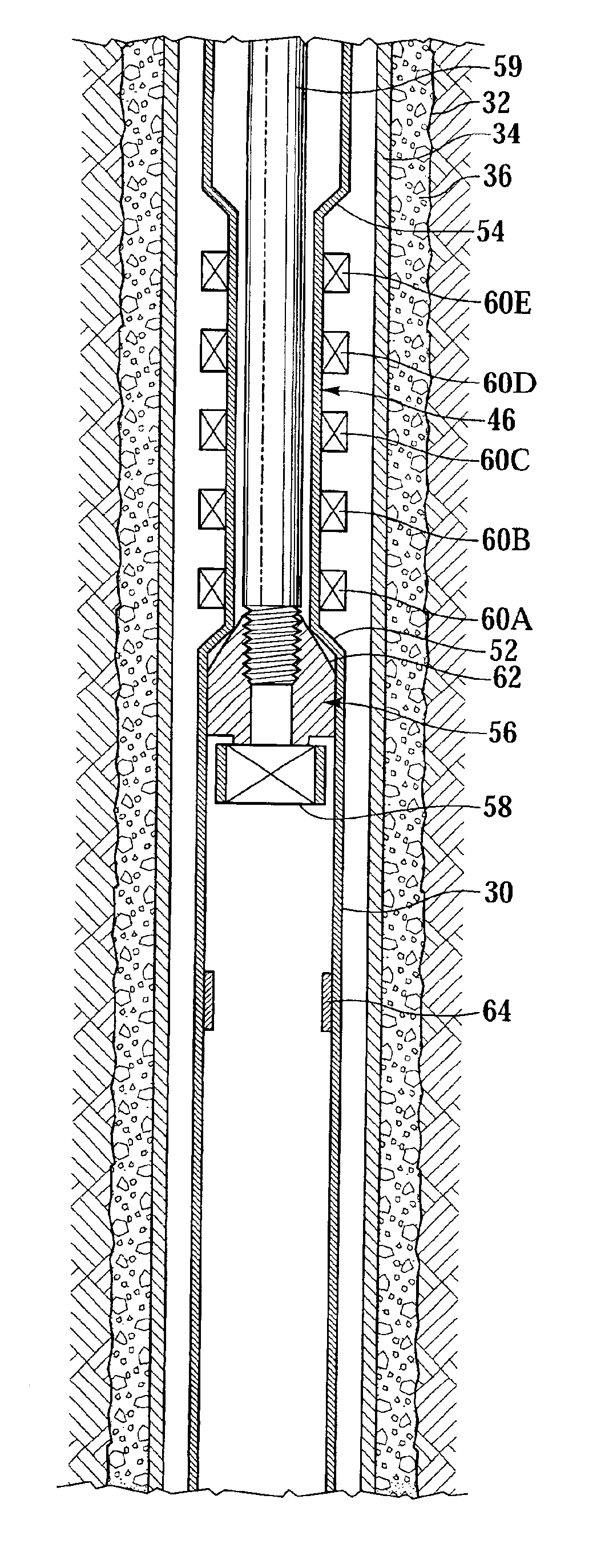

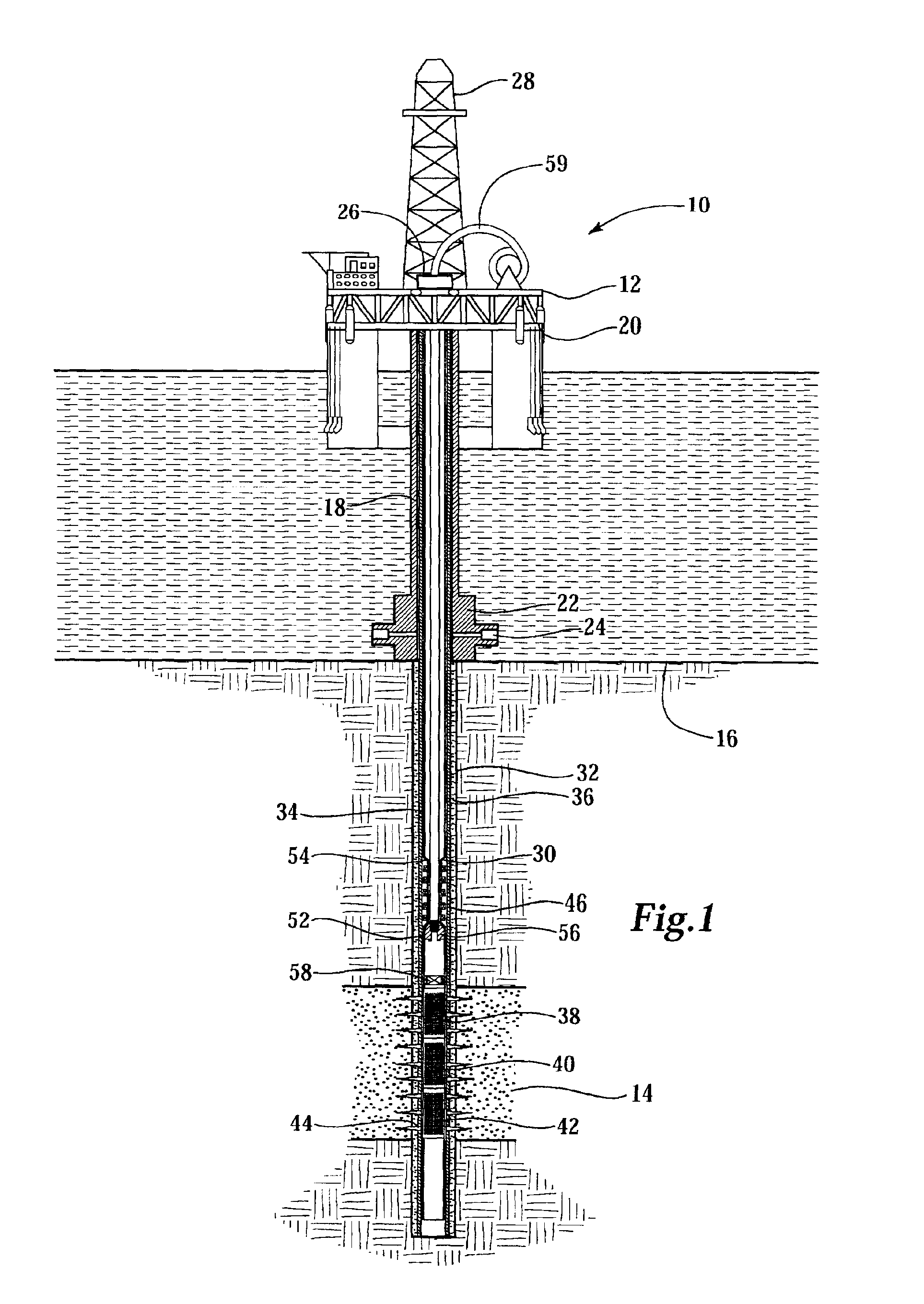

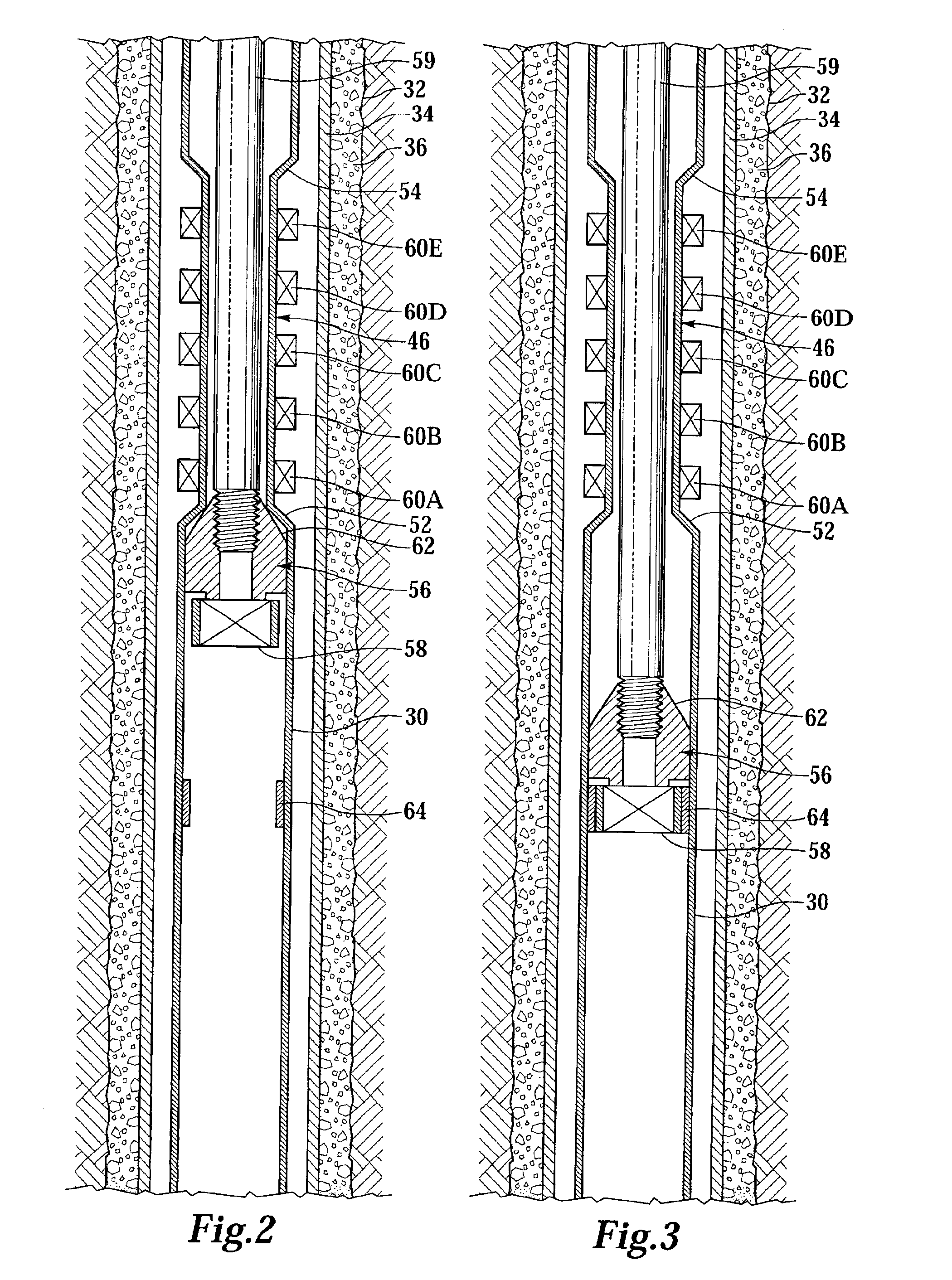

A well completion system for creating a seal between a production tubing (30) and a well casing (34) positioned within a wellbore (32) comprises a production packer (46) that includes a section of the production tubing (30) and at least one seal element (60). The production tubing (30) is then positioned within the well casing (34) that lines the wellbore (32). An expander member (56) that is positioned within the production tubing (30) then travels longitudinally through the production packer (46) to expand the section of the production tubing (30) downhole that includes the seal element (60). This expansion creates a sealing and gripping relationship between the production tubing (30) and the well casing (34).

Owner:HALLIBURTON ENERGY SERVICES INC

Full bore automatic gun release module

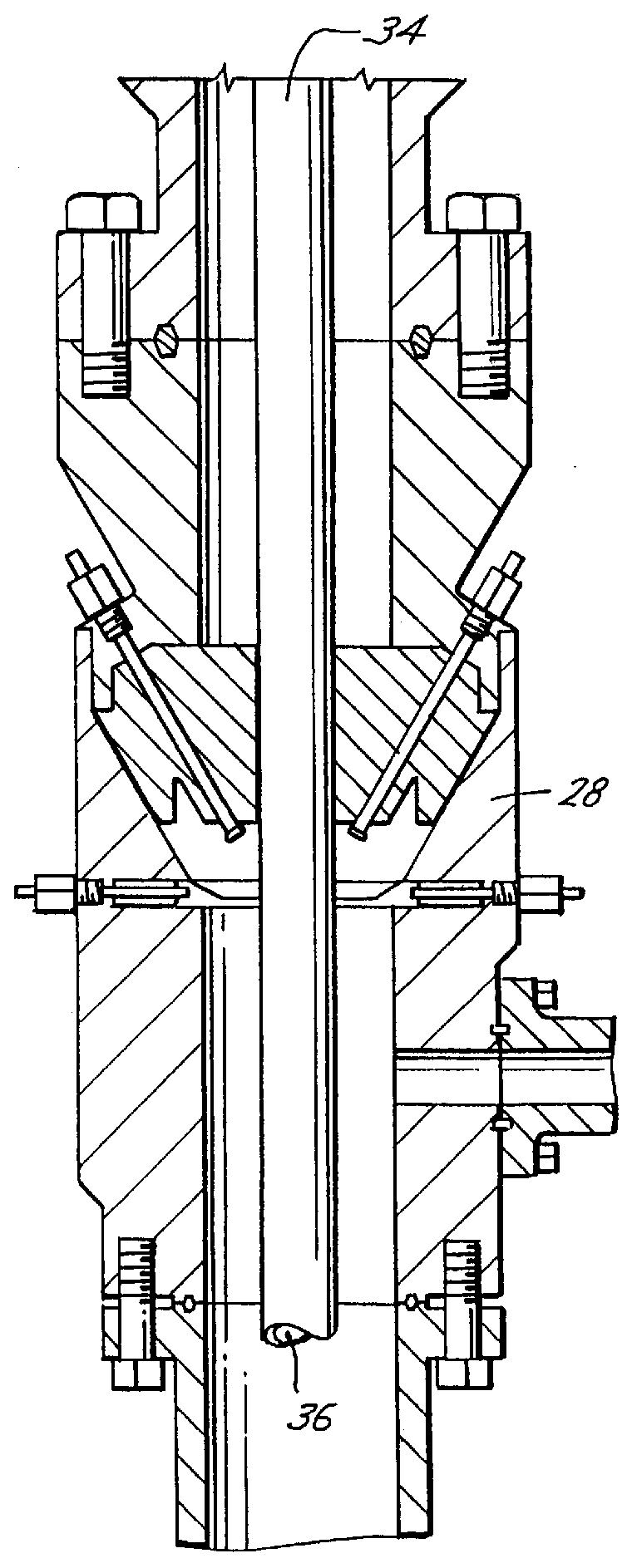

A well completion procedure and apparatus comprises a first assembly that includes production tubing combined with a production packer and an internal bore latching profile. A second assembly comprises an explosive perforating gun secured to a latching mechanism. The perforating gun and latching mechanism are dimensioned to freely traverse the flow bore of the production tubing for downhole retrieval and return after the packer is set. The latching mechanism may be released by discharge of the gun.

Owner:BAKER HUGHES INC

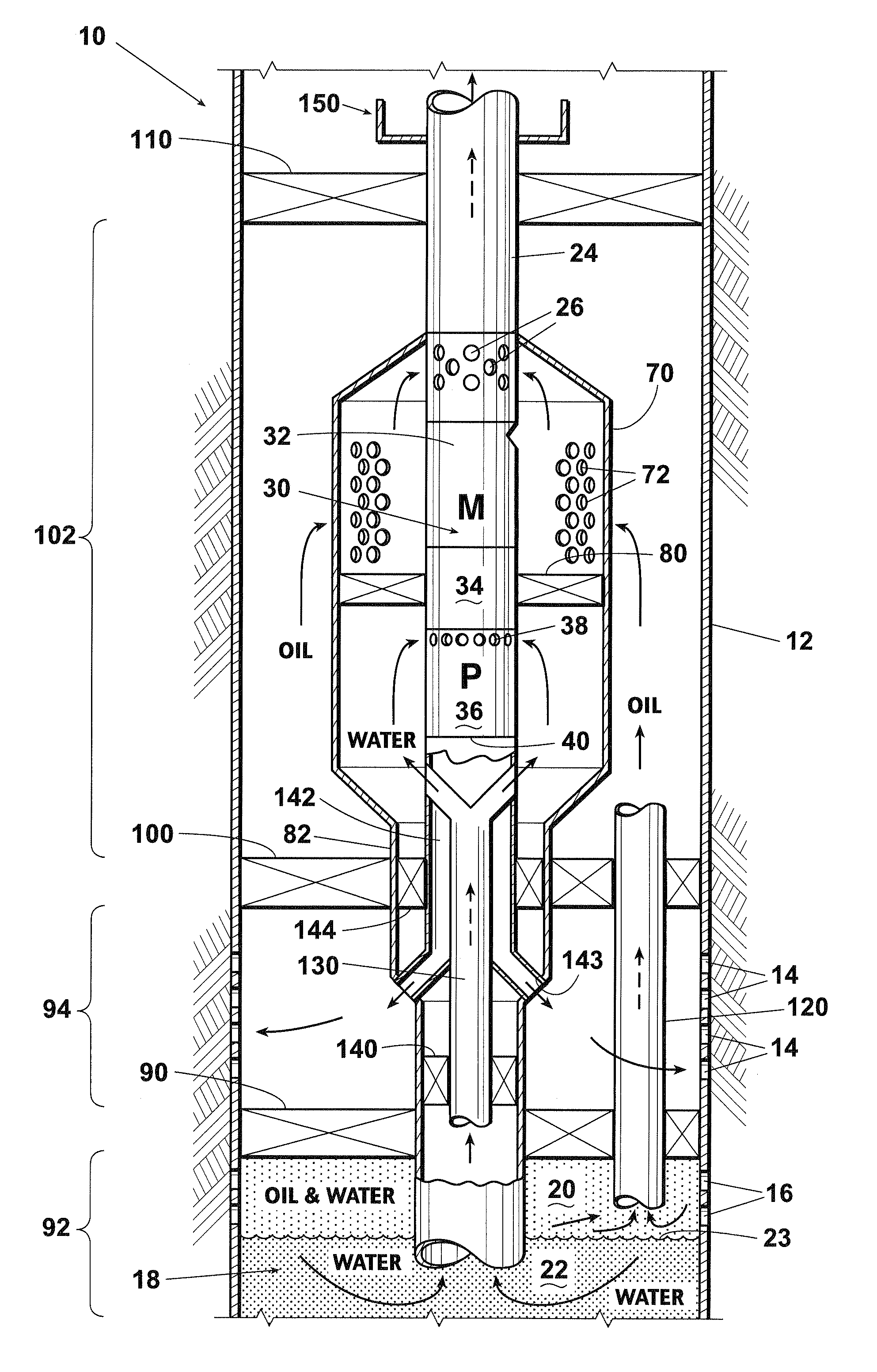

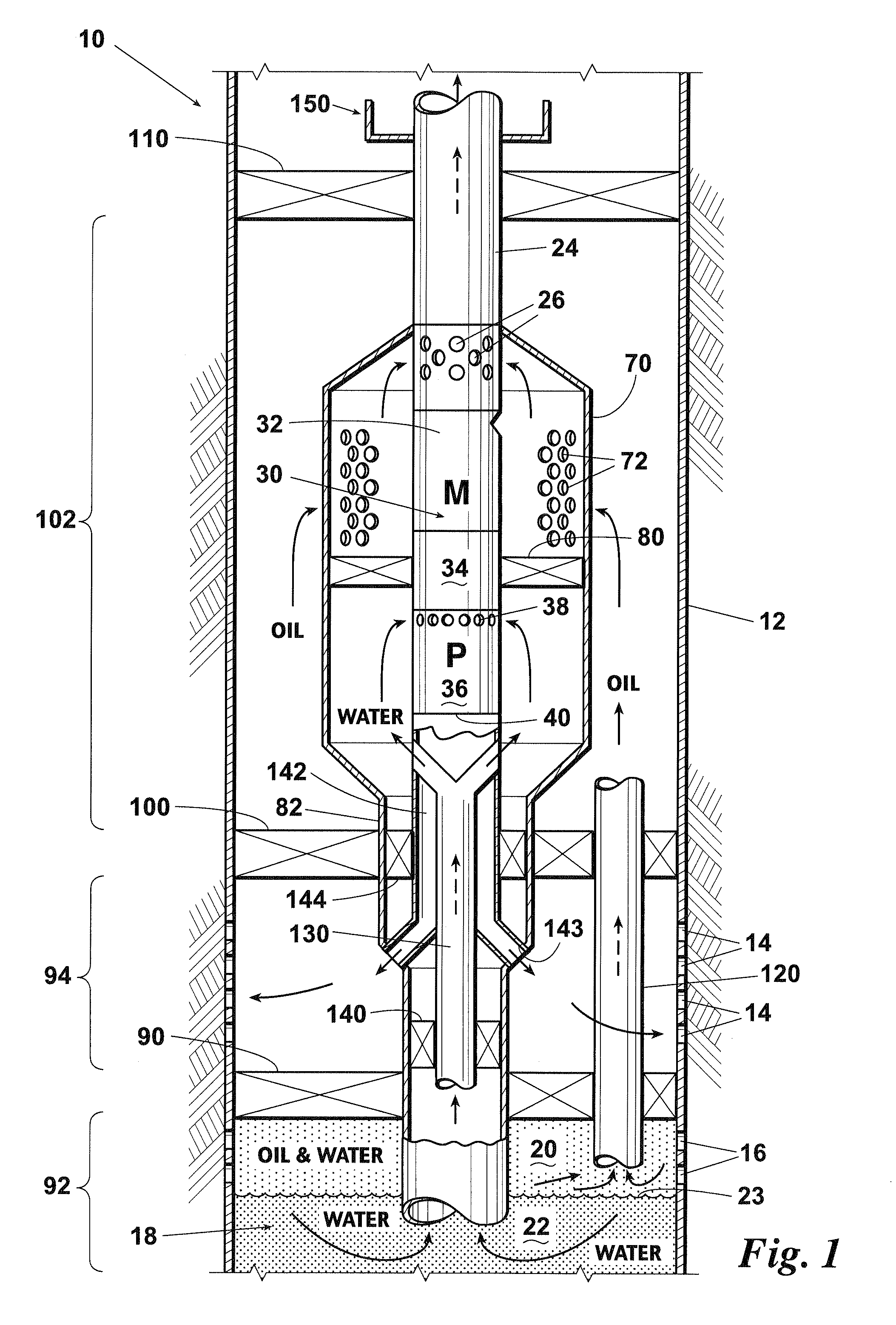

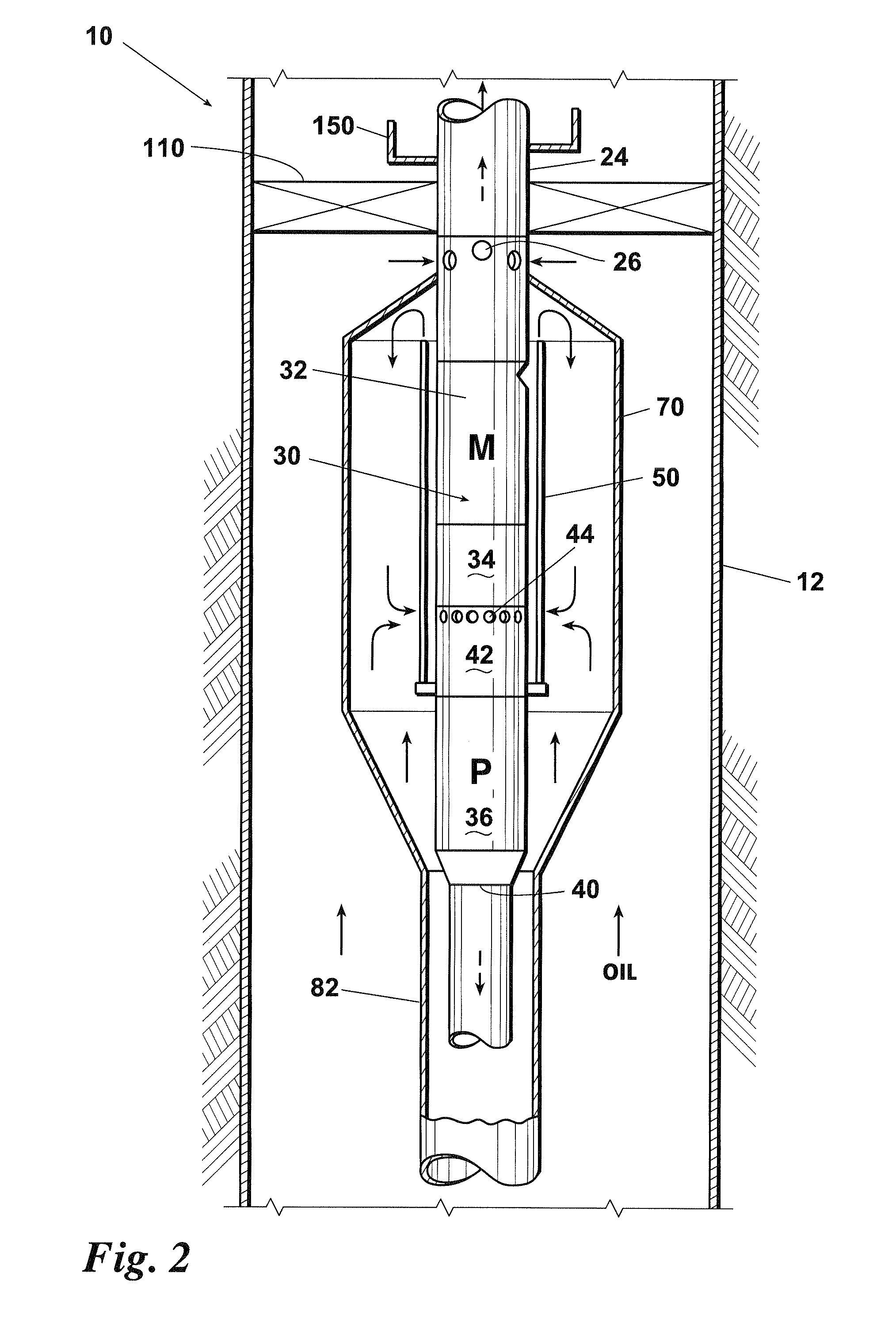

Inverted electrical submersible pump completion to maintain fluid segregation and ensure motor cooling in dual-stream well

InactiveUS20080093085A1Improve heat transfer characteristicsReduce necessityFluid removalProduction packerElectric machinery

An electrical submersible pump (ESP) completion installed in casing perforated for water disposal and production. A packer separates the disposal zone and the production zone. An inverted ESP assembly is located inside of a canister. The ESP and canister are lowered on a tubing string into the casing. The canister has a downwardly extending canister extension flow-directing member that communicates with water in the casing and which passes through the disposal zone. Water is pumped down the canister extension member into the disposal zone and formation. Well fluids are drawn up the extension from the production zone. Various configurations are disclosed to facilitate flowing well fluids, e.g., oil-rich mixture or water passed the motor for cooling the motor of the inverted ESP while maintaining fluid segregation. The completion is particularly suited for production wells wherein the oil and water have a strong tendency to naturally segregate within the wellbore.

