Multi-layer intelligent tubular column controlled by single pipeline

A pipeline and intelligent technology, applied in the fields of fluid production, measurement, wellbore/well components, etc., can solve the problems of limited number of liquid flooding completion intervals, high cost of hydraulic control pipelines, and poor tool reliability, etc. The effect of improving performance and timeliness, reducing labor intensity and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing.

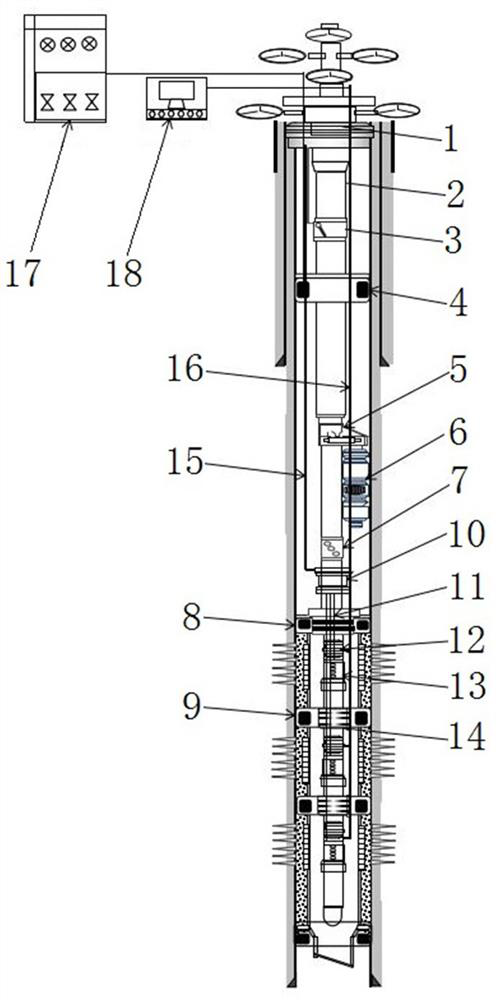

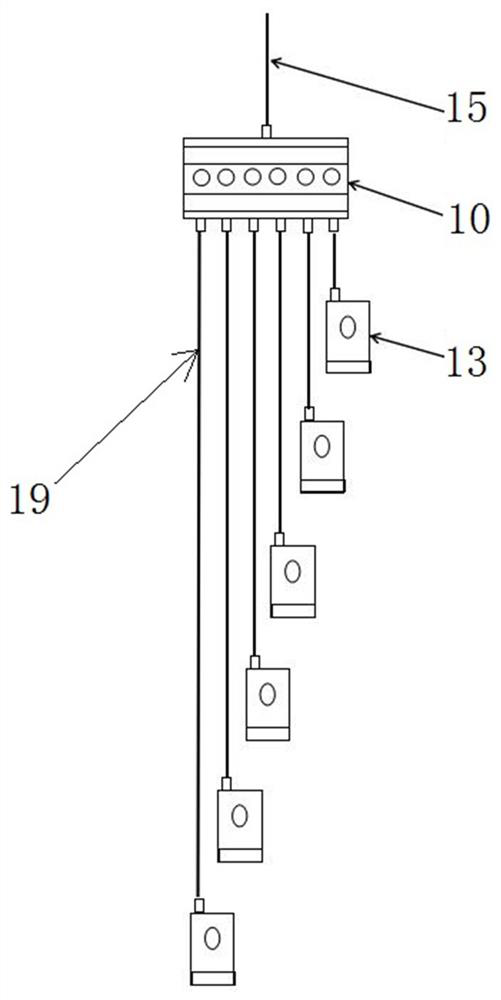

[0017] A single pipeline control multi-layer intelligent pipe string, including sealer 1, oil pipe 2, safety valve 3, production packer 4, joint 5, electric pump 6, circulation sliding sleeve 7, decoder 10, positioning sealing assembly Cheng 11, data acquisition instrument 12, multi-level control unit 13, isolation seal assembly 14, isolation packer 9, top packer 8, main pipeline 15, branch pipeline 19, cable 16, data acquisition system 18 and control system 17. The top of the oil pipe 2 is connected to the Christmas tree, the outer wall of the oil pipe 2 and the inner wall of the wellhead are installed with a sealer 1, and the bottom of the oil pipe 2 is sequentially installed with a safety valve 3, a production packer 4, a joint 5, Electric pump 6, circulating sliding sleeve 7, decoder 10, positioning sealing assembly 11, data acquisition instrument 12, multi-stage contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com