Rapid induced flow completion pipe column for subsurface nitrogen making gas well

A completion string and nitrogen technology, applied in wellbore/well components, drill pipe, casing, etc., can solve the problems of complex operation procedures, high risks, low efficiency, etc., and achieve simple operation procedures, less operation equipment, Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

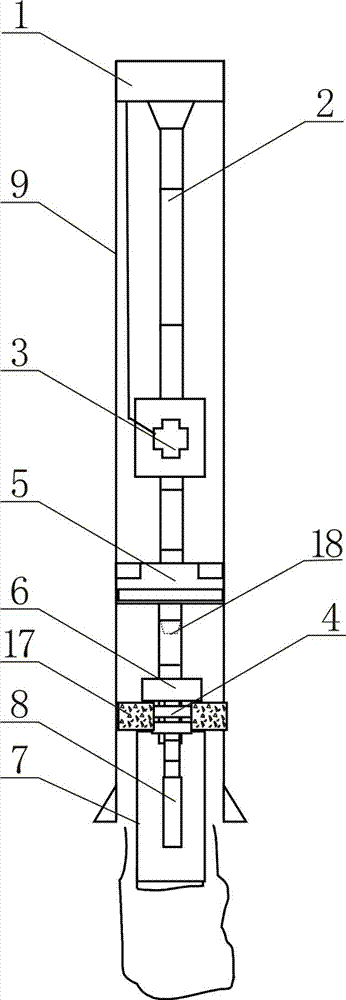

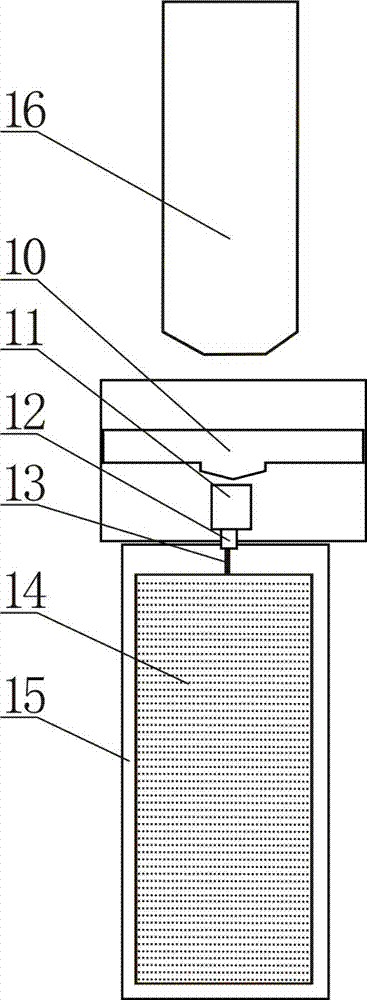

[0020] Such as figure 1 , 2 As shown, the rapid blowout induction completion string of the downhole nitrogen gas well is mainly composed of tubing hanging 1, tubing 2, downhole safety valve 3, production packer 5, insertion positioning seal 6, blind pipe 7, downhole nitrogen generating blowout induction device 8 and Mandrel 18 Composition, wherein, the upper end of the oil pipe 2 is suspended in the oil well 9 through the oil pipe hanger 1, the downhole safety valve 3 and the production packer 5 are respectively arranged on the oil pipe 2, and the lower end of the oil pipe 2 is inserted into the positioning seal 6 and the blind pipe 7 connection, the insertion positioning seal 6 is inserted into the sealing cylinder of the sand control packer 17 in the oil well 9, and the downhole nitrogen generating blowout device 8 is arranged in the blind pipe 7. A sealing ring 4 is provided between the insertion positioning seal 6 and the sealing cylinder of the sand control packer 17; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com