Owner:BAKER HUGHES INC

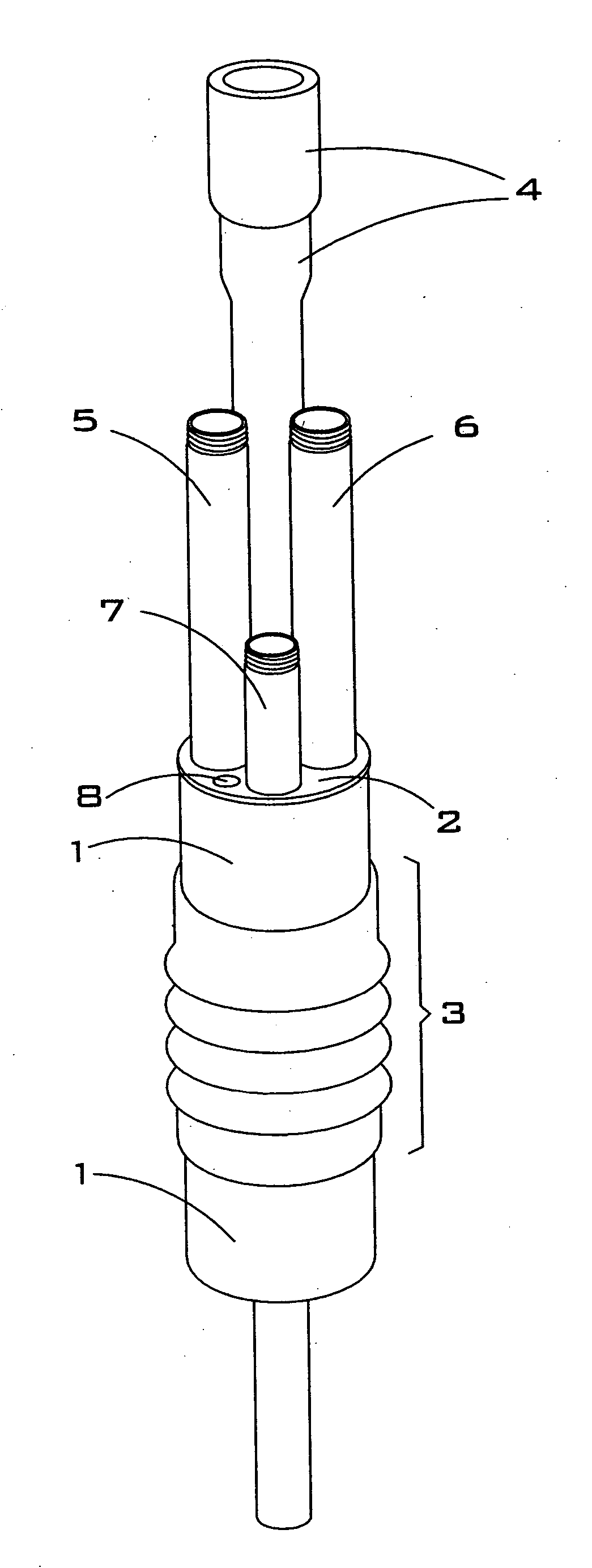

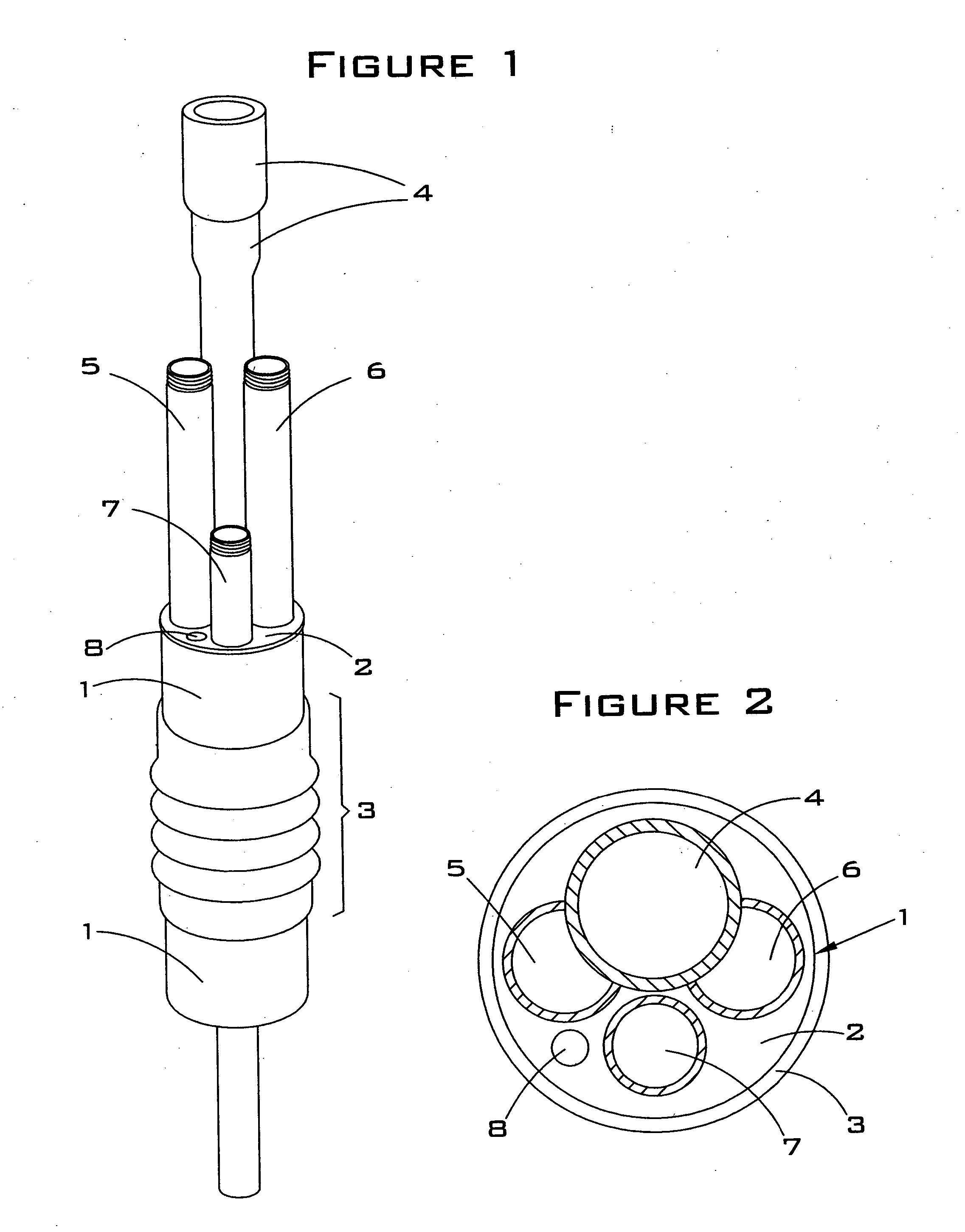

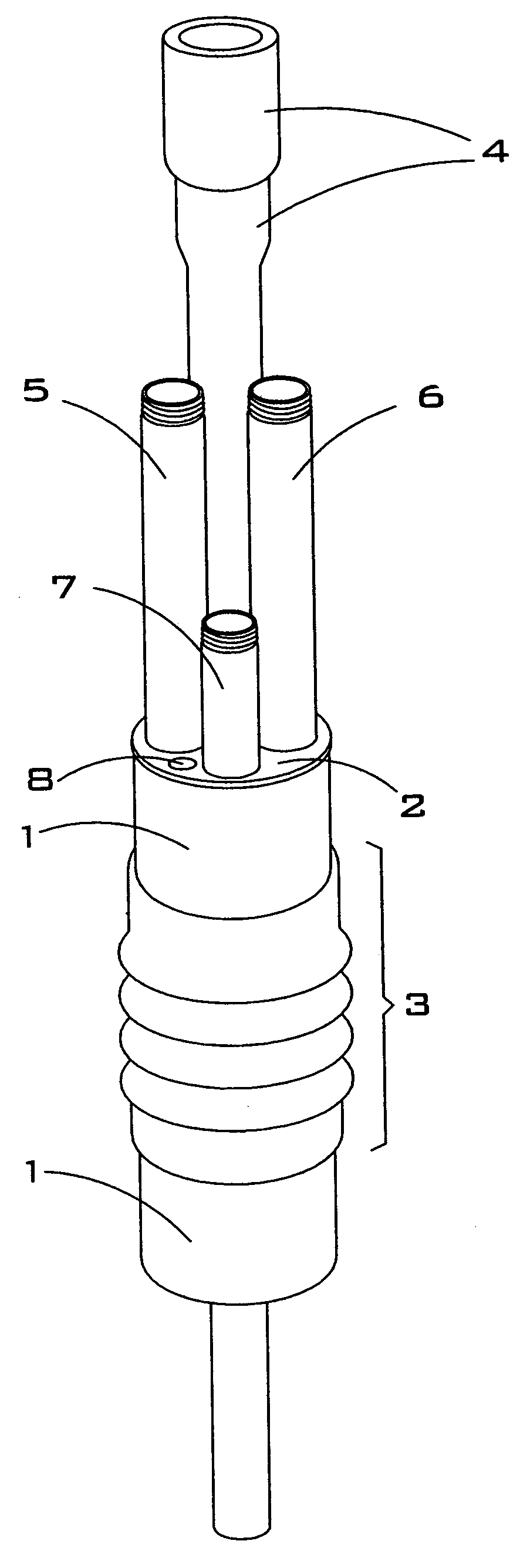

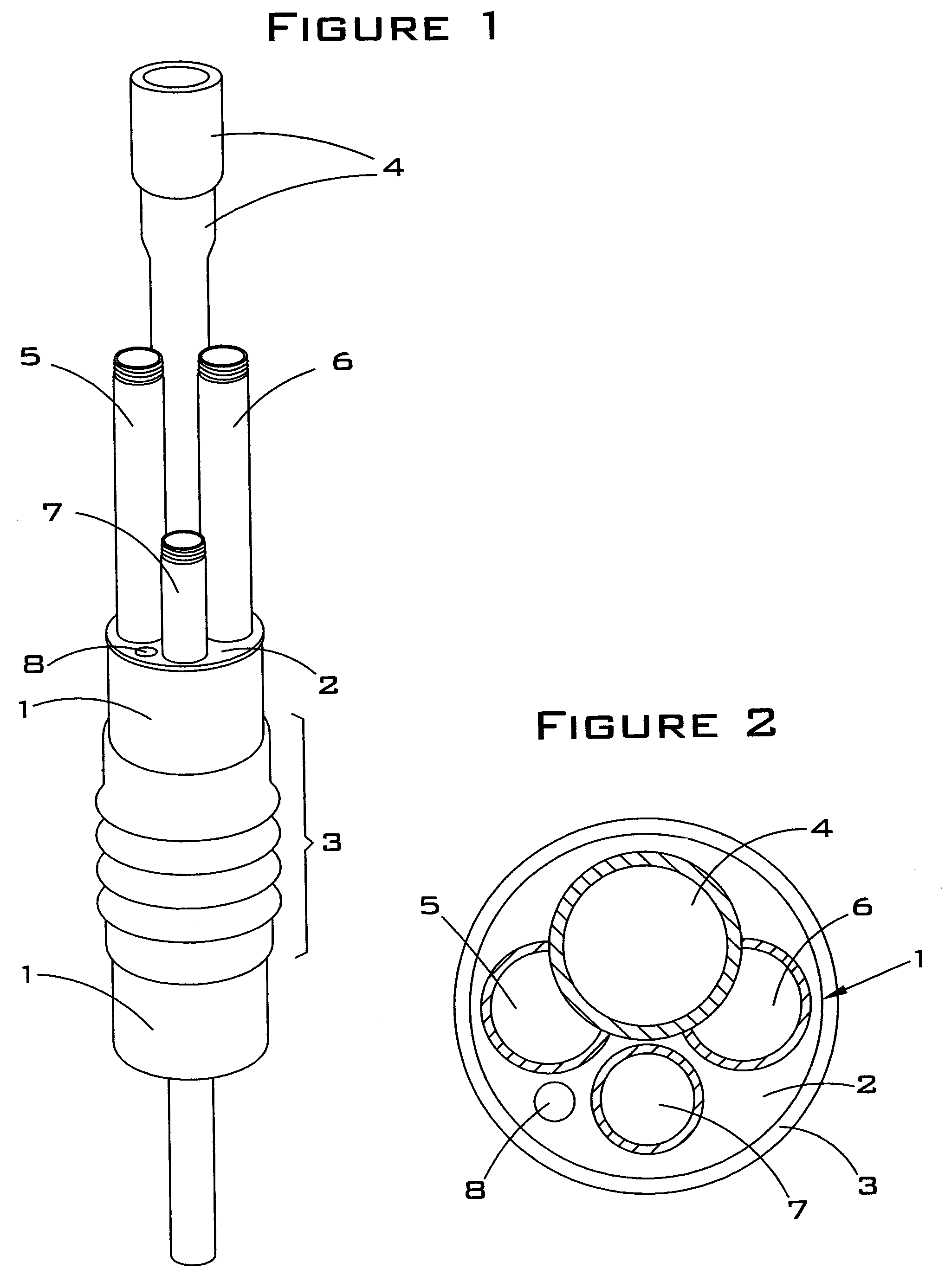

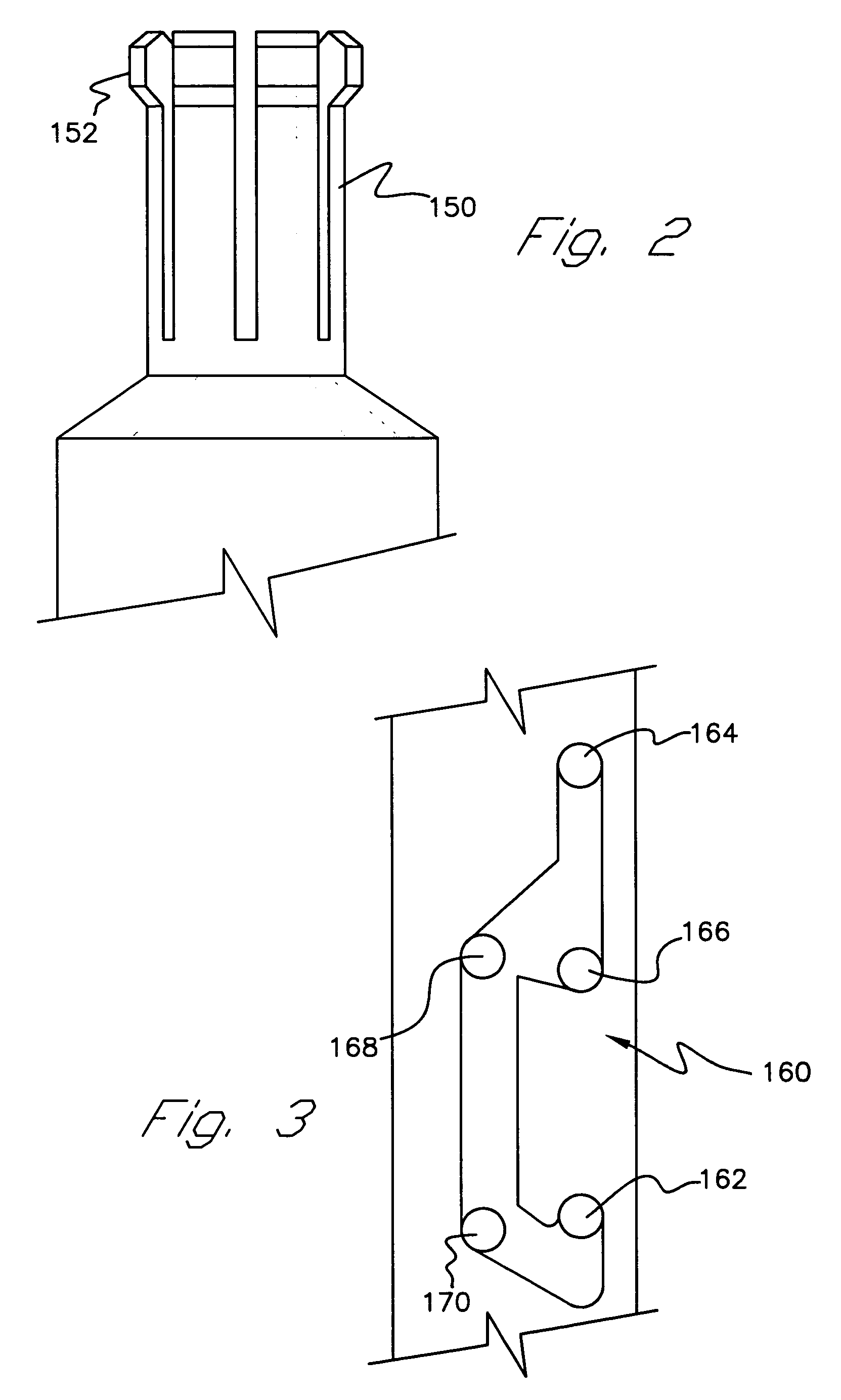

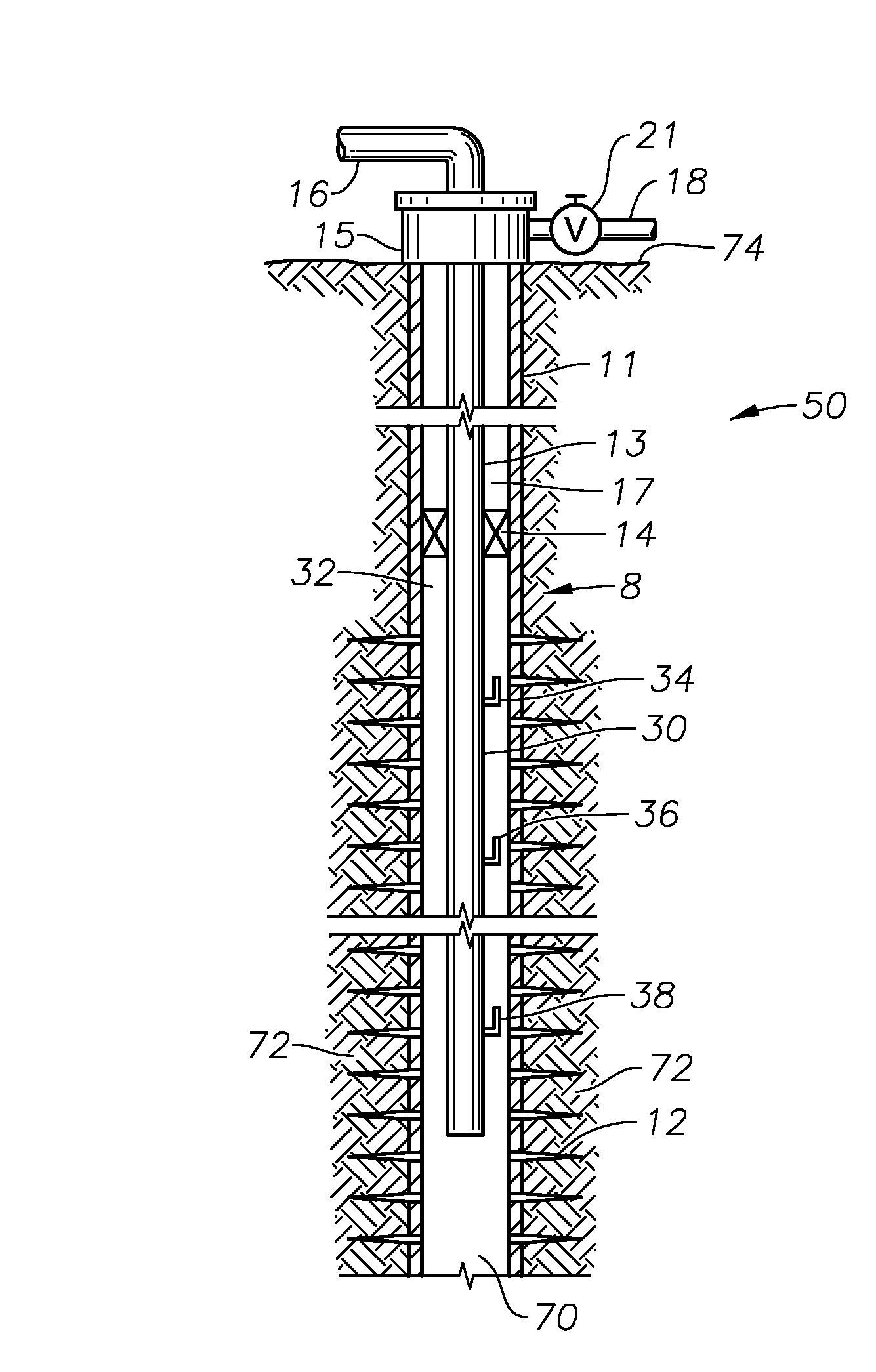

Multi-string production packer

A production packer comprising a packer body, a flat plate, a sealing element, production tubing, water overflow tubing, gas vent tubing, pump cable pack-off tubing, and an optional pressure transducer port. The flat plate is welded onto the top of the packer body. The sealing element is bonded to the outside of the packer body. In the preferred embodiment, the packer body is a steel pipe, and the flat plate is made of steel. The packer is placed inside a production casing, and the diameter of the sealing element is greater than the diameter of the production casing. The sealing element is made out of a material that is durable enough to withstand the pressures associated with a production packer, flexible enough to fit inside the production casing, and elastic enough to create a seal between the packer body and the production casing.

Owner:ZIMMERMAN C DUANE

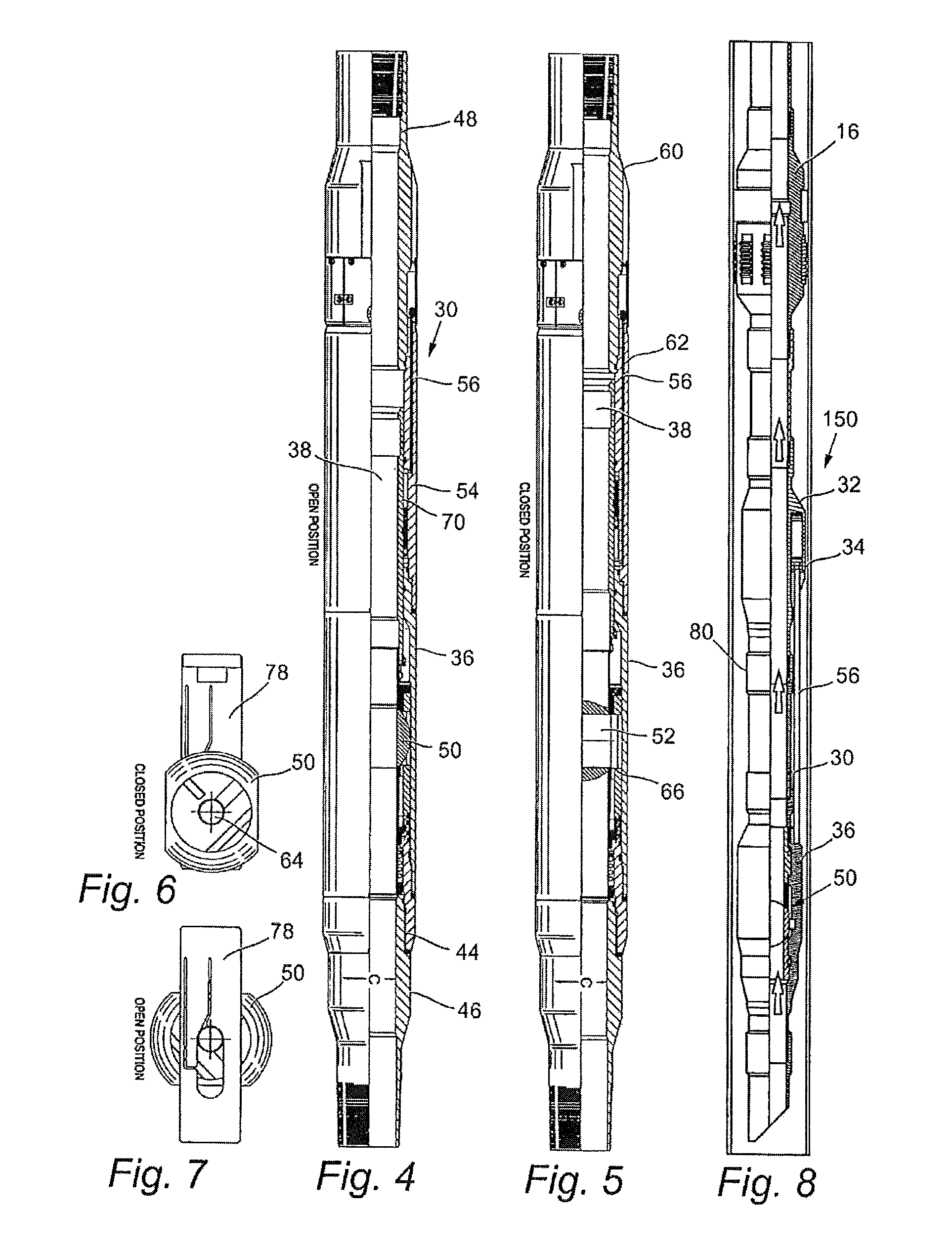

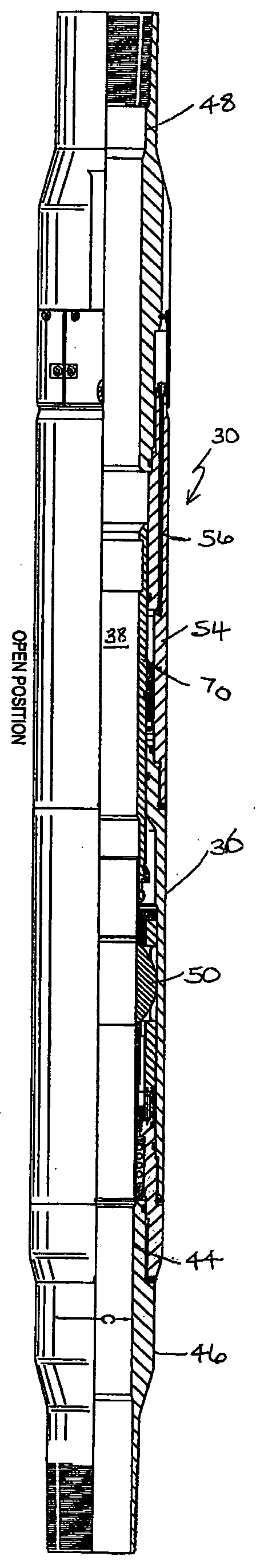

Electronic completion installation valve

Apparatus and method for a providing a completion assembly for running at an end of a completion string which provides a remotely operable tubing mounted valve used to control the flow of fluids through the tubing in hostile well conditions. The tubing mounted completion assembly has a tubular body for connection in the string below a production packer with a through bore from a first inlet and a first outlet coaxially aligned with the string; a downhole electronic actuating mechanism, a downhole hydraulic pump and a hydraulically operated ball valve member. The actuating mechanism operates the hydraulic pump to provide a hydraulic control line to control movement the valve member from a first position, where the member is open and a through bore is created between the inlet and outlet of the assembly, to a second position, where the valve seals the throughbore and, finally, back to the first position.

Owner:HALLIBURTON MFG & SERVICES

Electronic completion installation valve

Apparatus and method for a providing a completion assembly for running at an end of a completion string which provides a remotely operable tubing mounted valve used to control the flow of fluids through the tubing in hostile well conditions. The tubing mounted completion assembly has a tubular body for connection in the string below a production packer with a through bore from a first inlet and a first outlet coaxially aligned with the string; a downhole electronic actuating mechanism, a downhole hydraulic pump and a hydraulically operated ball valve member. The actuating mechanism operates the hydraulic pump to provide a hydraulic control line to control movement the valve member from a first position, where the member is open and a through bore is created between the inlet and outlet of the assembly, to a second position, where the valve seals the throughbore and, finally, back to the first position.

Owner:HALLIBURTON MFG & SERVICES

Well abandonment using vibration to assist cement placement

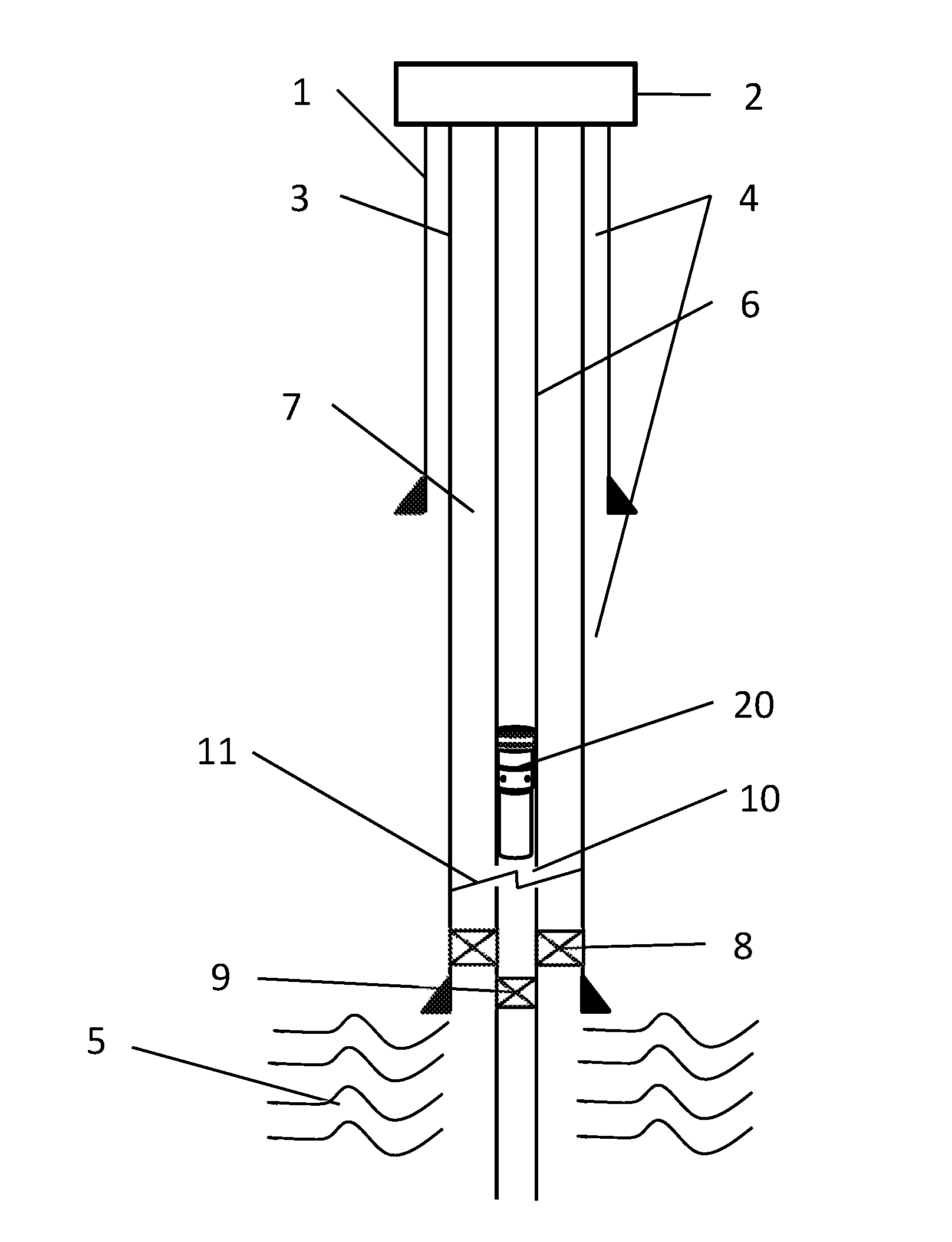

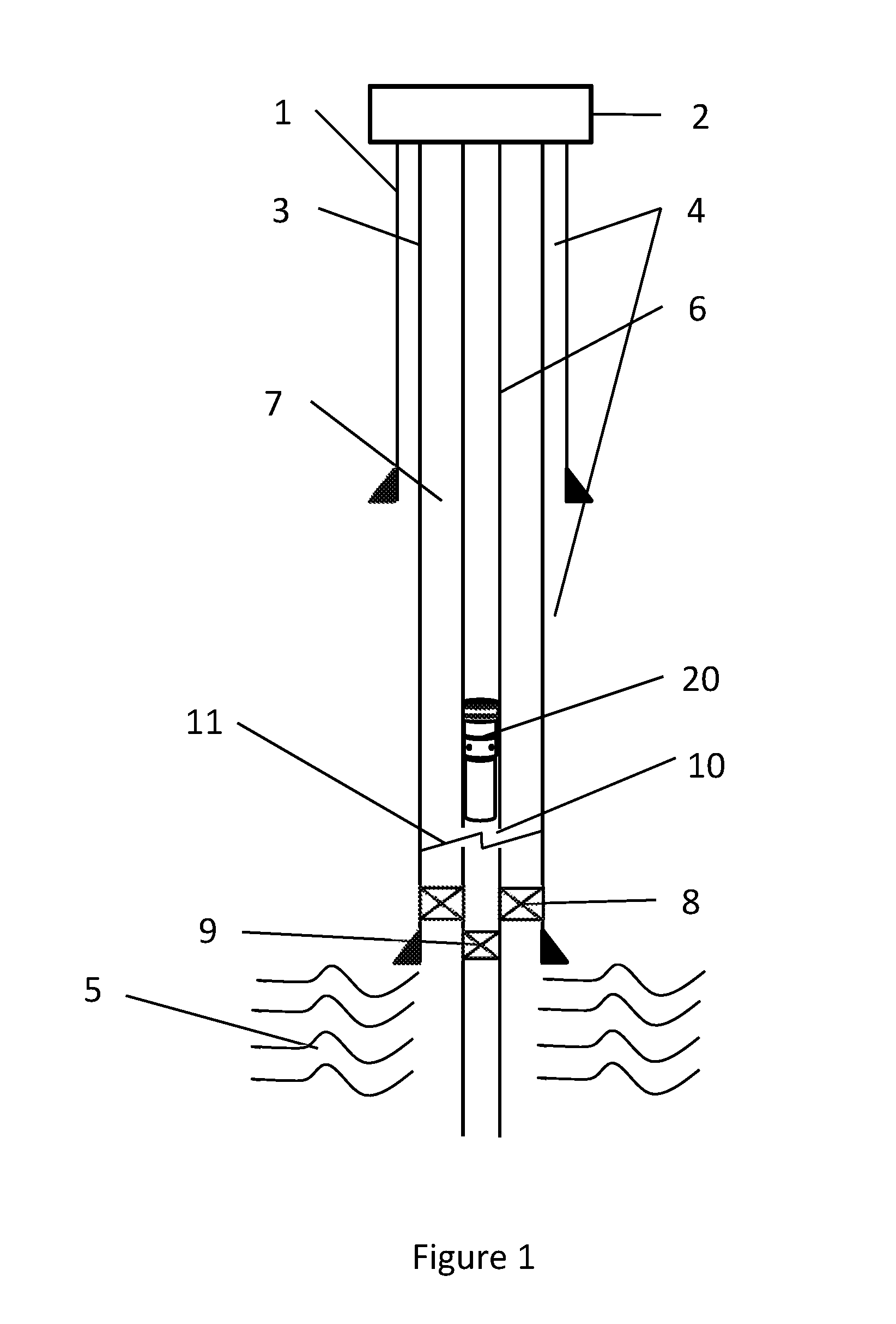

ActiveUS20170016305A1Degree of vibration can be maximizedTuning frequencyVibration devicesSealing/packingProduction packerWell cementing

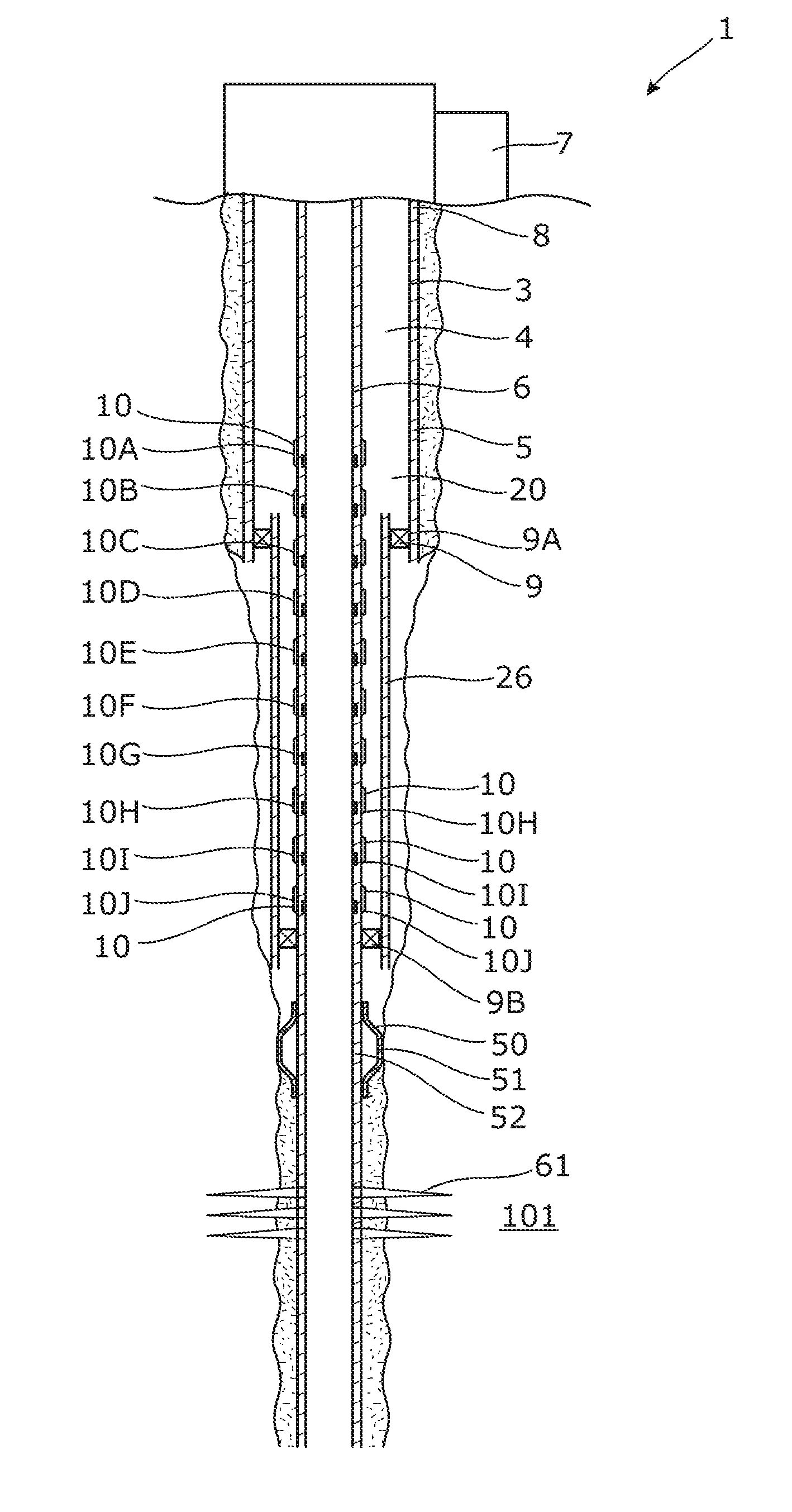

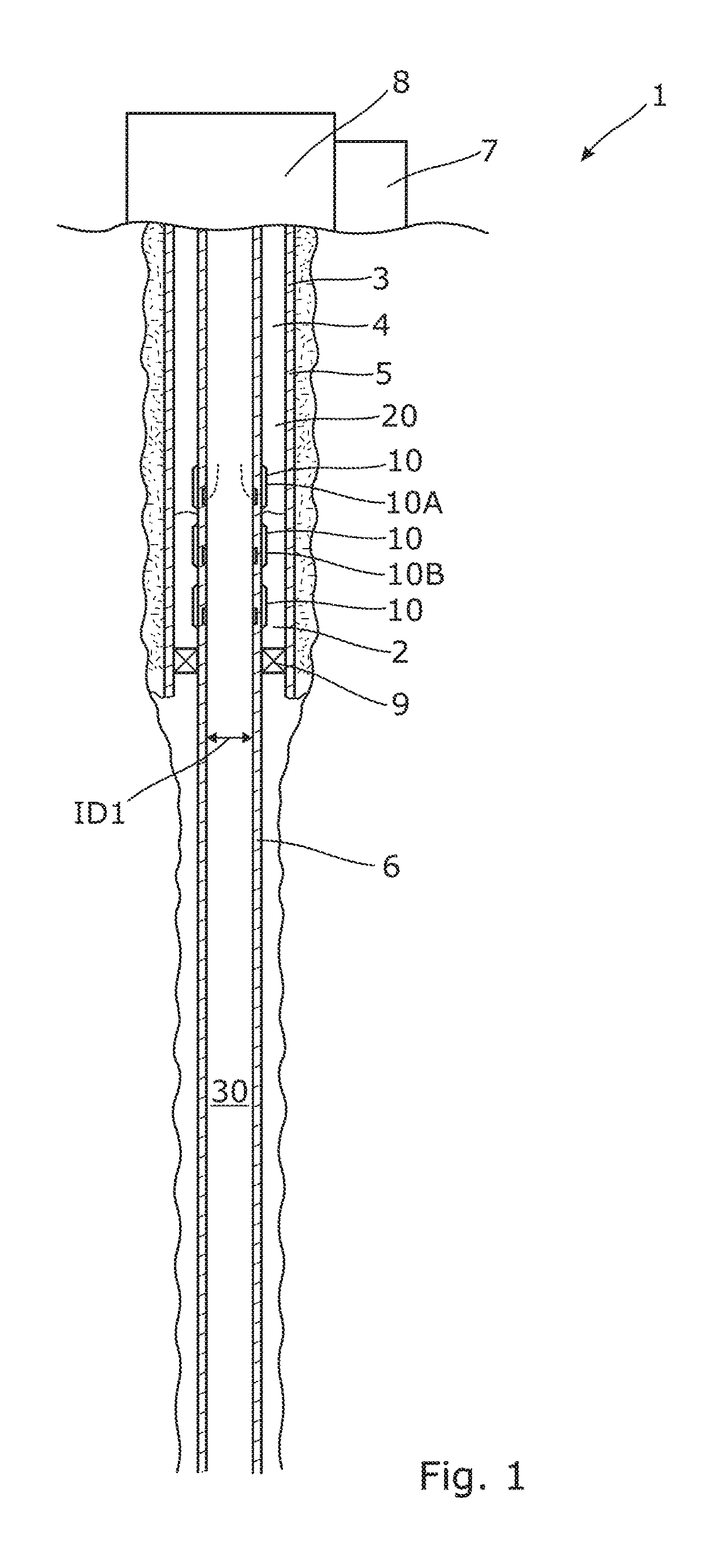

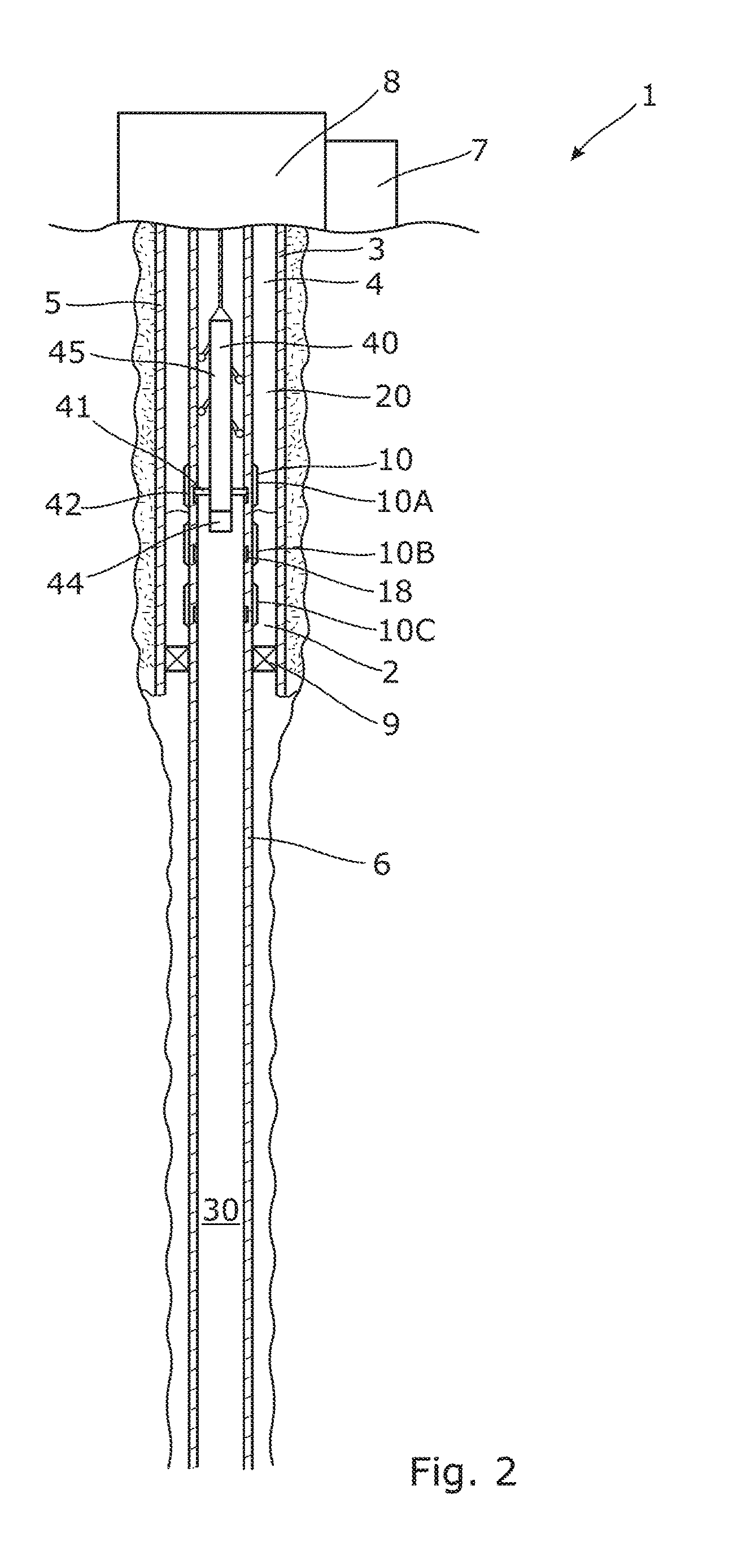

A method of cementing an oil or gas well for abandonment comprises cutting the production tubing 6 above the production packer 8, setting a tubing plug 9 in the tubing and then cutting the tubing. A bridge plug may be installed at the level of the cut, which spans the full diameter of the well casing 3. An agitator assembly 20 comprising an agitator 24, packer 21 and burst sub 23, with a running tool fitted to the top, is run down the tubing on wire line. Cement is then injected into the tubing 6, which flows through the agitator assembly and causes the tubing to vibrate. The cement fills the tubing but also flows back up the A annulus between the casing and production tubing. Vibration of the tubing assists the formation of a good quality cement plug extending all around the annulus over a substantial length of the well.

Owner:CONOCOPHILLIPS CO

Patriot retrievable production packer

Owner:FORUM US

Multi-string production packer and method of using the same

A production packer comprising a packer body, a flat plate, a sealing element, production tubing, water overflow tubing, gas vent tubing, pump cable pack-off tubing, and an optional pressure transducer port. The flat plate is welded onto the top of the packer body. The sealing element is bonded to the outside of the packer body. In the preferred embodiment, the packer body is a steel pipe, and the flat plate is made of steel. The packer is placed inside a production casing, and the diameter of the sealing element is greater than the diameter of the production casing. The sealing element is made out of a material that is durable enough to withstand the pressures associated with a production packer, flexible enough to fit inside the production casing, and elastic enough to create a seal between the packer body and the production casing.

Owner:ZIMMERMAN C DUANE

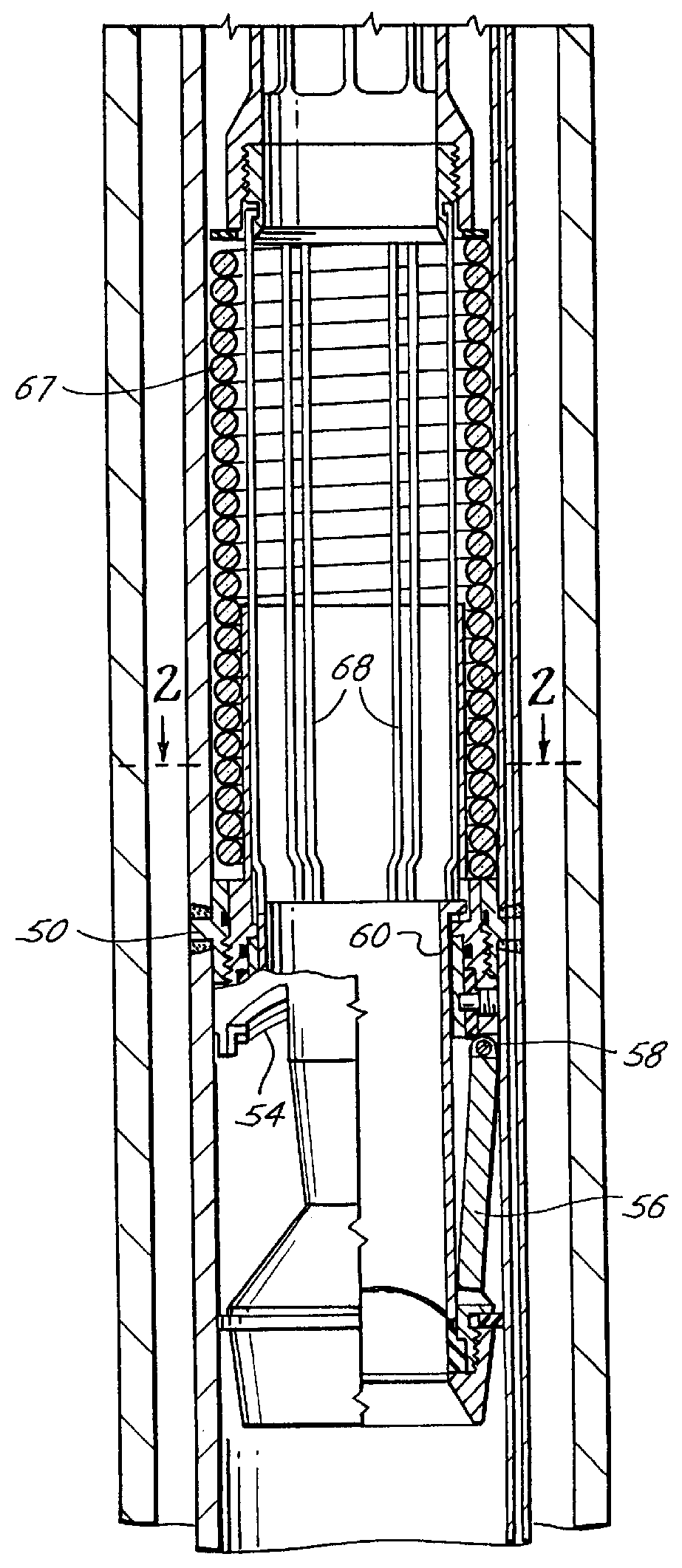

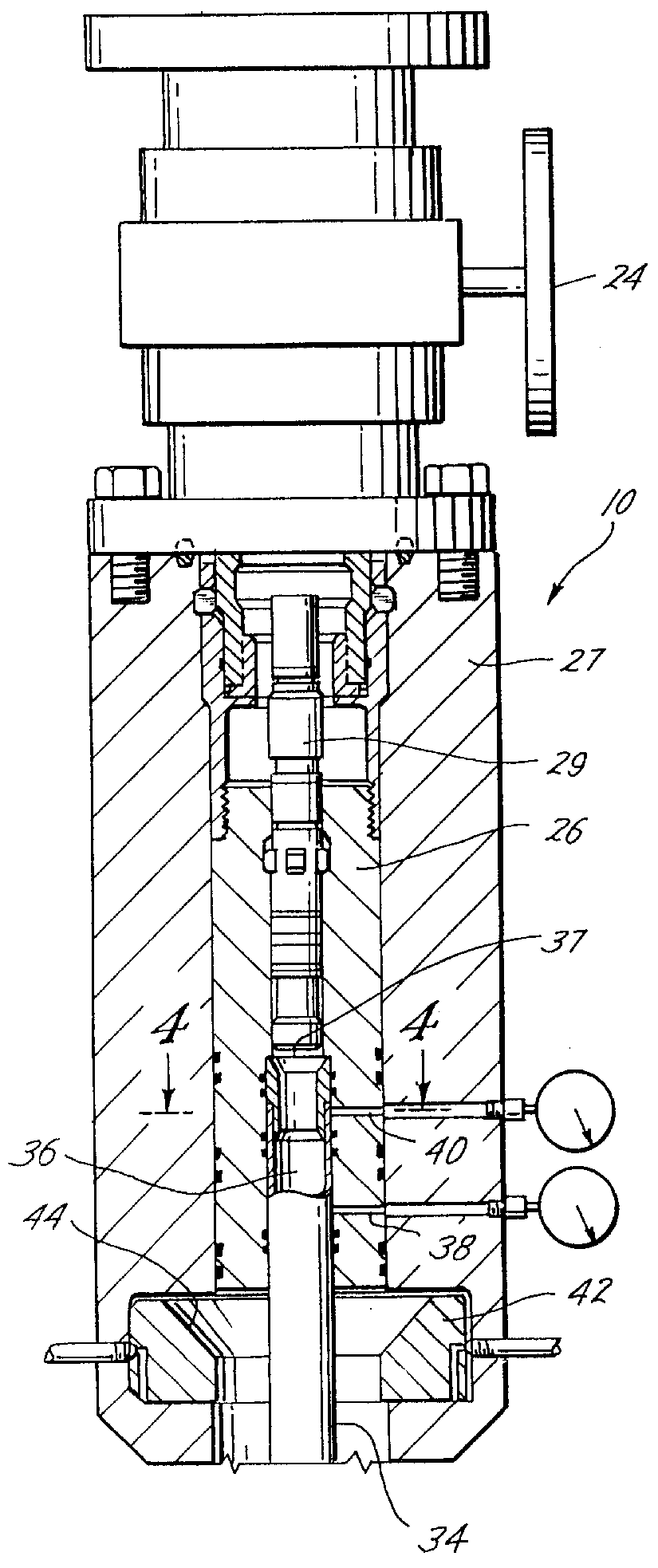

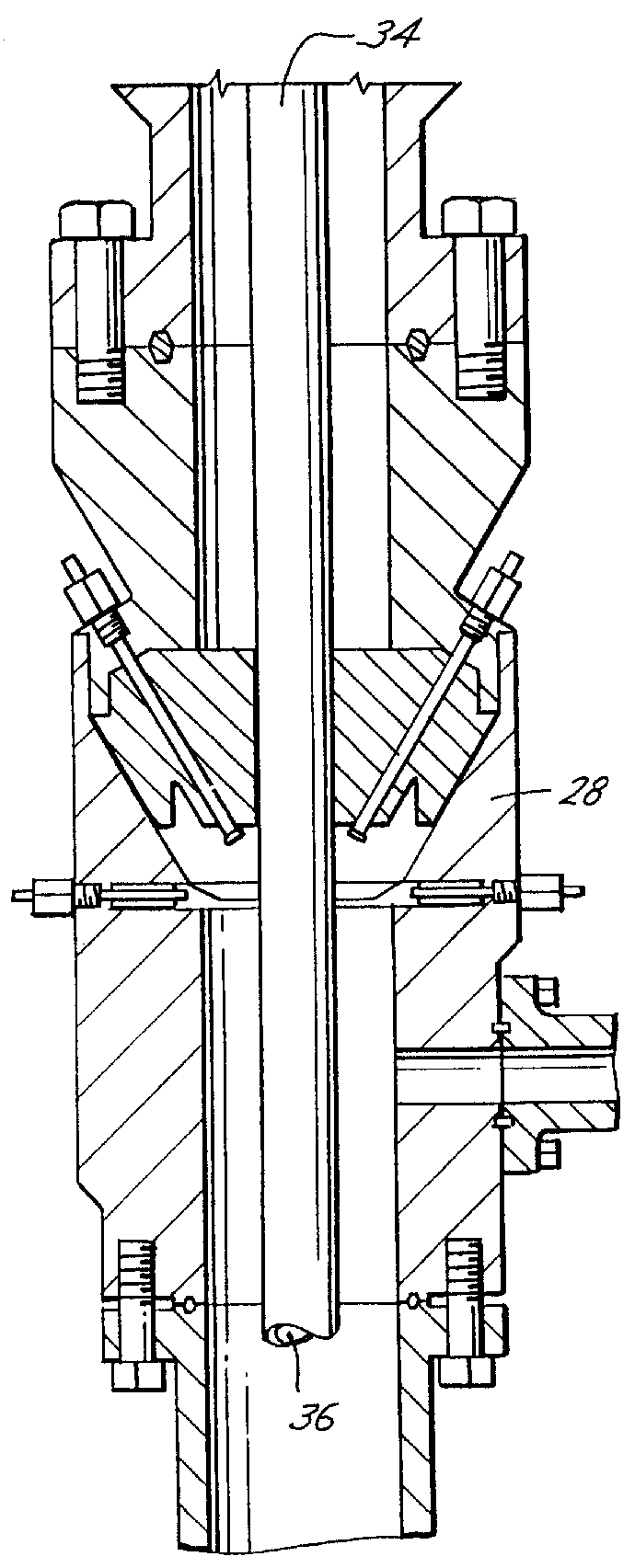

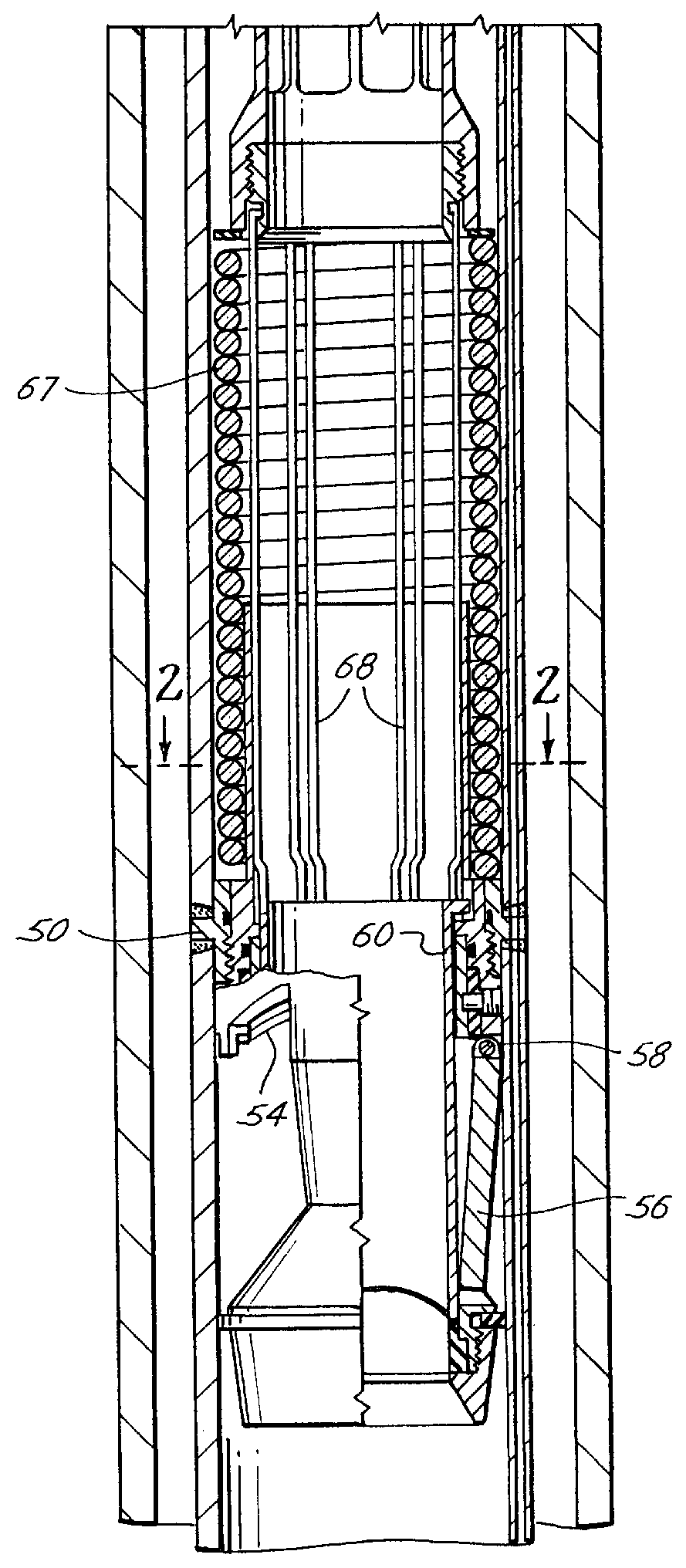

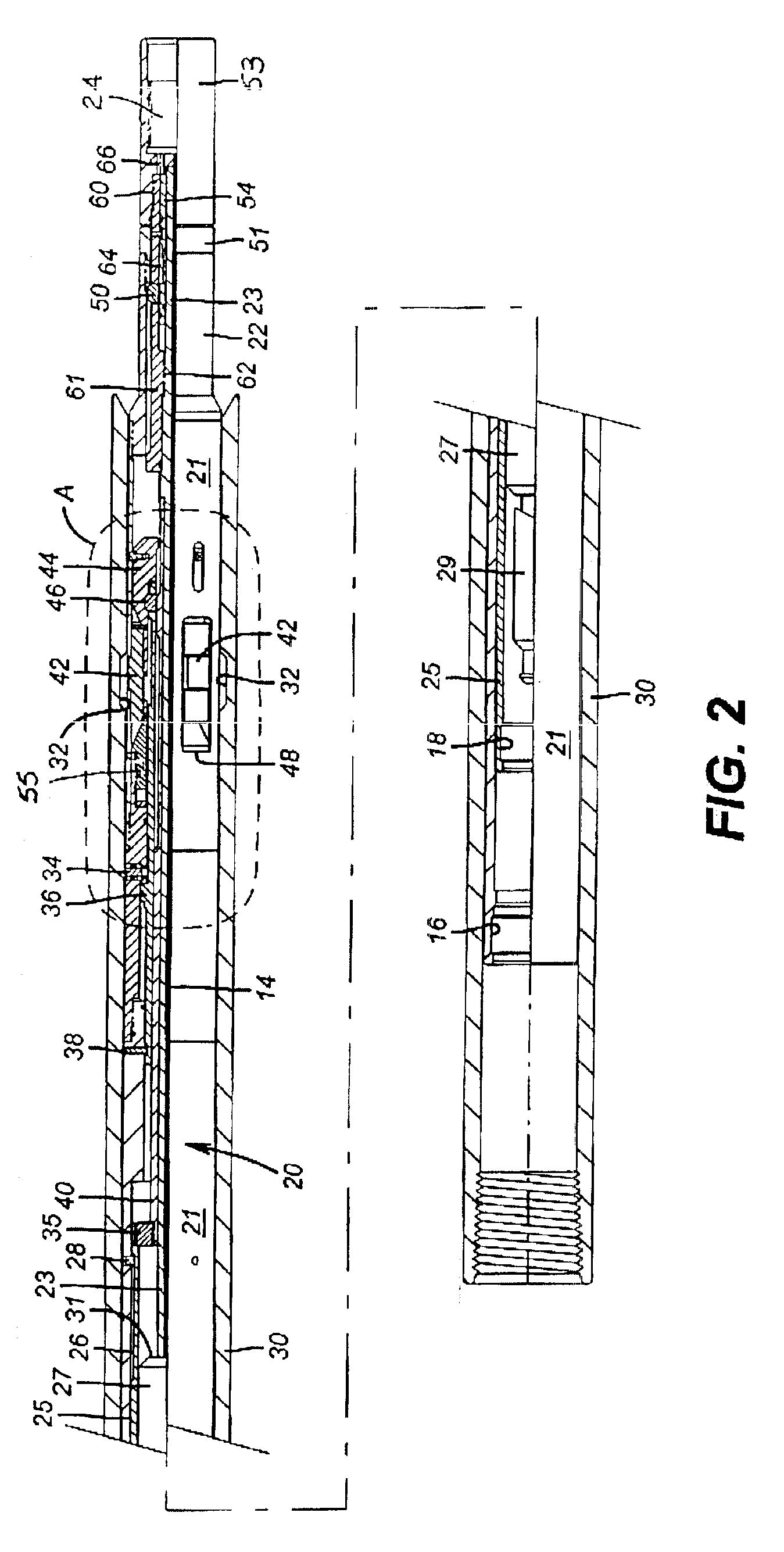

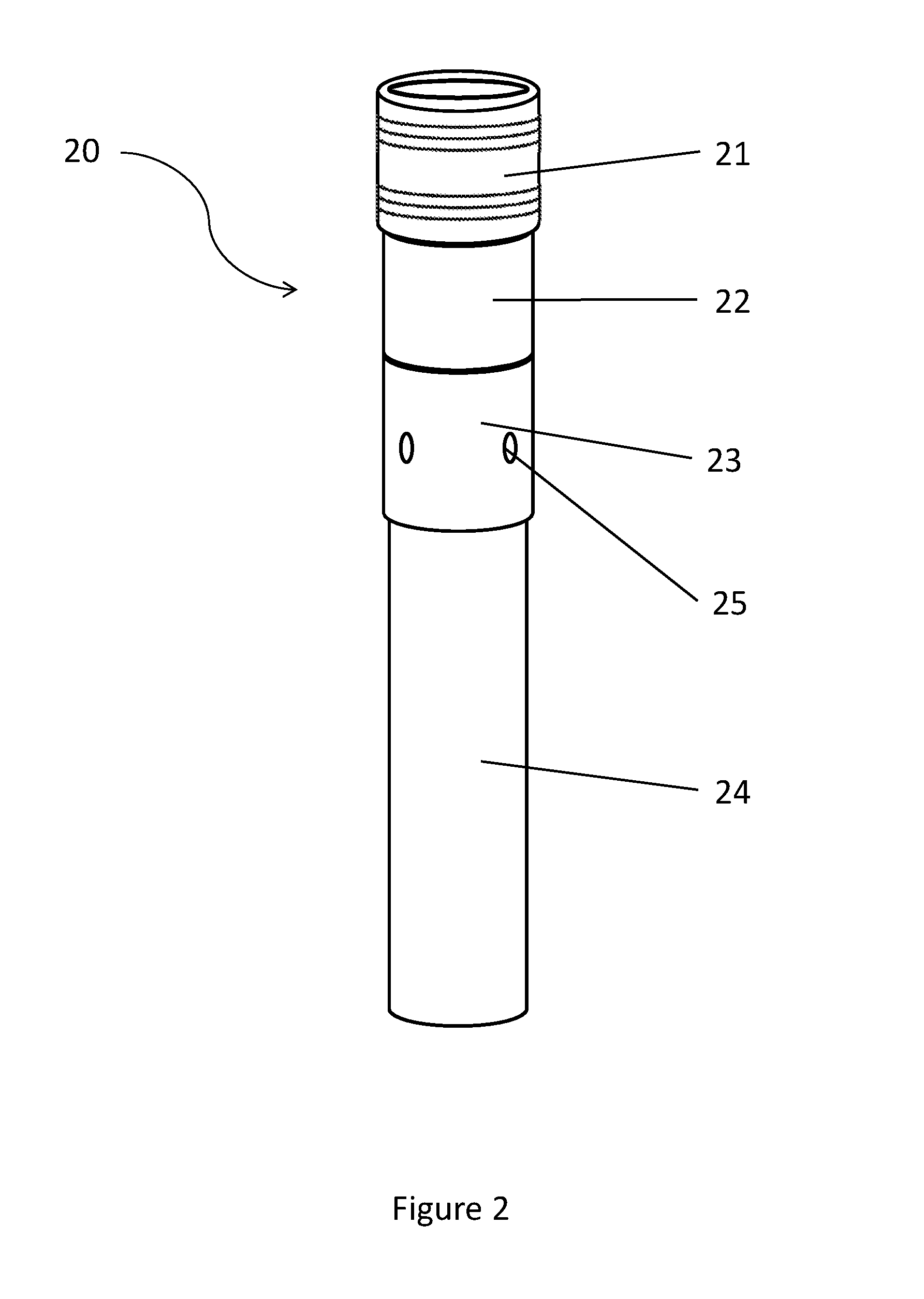

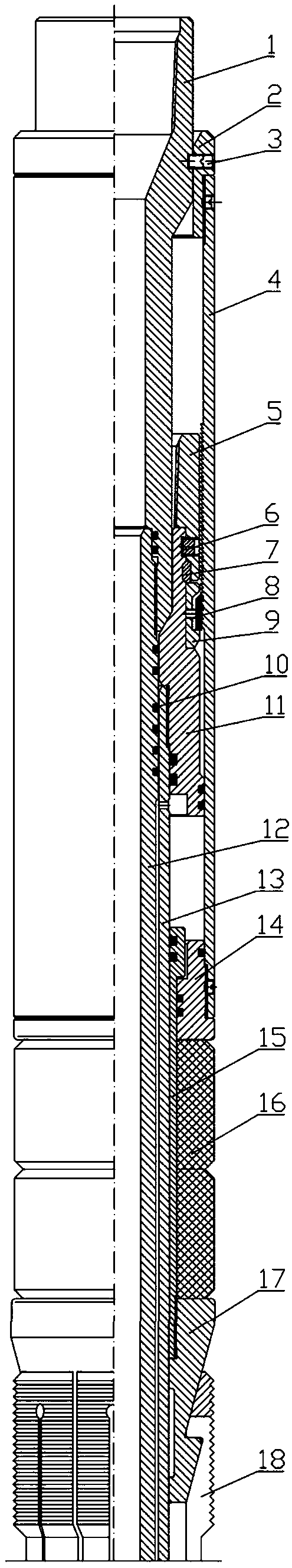

Patriot retrievable production packer

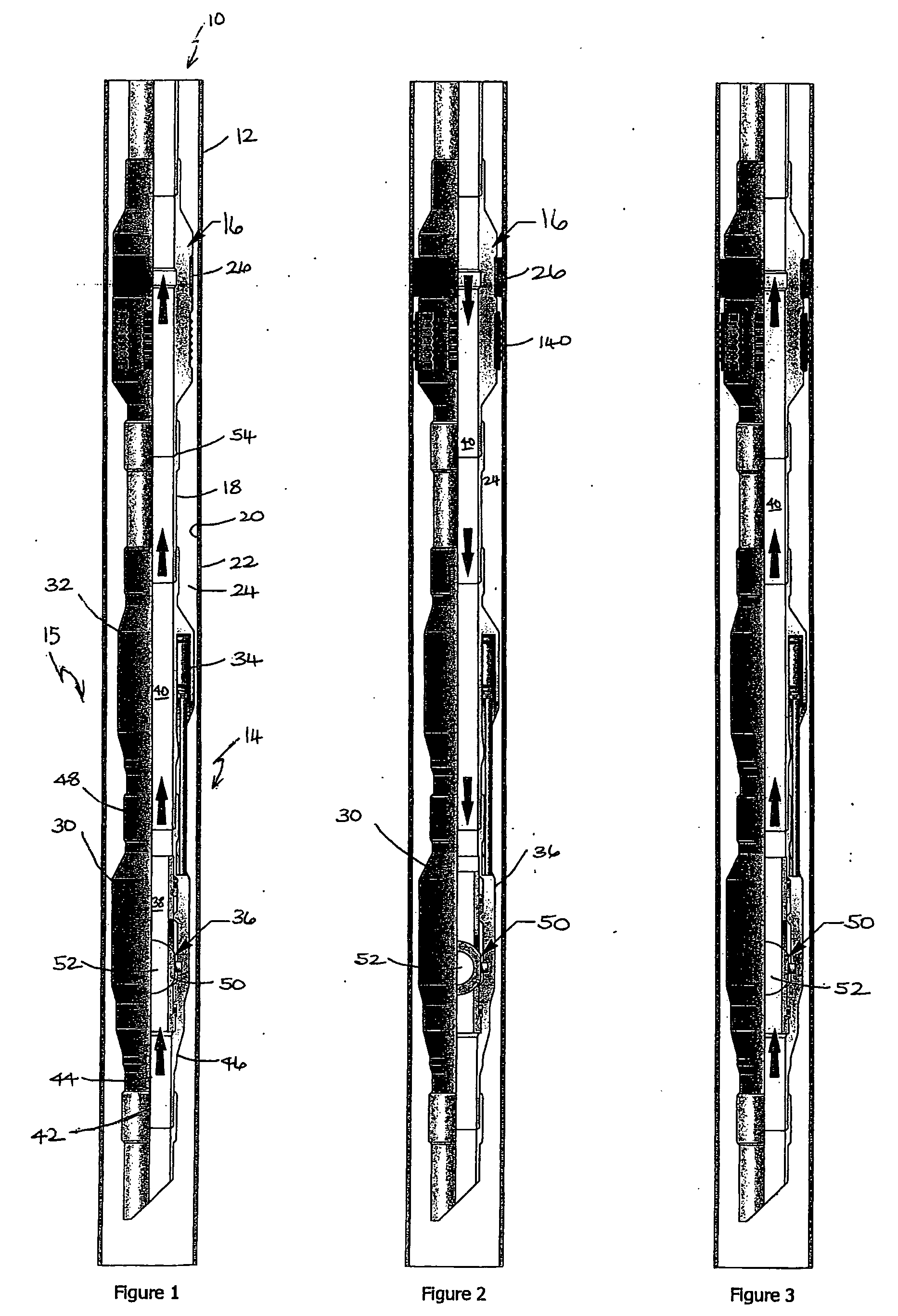

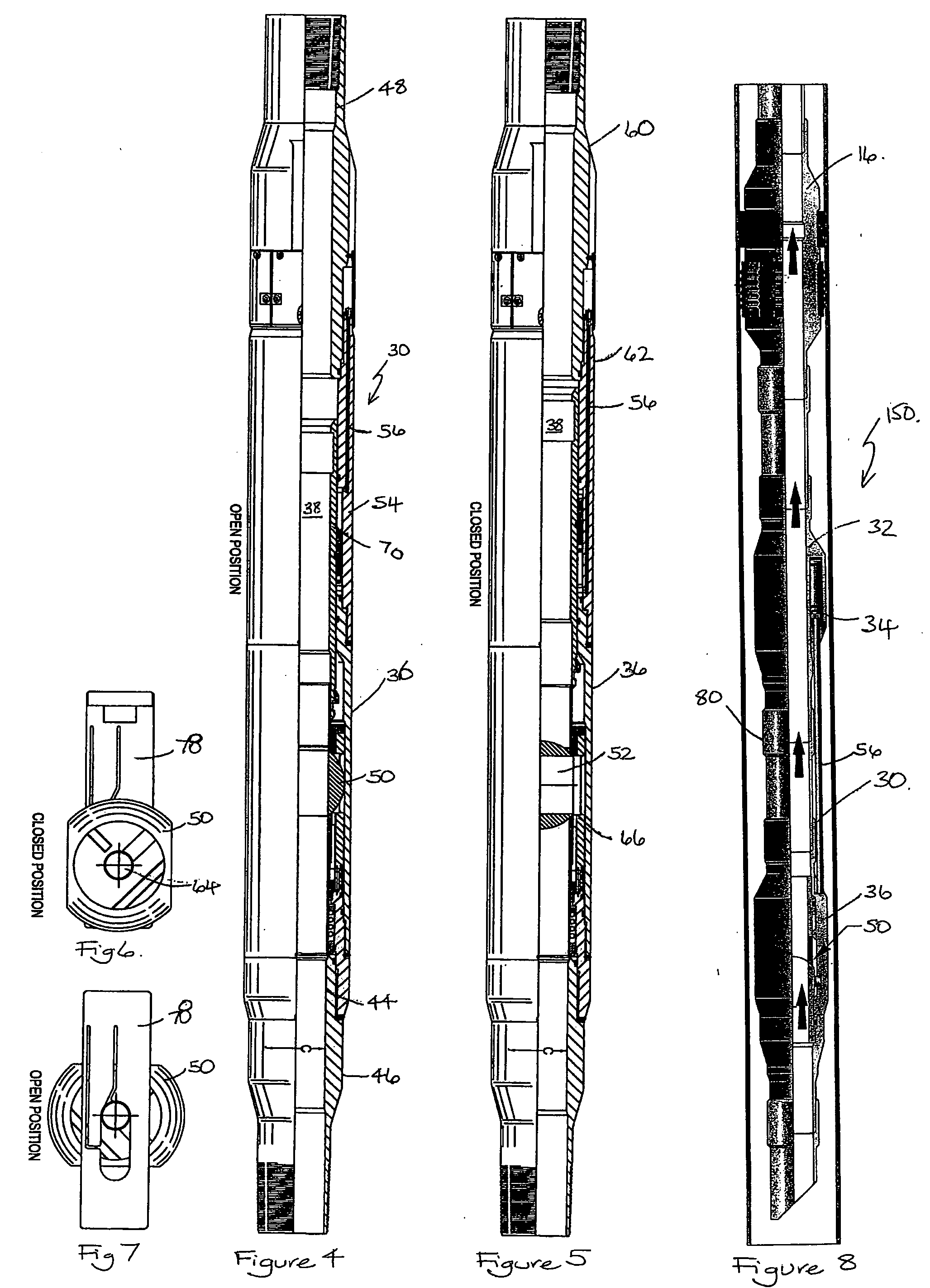

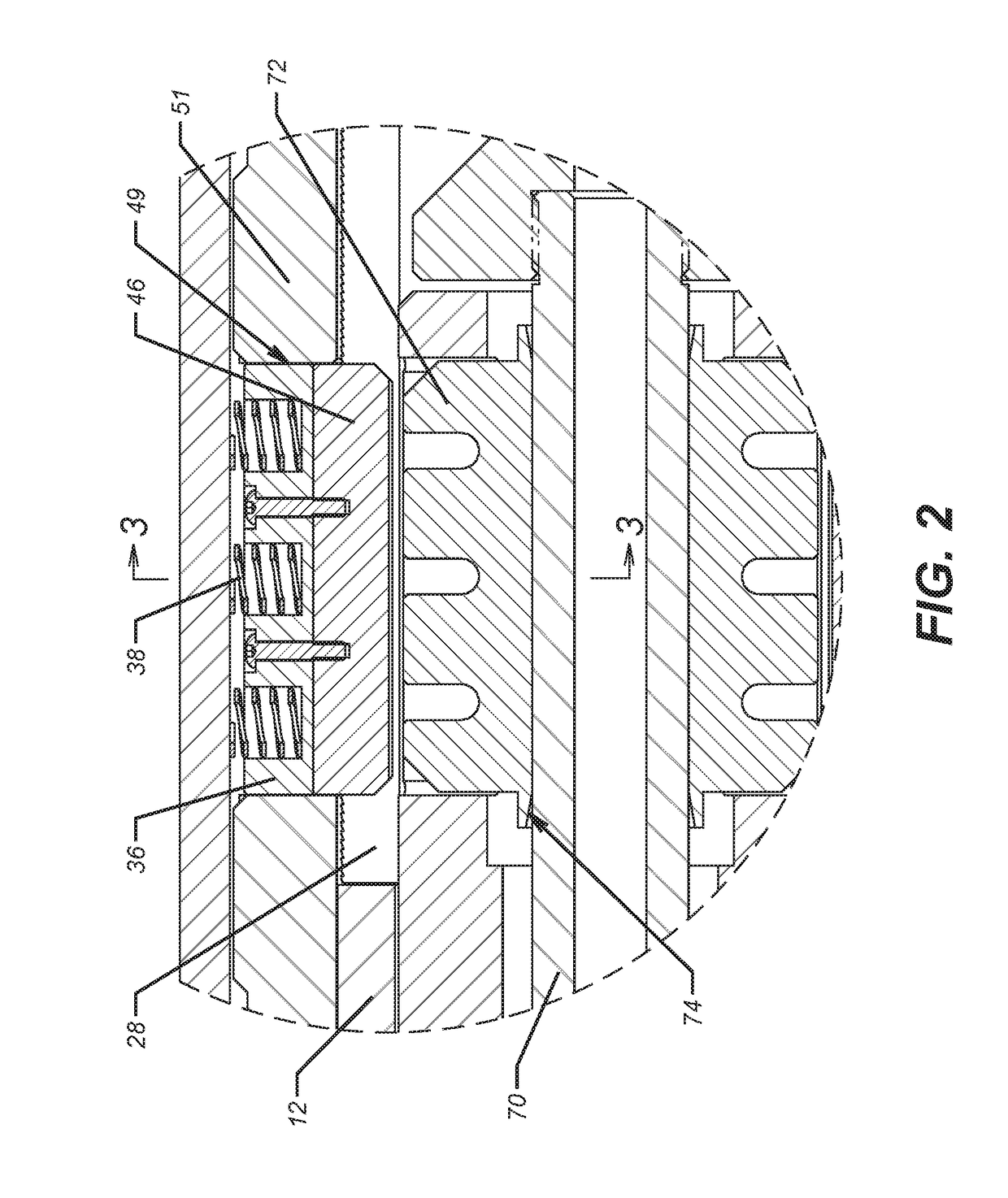

The present invention provides a tool capable of being set and released without requiring the complexity of former tools. A novel arrangement of a push sleeve in the spring body eliminates the need for several shear pins while an internal J slot formed directly on the mandrel significantly reduces the size of the lower drag body and thus the length of the tool. These and other improvements to the packer tool result in a significantly simplified tool capable of meeting the full requirements of a production packer.

Owner:SOMMERS MICHAEL T +1

Patriot retrievable production packer

The present invention provides a tool capable of being set and released without requiring the complexity of former tools. A novel arrangement of a push sleeve in the spring body eliminates the need for several shear pins while an internal J slot formed directly on the mandrel significantly reduces the size of the lower drag body and thus the length of the tool. These and other improvements to the packer tool result in a significantly simplified tool capable of meeting the full requirements of a production packer.

Owner:FORUM US

Gas well de-watering apparatus and method

InactiveUS20080164033A1Low densityDecreasing tubing pressureFluid removalSealing/packingProduction packerHigh rate

A system and method for systematically and economically recovering formation liquids from the bottom of a petroleum well are disclosed. In a preferred embodiment, the system and method are passive in that they utilize the existing formation pressure of the well to remove fluid build-up across the perforations of the well bore in a manner that is completely free from surface control. The system is comprised of strategically placed carrier subs with installed pressure regulating devices. These carrier subs are regularly spaced below the production packer, along the tail pipe section of the production tubing string and facing the perforated intervals of the well bore. The pressure of the trapped formation gas above the accumulating formation liquid is insufficient to remove all of the formation liquid within the entire length of the tubing string 13. However, an open pressure regulating device mounted on the tailpipe section of the tubing string allows a smaller portion of the formation liquid within the tubing string to be produced to the surface using the existing formation pressure. By systematically removing portions of the formation liquid from within the tubing string using the regularly spaced pressure regulating valves, the formation fluid build-up across the perforations is eliminated, and the petroleum well is able to produce at higher rates and for a longer period without intervention.

Owner:ALTECH INDS

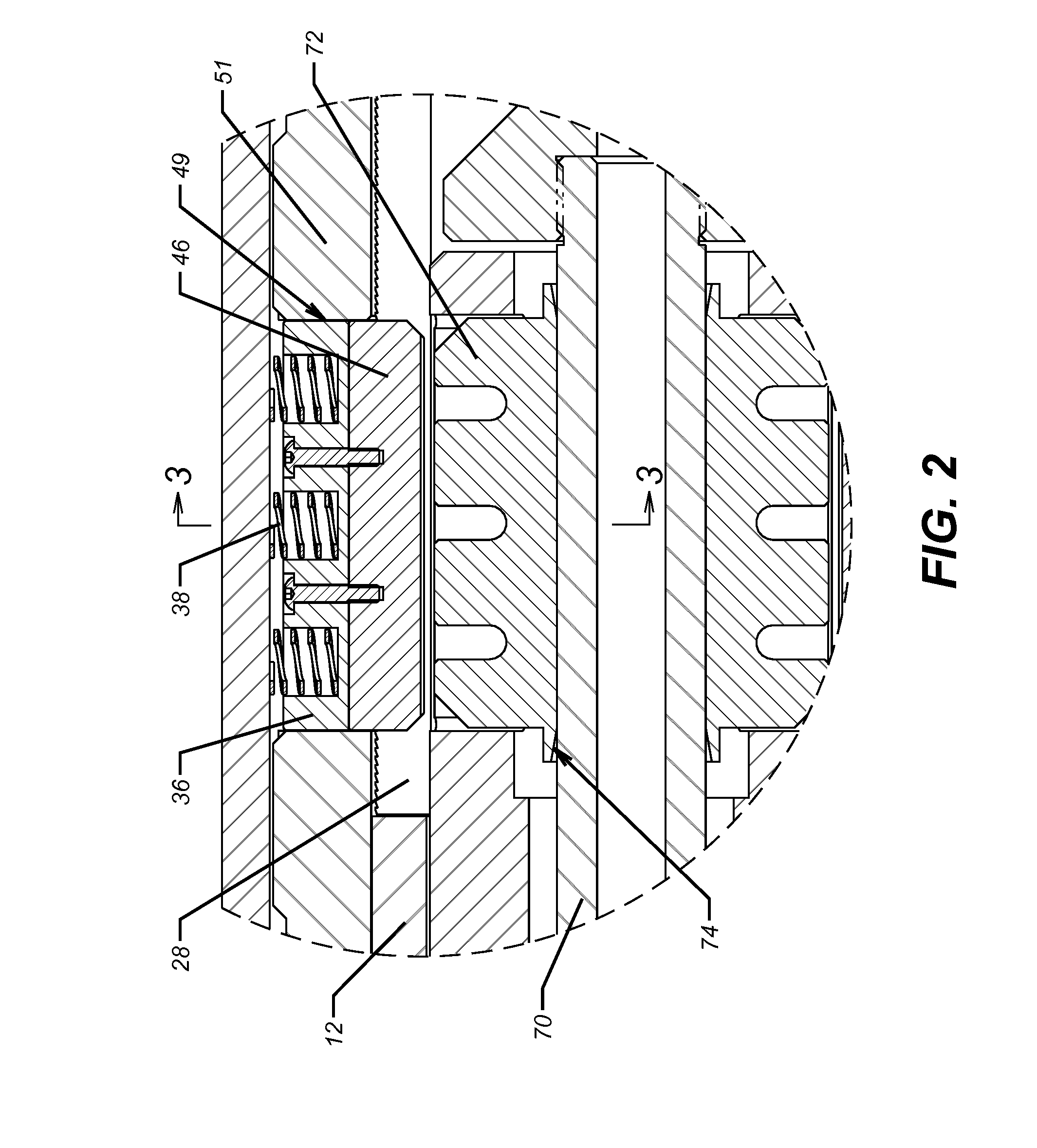

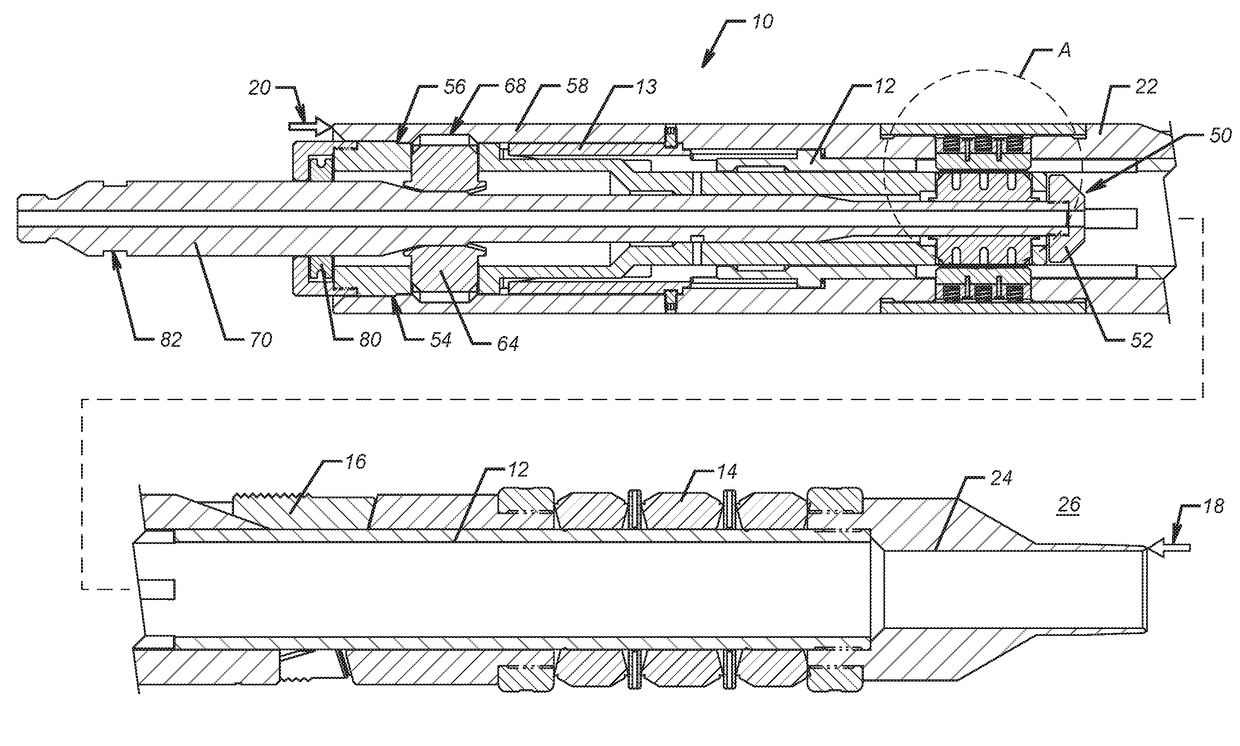

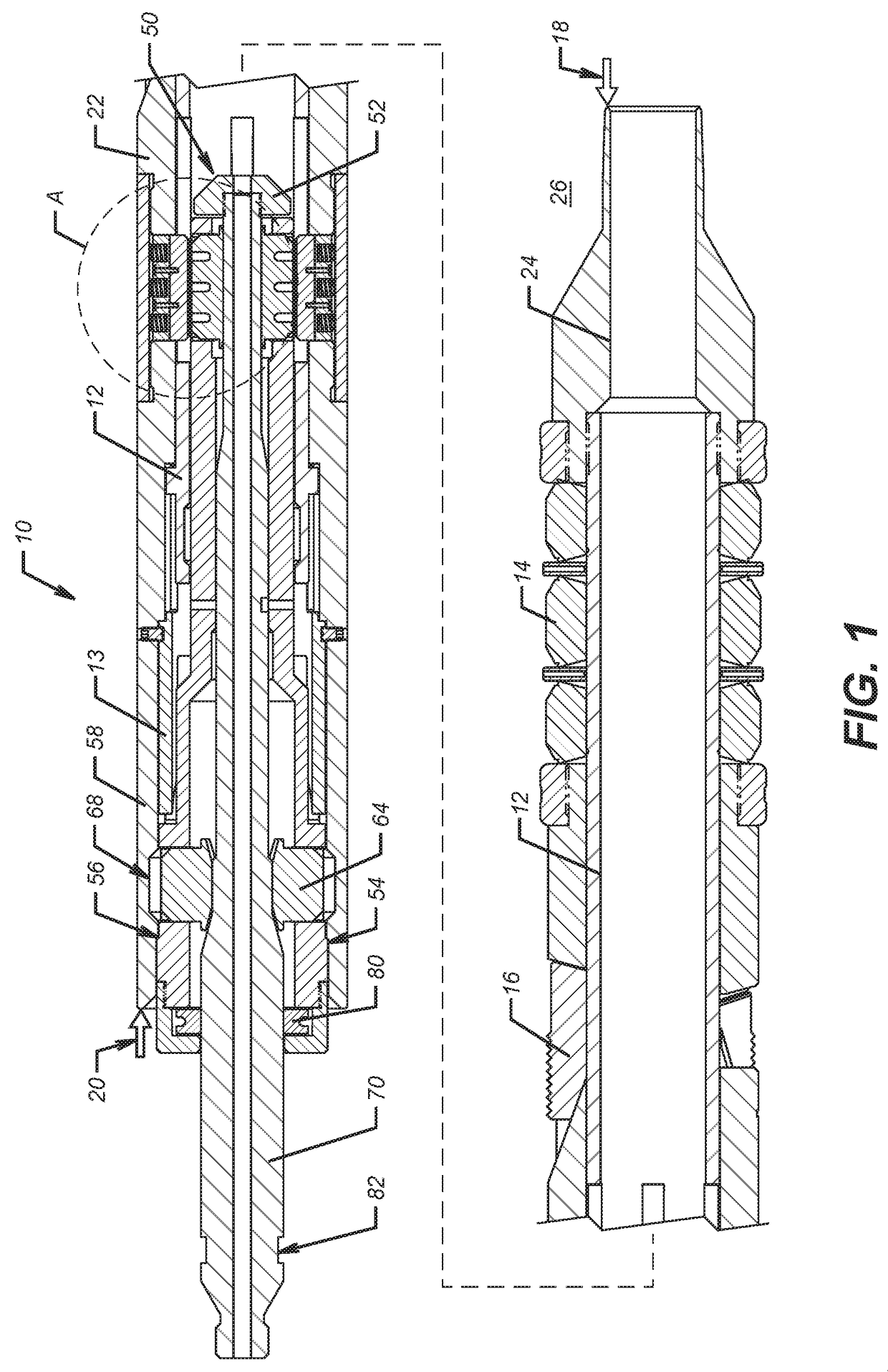

Radially Expandable Ratcheting Body Lock Ring for Production Packer Release

InactiveUS20160168945A1Substantial mechanical advantageFluid removalSealing/packingProduction packerEngineering

A releasable production packer employs lock ring segments that are biased radially inwardly for engaging a mating pattern external to the packer mandrel. The mandrel has openings aligned with the segments and a release tool that latches to the mandrel for support and then moves the segments radially outwardly away from engagement with the mandrel so that the slips and sealing elements can extend axially and retract radially. After those movements the packer is retrieved. The release tools moves the locking segments only radially for the maximum mechanical advantage without risk of bending or deforming small parts.

Owner:BAKER HUGHES INC

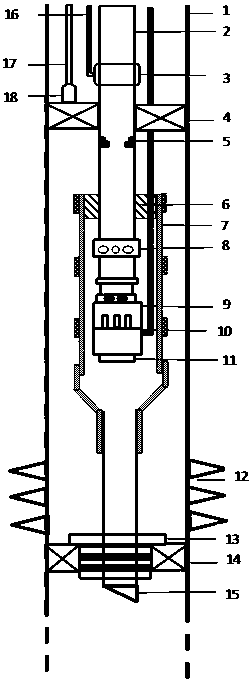

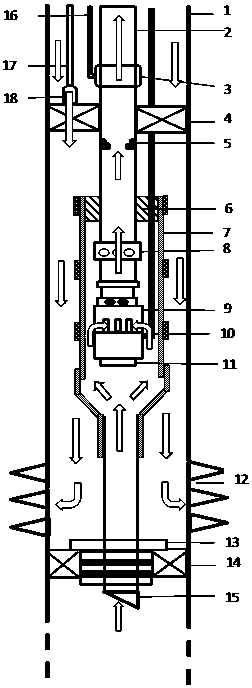

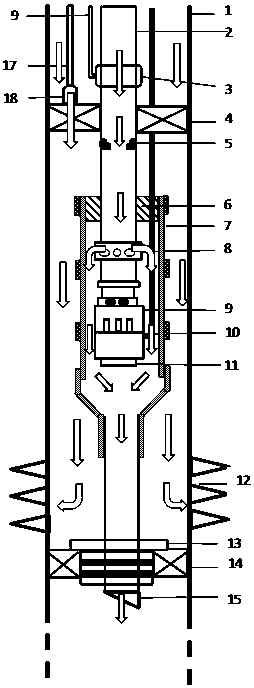

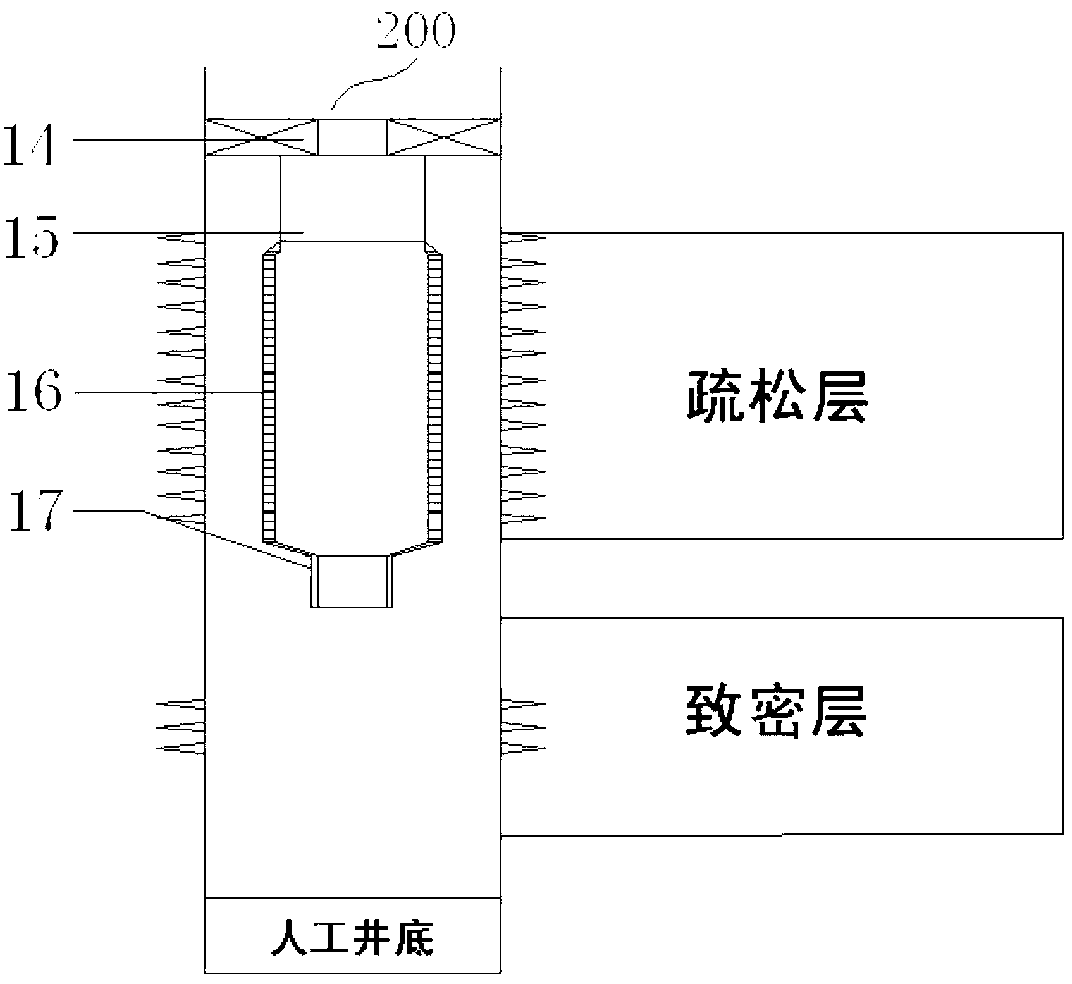

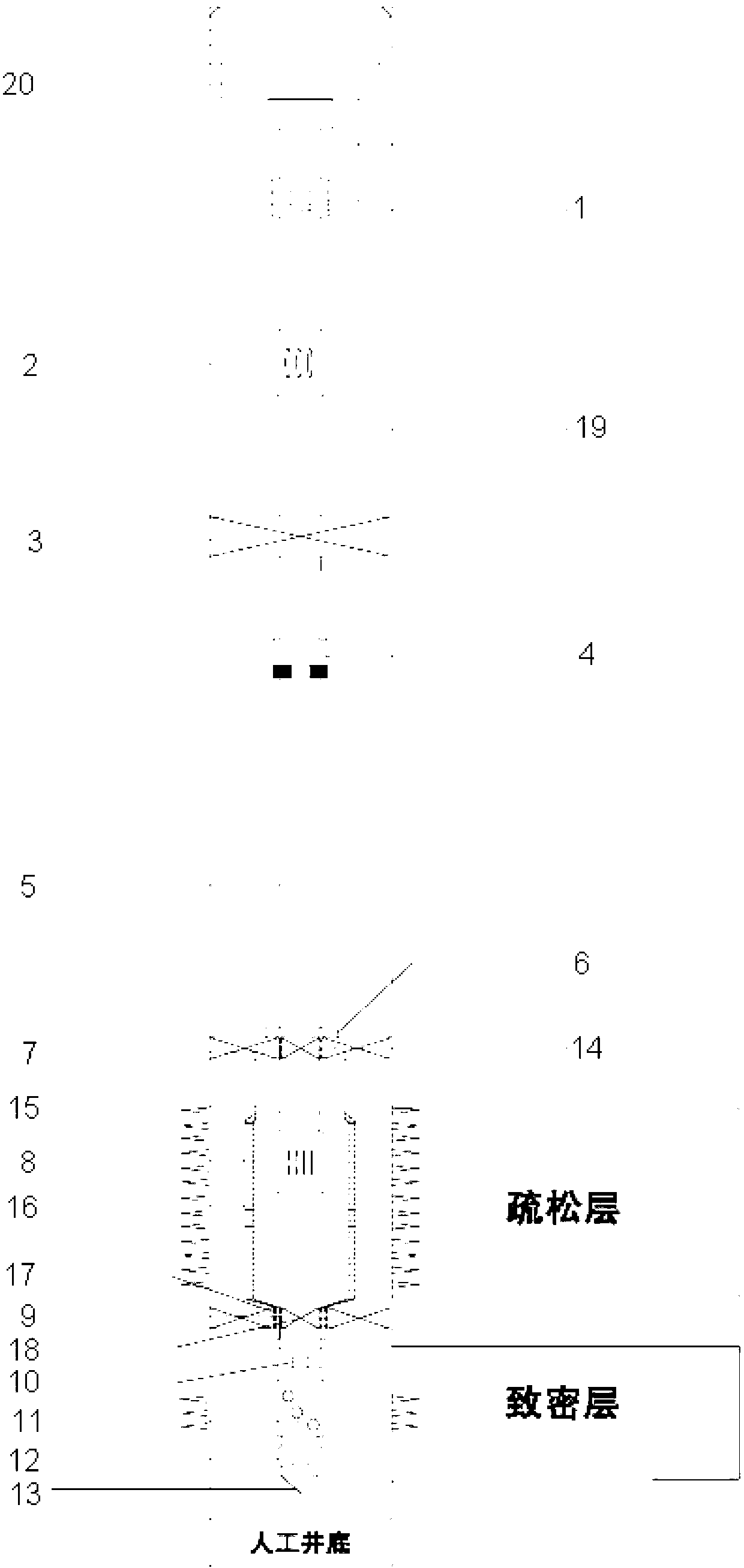

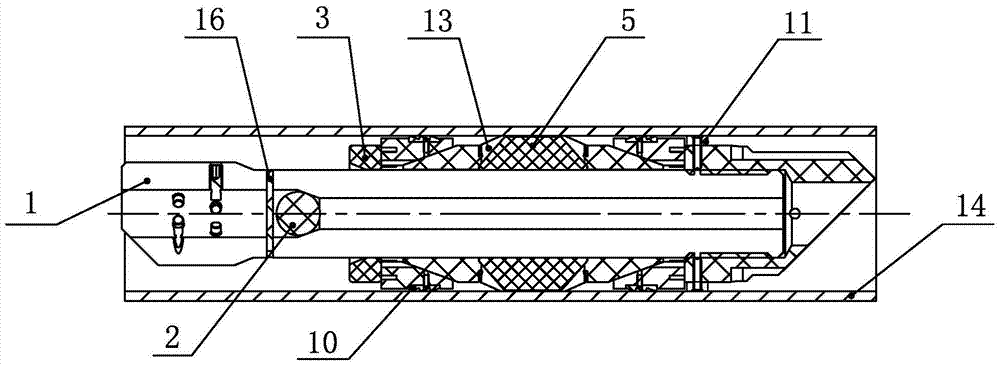

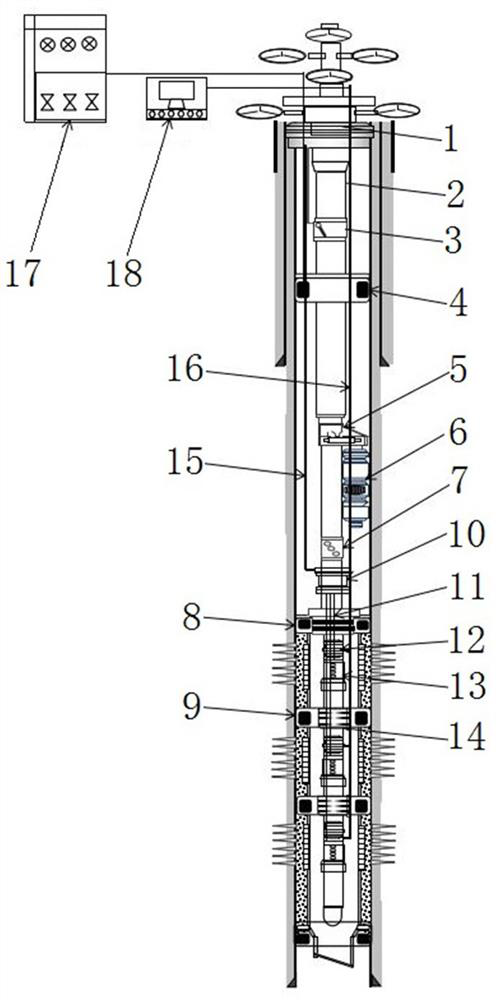

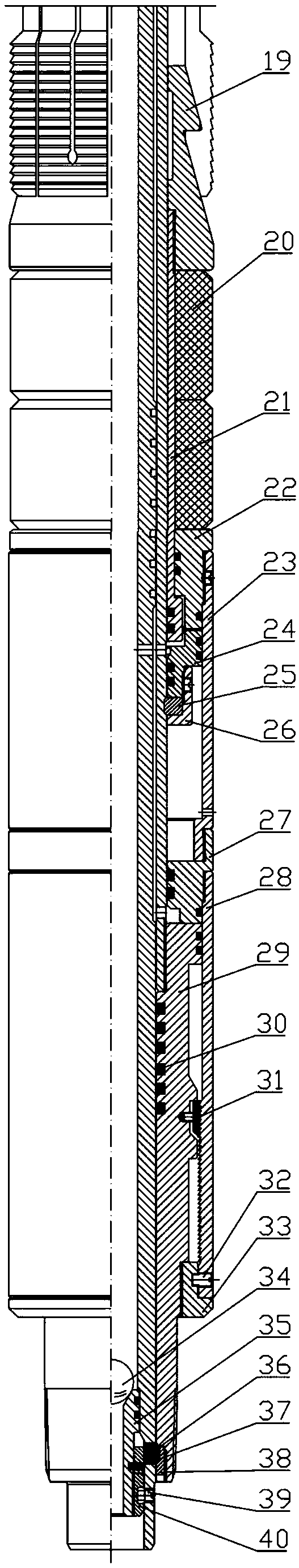

Well completion production pipe string capable of mining at lower part and injecting at upper part and with electric submersible pump

InactiveCN107740685AImprove efficiencyEnhanced overall recoveryFluid removalWell/borehole valve arrangementsProduction packerEngineering

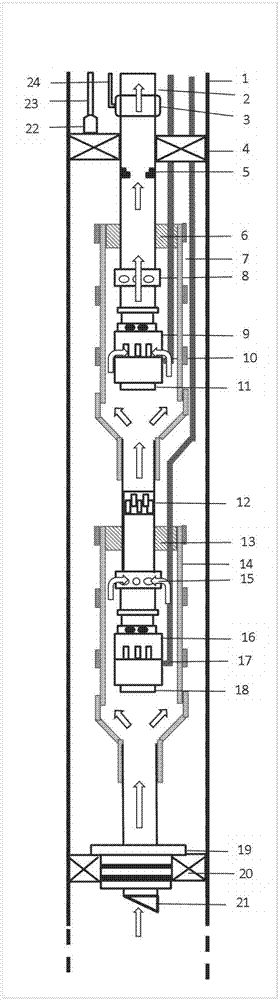

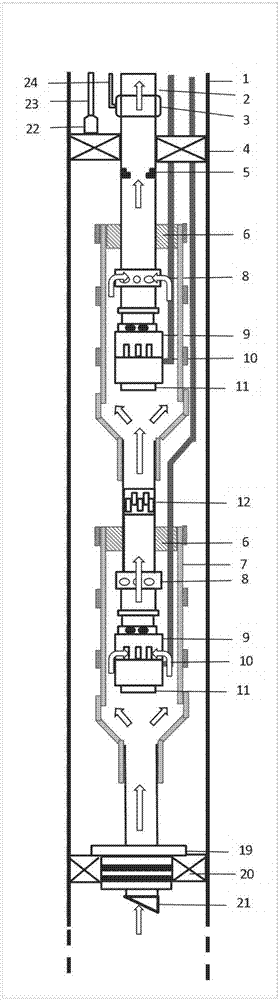

The invention discloses a well completion production pipe string capable of mining at the lower part and injecting at the upper part and with an electric submersible pump. The well completion production pipe string comprises a bushing capable of mining at the lower part and well injecting at the upper part, an oil pipe arranged in the bushing and a downhole tool arranged on the oil pipe. The downhole tool comprises a downhole safety valve arranged at the upper part of the oil pipe and connected with a hydraulic control pipeline and a bushing layering packer arranged at the bottom of the oil pipe and provided with a sealing barrel. The bushing layering packer is provided with a positioning sealing part in a matched mode. An over-cable production packer with an air releasing valve, a workingbarrel and a sealed electric submersible pump system are connected between the downhole safety valve and the positioning sealing part in sequence from top to bottom. An upper reservoir and a lower reservoir of the bushing are separated through the bushing layering packer. A positioning sealing guiding shoe is arranged at the lower end part of the oil pipe. According to the well completion production pipe string, the facts that precise water injecting of the upper reservoir is achieved through an annulus access and pumping production or precise water injecting of the lower reservoir is achieved through a sealing system and a channel in the oil pipe are achieved, and the annulus access and the channel in the oil pipe are independent and noninteracting, so that the upper reservoir and the lower reservoir of one well are controlled independently, and the cost of oilfield development and maintenance is reduced.

Owner:CHINA NAT OFFSHORE OIL CORP +1

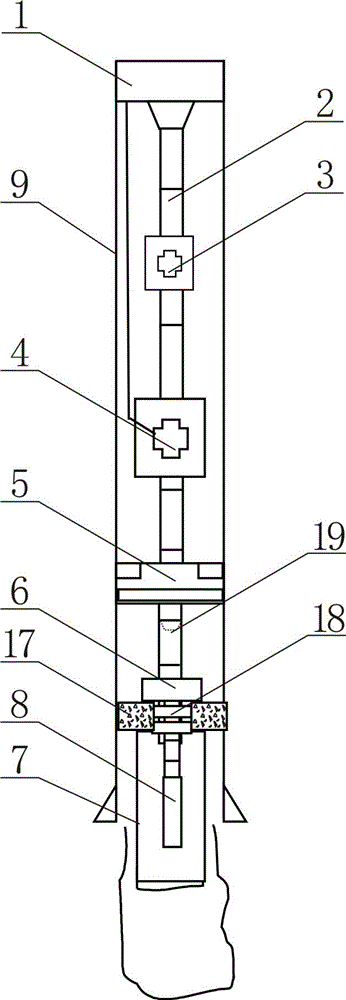

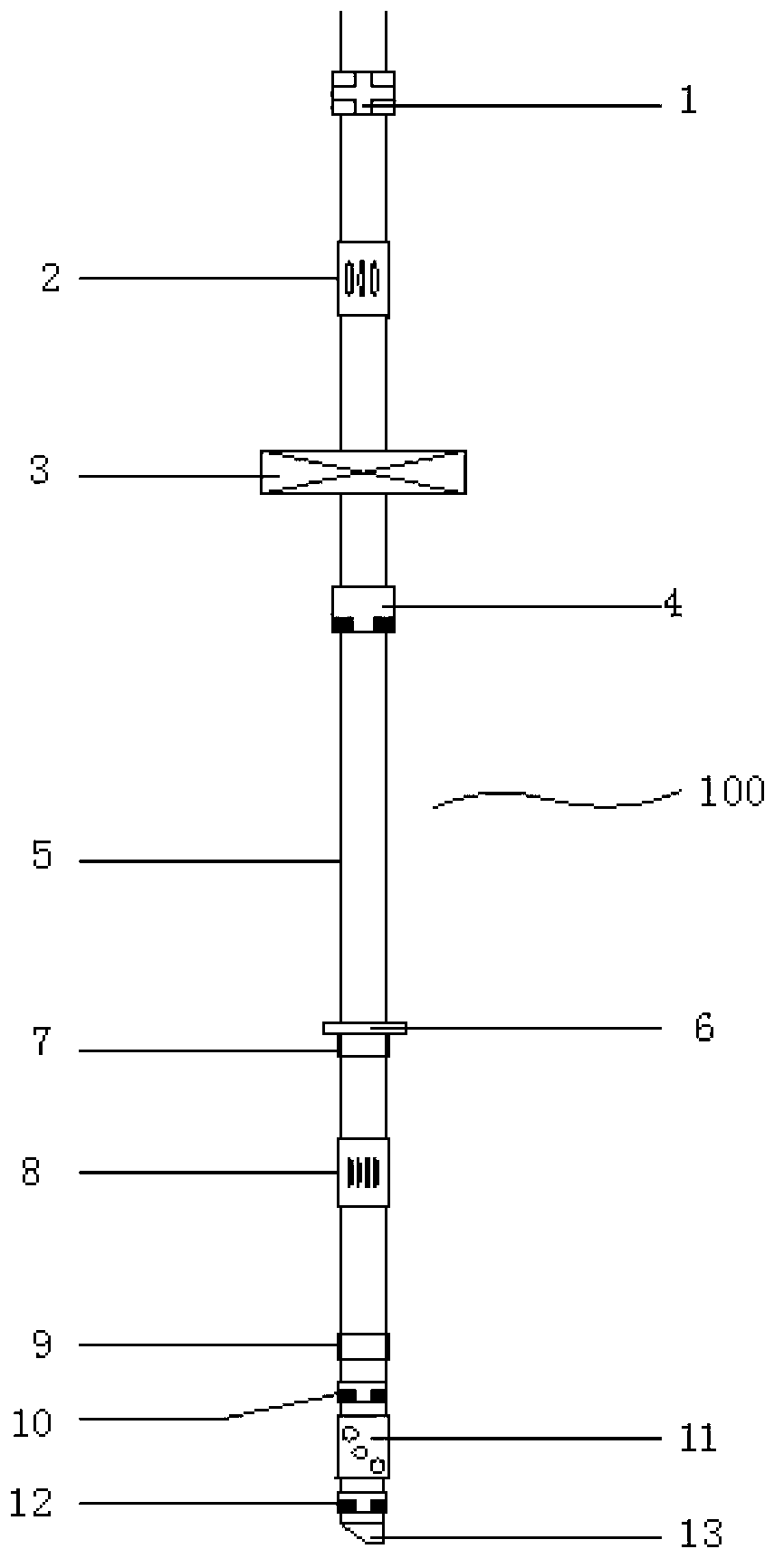

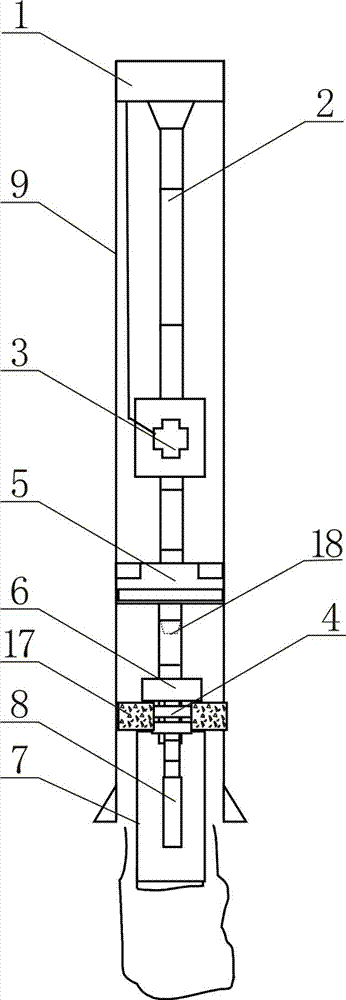

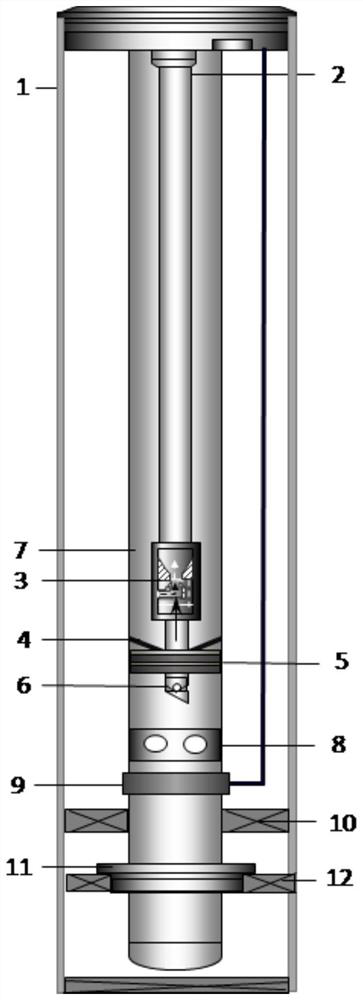

Underground nitrogen-making induced flow completion pipe string having pressure monitoring function

The invention discloses an underground nitrogen-making induced flow completion pipe string having a pressure monitoring function. The underground nitrogen-making induced flow completion pipe string is mainly composed of an oil pipe hanging part, an oil pipe, an underground safety valve, an underground pressure meter, a production packer, a working cylinder, an inserting positioning seal, a blind pipe and an underground nitrogen-making induced flow device. The upper end of the oil pipe is hung in an oil well through the oil pipe hanging part. The underground safety valve, the underground pressure meter, the production packer and the working cylinder are arranged on the oil pipe. The lower end of the oil pipe is connected with the blind pipe through the inserting positioning seal which is inserted into a sealing cylinder of a sand control packer in the oil well. The underground nitrogen-making induced flow device is inserted into the blind pipe. Due to adoption of the above structure, after a first safety shield of a gas well is built, a Christmas tree is assembled, and setting and seal examination are carried out on the production packer until the production packer is qualified, a large amount of nitrogen can be rapidly generated through dropbar excitation and the gas well is induced. Besides, in the long-term production process, the underground pressure is monitored in real time. The underground nitrogen-making induced flow completion pipe string has a good application and popularization prospect.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Fracture and sand prevention integrated completion pipe string and application method thereof

ActiveCN103321626ARealize stratified miningStratified Mining RipeFluid removalWell/borehole valve arrangementsProduction packerPunching

The invention relates to a fracture and sand prevention integrated completion pipe string and an application method thereof. The fracture and sand prevention integrated completion pipe string comprises a sand prevention pipe string and a fracture production pipe string; the fracture production pipe string comprises a safety valve, a first sliding sleeve, a production packer, a first landing joint, a locating seal, a first inserting seal, a second sliding sleeve, a second inserting seal, a second landing joint, a punching pipe, a NO-GO landing joint and a guiding shoe. The safety vale is arranged on the upper portion of an oil pipe. The first sliding sleeve, the production packer, the first landing joint and the locating seal are sequentially arranged on a portion, below the safety valve, of the oil pipe at intervals. The first inserting seal is arranged on a portion, tightly close to the bottom of the locating seal, of the oil pipe. The second sliding sleeve, the second inserting seal, the second landing joint, the punching pipe and the NO-GO landing joint are sequentially arranged on a portion, below the first inserting seal, of the oil pipe at intervals. The guiding shoe is arranged on the bottom of the oil pipe. The sand prevention pipe string comprises a top packer, a blind pipe, a sand prevention screen pipe and a third inserting seal, where the blind pipe, the sand prevention screen pipe and the third inserting seal are sequentially connected to the bottom of the top packer. Due to the adoption of the fracture and sand prevention integrated completion pipe string, fracture construction and sand prevention operation procedures are simplified, operation time is saved, operation cost is reduced, in addition, fracturing and production can be more convenient, selective single-layer development or multi-layer development can be achieved according to production needs, and production can be more flexible.

Owner:CHINA NAT OFFSHORE OIL CORP +1

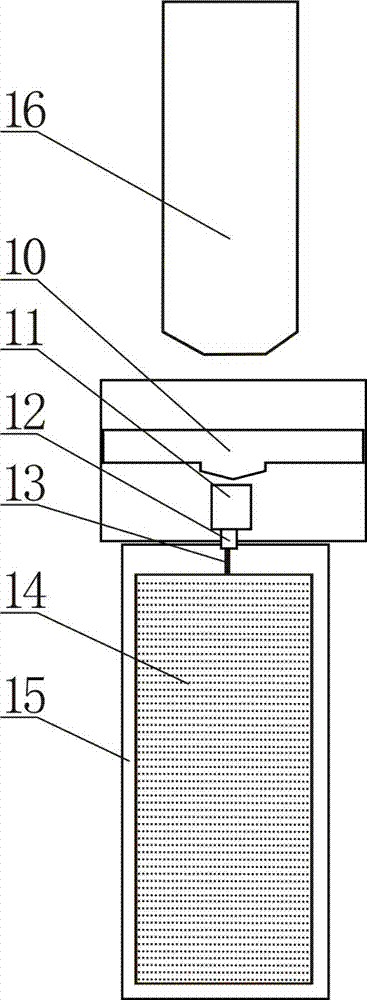

Ceramic slip composite bridge plug

The invention discloses a composite bridge plug made of ceramic slips, which comprises a central tube. The outer circumference of the central tube is sequentially provided with a push ring, an upper positioning cone, a rubber tube, a lower positioning cone and a spacer ring. The spacer ring is fixedly connected with the central tube, the push ring, the upper positioning vertebral body, the rubber tube and the lower positioning vertebral body can all move along the axial direction of the central tube, and the upper positioning One end is in contact with the push ring, a plurality of lower bases are provided on the circumference of the lower positioning vertebral body, one end of the lower base is in contact with the spacer ring, and ceramic slips are provided on the outer circumferences of the upper base and the lower base; The ceramic slip composite bridge plug of the present invention is quickly sent to the target layer through a cable or a coiled tubing, and is sealed by gunpowder or hydraulic setting to realize the isolation of production layers or non-target layers, so as to achieve the purpose of changing wellbore conditions and achieving isolation , to meet the follow-up construction requirements. After the construction is completed, it can achieve fast milling and flowback effects, which improves work efficiency.

Owner:CHENGDU JIAGE TECH CO LTD

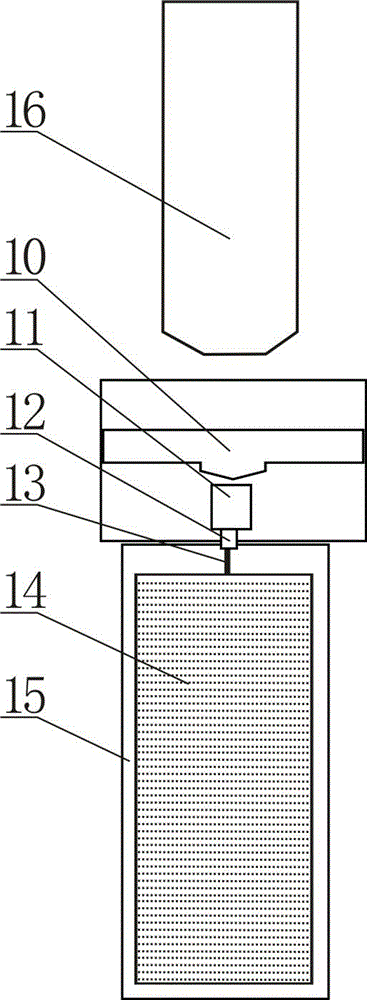

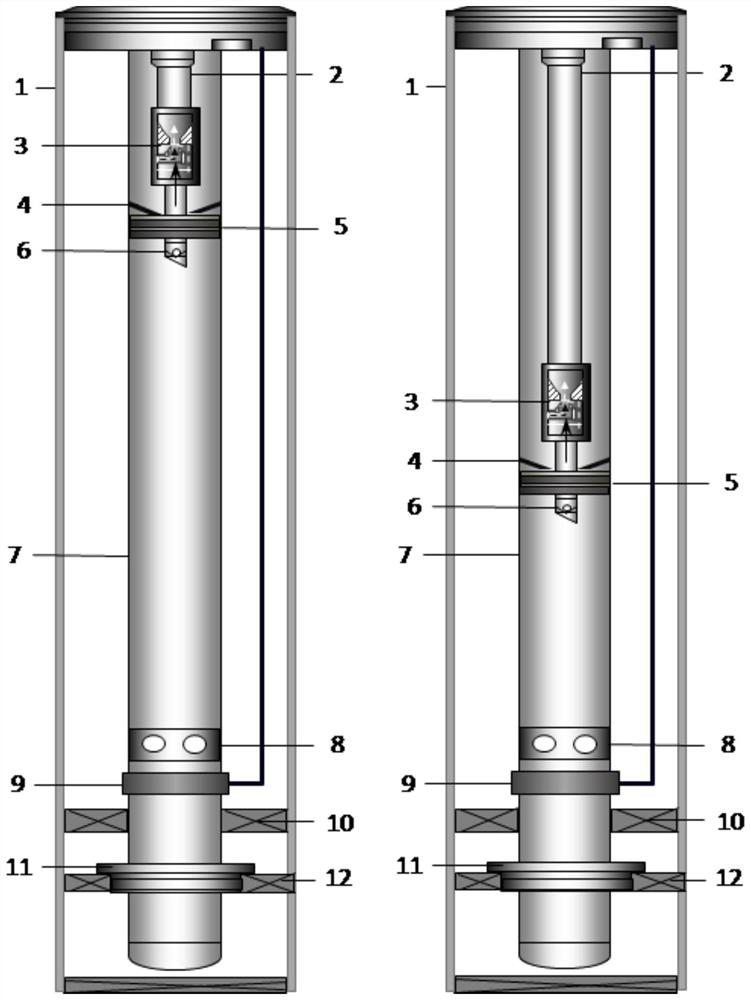

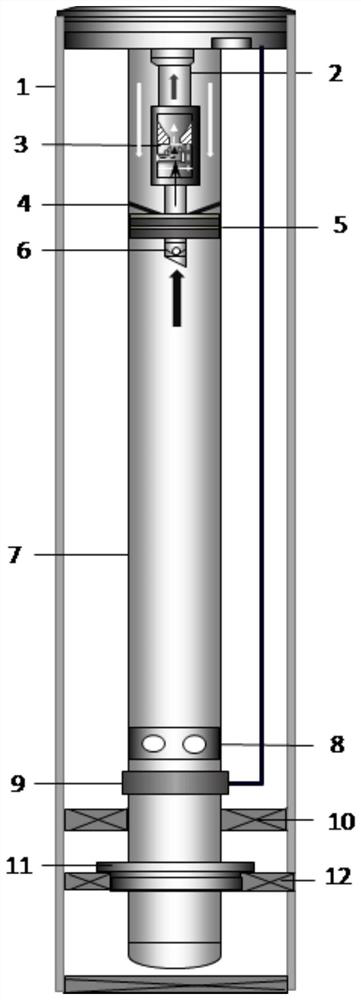

Rapid induced flow completion pipe column for subsurface nitrogen making gas well

InactiveCN104265250ASimplify operating proceduresImprove efficiencyDrilling rodsFluid removalProduction packerNitrogen gas

The invention discloses a rapid induced flow completion pipe column for a subsurface nitrogen making gas well. The rapid induced flow completion pipe column for the subsurface nitrogen making gas well is mainly formed by a mandrel hanger, an oil tube, a subsurface safety valve, a production packer, a working barrel, an insertion positioning seal, a blind tube and a subsurface nitrogen induced flow device; the upper end of the oil tube hangs inside an oil well through the mandrel hanger; the subsurface safety valve, the production packer and the working barrel are respectively arranged on the oil tube; the lower end of the oil tube is connected with the blind tube through the insertion positioning seal; the insertion positioning seal is inserted inside a sealing cylinder of a sand control packer inside the oil well; the subsurface nitrogen making induced flow device is inserted to the blind tube; the subsurface nitrogen making induced flow device is mainly formed by an ignition head, an exploder, a booster tube, a detonating cord, a gas generating agent and an outer casing; the ignition head is arranged at the top of the exploder; the exploder is connected with the detonating cord through the booster tube; the outer casing is full of the gas generating agent which is connected with the detonating cord. According to the above structural form, the rapid induced flow completion pipe column for the subsurface nitrogen making gas well has the advantages of being few in induced flow operation equipment, simple in operation process, high in efficiency, low in cost and stable and reliable.

Owner:CHINA NAT OFFSHORE OIL CORP +1

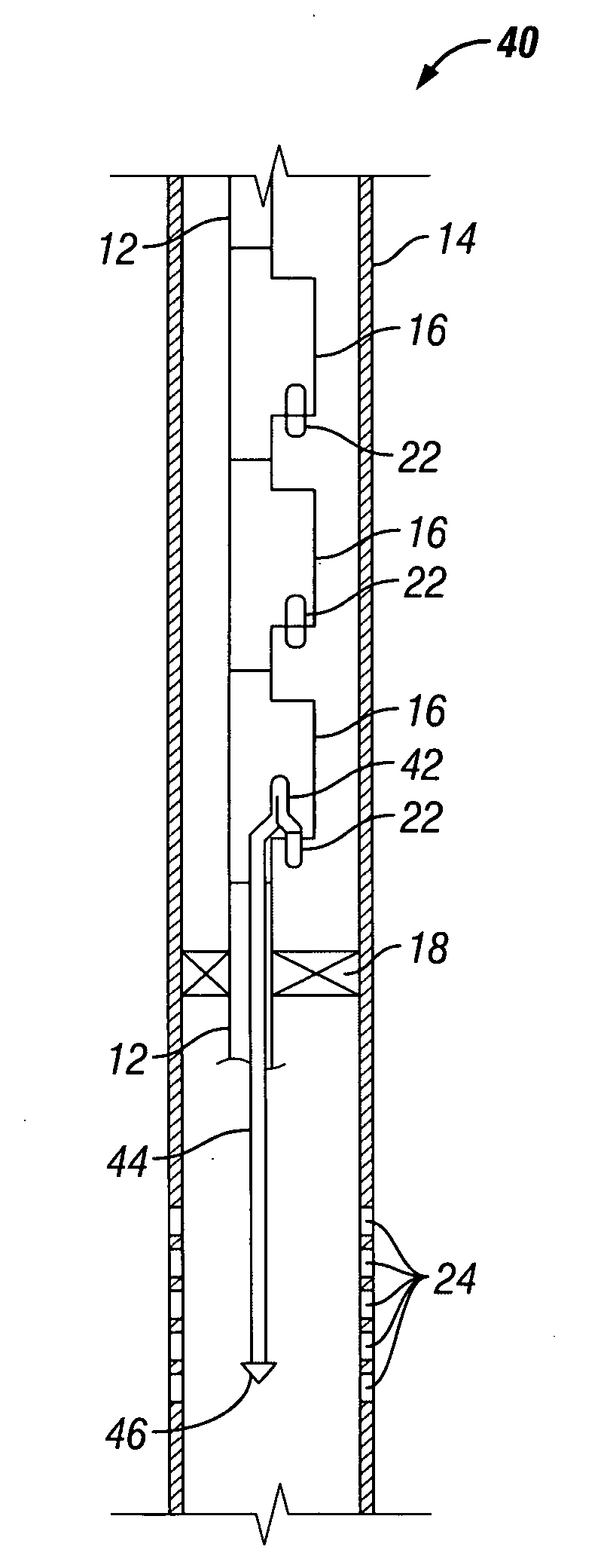

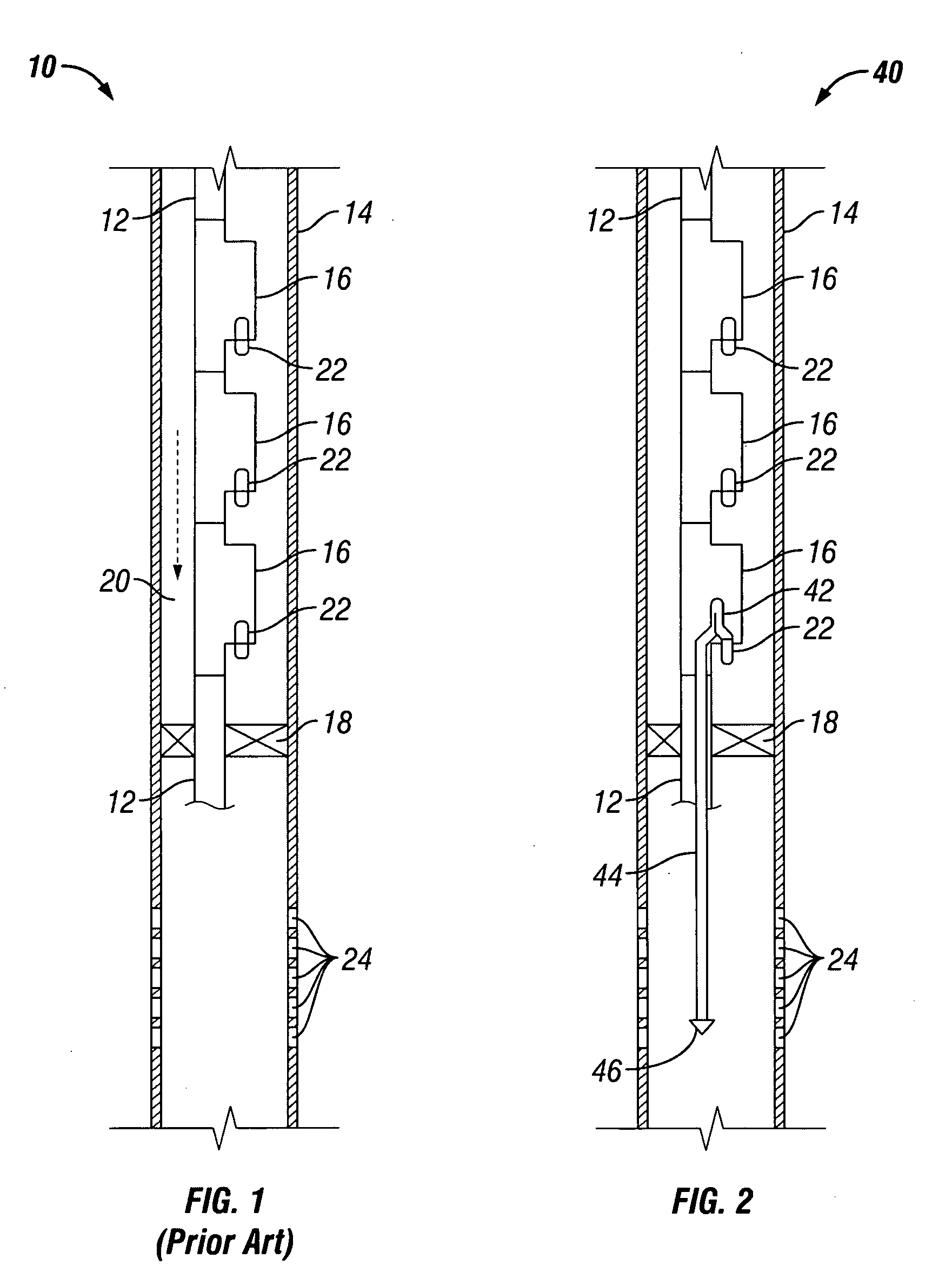

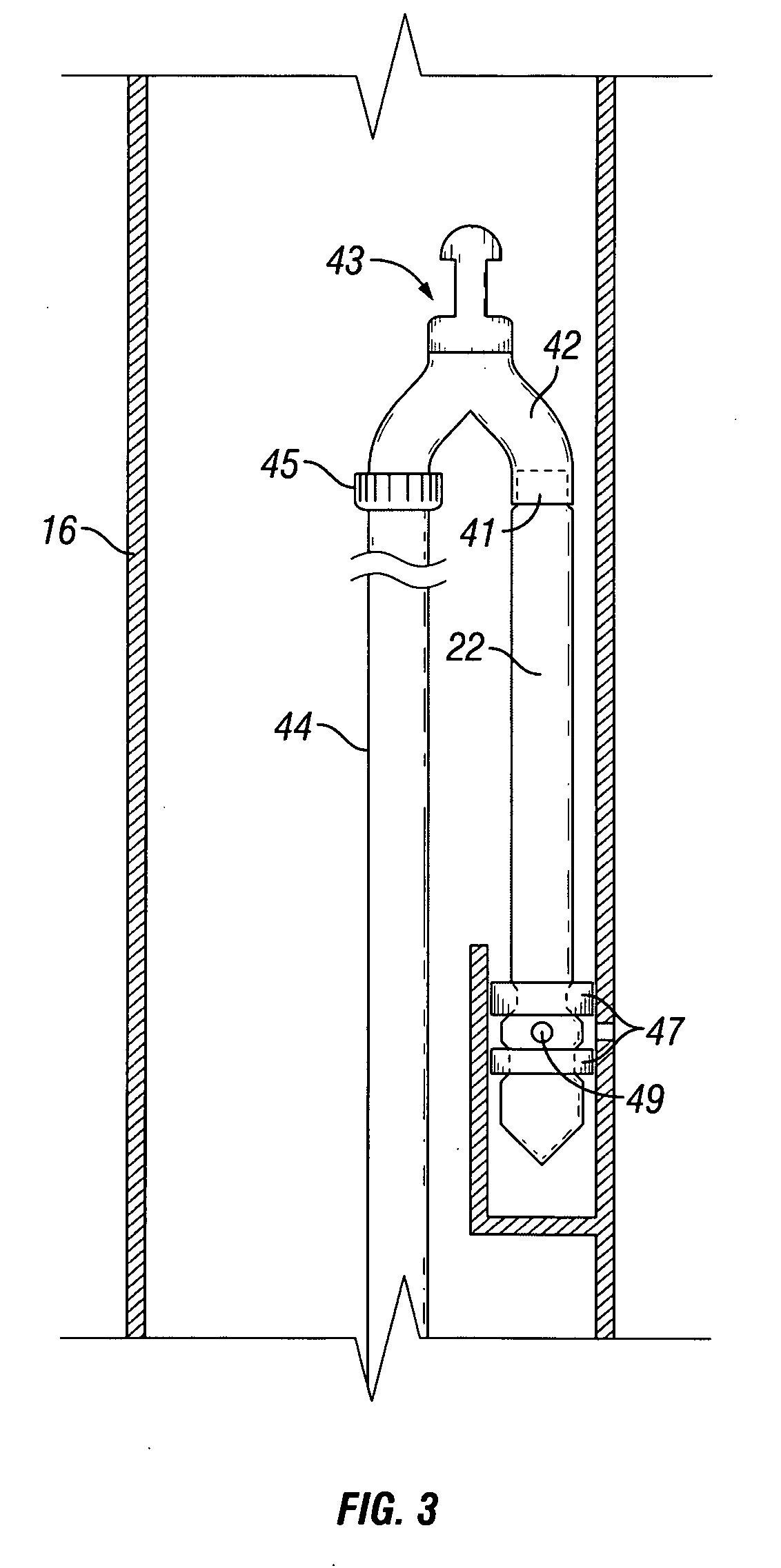

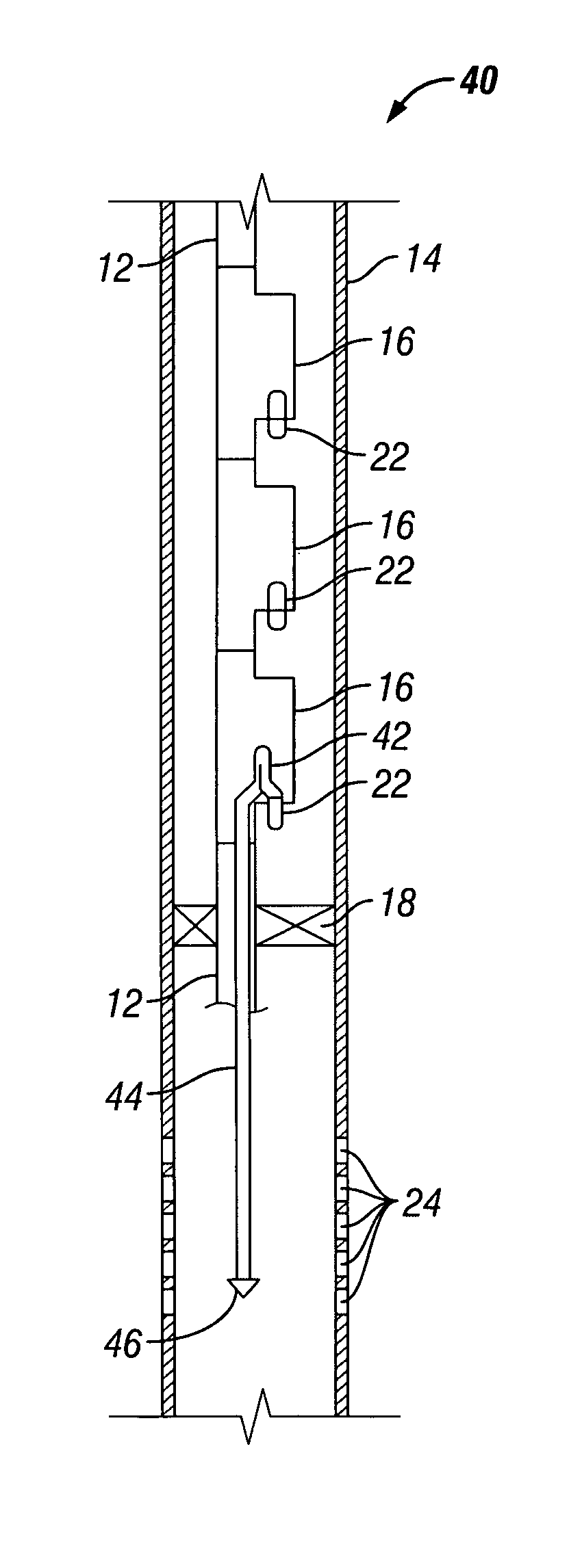

System and method for thru tubing deepening of gas lift

ActiveUS7954551B2Blowout preventionFluid removalWell/borehole valve arrangementsProduction packerInjection point

The present disclosure is directed to a gas lift system adapted to provide a gas injection point to a deeper location in a wellbore. A turn-over suspension mandrel can be landed inside a side pocket mandrel and connected to a gas lift valve on one end and a coil on the other end. A length of production tubing can extend from the side pocket mandrel. The production tubing can include a production packer to seal the annulus between the tubing and the well casing. The turn-over suspension mandrel can be constructed such that gas entering the gas lift valve is directed down through the coil and into the wellbore beneath the production packer. A plug can be placed at the bottom of the coil in order to prevent blowouts during installation of the gas lift system. An alternative embodiment of the present disclosure provides a coil and plug hung from a gas lift valve of a pack-off assembly.

Owner:BAKER HUGHES INC

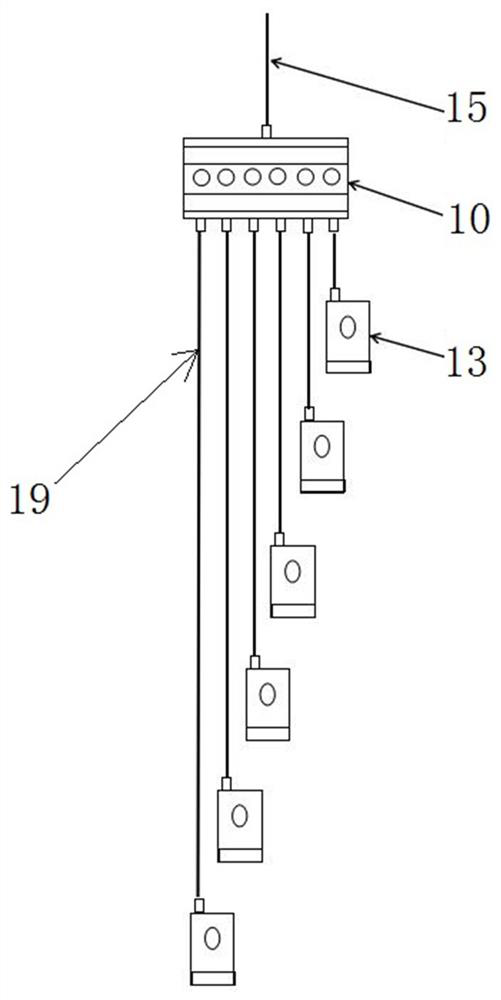

Multi-layer intelligent tubular column controlled by single pipeline

ActiveCN113914835AImprove reliabilityImprove timelinessSurveyConstructionsProduction packerControl system

The invention relates to the field of intelligent well completion of oil and gas well exploitation, and particularly provides a multi-layer intelligent tubular column controlled by a single pipeline. A Christmas tree is connected with the top of an oil pipe, and sealers are installed on the outer wall of the oil pipe and the inner wall of a wellhead. A safety valve, a production packer, a connector, an electric pump, a circulating sliding sleeve, a decoder, a positioning sealing assembly, a data acquisition instrument, a multi-stage control unit and an isolation sealing assembly are sequentially installed at the bottom of the oil pipe from top to bottom, the positioning sealing assembly is in interference sealing connection with a top packer, the isolation sealing assembly is in interference sealing connection with an isolation packer, the decoder is connected with the control system through a main pipeline, the bottom of the decoder is connected with the multi-stage control unit through a branch pipeline, and the data acquisition instrument is connected with a data acquisition system through a cable. The reliability and timeliness are improved, real-time detection and adjustment are achieved, cost is saved, operation safety is improved, operation difficulty is lowered, labor intensity is lowered, and the service life is prolonged.

Owner:DONGYING FLUID SCI & TECH

Tubing or annulus pressure operated borehole barrier valve

An operating system for a barrier valve or safety valve is responsive to increments in annulus or tubing pressure. An indexing device controls valves that selectively direct pressure applied to one side of an operating piston or the other for attaining the open and closed positions of the barrier valve. One such indexing device can be a j-slot. Other devices that operate a pair of hydraulic valves in tandem for pressure direction to one side of an actuation piston or another are contemplated. The system needs no electric power and there are no control lines needed to run below the production packer in the case of using annulus pressure to actuate the piston or at all if access to tubing pressure is provided from the vicinity of the barrier valve components.

Owner:BAKER HUGHES INC

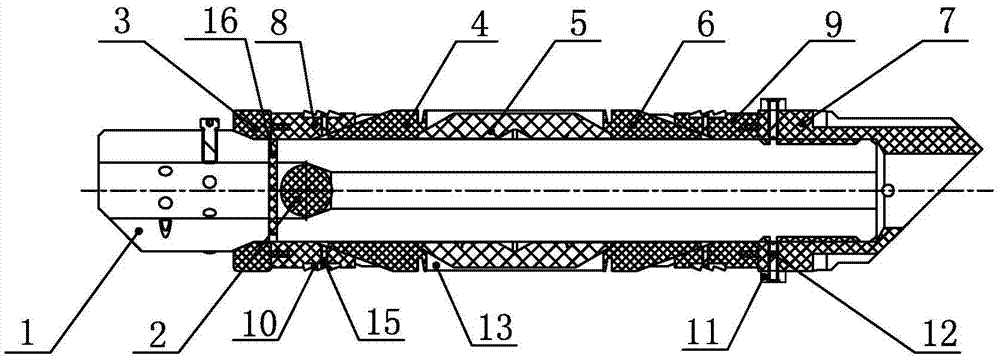

Insertion-pipe-type waterproof production packer and working method thereof

ActiveCN109538155AImproved setting and sealing effectImprove anti-corrosion performanceSealing/packingGeneral water supply conservationProduction packerIndustrial engineering

The invention discloses an insertion-pipe-type waterproof production packer and a working method thereof. The upper end of an insertion pipe is connected with an insertion pipe joint, a gap is formedbetween a center pipe and the insertion pipe, the center pipe and the insertion pipe are provided with overcurrent holes, insertion pipe sealing mechanisms are arranged at the upper and of the insertion pipe and the lower end of the center pipe, an unblocking device is arranged in the upper setting sealing mechanism, the upper setting sealing mechanism and a lower setting sealing mechanism are connected through an anchoring mechanism, and the upper setting sealing mechanism, the unblocking mechanism, an upper rubber cylinder, the anchoring mechanism, a lower rubber cylinder, the lower settingsealing mechanism and a releasing mechanism sleeve the center pipe in sequence from top to bottom. According to the insertion-pipe-type waterproof production packer, after isolated production is completed, an upper pipe column can freely lift and fall by inserting and extracting the insertion pipe, the problem that after conventional isolated production, when pump inspection or measure work is conducted, the packer needs to be deblocked and pulled out is solved, the setting sealing effect on the packer is obviously improved, the corrosion resistance of slips is effectively improved, the frequency of isolated production treatment is reduced, and the isolated production validity period is prolonged.

Owner:PETROCHINA CO LTD

Fixed-point dragging continuous liquid drainage tubular column for fixed-point dragging of offshore low-pressure gas well and liquid drainage method of fixed-point dragging continuous liquid drainage tubular column

PendingCN114278250AAvoid damageImprove liquid carrying capacityFluid removalSealing/packingProduction packerCoiled tubing

The invention provides an offshore low-pressure gas well immovable string fixed-point dragging continuous liquid drainage string and a liquid drainage method thereof.A production oil pipe is arranged in a sleeve, a top packer is arranged between the inner wall of the tail end of the sleeve and the outer wall of the tail end of the production oil pipe, and a positioning seal is arranged on the production oil pipe above the top packer; a deep well safety valve and a circulating sliding sleeve are sequentially arranged on the portion, above the positioning seal, of the production oil pipe from bottom to top, a production packer is arranged between the inner wall of the casing pipe and the outer wall of the production oil pipe, an in-pipe packer is arranged in the production oil pipe, a continuous oil pipe is arranged in the production oil pipe, and the tail end of the continuous oil pipe penetrates through the in-pipe packer. A check valve is arranged at the tail end of the continuous oil pipe and located below the in-pipe packer, and a gas jet pump is arranged on the continuous oil pipe above the in-pipe packer. The liquid drainage pipe column has the technical advantages of being remarkable in liquid drainage effect, reliable in construction operation and the like in the aspect of low-pressure-coefficient horizontal gas well drainage.

Owner:CHINA NAT OFFSHORE OIL CORP +2

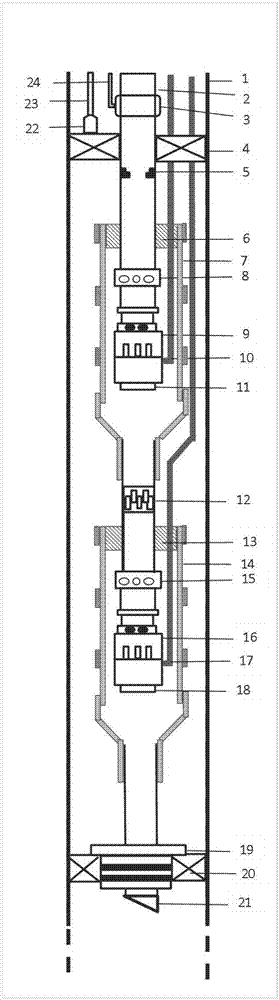

Downhole system for unloading liquid

ActiveUS20160376880A1More cost efficientCost efficientSurveyConstructionsProduction packerCheck valve

The present invention relates to a downhole system for unloading a liquid of a well in an annulus between an intermediate casing and a production tubular metal structure. The downhole system comprises the intermediate casing; a pump at a top of the well, configured to pressurise the annulus to displace the liquid in the annulus; the production tubular metal structure having a first inner diameter, arranged partly in the intermediate casing, thereby defining the annulus; a production packer arranged between the intermediate casing and the production tubular metal structure, and a first liquid unloading assembly and a second liquid unloading assembly, each comprising a tubular part having a wall having a second inner diameter, an outer face and an aperture, the tubular part being configured to be mounted as part of the production tubular metal structure; and a check valve connected with the outer face, the check valve having an inlet in fluid communication with the annulus and an outlet in fluid communication with the aperture. The downhole system further comprises a sliding sleeve arranged to slide along an inner face of the tubular part between an open position and closed position to open or close the aperture. Furthermore, the present invention relates to a liquid unloading method for unloading liquid of a well in an annulus between an intermediate casing and a production tubular metal structure.

Owner:WELLTEC OILFIELD SOLUTIONS AG

Oil-gas well serial double-submersible-electric-pump airtight production pipe column

The invention discloses an oil-gas well serial double-submersible-electric-pump airtight production pipe column. The pipe column comprises a casing in an oil production well, an oil pipe in the casing, an underground safety valve which is arranged on the upper portion of the oil pipe and connected with a liquid control pipeline, and a casing packer which is arranged at the bottom of the oil pipe, internally provided with a positioning seal and a guide shoe and provided with a sealing cylinder; a cable production packer, an upper airtight electric submersible pump system, an underground tool direction adjusting device and a lower airtight electric submersible pump system are sequentially connected between the underground safety valve and the positioning seal in series from top to bottom. The upper and lower airtight electric submersible pump systems comprise airtight hangers and airtight system tanks connected with the lower portions of the airtight hangers. The packer is used for isolating stratum liquid from the portion, above the packer, of the casing at a deep position of a shaft, and casing protection liquid can be inserted into an annulus, between the oil pipe and the casing, above the casing packer, so that the production casing is effectively protected and prevented from being eroded by fluids high in sulfur content and high in corrosivity.

Owner:CHINA NAT OFFSHORE OIL CORP +1

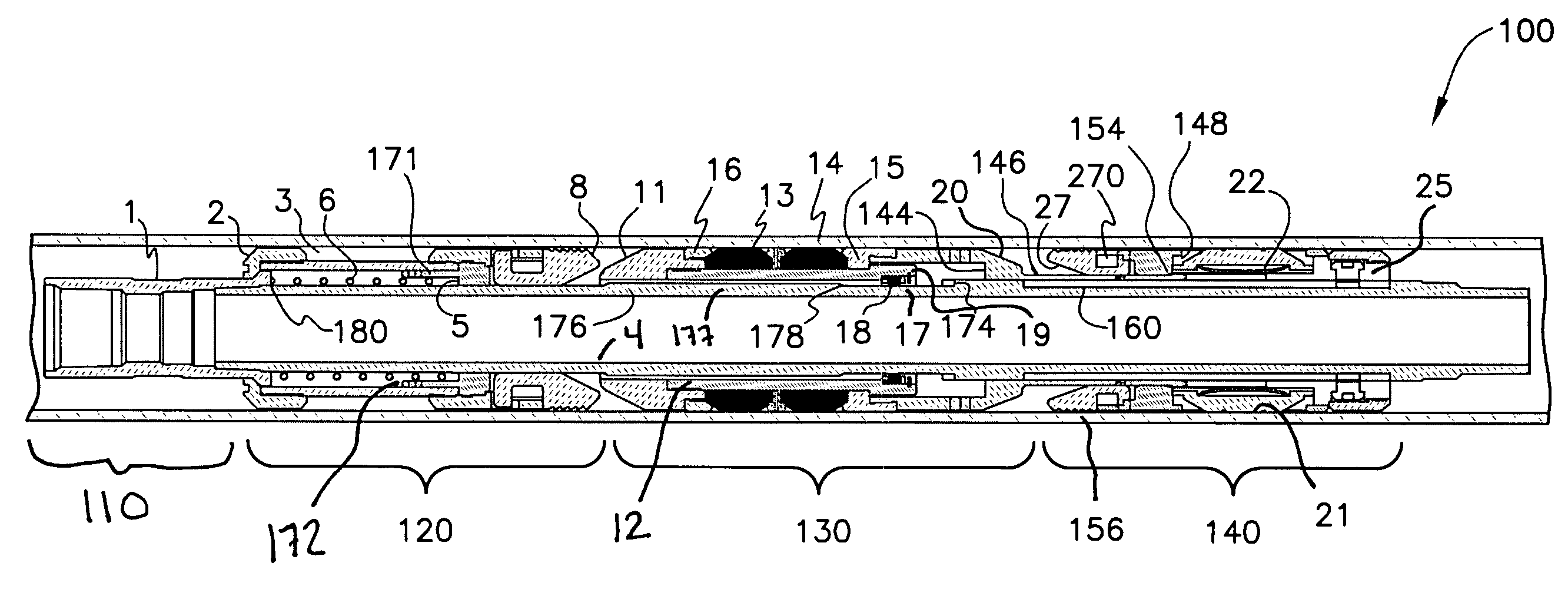

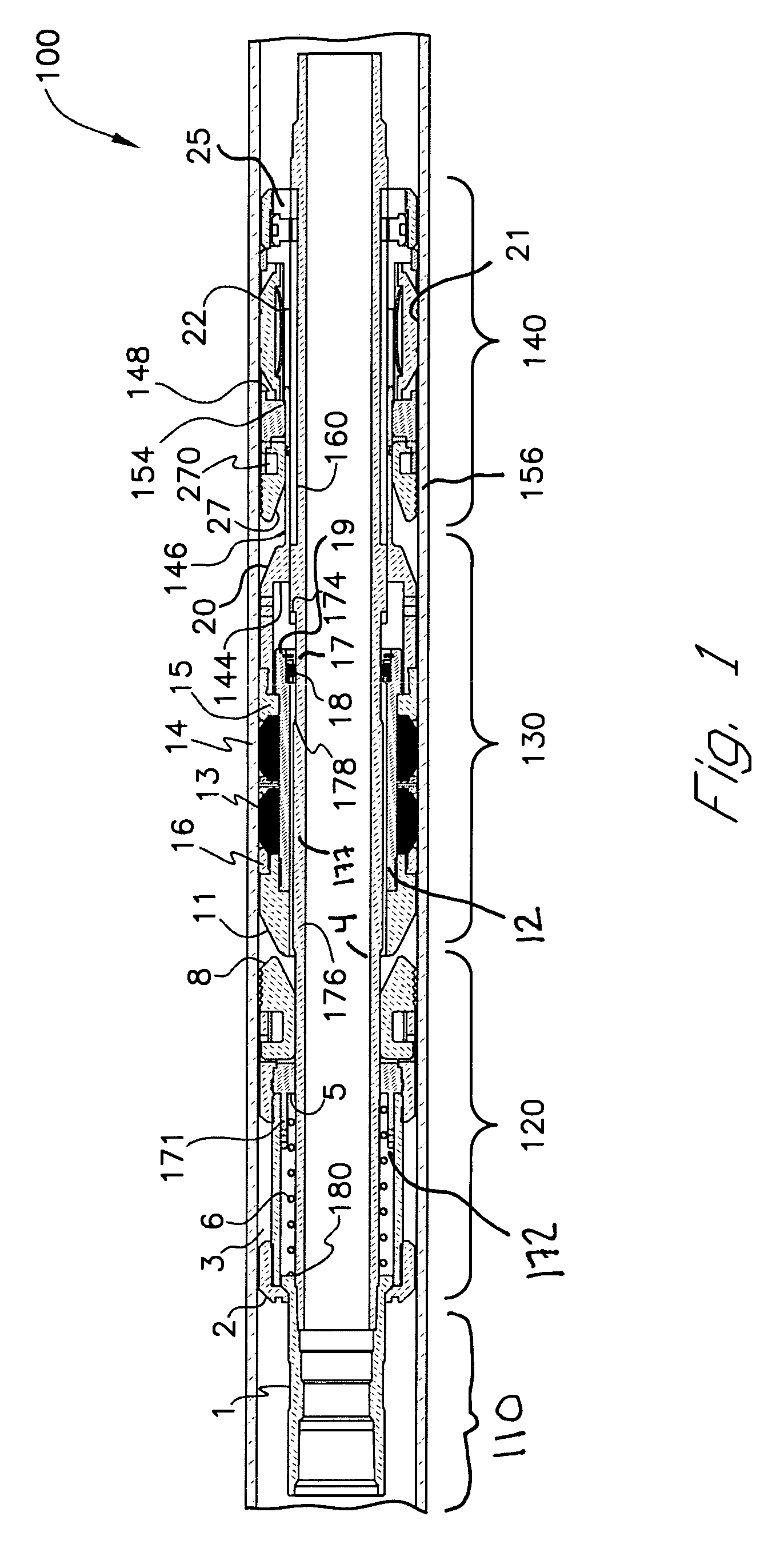

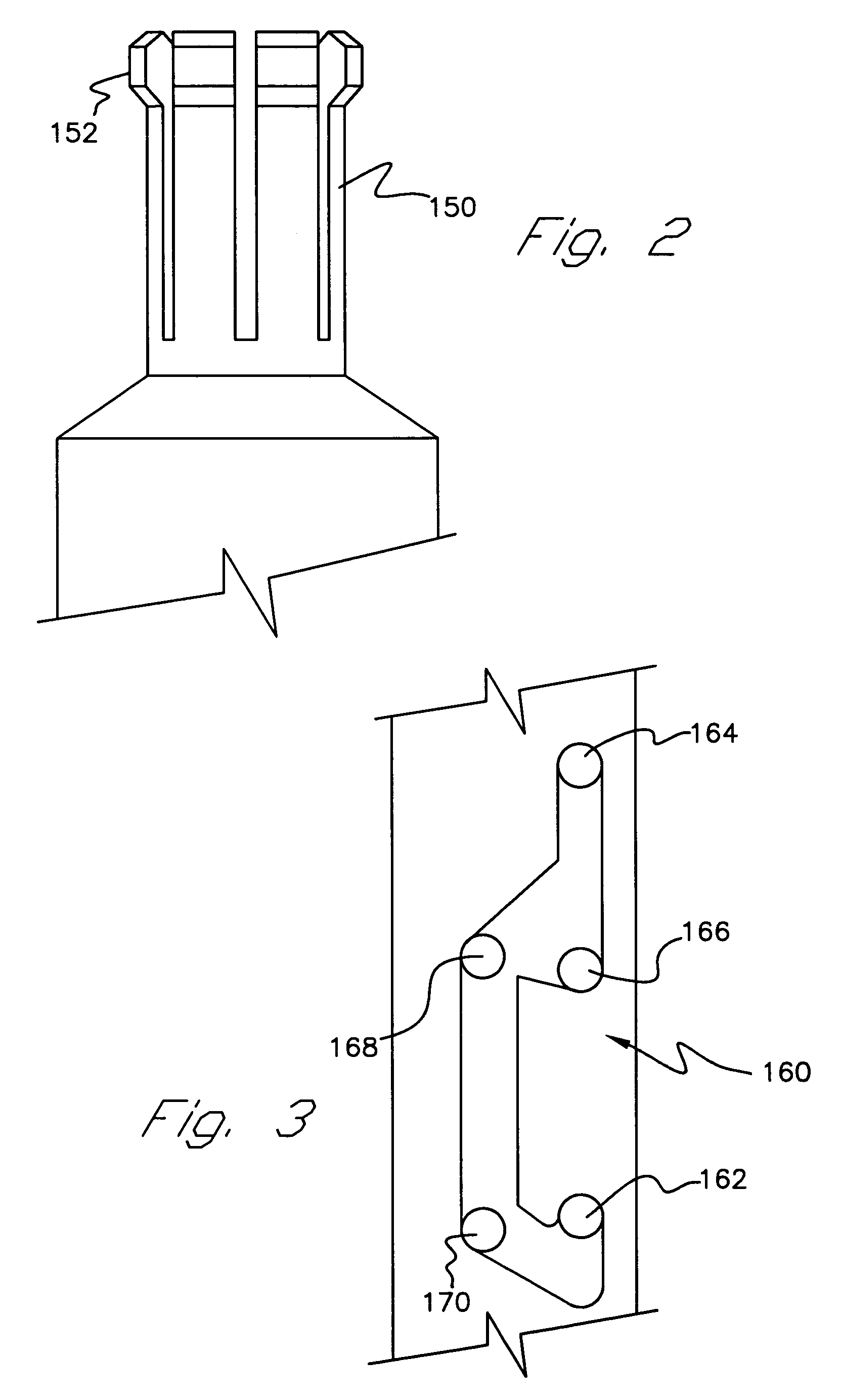

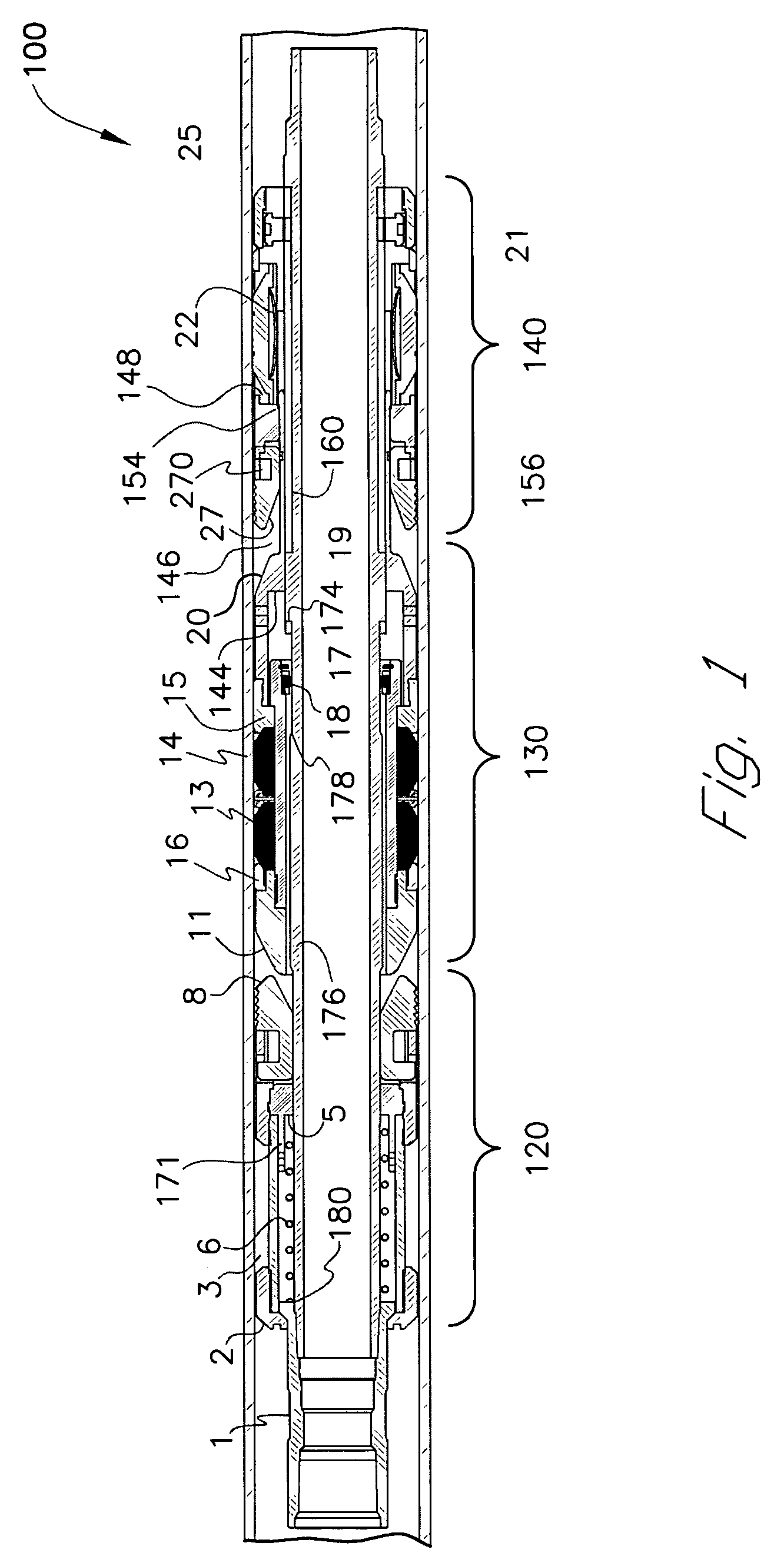

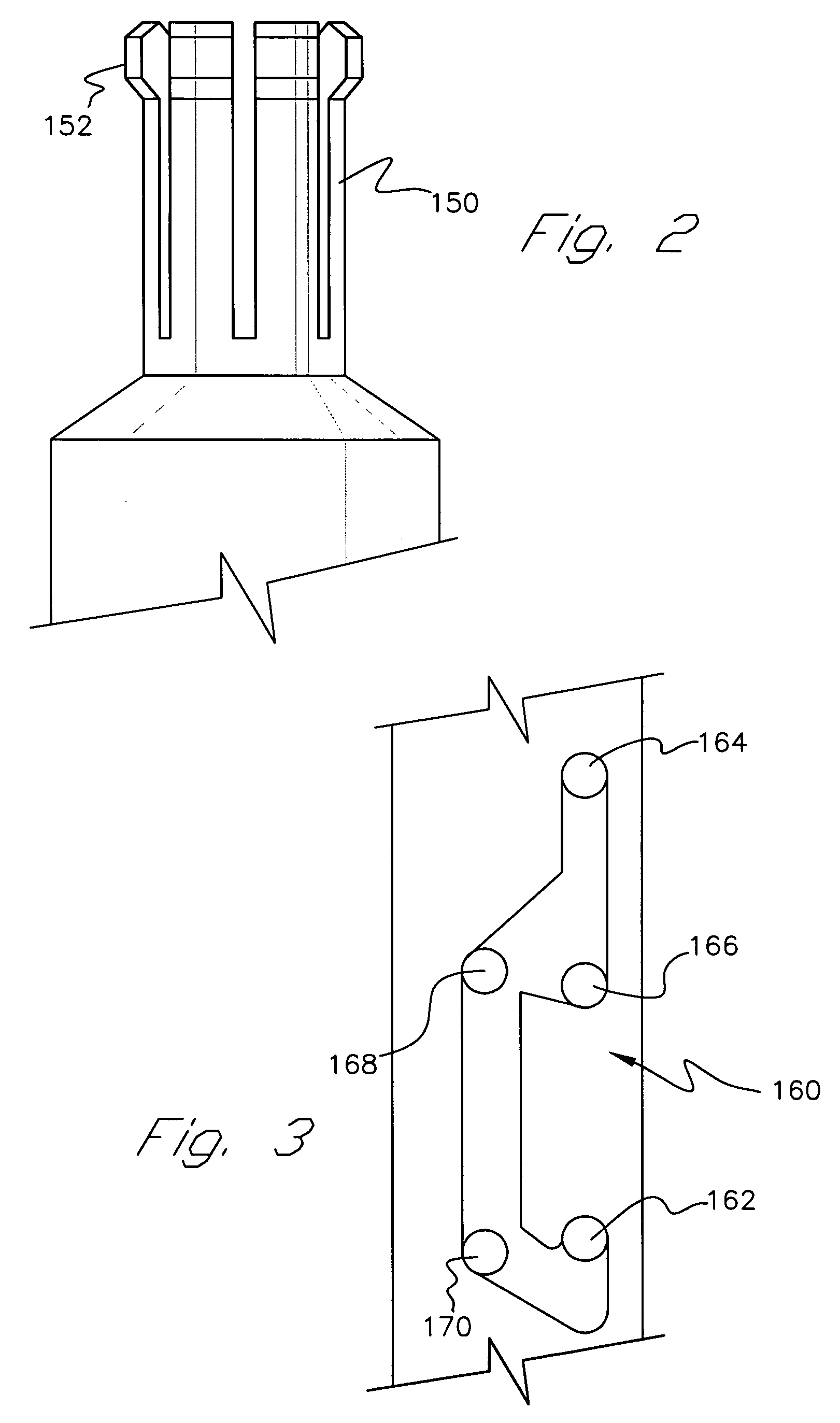

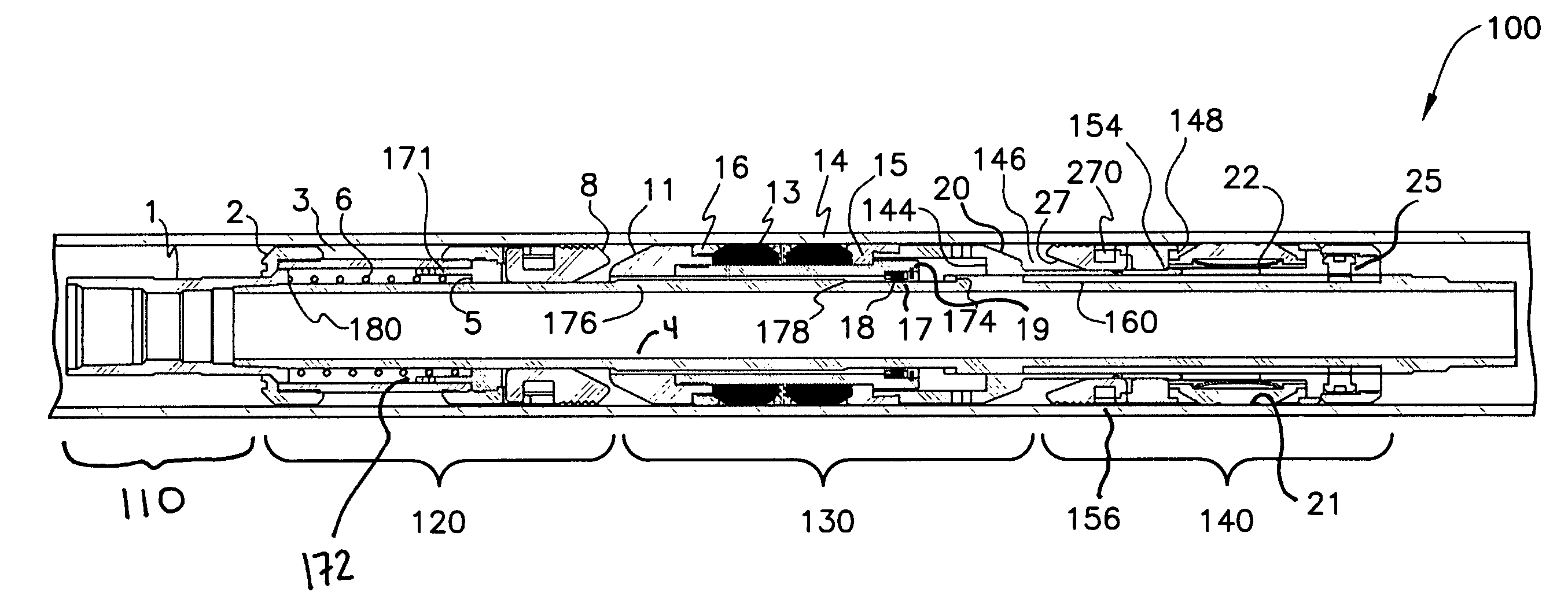

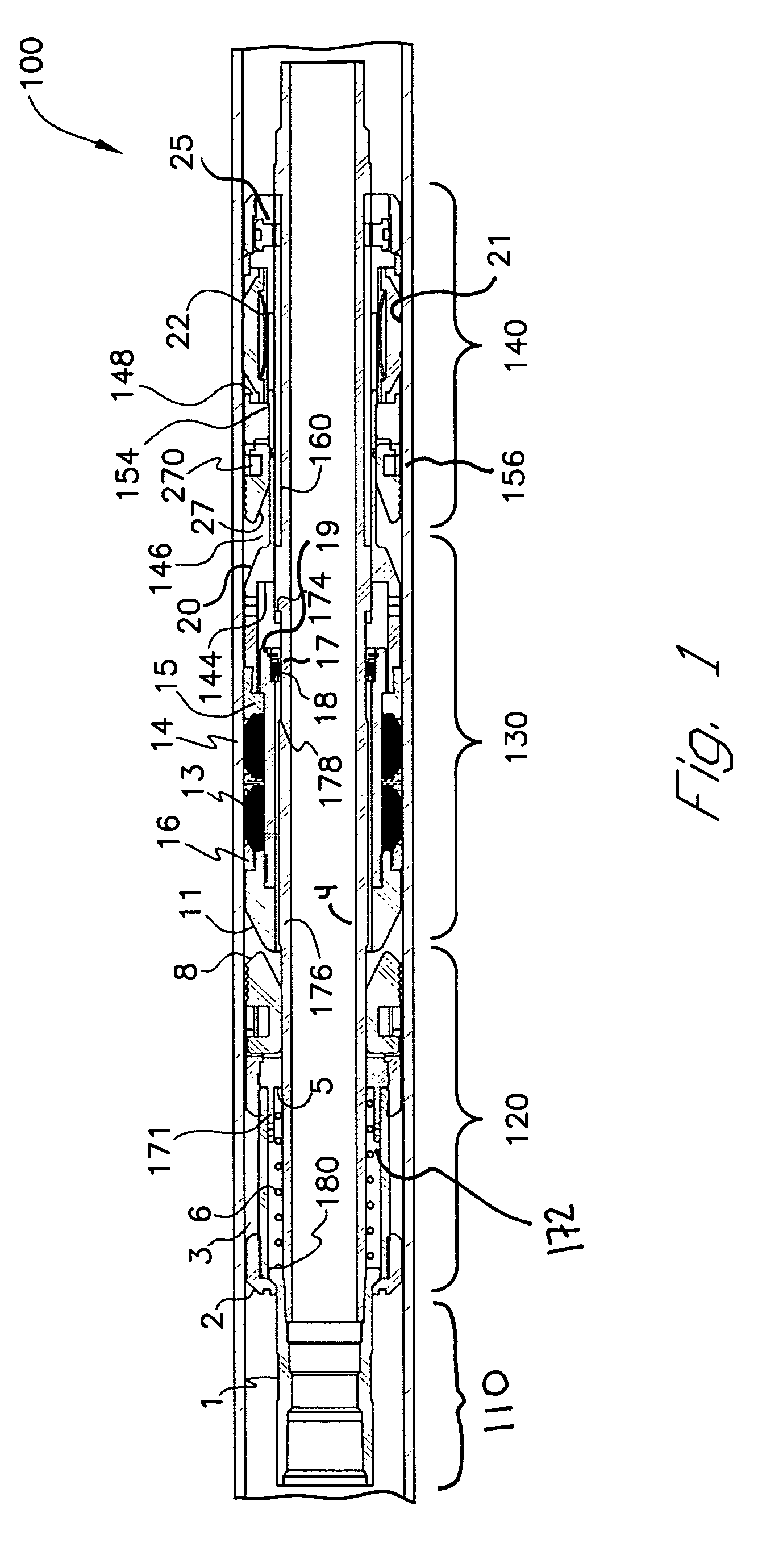

Radially Expandable Ratcheting Body Lock Ring for Production Packer Release

A releasable production packer employs lock ring segments that are biased radially inwardly for engaging a mating pattern external to the packer mandrel. The mandrel has openings aligned with the segments and a release tool that latches to the mandrel for support and then moves the segments radially outwardly away from engagement with the mandrel so that the slips and sealing elements can extend axially and retract radially. After those movements the packer is retrieved. The release tools moves the locking segments only radially for the maximum mechanical advantage without risk of bending or deforming small parts.

Owner:BAKER HUGHES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com